Even though I now know that it's entirely pointless to listen to any CD/waveguide combination without proper EQ, I'll relate my experiences anyway.

For the last comparison, I put the BMS 4540 drivers into the 1086s last night, and like with the B&C, wasn't impressed. The same 3-6khz peakiness showed with the BMS driver. The same small sweet spot, and kinda muddy, undefined presentation. Now, before anyone gets their panties all in a bunch, I'll reprint what I wrote in an earlier post to avoid any confusion about whether we're all in agreement on the EQ thing. (we are, it's just that some of you may not have read my previous post)

"These drivers (BMS) are quite a bit different than the B&C. I've got a 1.5uF cap on them to get some flatter response and they're kinda-sorta +- 3db between 2khz and 10khz now. Not bad overall, but they're a little less full bodied than the B&C and a bit edgier. The B&C are pretty smooth throughout their range and it's probably because they start with a much flatter FR. A better attempt at EQing the BMS would probably help, but I could live with them the way they are."

With a simple cap on the BMS driver, I'm seeing roughly a 6db spread between 2-10khz - ballpark good enough to get the gist of the driver's character. The B&C DE250 has no EQ at all, simply because it's so darned flat anyway (remember I'm just looking at big pictures here, not details). Neither of these drivers (and after EQ for the BMS) shows the radical 3-6khz peakiness in either the ENG90 or the PE waveguide. When either driver is put into the XT1096, using the same XO (1.5khz), they both show 6+db peaks now between 3-6khz. So when I say they're peaky, I'm talking about the horn, not the driver, and it's relative to the fact that both drivers are NOT peaky between 3-6khz in the other two waveguides. It has nothing to do with the natural uplifted response of the drivers (especially the BMS) in that area.

The B&C driver in the ENG90 waveguide is flat as a pancake thru that same area and the BMS in the PE waveguide shows only 2-3db peakiness. So what's happening here? Bad driver/horn mismatch or just plain bad horn?

Well that's it. 2 drivers, three waveguides, kinda sorta EQ'd, plug 'em in and listen. So what did I learn thru all this pointless listening? Well, first of all, I like the B&C drivers better than I like the BMS drivers. Second, not every horn/waveguide is going to be interchangeable with every driver. I can live with that. Third, I like the ENG90 style waveguides, which I think might be closer to a Geddes style than not. They seem to share the same basic physical features of Earl's descriptions, which is not to say they are the same, just that the fundamental idea seems to be there. Fourth, I don't think I like what the XT1086 is doing, and I was surprised how much I liked the BMS driver in the cheap PE WG. If I can figure out how to get the 4540 to keep from spitting all over me, I'm gonna persue that combination.

And fifth, and most importantly, I'll never buy another dome tweeter again. The B&C DE250/ENG90 combination (right out of the box, no EQ) has convinced me that I've been missing the boat all my life. And in spite of the pointlessness of listening to imperfectly EQ'd waveguides, I still managed to pick up a few bits of information. Imagine that.

Anyway, once again, take this for what it's worth - a quick look at something I know very little about at this point. Personally, I'm kinda pumped about where this can go with a little work. Now I guess I gotta get serious and do them right.

For the last comparison, I put the BMS 4540 drivers into the 1086s last night, and like with the B&C, wasn't impressed. The same 3-6khz peakiness showed with the BMS driver. The same small sweet spot, and kinda muddy, undefined presentation. Now, before anyone gets their panties all in a bunch, I'll reprint what I wrote in an earlier post to avoid any confusion about whether we're all in agreement on the EQ thing. (we are, it's just that some of you may not have read my previous post)

"These drivers (BMS) are quite a bit different than the B&C. I've got a 1.5uF cap on them to get some flatter response and they're kinda-sorta +- 3db between 2khz and 10khz now. Not bad overall, but they're a little less full bodied than the B&C and a bit edgier. The B&C are pretty smooth throughout their range and it's probably because they start with a much flatter FR. A better attempt at EQing the BMS would probably help, but I could live with them the way they are."

With a simple cap on the BMS driver, I'm seeing roughly a 6db spread between 2-10khz - ballpark good enough to get the gist of the driver's character. The B&C DE250 has no EQ at all, simply because it's so darned flat anyway (remember I'm just looking at big pictures here, not details). Neither of these drivers (and after EQ for the BMS) shows the radical 3-6khz peakiness in either the ENG90 or the PE waveguide. When either driver is put into the XT1096, using the same XO (1.5khz), they both show 6+db peaks now between 3-6khz. So when I say they're peaky, I'm talking about the horn, not the driver, and it's relative to the fact that both drivers are NOT peaky between 3-6khz in the other two waveguides. It has nothing to do with the natural uplifted response of the drivers (especially the BMS) in that area.

The B&C driver in the ENG90 waveguide is flat as a pancake thru that same area and the BMS in the PE waveguide shows only 2-3db peakiness. So what's happening here? Bad driver/horn mismatch or just plain bad horn?

Well that's it. 2 drivers, three waveguides, kinda sorta EQ'd, plug 'em in and listen. So what did I learn thru all this pointless listening? Well, first of all, I like the B&C drivers better than I like the BMS drivers. Second, not every horn/waveguide is going to be interchangeable with every driver. I can live with that. Third, I like the ENG90 style waveguides, which I think might be closer to a Geddes style than not. They seem to share the same basic physical features of Earl's descriptions, which is not to say they are the same, just that the fundamental idea seems to be there. Fourth, I don't think I like what the XT1086 is doing, and I was surprised how much I liked the BMS driver in the cheap PE WG. If I can figure out how to get the 4540 to keep from spitting all over me, I'm gonna persue that combination.

And fifth, and most importantly, I'll never buy another dome tweeter again. The B&C DE250/ENG90 combination (right out of the box, no EQ) has convinced me that I've been missing the boat all my life. And in spite of the pointlessness of listening to imperfectly EQ'd waveguides, I still managed to pick up a few bits of information. Imagine that.

Anyway, once again, take this for what it's worth - a quick look at something I know very little about at this point. Personally, I'm kinda pumped about where this can go with a little work. Now I guess I gotta get serious and do them right.

AJ said:The B&C driver in the ENG90 waveguide is flat as a pancake thru that same area and the BMS in the PE waveguide shows only 2-3db peakiness. So what's happening here? Bad driver/horn mismatch or just plain bad horn?

Anyway, once again, take this for what it's worth - a quick look at something I know very little about at this point. Personally, I'm kinda pumped about where this can go with a little work. Now I guess I gotta get serious and do them right.

The DE250 is never flat - to my +- 2dB requirement on any waveguide that I have built. So if you are getting this thats great. I work for smoothness and nearly flat - but more at off-axis positions than on-axis. I'll sacrifice the on-axis response to improve the off-axis response. (The reason here is discussed in my other thread when we talk about power response versus axial response.)

The DE250 has its diaphragm resonance at about 2 khz where (on my waveguides) it peaks and then drops very quickly below that point. This resonance is in the driver and if you want to operate the waveguide below it you have to somehow EQ the response back up. I drop down this peak with a parallel LCR, which has the effect of basically bringing up the response below resonance. If you don't do something about this resonance you need to keep the crossover point above about 2 kHz. - which is too high for my needs.

In my waveguides, with the DE250, I see a second resoance at about 4 kHz. I EQ this down with a 2nd parallel LRC. To EQ the CD response loss I use a RC parallel combination in series. Out in front of this is a third order HP filter. See attached. The values shown are for a TAD 4001 driver NOT the DE250. For the DE250 I use a second shorting leg at the output tuned to about 4 kHz.

As far as what you are learning thats all great. I think that you, and others as well, should understand that it takes about 90% of the engineering going the last 10% of the design. And to get the last 1% optimized can often take as long (or longer) than the first 99%. So have fun in this early stage because things go quickly and your learning improves dramatically, because to get the next 10% you need to spend a lot of time (and usually money). Hopefully you can find others who are willing to give you some insights from there own fine tuning.

To get that last 1% - well thats what I do.

Attachments

Hey Earl

"The DE250 is never flat - to my +- 2dB requirement on any waveguide that I have built."

Okay, so maybe a pancake with walnuts and whipped cream. I was being a little hyperbolic to stress a point.

Thanks for the response Earl, I appreciate it. I've been following your work for quite awhile and I like your approach. I don't have the engineering skills to really understand it all, but I do have the mechanical skills to build your waveguides - it makes it feasible for me to experiment with some finely tuned designs. I'm a machinist, retired from the floor, but I'm still working for myself writing post processors for Cad/Cam software. I've got a buddy down the street with a full blown machine shop at my disposal (well, if I can work between his real jobs ) so, building waveguides based on your work is practical for me. If the ENG90 is an indication of what can happen with the OS waveguides, it's where I want to go.

) so, building waveguides based on your work is practical for me. If the ENG90 is an indication of what can happen with the OS waveguides, it's where I want to go.

" And to get the last 1% optimized can often take as long (or longer) than the first 99%."

I hear ya' - it's true of any speaker you build. I was surprised when I started DIYing how easy it was to get something quite listenable, but only 95% optimized...I tend to use my imagination for the last 5%.

I'll have some time to start tweaking the whole mess early next year - I've got 16 12 inch woofers on the way for some OB bass trials that will take a coupla weeks to sort out first - so I'll probably be bugging you with questions. Hope you don't mind. I'll try not to make a pest of myself.

"The DE250 is never flat - to my +- 2dB requirement on any waveguide that I have built."

Okay, so maybe a pancake with walnuts and whipped cream. I was being a little hyperbolic to stress a point.

Thanks for the response Earl, I appreciate it. I've been following your work for quite awhile and I like your approach. I don't have the engineering skills to really understand it all, but I do have the mechanical skills to build your waveguides - it makes it feasible for me to experiment with some finely tuned designs. I'm a machinist, retired from the floor, but I'm still working for myself writing post processors for Cad/Cam software. I've got a buddy down the street with a full blown machine shop at my disposal (well, if I can work between his real jobs

" And to get the last 1% optimized can often take as long (or longer) than the first 99%."

I hear ya' - it's true of any speaker you build. I was surprised when I started DIYing how easy it was to get something quite listenable, but only 95% optimized...I tend to use my imagination for the last 5%.

I'll have some time to start tweaking the whole mess early next year - I've got 16 12 inch woofers on the way for some OB bass trials that will take a coupla weeks to sort out first - so I'll probably be bugging you with questions. Hope you don't mind. I'll try not to make a pest of myself.

something wrong with the throats

I got some Eminence APT tweeters on hand. And those Dayton wave guides on PE look interesting, so I bought some for experiment.

Yesterday I received 8" & 12" ones:

http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=270-308

http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=270-312

And the adaptor for APT:

http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=290-539

Assembled together, they look odd:

Mated with APT:

Mated with some other 1" driver:

See what I mean? There's a flat ring area around the throat, forming a step along the inner wall expansion.

The "throat" of the WG is actually 29.3mm, instead of 25.4mm. That's where the ~2mm step comes from.

I'm moving in a few days, my system was disconnected and packed. So I can not try them now.

This must be wrong. Anyone found this and also found the actual infuences on sound?

I'm thinking chamfering off the step to make it smooth....

I got some Eminence APT tweeters on hand. And those Dayton wave guides on PE look interesting, so I bought some for experiment.

Yesterday I received 8" & 12" ones:

http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=270-308

http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=270-312

And the adaptor for APT:

http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=290-539

Assembled together, they look odd:

Mated with APT:

Mated with some other 1" driver:

See what I mean? There's a flat ring area around the throat, forming a step along the inner wall expansion.

The "throat" of the WG is actually 29.3mm, instead of 25.4mm. That's where the ~2mm step comes from.

I'm moving in a few days, my system was disconnected and packed. So I can not try them now.

This must be wrong. Anyone found this and also found the actual infuences on sound?

I'm thinking chamfering off the step to make it smooth....

Re: something wrong with the throats

From experince I can tell you that the throat area is extremely critical to the sound. This is where all of the wave shaping takes place and if its not right then the sound isn't right. This is where virtually all of the waveguides that I have seen get it wrong.

We found that when this area is done correctly, I can even measure the production tollerances of the fiberglass waveguides from the mating at this junction.

CLS said:This must be wrong. Anyone found this and also found the actual infuences on sound?

From experince I can tell you that the throat area is extremely critical to the sound. This is where all of the wave shaping takes place and if its not right then the sound isn't right. This is where virtually all of the waveguides that I have seen get it wrong.

We found that when this area is done correctly, I can even measure the production tollerances of the fiberglass waveguides from the mating at this junction.

CLS said:So, I guess it's hard to get a "correct" contour by my own hand and primitive hand-held tool

Then, how about some sound absorbing stuff around that step?

You are asking if this "error" can be corrected; I don't think so. You can try and do the best you can, but it will always be less than ideal. How much less? It can take a lot of experimenting to answer that question.

CLS said:So, I guess it's hard to get a "correct" contour by my own hand and primitive hand-held tool

Then, how about some sound absorbing stuff around that step?

Since you already got the wave guard, you can try to correct it & see how it goes. One cheap and easy option I can think off is fill the 29.3mm hole with water soluble filler. Shape & smooth the exit the way you think it should. Once it is dried. Use a 25.5mm drill head and drill a hole - slowly without cracking the filler. That should fit the compress driver nicely. Test it and if it is good, use something more permanent like the filler they used on car body. If it doesn't work... wash it down and try another option.

Have fun

Finally, I spared some time for this stuff....

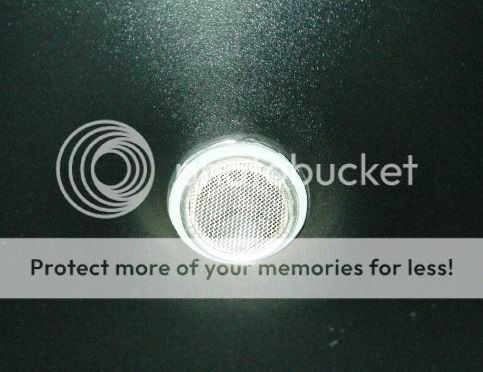

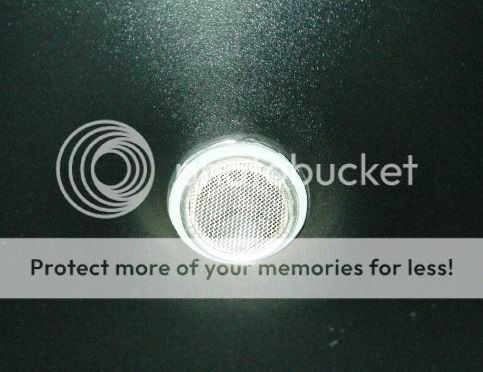

I just filed the adaptor to fit the throat of WG. This is the comparison of the treated one and the original:

And this is the adaptor and the original APT WG.

This is the assembly of the dirver/adaptor/8" WG:

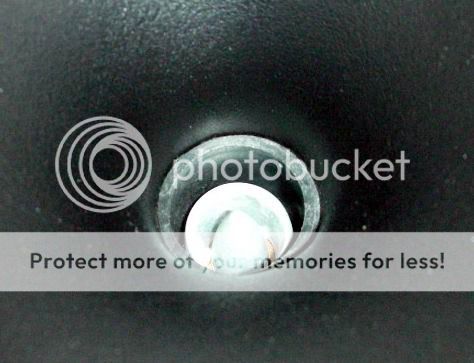

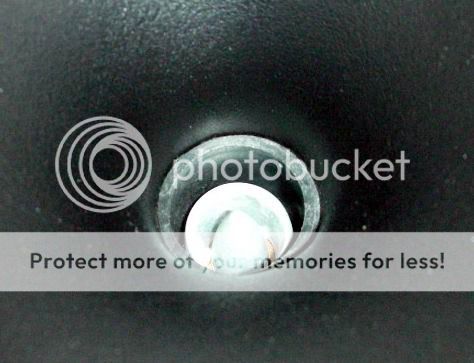

This is the close up of throat:

I got NO scientific measure to the hand filing and the results of work. I simply examined the suface by finger's touch and made them as smooth as can be.

As smooth as they are, but there's still a catch in the contour: the phase plug of the driver must be a crucial part of the entire expansion. Unfortunately that's the part I can not figure by bare hands and eyes.

Anyway, these stuff are only cheap toys, so be it.

This is the temporary setup of the 12" ones and my simple 8" fullranger in OB:

Since this is only a temporary trial, so the integration is very crude. I keep the fullrangers doing their fullrange job, and cut the low end of tweeter by a 4.7uF cap.

Of course that can not be balanced. I shelf down several dB's to the high frequecy region by the upstream digital EQ. Then it sounded just right.

It looks very odd by the physically bigger "tweeter"of the system, but it does sound natural and open. The highs from the WG spreads wider and extends higher than the 8" fullranger itself, so the response in room is much better. It sounds very even everywhere in this relatively small space.

For a cheap experimental trial, this is a satisfied result to me

I just filed the adaptor to fit the throat of WG. This is the comparison of the treated one and the original:

And this is the adaptor and the original APT WG.

This is the assembly of the dirver/adaptor/8" WG:

This is the close up of throat:

I got NO scientific measure to the hand filing and the results of work. I simply examined the suface by finger's touch and made them as smooth as can be.

As smooth as they are, but there's still a catch in the contour: the phase plug of the driver must be a crucial part of the entire expansion. Unfortunately that's the part I can not figure by bare hands and eyes.

Anyway, these stuff are only cheap toys, so be it.

This is the temporary setup of the 12" ones and my simple 8" fullranger in OB:

Since this is only a temporary trial, so the integration is very crude. I keep the fullrangers doing their fullrange job, and cut the low end of tweeter by a 4.7uF cap.

Of course that can not be balanced. I shelf down several dB's to the high frequecy region by the upstream digital EQ. Then it sounded just right.

It looks very odd by the physically bigger "tweeter"of the system, but it does sound natural and open. The highs from the WG spreads wider and extends higher than the 8" fullranger itself, so the response in room is much better. It sounds very even everywhere in this relatively small space.

For a cheap experimental trial, this is a satisfied result to me

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Another PR170M0/Waveguide experiment