Hi all

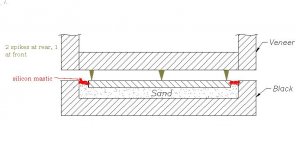

I'm getting close to finishing the veneering on my bass speaker boxes and its time to make some plinths for them to sit on. Following on from a previous thread about plinths where someone suggested using a sand box , I thought about a design as shown in the attachment.

I want to keep the plinth no wider than the speaker, because I think that this looks better. I have suspended wooden floors, so the idea of the design is to absorb vibrations in the sand, which effectively forms the connection between the speaker box (which is 25mm MDF) and the base of the plinth, which sits on the floor, maybe with spikes or bluetak.

One potential problem is that if the speaker is bumped from the side then it may kick over a bit. Hopefully it wouldn't fall if the sliding joint is tight enough, however I could always put some pins through from the side across the sliding joint and into a clearance hole. It wouldn't touch in normal operation but would stop it from falling over.

Any comments on this design from the knowledgable and helpful bods out there?

Mick

I'm getting close to finishing the veneering on my bass speaker boxes and its time to make some plinths for them to sit on. Following on from a previous thread about plinths where someone suggested using a sand box , I thought about a design as shown in the attachment.

I want to keep the plinth no wider than the speaker, because I think that this looks better. I have suspended wooden floors, so the idea of the design is to absorb vibrations in the sand, which effectively forms the connection between the speaker box (which is 25mm MDF) and the base of the plinth, which sits on the floor, maybe with spikes or bluetak.

One potential problem is that if the speaker is bumped from the side then it may kick over a bit. Hopefully it wouldn't fall if the sliding joint is tight enough, however I could always put some pins through from the side across the sliding joint and into a clearance hole. It wouldn't touch in normal operation but would stop it from falling over.

Any comments on this design from the knowledgable and helpful bods out there?

Mick

Attachments

Thanks for your replies Pete and Rob

You might be right about the sliding joint Rob. In theory it should be OK, but in practice it may end up binding up. With my enclosure design I need a piece that attaches to the base part (item 1 in the attachment), as the base is removable for access into the bottom part of the speaker. By attaching it to another piece (item2) I can screw the whole lot to the bottom of the speaker walls.

I like your idea with the spikes, but I'm wondering if I could achieve something similar by just widening the gap in the sliding joint. The difference would be the lack of the silicone sealant and also the lack of the spikes. I don't really understand spikes enough to know how they would contribute acoustically in this situation. The attachment shows another design.

Pete - have you tried the mouse pad? Is it acoustically isolating across a wide frequency range?

Thanks

Mick

You might be right about the sliding joint Rob. In theory it should be OK, but in practice it may end up binding up. With my enclosure design I need a piece that attaches to the base part (item 1 in the attachment), as the base is removable for access into the bottom part of the speaker. By attaching it to another piece (item2) I can screw the whole lot to the bottom of the speaker walls.

I like your idea with the spikes, but I'm wondering if I could achieve something similar by just widening the gap in the sliding joint. The difference would be the lack of the silicone sealant and also the lack of the spikes. I don't really understand spikes enough to know how they would contribute acoustically in this situation. The attachment shows another design.

Pete - have you tried the mouse pad? Is it acoustically isolating across a wide frequency range?

Thanks

Mick

Attachments

Hi Mick,

The sealent I suggested was just to keep the wood in place (so it doesn't move and touch any sides. I thought the spikes were meant to minimise contact between 2 surfaces, and thus lower transmitted vibrations - I'm sure someone here can give a proper scientific explanation.

What about using a slab of concrete that your "bit that screws in the seaker" can slot over (push fit) that is high enough to keep it off the bottom plate. You could glue the concrete to the bottom plate, pretty much like your second drawing except there will be air instead of sand down the thin gap at the sides.

If that didn't make any sense I'll mess another of your drawings up in mspaint.

cheers

Rob

The sealent I suggested was just to keep the wood in place (so it doesn't move and touch any sides. I thought the spikes were meant to minimise contact between 2 surfaces, and thus lower transmitted vibrations - I'm sure someone here can give a proper scientific explanation.

What about using a slab of concrete that your "bit that screws in the seaker" can slot over (push fit) that is high enough to keep it off the bottom plate. You could glue the concrete to the bottom plate, pretty much like your second drawing except there will be air instead of sand down the thin gap at the sides.

If that didn't make any sense I'll mess another of your drawings up in mspaint.

cheers

Rob

Pete Mazz said:How about sandwiching a mousepad between the bottom of the speaker and a base plate. Use a flexible adhesive and should work pretty well.

Pete

Hi

I have tried the mousepad thing (several layers), it was very "springy" and the sub was rocking, now I have thick felt under and thats much better.

Keld

Thanks for your ideas Rob and Keld

Rob

I didn't quite follow your idea. Any chance of a diagram?

Any chance of a diagram?

I thought that spikes may increase vibration transmission, but I'm not sure how.

There are two conflicting aims here. One is to disipate vibrational energy away from the speaker walls, which are excited by the driver. The other is not to excite the floor, which can also produce sound when excited. So by coupling the speaker well to the floor, the problem may be transferred from the cabinet to the floor. My design was aiming to use the sand to dampen/absorb vibrational energy transmission from the speakers. Using a concrete slab, as you suggested, would further help by absorbing vibrational energy but produce low vibration amplitude due to its high mass to area ratio.

Any other thoughts?

Mick

Rob

I didn't quite follow your idea.

Any chance of a diagram?

Any chance of a diagram?I thought that spikes may increase vibration transmission, but I'm not sure how.

There are two conflicting aims here. One is to disipate vibrational energy away from the speaker walls, which are excited by the driver. The other is not to excite the floor, which can also produce sound when excited. So by coupling the speaker well to the floor, the problem may be transferred from the cabinet to the floor. My design was aiming to use the sand to dampen/absorb vibrational energy transmission from the speakers. Using a concrete slab, as you suggested, would further help by absorbing vibrational energy but produce low vibration amplitude due to its high mass to area ratio.

Any other thoughts?

Mick

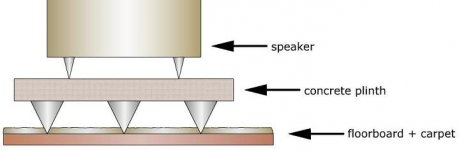

Attached is a picture of the setup I'm about to try.

The plinths are concrete slabs (high mass) on a tripod of aluminium cones (for stability) and the speaker sits on top on its spikes.

They should tighten up the bass a bit - placing speakers on carpet usually is a bad idea, even with spikes, but by using a relatively high mass plinth gives the speakers a good solid base to work with. Using three feet is, as well all know, the only way to go to get a really solid, evenly weighted, base.

Any comments would be good.

The plinths are concrete slabs (high mass) on a tripod of aluminium cones (for stability) and the speaker sits on top on its spikes.

They should tighten up the bass a bit - placing speakers on carpet usually is a bad idea, even with spikes, but by using a relatively high mass plinth gives the speakers a good solid base to work with. Using three feet is, as well all know, the only way to go to get a really solid, evenly weighted, base.

Any comments would be good.

Attachments

I just got a quote back from a specialist plinth maker - they wanted £200 for the pair including delivery!

I think I'll try your idea, although if prices are like that I may stick with the concrete slabs which, although being slightly industrial looking, are quite attractive.

Maybe I'll resort to finding a nice headstone - I'm sure whoever it belongs to will appreciate it going to good use!

I think I'll try your idea, although if prices are like that I may stick with the concrete slabs which, although being slightly industrial looking, are quite attractive.

Maybe I'll resort to finding a nice headstone - I'm sure whoever it belongs to will appreciate it going to good use!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Plinth design for comment