Hello everyone,

Been away for a while reading, learning. I think I feel a bit like Alice falling down the rabbit hole sometimes. As part of course I believe I am now getting reliable measurement data from Speaker Workshop as to utilize the cross over designer features and I have begun to carefully measure all the drivers to obtain a good modeling.

In that regard the tweeter measurement has exposed some kind of destructive cancellation when the driver rests flush mounted in the cabinet. I have tried extending the baffle using cardboard both vertically and/or horizontally. I also tried covering the upper portion of the baffle around the tweeter with felt containing a small hole (30mm) exposing just the dome. The location and the severity of the dip remained unchanged! However pulling the tweeter out about 100 mm from the baffle changes the response dramatically. The original dip disappears but is replaced with two sharp dips located on opposite sides of where the dip previously occurred. If I remove the tweeter from the baffle and measure its response positioned resting on top of the cabinet, the dip disappears. I have read much about diffraction and although it appears to explain the location it does not explain the severity of almost 8 db.

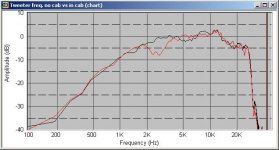

Below is a chart showing the anomaly. The red line is the tweeter flush mounted on the baffle. The black line is the tweeter removed from the baffle and measured sitting on top of the cab.

My only theory at this point is that the design of the tweeter faceplate is creating a waveform that when encountering the baffle creates a very destructive cancellation that so happens to be centered around a baffle step diffraction dip.

I am hoping the experience on this board can help me make some sense of this. I don't know what else to try short of removing the grill and applying felt directly to the tweeter faceplate. The process will damage the grill; there is risk of damaging the dome and the felt test I tried above doesn't strongly suggest it would help anyway.

Measurements farfield 1M gated.

The box is 220 x 1080 X 310 (WxHxD)mm

The Accuton C23 is horizontally centered on the baffle 110mm from the top.

Been away for a while reading, learning. I think I feel a bit like Alice falling down the rabbit hole sometimes. As part of course I believe I am now getting reliable measurement data from Speaker Workshop as to utilize the cross over designer features and I have begun to carefully measure all the drivers to obtain a good modeling.

In that regard the tweeter measurement has exposed some kind of destructive cancellation when the driver rests flush mounted in the cabinet. I have tried extending the baffle using cardboard both vertically and/or horizontally. I also tried covering the upper portion of the baffle around the tweeter with felt containing a small hole (30mm) exposing just the dome. The location and the severity of the dip remained unchanged! However pulling the tweeter out about 100 mm from the baffle changes the response dramatically. The original dip disappears but is replaced with two sharp dips located on opposite sides of where the dip previously occurred. If I remove the tweeter from the baffle and measure its response positioned resting on top of the cabinet, the dip disappears. I have read much about diffraction and although it appears to explain the location it does not explain the severity of almost 8 db.

Below is a chart showing the anomaly. The red line is the tweeter flush mounted on the baffle. The black line is the tweeter removed from the baffle and measured sitting on top of the cab.

My only theory at this point is that the design of the tweeter faceplate is creating a waveform that when encountering the baffle creates a very destructive cancellation that so happens to be centered around a baffle step diffraction dip.

I am hoping the experience on this board can help me make some sense of this. I don't know what else to try short of removing the grill and applying felt directly to the tweeter faceplate. The process will damage the grill; there is risk of damaging the dome and the felt test I tried above doesn't strongly suggest it would help anyway.

Measurements farfield 1M gated.

The box is 220 x 1080 X 310 (WxHxD)mm

The Accuton C23 is horizontally centered on the baffle 110mm from the top.

Attachments

ttruman said:Hello everyone,

Been away for a while reading, learning. I think I feel a bit like Alice falling down the rabbit hole sometimes. As part of course I believe I am now getting reliable measurement data from Speaker Workshop as to utilize the cross over designer features and I have begun to carefully measure all the drivers to obtain a good modeling.

In that regard the tweeter measurement has exposed some kind of destructive cancellation when the driver rests flush mounted in the cabinet. I have tried extending the baffle using cardboard both vertically and/or horizontally. I also tried covering the upper portion of the baffle around the tweeter with felt containing a small hole (30mm) exposing just the dome. The location and the severity of the dip remained unchanged! However pulling the tweeter out about 100 mm from the baffle changes the response dramatically. The original dip disappears but is replaced with two sharp dips located on opposite sides of where the dip previously occurred. If I remove the tweeter from the baffle and measure its response positioned resting on top of the cabinet, the dip disappears. I have read much about diffraction and although it appears to explain the location it does not explain the severity of almost 8 db.

Below is a chart showing the anomaly. The red line is the tweeter flush mounted on the baffle. The black line is the tweeter removed from the baffle and measured sitting on top of the cab.

My only theory at this point is that the design of the tweeter faceplate is creating a waveform that when encountering the baffle creates a very destructive cancellation that so happens to be centered around a baffle step diffraction dip.

I am hoping the experience on this board can help me make some sense of this. I don't know what else to try short of removing the grill and applying felt directly to the tweeter faceplate. The process will damage the grill; there is risk of damaging the dome and the felt test I tried above doesn't strongly suggest it would help anyway.

Measurements farfield 1M gated.

The box is 220 x 1080 X 310 (WxHxD)mm

The Accuton C23 is horizontally centered on the baffle 110mm from the top.

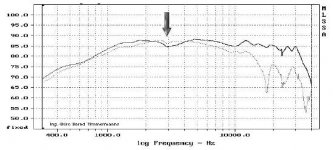

Hmm, my bet on this is still that it is diffraction that causes it. A simulation of the baffle step shows that the placement on the baffle is far from optimal. I suppose it has to do with that the tweeter is mounted 110 mm from three edges, and that produces a dip of some 4-5 dB at ~2600 Hz.

An externally hosted image should be here but it was not working when we last tested it.

Another thing, which is a longshot; as far as I can see from the measurement, the resolution is ~100 Hz. That would mean that the gating window is ~10 ms (?), which in turn means that the pathway of the first reflection must be no less than 0,01*345=3,45 m. Is that so? Could it be that you also have a reflection from one of the room surfaces inside the gating window?

Re: Re: Stuck in a dip

Should be :

...at least 0,01*345=3,45 m longer than the direct pathway...

Svante said:Another thing, which is a longshot; as far as I can see from the measurement, the resolution is ~100 Hz. That would mean that the gating window is ~10 ms (?), which in turn means that the pathway of the first reflection must be no less than 0,01*345=3,45 m. Is that so? Could it be that you also have a reflection from one of the room surfaces inside the gating window?

Should be :

...at least 0,01*345=3,45 m longer than the direct pathway...

Considering the relatively long wavelengths in question (circa: 110mm), you may need a layer of damping material that's in the vicinity of 3~4cm thick.

How about covering the corners and box edges with some pieces of sheep-skin rug? A 100mm x 660mm strip (with two cutouts for the overlapping corners) may be sufficient.

Cheers,

Lech

How about covering the corners and box edges with some pieces of sheep-skin rug? A 100mm x 660mm strip (with two cutouts for the overlapping corners) may be sufficient.

Cheers,

Lech

not convinced it's all baffle step

Hi Svante,

I am little confused by your interpretation of the simulation. Based on the graph I agree with the frequency but the dip amplitude appears to be about -2.5 db given a mean of the 6db on the chart. Apparently I am not interpreting that correctly. I also don’t see the adjacent peak in my measurement which is the same amplitude as the dip. The tweeter exhibits the classic smooth 12db roll off of a closed box system when not measured in the baffle so I would expect to see the effects of the peak as well. Yes I am confused. Additionally I mentioned extending the baffle with cardboard in both horizontal and vertical directions. The dip did not move or change amplitude.

If I do its not apparent in the pulse response. But it’s worth double checking everything again except this time I will use the formula to calculate the arrival of the surface reflections D/R=T and see if they match the pulse response indicators. Maybe I am doing something wrong. I know the floor arrives at ~10ms. I can clearly see it and reduce it by acoustically padding the floor. The ceiling is approximately the same distance away and is hung acoustical tile.

Hi Svante,

Svante said:Hmm, my bet on this is still that it is diffraction that causes it. A simulation of the baffle step shows that the placement on the baffle is far from optimal. I suppose it has to do with that the tweeter is mounted 110 mm from three edges, and that produces a dip of some 4-5 dB at ~2600 Hz.

I am little confused by your interpretation of the simulation. Based on the graph I agree with the frequency but the dip amplitude appears to be about -2.5 db given a mean of the 6db on the chart. Apparently I am not interpreting that correctly. I also don’t see the adjacent peak in my measurement which is the same amplitude as the dip. The tweeter exhibits the classic smooth 12db roll off of a closed box system when not measured in the baffle so I would expect to see the effects of the peak as well. Yes I am confused. Additionally I mentioned extending the baffle with cardboard in both horizontal and vertical directions. The dip did not move or change amplitude.

Svante [/i][B] Another thing said:Could it be that you also have a reflection from one of the room surfaces inside the gating window?

If I do its not apparent in the pulse response. But it’s worth double checking everything again except this time I will use the formula to calculate the arrival of the surface reflections D/R=T and see if they match the pulse response indicators. Maybe I am doing something wrong. I know the floor arrives at ~10ms. I can clearly see it and reduce it by acoustically padding the floor. The ceiling is approximately the same distance away and is hung acoustical tile.

Hi Lech,

Did you experience a similar issue with your two way Accuton configuration? What doesn’t make sense to me is that if I change the baffle dimensions using cardboard, the anomaly does not change. The measurements taken with the extended baffle combinations do show a slight influence in the frequency response like those in BSD simulations.

I assume you mean around the tweeter area. I think that much material would severely affect the off axis dispersion characteristics. But it may be worth trying to in narrow down the cause.CeramicMan said:Considering the relatively long wavelengths in question (circa: 110mm), you may need a layer of damping material that's in the vicinity of 3~4cm thick.

CeramicMan said:How about covering the corners and box edges with some pieces of sheep-skin rug? A 100mm x 660mm strip (with two cutouts for the overlapping corners) may be sufficient.

Did you experience a similar issue with your two way Accuton configuration? What doesn’t make sense to me is that if I change the baffle dimensions using cardboard, the anomaly does not change. The measurements taken with the extended baffle combinations do show a slight influence in the frequency response like those in BSD simulations.

Inductor said:Hi, -2,5dB, -2,5dB = ... (a lot)

Hi Inductor,

I think in order for that to be usefull, the particulars of the circumstances under which that measurement was taken must be known. Assuming that the measurement was taken without the unit being flush mounted in baffle as you suggest

is it should resonable to expect that I would see the same dip in my my out of baffle measurement, which I dont. In all fairness it may very well be, as Svante suggested, my measurements may not be accurate. I will check my setup this evening and confirm my original results.

ttruman said:

Assuming that the measurement was taken without the unit being flush mounted in baffle as you suggest is it should resonable to expect that I would see the same dip in my my out of baffle measurement, which I dont.

Yes. I know. Something fishy (for a $200,00 driver).

Inductor said:Yes. I know. Something fishy (for a $200,00 driver).

I don't believe that's been established yet.

If you do end up putting wool or other material around the tweeter, I'd recommend making the tweeter-facing side into a star shape so there are no edges concentric with the dome, which would give you another discontinuity, admittedly smaller because of the absorptive nature of the stuff, but still there.

Re: not convinced it's all baffle step

Well, it is true that your dip appears larger, but you can actually have the peak at 1500 Hz, without noticing it. The driver, as i see it on measurements I find on the web, seems to start rolling off at 2000 Hz, so the peak is more or less compensated by the roll-off.

If I simulate the same thing in Basta!, which has the same diffraction engine as The Edge, this becomes reasonably visible. The response curve of the infinitely baffled tweeter matches the responses I found reasonably good, except from the 10k+ range.

The simulation then looks like this.

The green curve is there to demonstrate that slight adjustments in the microphone position smoothes out the ripple at higher frequencies. Rounding the edges of the box can have similar effects.

When it is put on top of your measurement, it is reasonably clear that diffraction contributes to that dip. I trust the diffraction simulation, I have seen it match so many measurements now that I can say with confidence that diffraction is at least part of the issue here.

PS, it seems less likely to me that room reflections is the cause, you seem to have that under control.

PS2, the harsh advice here would be to re-design the baffle and place the tweeter based on diffraction simulations. Sorry about that, it is always hard to say this when a lot of work is invested in fine woodwork.

You could, just to test it, you could put the tweeter in a piece of MDF 220 mm wide, but slightly to the side and slightly lower:

PS3, about the cardboard extension, I am surprised that it did not change the response. In my experience, cardboard is fine for quick and dirty diffraction tests. However, it is very important that the attachment between the box and the cardboard is tight, otherwise the diffraction will be there anyway.

What happens if you put the (free) driver in a piece of cardboard of the same geometry and size as the baffle? (You dont need the lower half metre I guess. a piece of 220x500 mm would do.)

ttruman said:Hi Svante,

I am little confused by your interpretation of the simulation. Based on the graph I agree with the frequency but the dip amplitude appears to be about -2.5 db given a mean of the 6db on the chart. Apparently I am not interpreting that correctly. I also don’t see the adjacent peak in my measurement which is the same amplitude as the dip. The tweeter exhibits the classic smooth 12db roll off of a closed box system when not measured in the baffle so I would expect to see the effects of the peak as well. Yes I am confused. Additionally I mentioned extending the baffle with cardboard in both horizontal and vertical directions. The dip did not move or change amplitude.

Well, it is true that your dip appears larger, but you can actually have the peak at 1500 Hz, without noticing it. The driver, as i see it on measurements I find on the web, seems to start rolling off at 2000 Hz, so the peak is more or less compensated by the roll-off.

If I simulate the same thing in Basta!, which has the same diffraction engine as The Edge, this becomes reasonably visible. The response curve of the infinitely baffled tweeter matches the responses I found reasonably good, except from the 10k+ range.

The simulation then looks like this.

An externally hosted image should be here but it was not working when we last tested it.

The green curve is there to demonstrate that slight adjustments in the microphone position smoothes out the ripple at higher frequencies. Rounding the edges of the box can have similar effects.

When it is put on top of your measurement, it is reasonably clear that diffraction contributes to that dip. I trust the diffraction simulation, I have seen it match so many measurements now that I can say with confidence that diffraction is at least part of the issue here.

An externally hosted image should be here but it was not working when we last tested it.

PS, it seems less likely to me that room reflections is the cause, you seem to have that under control.

PS2, the harsh advice here would be to re-design the baffle and place the tweeter based on diffraction simulations. Sorry about that, it is always hard to say this when a lot of work is invested in fine woodwork.

You could, just to test it, you could put the tweeter in a piece of MDF 220 mm wide, but slightly to the side and slightly lower:

An externally hosted image should be here but it was not working when we last tested it.

PS3, about the cardboard extension, I am surprised that it did not change the response. In my experience, cardboard is fine for quick and dirty diffraction tests. However, it is very important that the attachment between the box and the cardboard is tight, otherwise the diffraction will be there anyway.

What happens if you put the (free) driver in a piece of cardboard of the same geometry and size as the baffle? (You dont need the lower half metre I guess. a piece of 220x500 mm would do.)

Re: Re: not convinced it's all baffle step

I've had good results on a tall baffle by placing the tweeter about 40% of the distance from one edge, ie on a 10 inch baffle placing it 4 inches from one side and 6 inches from the other.

I came to this by trying to disperse the diffraction modes evenly across frequency, so one distance should be 1.0 and the other 1.414 (square root of 2). The mode frequencies then occur at multiples of both distances: 1.0, 1.414, 2.0, 2.828, and so on. The total distance is 1.0 + 1.414 = 2.414, so the portions are 1.0/2.414 and 1.414/2.414, or about 41.4% and 58.6% of the baffle width. It's not perfect, but it's a good starting point.

With three edges (left, right, top) you can try for the cube root of 2, which gives you three possibilities, ranked in order of distance of the tweeter from the top edge (all percentages relative to baffle width):

a) distance from top: 35%

distance from side A: 44%

distance from side B: 56%

b) distance from top: 49%

distance from side A: 39%

distance from side B: 61%

c) distance from top: 70%

distance from side A: 44%

distance from side B: 56%

I just simulated a and b on TheEdge: both still have a dip around 3 kHz on your baffle width, but it's fairly narrow and only 1 dB instead of the previous 4 dB problem. A bit of roundover on the edges doesn't hurt, either. Even a 3/4" radius helps.

Svante said:[...]

PS2, the harsh advice here would be to re-design the baffle and place the tweeter based on diffraction simulations. Sorry about that, it is always hard to say this when a lot of work is invested in fine woodwork.

I've had good results on a tall baffle by placing the tweeter about 40% of the distance from one edge, ie on a 10 inch baffle placing it 4 inches from one side and 6 inches from the other.

I came to this by trying to disperse the diffraction modes evenly across frequency, so one distance should be 1.0 and the other 1.414 (square root of 2). The mode frequencies then occur at multiples of both distances: 1.0, 1.414, 2.0, 2.828, and so on. The total distance is 1.0 + 1.414 = 2.414, so the portions are 1.0/2.414 and 1.414/2.414, or about 41.4% and 58.6% of the baffle width. It's not perfect, but it's a good starting point.

With three edges (left, right, top) you can try for the cube root of 2, which gives you three possibilities, ranked in order of distance of the tweeter from the top edge (all percentages relative to baffle width):

a) distance from top: 35%

distance from side A: 44%

distance from side B: 56%

b) distance from top: 49%

distance from side A: 39%

distance from side B: 61%

c) distance from top: 70%

distance from side A: 44%

distance from side B: 56%

I just simulated a and b on TheEdge: both still have a dip around 3 kHz on your baffle width, but it's fairly narrow and only 1 dB instead of the previous 4 dB problem. A bit of roundover on the edges doesn't hurt, either. Even a 3/4" radius helps.

ttruman - I have a very similar problem, but at a slightly higher frequency. My baffle diffraction sim indicates I will have 2-3db of ripple, but I measure 5-6db.

http://www.diyaudio.com/forums/showthread.php?s=&threadid=103064

The problem is within an octave of my crossover frequency, so modeling is a pain. It's driving me nuts.

Off axis it does get better, but I still have a bump at 4khz.

Dan

http://www.diyaudio.com/forums/showthread.php?s=&threadid=103064

The problem is within an octave of my crossover frequency, so modeling is a pain. It's driving me nuts.

Off axis it does get better, but I still have a bump at 4khz.

Dan

owdi said:

...http://www.diyaudio.com/forums/showthread.php?s=&threadid=103064

The problem is within an octave of my crossover frequency, so modeling is a pain. It's driving me nuts.

Off axis it does get better, but I still have a bump at 4khz.

Dan

You said; "The 2.5khz dip is gone" because you measured at "15 degrees off axis"?

Inductor said:

You said; "The 2.5khz dip is gone" because you measured at "15 degrees off axis"?

Sure. That makes perfect sense because an edge presents a discontinuity to the plane wave coming from the driver. The plane wave will diffract from the edge, possibly causing constructive or destructive interference, which could be what you're seeing here.

DSP_Geek said:

Sure. That makes perfect sense because an edge presents a discontinuity to the plane wave coming from the driver. The plane wave will diffract from the edge, possibly causing constructive or destructive interference, which could be what you're seeing here.

There's still the question of the extent to which the baffle 'loads' the speaker driver.

The baffle step is an extreme case, but the secondary dip could also be present at a variety of angles, leading to an overall unevenness in the speaker's power response.

ttruman said:

Did you experience a similar issue with your two way Accuton configuration? What doesn’t make sense to me is that if I change the baffle dimensions using cardboard, the anomaly does not change. The measurements taken with the extended baffle combinations do show a slight influence in the frequency response like those in BSD simulations.

At the time, I didn't really pay much attention to the baffle step, otherwise I would've made the baffle wider and with a much bigger chamfer. Plus I didn't have any measurement setup, other than an oscilloscope.

Maybe the cardboard is just too soft to have much effect at those frequencies?

Cheers,

Re: Re: not convinced it's all baffle step

Never an argument there but the pictures do show the truth of it. The question now is why it is so deep. As Inductor pointed out the OEM frequency sweep does show a dip that could explain it.

So maybe my out of baffle measurement is flawed. The Accuton site has not been updated in some years so I am still unsure if that is useable as a reference.

I do believe I have several large pieces of 1” MDF around here somewhere. I will attempt the test this weekend.

Well, learning doesn’t always take you down a linear path. It is my first speaker project and part of learning is doing. Did I learn this lesson it the hard way? Yup, sure did. It’s not the first time and certainly won’t be the last. I learn a great deal from my mistakes, so truly, I am glad I make so many of them.

I did tape the seams (partly) on the side extension but not the top. I will try this again. Looks like I will have a busy weekend!

Svante said:When it is put on top of your measurement, it is reasonably clear that diffraction contributes to that dip. I trust the diffraction simulation, I have seen it match so many measurements now that I can say with confidence that diffraction is at least part of the issue here.

Never an argument there but the pictures do show the truth of it. The question now is why it is so deep. As Inductor pointed out the OEM frequency sweep does show a dip that could explain it.

So maybe my out of baffle measurement is flawed. The Accuton site has not been updated in some years so I am still unsure if that is useable as a reference.

Svante said:You could, just to test it, you could put the tweeter in a piece of MDF 220 mm wide, but slightly to the side and slightly lower:

An externally hosted image should be here but it was not working when we last tested it.

I do believe I have several large pieces of 1” MDF around here somewhere. I will attempt the test this weekend.

Svante said:PS2, the harsh advice here would be to re-design the baffle and place the tweeter based on diffraction simulations. Sorry about that, it is always hard to say this when a lot of work is invested in fine woodwork.

Well, learning doesn’t always take you down a linear path. It is my first speaker project and part of learning is doing. Did I learn this lesson it the hard way? Yup, sure did. It’s not the first time and certainly won’t be the last. I learn a great deal from my mistakes, so truly, I am glad I make so many of them.

Svante said:PS3, about the cardboard extension, I am surprised that it did not change the response. In my experience, cardboard is fine for quick and dirty diffraction tests. However, it is very important that the attachment between the box and the cardboard is tight, otherwise the diffraction will be there anyway.

What happens if you put the (free) driver in a piece of cardboard of the same geometry and size as the baffle? (You dont need the lower half metre I guess. a piece of 220x500 mm would do.)

[/B]

I did tape the seams (partly) on the side extension but not the top. I will try this again. Looks like I will have a busy weekend!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Stuck in a dip