Speaker Project Raal JKN 1

This speaker project has been in progress for some time now close to 2 years in fact but finally the construction is going ahead.

Firstly a brief note how JKN 1 came to reality. The idea was to construct a MTM design with a ribbon tweeter. The System is base on active setup using DEQX no passive crossovers MTM sealed box was a must crossing at 80HZ where mine Whise acoustic profunders 624 (modified) Subs takes over

I was looking for a good Ribbon tweeter some time back the choices were

Raven R1

Raven R2

Raven R3

Aurum Cantum

Raal 140 15D

I have tried some Ribbon drivers before but was looking for some which could be cross around 2000 HZ the contender were R2 and R3. R3 was too expensive and R2 was still in mine mind. I have talked to a guy from Czech Republic and recommend trying the Raal 140 as it is good. I did checked the Raal website see the (pictures) graphs and all was looking good crossing at 1600HZ “well” .I did took the plunge and order these drivers and now I’m happy that I did really happy with it’s performance.

This speaker project has been in progress for some time now close to 2 years in fact but finally the construction is going ahead.

Firstly a brief note how JKN 1 came to reality. The idea was to construct a MTM design with a ribbon tweeter. The System is base on active setup using DEQX no passive crossovers MTM sealed box was a must crossing at 80HZ where mine Whise acoustic profunders 624 (modified) Subs takes over

I was looking for a good Ribbon tweeter some time back the choices were

Raven R1

Raven R2

Raven R3

Aurum Cantum

Raal 140 15D

I have tried some Ribbon drivers before but was looking for some which could be cross around 2000 HZ the contender were R2 and R3. R3 was too expensive and R2 was still in mine mind. I have talked to a guy from Czech Republic and recommend trying the Raal 140 as it is good. I did checked the Raal website see the (pictures) graphs and all was looking good crossing at 1600HZ “well” .I did took the plunge and order these drivers and now I’m happy that I did really happy with it’s performance.

Attachments

Mid/bass

As for mine Mid/bass I have been recommended to used some from those companies

PHL

Accutons

AudioTechnology

On the end I have decided to go for the PHL it suppose to be good match with Raal 140 D15

I have bought PHL 1220 which I’m happy with but the new 1360 are suppose ably better drivers and thinking to replace them in future upgrade. Note that all the Mid/bass Phl’s drivers have the same (dimensions) and mounting configuration so very easy to upgrade.

As for mine Mid/bass I have been recommended to used some from those companies

PHL

Accutons

AudioTechnology

On the end I have decided to go for the PHL it suppose to be good match with Raal 140 D15

I have bought PHL 1220 which I’m happy with but the new 1360 are suppose ably better drivers and thinking to replace them in future upgrade. Note that all the Mid/bass Phl’s drivers have the same (dimensions) and mounting configuration so very easy to upgrade.

Attachments

Design

The next search (step) was to find right design (enclosures.) I did not want to just make a box was looking for something different. I have to mention that at the same time friend of mine Mark was after some enclosures for his 3 way design using same drivers that is MT (Raal 140 15D and 1 off PHL 1220) for his bass he decided to used Peerless. He has been

Contacting Alex from Raal if he has any idea as a matter of fact he is a designer as well and he send us some of his design he has done in the past we had a look at it and it was clear than to me (us) that Alex is our guy. Mark has some of his ideas and let Alex know what he like to do it took some time as it turns out to be more complicated design than originally planed. I wont explain how Marks 300KG each speakers come alive I will concentrate on mine MTM 130 KG bookshelf.

Brief summary of mine MTM’s

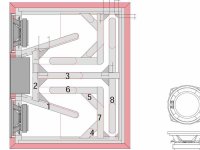

It is a sealed box design with 2 close transmition lines for both mid/bass drivers

The box is going to be constructed from 2 separated Ply’s (909 subdue 24mm external and 28 hardwood ply armor ply 34f for internal and bracing. Note that 909 Subdue ply is special made ply used in boating, aero industries especially used as a soundproof part ions’ around engines and so on. The 909 ply is basically 2 pieces of 12 mm ply and in the middle 5 mm wave bar is press and glued.

The box is going to be 50 mm thick all around. When I saw this project on the plans I was really exited Alex obviously knows his stuff. Here is what Alex stated when he finishes our drawings.

Anyway, your's and Mark's speakers will be over-the-top in every way. You know, I'm really sorry that I wouldn't be able to listen to them! The internal lossy transmission line will be a black hole for back radiation and the box itself will be totally "dead". I can imagine when you hear the clarity and lack of box coloration..4

The next search (step) was to find right design (enclosures.) I did not want to just make a box was looking for something different. I have to mention that at the same time friend of mine Mark was after some enclosures for his 3 way design using same drivers that is MT (Raal 140 15D and 1 off PHL 1220) for his bass he decided to used Peerless. He has been

Contacting Alex from Raal if he has any idea as a matter of fact he is a designer as well and he send us some of his design he has done in the past we had a look at it and it was clear than to me (us) that Alex is our guy. Mark has some of his ideas and let Alex know what he like to do it took some time as it turns out to be more complicated design than originally planed. I wont explain how Marks 300KG each speakers come alive I will concentrate on mine MTM 130 KG bookshelf.

Brief summary of mine MTM’s

It is a sealed box design with 2 close transmition lines for both mid/bass drivers

The box is going to be constructed from 2 separated Ply’s (909 subdue 24mm external and 28 hardwood ply armor ply 34f for internal and bracing. Note that 909 Subdue ply is special made ply used in boating, aero industries especially used as a soundproof part ions’ around engines and so on. The 909 ply is basically 2 pieces of 12 mm ply and in the middle 5 mm wave bar is press and glued.

The box is going to be 50 mm thick all around. When I saw this project on the plans I was really exited Alex obviously knows his stuff. Here is what Alex stated when he finishes our drawings.

Anyway, your's and Mark's speakers will be over-the-top in every way. You know, I'm really sorry that I wouldn't be able to listen to them! The internal lossy transmission line will be a black hole for back radiation and the box itself will be totally "dead". I can imagine when you hear the clarity and lack of box coloration..4

Attachments

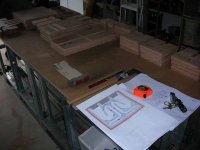

Material

Material for the internal box and braces turn up (it had to be made as 28mm is not standard size) unfortunately we have found out that all the sheets have to be mill down to more precise measurement .They have up to 1mm and some up to 2mm differences within a sheet we would get away with 0.3. so milling is essential.

Material for the internal box and braces turn up (it had to be made as 28mm is not standard size) unfortunately we have found out that all the sheets have to be mill down to more precise measurement .They have up to 1mm and some up to 2mm differences within a sheet we would get away with 0.3. so milling is essential.

Attachments

Next step I have round all the bits inside the transmition line. Just going to check some prices at local stores need a router hopefully not too expensive.

Trying to put it together

I was trying to put more pictures on one post and did not have much luck with it is there a way?

Trying to put it together

I was trying to put more pictures on one post and did not have much luck with it is there a way?

Attachments

JiriAU said:edjosh23 Thanks a lot

Hi Lindell thanks mate. BTW I have followed the link you have on the bottom on the page. Beautiful studio well unreal I should say do you work there?

.

Yay, It's my place where I do all the hits...

Seriously nice studio. Built in the 70's by Tom Hidley. There's been some renovation thru out the years though.

Check the big main monitors in the A studio.....

Just update on mine project. First some holes have to be drill for speaker cables

and gluing and cutting damping tiles (4VS) .This tiles again are used in boating and particularly in air crafts to damp /reduce a noise .This tiles are very heavy they are around 5kg each!! But easy to apply as they are self-adhesive nevertheless I will be tiling if I can used this terms for a week if lucky it is really tricky a time consuming job.

and gluing and cutting damping tiles (4VS) .This tiles again are used in boating and particularly in air crafts to damp /reduce a noise .This tiles are very heavy they are around 5kg each!! But easy to apply as they are self-adhesive nevertheless I will be tiling if I can used this terms for a week if lucky it is really tricky a time consuming job.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Speaker Project Raal JKN 1