QTS

Hello.... you are not missing anything..... The Peerless is a compromise... fairly high Q for a hi-fi woofer, a lot of Xmax and a decent price - availability. They typically have an actual Q around .6 and once you put the inductor in series and get it mounted on the baffle you are close to an operating QTS' of .7.

The PE 18" sub would end up around .53 QTS', but it does have the advantage of efficiency that can be traded away and being 4 ohms the required series inductor can be a smaller value, say 12 - 15 UH.

But with all changes, the cross over would need attention and the Vifa would no longer have enough efficiency. As the baffle grows in width and the distance from the front center of the woofer to the rear edge of the wing increase, the operating efficiency of the total system increases.

With the 18" you would end up around 90 dbw with a cut off around 40 HZ assuming a 4-6" wing depth on a 20" total width baffle. (A 16" path length)

FYI, the standard path length for the original Manzanita is 11".

There are several 6 - 8" full range drivers now available that can be used with the 18, but the better ones are $100 or more each. Again, a lot of crossover work to get them to integrate with the 18.

Hope the above helps.

Hello.... you are not missing anything..... The Peerless is a compromise... fairly high Q for a hi-fi woofer, a lot of Xmax and a decent price - availability. They typically have an actual Q around .6 and once you put the inductor in series and get it mounted on the baffle you are close to an operating QTS' of .7.

The PE 18" sub would end up around .53 QTS', but it does have the advantage of efficiency that can be traded away and being 4 ohms the required series inductor can be a smaller value, say 12 - 15 UH.

But with all changes, the cross over would need attention and the Vifa would no longer have enough efficiency. As the baffle grows in width and the distance from the front center of the woofer to the rear edge of the wing increase, the operating efficiency of the total system increases.

With the 18" you would end up around 90 dbw with a cut off around 40 HZ assuming a 4-6" wing depth on a 20" total width baffle. (A 16" path length)

FYI, the standard path length for the original Manzanita is 11".

There are several 6 - 8" full range drivers now available that can be used with the 18, but the better ones are $100 or more each. Again, a lot of crossover work to get them to integrate with the 18.

Hope the above helps.

thanks John

still a bit confused, you say..

"But with all changes, the cross over would need attention and the Vifa would no longer have enough efficiency."

What Vifa?

BTW my thoughts are to use the woofer below 500 hz. Hand off to a small curved planermagnetic driver ( 91db sens.) above that .

My concerns are are how the baffle size , driver Q, and driver/ x over interaction all blend to get any roll off started at 500. I wonder if its really even possible as In my calcs it seems a crossover around 250 hz is best within the limitations of reasonable baffle size etc are concerned

still a bit confused, you say..

"But with all changes, the cross over would need attention and the Vifa would no longer have enough efficiency."

What Vifa?

BTW my thoughts are to use the woofer below 500 hz. Hand off to a small curved planermagnetic driver ( 91db sens.) above that .

My concerns are are how the baffle size , driver Q, and driver/ x over interaction all blend to get any roll off started at 500. I wonder if its really even possible as In my calcs it seems a crossover around 250 hz is best within the limitations of reasonable baffle size etc are concerned

The Vifa/Peerless TC9FD has been a part of this design for a long time. It's the current tweeter.

See here at post 1601.

Fast, fun, Inexpensive OB project

Or post 455.

See here at post 1601.

Fast, fun, Inexpensive OB project

Or post 455.

hello,

I have been following the thread for the last year or so and I'm finally going to make the project.

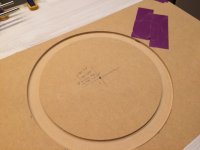

I'll have plenty of questions, but one quick one. To my eye, surface-mounting the drivers does not look attractive. Cutting a rabbet for the 830669 is trivial, but the shape of the TC9 is a challenge. I am working on a mounting method of routing the rear of the baffle 3.900" to a depth of .620 (leaving .130 of material), cutting the through hole to about 2.980" and rounding off the front of the the .130" of material.

So, the TC9 will recessed .130, but the front rounded. This will look nice, but will it hurt the dispersion? Will I introduce too much vibration in the .130x.460 section?

The router work is tricky:

1. Establish a through pin hole to mount the circle jig

2. Route the 3.900" diameter around the perimeter, to .620 depth but leave the middle.

3. Cut the 2.980" hole through

4. Flip and round-over the inside of the 2.980" hole. (1/8" radius seems to look nice).

5. Flip and route out the remainder of the .620 recess.

I need to cut the round-over before finishing the rear recess area because the router bit offset bearing needs material to ride on.

I probably will make my test baffles surface mount for the TC9, but will continue to work on this method on scrap material.

I also, plan to cut baffle extensions to go to the floor to test also.

I need to figure out if this design will work in my strange large mostly-open workshop/office area before I spend too much time on final woodwork.

Finally, many thanks to John and Pano for their efforts.

I have been following the thread for the last year or so and I'm finally going to make the project.

I'll have plenty of questions, but one quick one. To my eye, surface-mounting the drivers does not look attractive. Cutting a rabbet for the 830669 is trivial, but the shape of the TC9 is a challenge. I am working on a mounting method of routing the rear of the baffle 3.900" to a depth of .620 (leaving .130 of material), cutting the through hole to about 2.980" and rounding off the front of the the .130" of material.

So, the TC9 will recessed .130, but the front rounded. This will look nice, but will it hurt the dispersion? Will I introduce too much vibration in the .130x.460 section?

The router work is tricky:

1. Establish a through pin hole to mount the circle jig

2. Route the 3.900" diameter around the perimeter, to .620 depth but leave the middle.

3. Cut the 2.980" hole through

4. Flip and round-over the inside of the 2.980" hole. (1/8" radius seems to look nice).

5. Flip and route out the remainder of the .620 recess.

I need to cut the round-over before finishing the rear recess area because the router bit offset bearing needs material to ride on.

I probably will make my test baffles surface mount for the TC9, but will continue to work on this method on scrap material.

I also, plan to cut baffle extensions to go to the floor to test also.

I need to figure out if this design will work in my strange large mostly-open workshop/office area before I spend too much time on final woodwork.

Finally, many thanks to John and Pano for their efforts.

I need to figure out if this design will work in my strange large mostly-open workshop/office area before I spend too much time on final woodwork.

If this is true build the Ultra for a larger space.

If this is true build the Ultra for a larger space.

Thanks, but the Ultra is a baffle too wide for my taste.

If it is just the low end under 300Hz that is impacted, I would prefer to add a couple of small sealed subs controlled by a minidsp. That setup could be made to fit a cabinet similar in style to Linkwitz's Orion. I find those to be attractive.

He does have the advantage of a baffle only 13" wide.

If your sealed bass unit goes up to 300hz, just do a simple hybrid, with two widerangers like the tc9 if you need either sensitivity or max output to match your bass's output.

Kind of an open baffle most of the way version of XRK's low-crossed two way. I have seen pictures of a build like this, but cannot remember where.

Kind of an open baffle most of the way version of XRK's low-crossed two way. I have seen pictures of a build like this, but cannot remember where.

Oriron baffle width

Had a brief discussion with SL at a N CA DIY gathering a few years ago about that topic... the 13" width is a compromise... that distance along with the wing depth was as small as possible and still be able to actively correct the dual 10" Peerless woofers to a flat response down into the upper 20 Hz area.

Keeping the speaker foot print and overall size as practical as possible was a big consideration. WAF and so forth.

Any narrower width or wing depth, you run out of woofer displacement. In an OB or cardioid design the path distance from the center of the woofer to the rear edge of a wing sets the over all system efficiency. Long path, higher efficiency. Other things happen with more width too, so path length is one of several factors in a successful design.

Don't recall what his acoustic out put minimum goals were. But suspect a around 100 db or a bit more at 1 meter down into the 20's. If you know the actual baffle dimensions you can go to his site and use his calculator:

Electro-acoustic models

Had a brief discussion with SL at a N CA DIY gathering a few years ago about that topic... the 13" width is a compromise... that distance along with the wing depth was as small as possible and still be able to actively correct the dual 10" Peerless woofers to a flat response down into the upper 20 Hz area.

Keeping the speaker foot print and overall size as practical as possible was a big consideration. WAF and so forth.

Any narrower width or wing depth, you run out of woofer displacement. In an OB or cardioid design the path distance from the center of the woofer to the rear edge of a wing sets the over all system efficiency. Long path, higher efficiency. Other things happen with more width too, so path length is one of several factors in a successful design.

Don't recall what his acoustic out put minimum goals were. But suspect a around 100 db or a bit more at 1 meter down into the 20's. If you know the actual baffle dimensions you can go to his site and use his calculator:

Electro-acoustic models

Hi John,

Yes I have read some of Linkwitz writings about trying to limit size. I'm not quite ready to invest in Orions! The 15" of the Manzanita should work aesthetically for me, I just need to test it out - the proof of the pudding is in the eating.

Do you have any thoughts on the original mounting method question?

Yes I have read some of Linkwitz writings about trying to limit size. I'm not quite ready to invest in Orions! The 15" of the Manzanita should work aesthetically for me, I just need to test it out - the proof of the pudding is in the eating.

Do you have any thoughts on the original mounting method question?

For those of us that are woodworking challenged there's also the simplicity of felt for around the tweeter. It also makes the speaker look more balanced.

Fast, fun, Inexpensive OB project

It's message #1433.

Fast, fun, Inexpensive OB project

It's message #1433.

Last edited:

For those of us that are woodworking challenged there's also the simplicity of felt for around the tweeter. It also makes the speaker look more balanced.

Fast, fun, Inexpensive OB project

It's message #1433.

Hi Barry,

Coincidentally, I just read that page today. That is a good idea all around.

Please tell me about the felt used and how it is attached.

Thanks,

Jerry

It is neat to observe the various approaches builders take to find what works for them in their given situations....

The basic design is only a starting point... so many ways to go....

I will be releasing an up dated design based around the GRS 15- Vifa TC9 3.5" mid-tweeter soon. It does require a bit more of simple wood working, but, it can be done with a standard jig or table saw...

Basically, it optimizes wing dimensions with glue on wing parts... but it does provide significant improvements in operating efficiencies with a bit more bass extension.

The basic design is only a starting point... so many ways to go....

I will be releasing an up dated design based around the GRS 15- Vifa TC9 3.5" mid-tweeter soon. It does require a bit more of simple wood working, but, it can be done with a standard jig or table saw...

Basically, it optimizes wing dimensions with glue on wing parts... but it does provide significant improvements in operating efficiencies with a bit more bass extension.

Please tell me about the felt used and how it is attached.

Hi Jerry,

Nothing fancy with the felt. It was left over from covering the back of another open baffle speaker so it got used around the Ultra tweeters. It isn't wool (which has the reputation of being the right stuff for this application) it's just a mix of synthetics. One of the folks in this thread suggested using Scotch Brite pads as they work even better.

It's just attached with tape on the back as I wanted to try it out to see if it made any audible difference and it did. It probably should have been sprayed with glue and attached properly but it just never happened.

On first listen it sounded like it took too much life out of the music but over some time it was evident it removed some grunge that shouldn't have been there. It was not obvious on the initial listen.

I've toyed with covering the back of the baffle with the stuff but experimented before doing it up permanently. In my room padding the entire rear seems to be too much. But a few carefully placed pieces on the back in the general area of the tweeter can do some nice things. Other posters report that covering the entire baffle works well. It's probably ear and room dependent.

Good luck with the build. It's a fun project.

I will be releasing an up dated design based around the GRS 15- Vifa TC9 3.5" mid-tweeter soon. It does require a bit more of simple wood working, but, it can be done with a standard jig or table saw...

Hi John,

Is this going to be an update to the stand mounted Manzi or the floor standing Ultra?

Thanks for keeping it interesting.

Barry

Hello Barry!

The new update will be with the stand mounted Manzi... simple stuff... trying to keep the design as low cost as possible... Baffle tweaks... minor crossover tweaks. Retaining the $100 material cost for each speaker.

Evolutionary... not revolutionary.... Kinda like the Boeing 737... or more fittingly, the VW Bug.... Getting another 3+ db of efficiency being the main improvement.

The new update will be with the stand mounted Manzi... simple stuff... trying to keep the design as low cost as possible... Baffle tweaks... minor crossover tweaks. Retaining the $100 material cost for each speaker.

Evolutionary... not revolutionary.... Kinda like the Boeing 737... or more fittingly, the VW Bug.... Getting another 3+ db of efficiency being the main improvement.

- Home

- Loudspeakers

- Multi-Way

- Fast, fun, Inexpensive OB project