I have ordered these.

http://www.audiocircle.com/circles/index.php?topic=43286.0

The cabinets themselves are constructed using constrained layer damping. You'll notice that the front baffles are of solid wood construction. These are CNCed to form the waveguide. I have the option of American Cherry, American Walnut, Red Oak, Maple, English Beech, or custom choice at extra cost. As I don't really care how they look, I was wondering if the hardness of the wood would affect either the resonance or the propagation of the tweeter. Would this be a real concern, or am I postulating a distinction without a difference?

http://www.audiocircle.com/circles/index.php?topic=43286.0

The cabinets themselves are constructed using constrained layer damping. You'll notice that the front baffles are of solid wood construction. These are CNCed to form the waveguide. I have the option of American Cherry, American Walnut, Red Oak, Maple, English Beech, or custom choice at extra cost. As I don't really care how they look, I was wondering if the hardness of the wood would affect either the resonance or the propagation of the tweeter. Would this be a real concern, or am I postulating a distinction without a difference?

Nice thread.

Best.

Some details abot ash and cherry.

http://audioroundtable.com/Craftsmen/messages/723.html

M's Systems Wood Cylindrical Stereo Speakers

http://www.gizmodo.com.au/2007/06/ms_systems_wood_cylindrical_st.html

Best.

Some details abot ash and cherry.

http://audioroundtable.com/Craftsmen/messages/723.html

M's Systems Wood Cylindrical Stereo Speakers

http://www.gizmodo.com.au/2007/06/ms_systems_wood_cylindrical_st.html

Hmmmmm. Thanks for the reply, Inductor, but not really what I was looking for. I don't care what the cabinet looks like. I was wondering if the hardness of the wood, measured in the Janka wood hardness scale, has any effect on the measured, or percieved, performance of the speaker system.

http://www.woodsthebest.com/wood/jankaWoodHardnessScale.htm

http://www.woodsthebest.com/wood/jankaWoodHardnessScale.htm

I would (bad pun ?) think that the only reason a particular type of wood to have an effect on sound would be if the enclosure was big enough to allow the panel to resonate.

If this is an issue though, just add a bit of cross bracing to that panel.

Basically unless the cabinet has a single unbraced panel of a few feet across, I personally don't see it as an issue.

EDIT; just had a look at your link to the speakers.

I can't see why the timber choice would have any effect at all.

Oh, and YUMMM, they are sexyyyy.

If this is an issue though, just add a bit of cross bracing to that panel.

Basically unless the cabinet has a single unbraced panel of a few feet across, I personally don't see it as an issue.

EDIT; just had a look at your link to the speakers.

I can't see why the timber choice would have any effect at all.

Oh, and YUMMM, they are sexyyyy.

"Harder" woods tend to have greater rigidity and therefore a higher resonant frequency. They require more energy to excite and therefore to transmit sound energy from the inside to the outside of the enclosure. At the resonant frequency, sound is more easily transmitted through the enclosure making the enclosure a speaker of sorts at that frequency. This is a form of distortion. The higher the frequency of the resonance, the easier it is for stuffing and damping to absorb the acoustical energy of the signal so that it does not make it's way out through the walls.

On the other hand, harder woods often have more mass, which lowers the resonant frequency. There is a frequency above which Mass becomes the dominant factor of blocking sound transmission and the greater the mass, the greater the inhibition of sound transmission. Finding the balance that best suits your needs is important. Unfortunately, hardness, alone, is not going to get you there.

Of note, the greatest amount of sound loss is going to be through the driver, itself (at least in a sealed enclosure).

An interesting article on the sound of various woods can be found at http://www.pantheonguitars.com/tonewoods.htm.

Jay

On the other hand, harder woods often have more mass, which lowers the resonant frequency. There is a frequency above which Mass becomes the dominant factor of blocking sound transmission and the greater the mass, the greater the inhibition of sound transmission. Finding the balance that best suits your needs is important. Unfortunately, hardness, alone, is not going to get you there.

Of note, the greatest amount of sound loss is going to be through the driver, itself (at least in a sealed enclosure).

An interesting article on the sound of various woods can be found at http://www.pantheonguitars.com/tonewoods.htm.

Jay

Just a little more information for you (adapted from http://squ1.com/archive/index.php?sound/transmission.html)

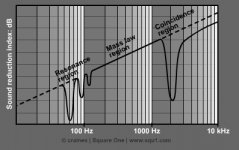

Sound attenuation in ordinary enclosures is the result of an interplay between mass, stiffness and damping. At low frequencies (below the resonance of the wall), transmission depends mainly on the stiffness of the wall, with damping and mass having little effect. The effectiveness of stiffness in the attenuation of sound transmission decreases by 6dB for every doubling of frequency (one octave).

At slightly higher frequencies the resonance of the wall begins to control its transmission behaviour. Because every panel has a finite boundary and edge fixings, it will have a series of natural frequencies at which it will vibrate more easily than others. These are called resonant frequencies and consist of a fundamental frequency (having the greatest effect), and integer multiples of this fundamental called harmonics (having less and less effect). The fundamental resonant frequency of a panel can be calculated as follows:

Fr = 0.45 * vL * b((1/l)² + (1/h)²)

and vl = sqrt(E / (p * (1 - s²)))

where:

b = the panel thickness (m),

l and h = length and height (m), and

vl = the longitudinal velocity of sound in the partition (m/s).

In the calculation of vl:

E = Young's modulus of elasticity,

s = it's Poisson ratio, and

p = density (kg/m³).

To calculate harmonic frequencies, simply replace the number 1 in the first equation with the required harmonic number.

At frequencies well above that of the lowest resonant frequency, the wall tends to behave as an assembly of much smaller masses and is then said to be mass controlled. It is within this range that the mass law directly applies.

R

= 20 log (2p f m / roc) dB

= 20 log (f m) - 47 dB

where:

f = the frequency (Hz),

m = the mass per unit area (kg/m²), and

roc = the characteristic impedance of air (basically, density times the speed of sound: taken to be between 410 and 420 rayls for 20°C and 1 atm).

High frequencies cause bending or ripple waves that travel longitudinally along a wall or panel. The wavelength of a bending wave is different from that of the incident sound wave which created it except at one frequency, the critical frequency. Unlike compressional waves, bending waves of different frequencies travel at different speeds. This means that for every frequency above the critical frequency, there will be an angle of incidence at which the wavelength of the bending wave is equal to the wavelength of the impacting sound. This condition is known as coincidence.

When coincidence occurs it gives rise to a far more efficient transfer of sound energy from one side of the panel to the other, hence the big coincidence-dip at the critical frequency.

The lowest frequency at which coincidence can occur is when the angle of incidence of the sound is at 90° (grazing incidence) and can be calculated from:

Fc = c² / (1.8 * h * vl * sin²(a))

where:

c = the speed of sound in air (m/s),

h = the panel thickness (m),

vl = the longitudinal velocity of sound in the partition (m/s), and

a = the angle of incidence.

Above the critical frequency, panel stiffness begins to play the most important role again.

Sound attenuation in ordinary enclosures is the result of an interplay between mass, stiffness and damping. At low frequencies (below the resonance of the wall), transmission depends mainly on the stiffness of the wall, with damping and mass having little effect. The effectiveness of stiffness in the attenuation of sound transmission decreases by 6dB for every doubling of frequency (one octave).

At slightly higher frequencies the resonance of the wall begins to control its transmission behaviour. Because every panel has a finite boundary and edge fixings, it will have a series of natural frequencies at which it will vibrate more easily than others. These are called resonant frequencies and consist of a fundamental frequency (having the greatest effect), and integer multiples of this fundamental called harmonics (having less and less effect). The fundamental resonant frequency of a panel can be calculated as follows:

Fr = 0.45 * vL * b((1/l)² + (1/h)²)

and vl = sqrt(E / (p * (1 - s²)))

where:

b = the panel thickness (m),

l and h = length and height (m), and

vl = the longitudinal velocity of sound in the partition (m/s).

In the calculation of vl:

E = Young's modulus of elasticity,

s = it's Poisson ratio, and

p = density (kg/m³).

To calculate harmonic frequencies, simply replace the number 1 in the first equation with the required harmonic number.

At frequencies well above that of the lowest resonant frequency, the wall tends to behave as an assembly of much smaller masses and is then said to be mass controlled. It is within this range that the mass law directly applies.

R

= 20 log (2p f m / roc) dB

= 20 log (f m) - 47 dB

where:

f = the frequency (Hz),

m = the mass per unit area (kg/m²), and

roc = the characteristic impedance of air (basically, density times the speed of sound: taken to be between 410 and 420 rayls for 20°C and 1 atm).

High frequencies cause bending or ripple waves that travel longitudinally along a wall or panel. The wavelength of a bending wave is different from that of the incident sound wave which created it except at one frequency, the critical frequency. Unlike compressional waves, bending waves of different frequencies travel at different speeds. This means that for every frequency above the critical frequency, there will be an angle of incidence at which the wavelength of the bending wave is equal to the wavelength of the impacting sound. This condition is known as coincidence.

When coincidence occurs it gives rise to a far more efficient transfer of sound energy from one side of the panel to the other, hence the big coincidence-dip at the critical frequency.

The lowest frequency at which coincidence can occur is when the angle of incidence of the sound is at 90° (grazing incidence) and can be calculated from:

Fc = c² / (1.8 * h * vl * sin²(a))

where:

c = the speed of sound in air (m/s),

h = the panel thickness (m),

vl = the longitudinal velocity of sound in the partition (m/s), and

a = the angle of incidence.

Above the critical frequency, panel stiffness begins to play the most important role again.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.