Hello, I am planning (and only planning at this stage) a 3 way system. I'm thinking about the mid-top speaker section as it would be one of the first things I could do if I build this.

I have chosen the Vifa XG18 and Morel MDT33 drivers for it. They will be electronically crossed with 24db LR filters (practically essential with the sensitivity mismatch) at between 2.2-3.5k (to be defined through listening tests primarily). I am currently planning to use a sealed enclosure; WinISD is showing 15.8 litres as the optimal size, response starts to roll off slowly at about 200hz. The low crossover will be between 200-270hz.

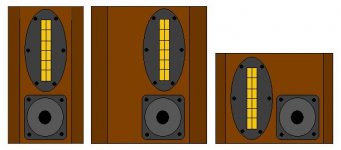

I am planning a laminated style enclosure in plywood. I am thinking about trying the B&W type shape attached. It seems it should help minimise baffle diffraction as well as reducing internal standing waves. With the laminated style construction I will also add the random wavy cuts on the inside to again reduce resonances. A single cross shaped brace will likely be integrated also.

I want to stuff the enclosure quite significantly to reduce any reflected waves exiting through the mid cone, how will this effect the dimensions I should use? Will it need to be made larger or is it not significant?

I believe there are programs to model baffle diffractions, does anybody know of them; are they free

The distance between the mid and tweeter can be quite critical I hear, how do you decide this distance. Are there equations/programs to help?

How difficult is the laminated style construction? I gather there will be a template to follow with a router? I haven't used a router before so will probably need some practise. Layers can be aligned by clamping then dowelling in stages, making gluing easier i'm thinking.

If constructed well could this design exhibit much better quality than B&W DM602s I have now? I find they have harshness and not a very open mid. Input appreciated

I have chosen the Vifa XG18 and Morel MDT33 drivers for it. They will be electronically crossed with 24db LR filters (practically essential with the sensitivity mismatch) at between 2.2-3.5k (to be defined through listening tests primarily). I am currently planning to use a sealed enclosure; WinISD is showing 15.8 litres as the optimal size, response starts to roll off slowly at about 200hz. The low crossover will be between 200-270hz.

I am planning a laminated style enclosure in plywood. I am thinking about trying the B&W type shape attached. It seems it should help minimise baffle diffraction as well as reducing internal standing waves. With the laminated style construction I will also add the random wavy cuts on the inside to again reduce resonances. A single cross shaped brace will likely be integrated also.

I want to stuff the enclosure quite significantly to reduce any reflected waves exiting through the mid cone, how will this effect the dimensions I should use? Will it need to be made larger or is it not significant?

I believe there are programs to model baffle diffractions, does anybody know of them; are they free

The distance between the mid and tweeter can be quite critical I hear, how do you decide this distance. Are there equations/programs to help?

How difficult is the laminated style construction? I gather there will be a template to follow with a router? I haven't used a router before so will probably need some practise. Layers can be aligned by clamping then dowelling in stages, making gluing easier i'm thinking.

If constructed well could this design exhibit much better quality than B&W DM602s I have now? I find they have harshness and not a very open mid. Input appreciated

Attachments

TheEdge is a quick baffle diffraction sim, very easy to use

BDS has more features***, but is more difficult to use.

I find myself using TheEdge much more than BDS, because it's much easier to quickly check off axis response. Despite spending hours in both programs, I still managed to screw up my last baffle

*** TheEdge can do a few things that BDS cannot, like model open baffles, and baffle with more than 4 corners.

The distance between the woofer and tweeter is critical. The closer they are, the better your vertical dispersion will be. With my current project, I'm having lot's of trouble pulling the listening axis down to tweeter level with only 14.5cm between the center of the tweeter and woofer.

Dan

BDS has more features***, but is more difficult to use.

I find myself using TheEdge much more than BDS, because it's much easier to quickly check off axis response. Despite spending hours in both programs, I still managed to screw up my last baffle

*** TheEdge can do a few things that BDS cannot, like model open baffles, and baffle with more than 4 corners.

The distance between the woofer and tweeter is critical. The closer they are, the better your vertical dispersion will be. With my current project, I'm having lot's of trouble pulling the listening axis down to tweeter level with only 14.5cm between the center of the tweeter and woofer.

Dan

Thanks a lot, I'll have a play with those

Did I see you've used an XG18 in one of your speakers? How do you find it, is it smooth sounding would you say?

I looked at some convertors earlier and am obviously missing something. Distance from centre to centre should be about 0.1 wavelength max of the frequency concerned (crossover frequency?). Calculators are showing the wavelength as 9993081.9333CM for 3Khz . Would be no problem if that was all there was to it

. Would be no problem if that was all there was to it

Did I see you've used an XG18 in one of your speakers? How do you find it, is it smooth sounding would you say?

I looked at some convertors earlier and am obviously missing something. Distance from centre to centre should be about 0.1 wavelength max of the frequency concerned (crossover frequency?). Calculators are showing the wavelength as 9993081.9333CM for 3Khz

Hi Dr. EM

My 3-way speakers were made using this method. What I did was design the templates (I made three different-shaped ones for different parts of the speaker) in Rhino3d, and had them professionally made. It cost about £65 IIRC.

I then duplicated the templates in 25mm MDF using a router with a template bit. It's a very easy process, but be warned - it takes a LOT of time. I think it was about a man-month to machine all the laminates for my speakers.

I ended up being somewhat unhappy with the deadness of my enclosures, despite the fact they are 2 inches thick at the front and back panels, and at least 1 inch thick everywhere else. Plus there's a lot of internal bracing. PLUS, I covered the inside with self-adhesive bitumen sheeting.

If I were to do it again I would want to try plywood or some other material.

AFAIK, it's nearly always best to simply make the distance between the mid and the tweeter as small as possible - it minimizes the comb filtering you get in the crossover region and makes the two units as close to a point-source as possible.

My 3-way speakers were made using this method. What I did was design the templates (I made three different-shaped ones for different parts of the speaker) in Rhino3d, and had them professionally made. It cost about £65 IIRC.

I then duplicated the templates in 25mm MDF using a router with a template bit. It's a very easy process, but be warned - it takes a LOT of time. I think it was about a man-month to machine all the laminates for my speakers.

I ended up being somewhat unhappy with the deadness of my enclosures, despite the fact they are 2 inches thick at the front and back panels, and at least 1 inch thick everywhere else. Plus there's a lot of internal bracing. PLUS, I covered the inside with self-adhesive bitumen sheeting.

If I were to do it again I would want to try plywood or some other material.

AFAIK, it's nearly always best to simply make the distance between the mid and the tweeter as small as possible - it minimizes the comb filtering you get in the crossover region and makes the two units as close to a point-source as possible.

Thanks for your input Wingfeather. Time is something I should have a lot of, since right now I have nowhere to put these speakers

. Lots of time to make and test things out. I don't know if you made the bass enclosure laminated style too though, i'm only doing a mid-top which will likely be much smaller.

. Lots of time to make and test things out. I don't know if you made the bass enclosure laminated style too though, i'm only doing a mid-top which will likely be much smaller.

I'm suprised your cabinets didn't end up very dead sounding, they sound solid enough. I will make sure I use ply this time though, my first thought was mainly to stop too much nasty dust being produced.

Where did you get your templates done incidently?

I'm suprised your cabinets didn't end up very dead sounding, they sound solid enough. I will make sure I use ply this time though, my first thought was mainly to stop too much nasty dust being produced.

Where did you get your templates done incidently?

Some more thoughts on midranges. The XG18 looks good but I must consider these others.

Monacor SPH-165KEP, I like the look of the response of this driver, with it falling at higher frequencies and no emphasis around 5-6k. Probably difficult to mount and would likely look out of place aesthestically though.

Peerless 832873, good extension and overall quite flat. Flattened edges on basket could blend in well with rounded cabinet sides. Does rise in the top end though, not heard any subjective opinions.

Audax HM100Z0, really nice response and excellent subjective opinions. Very different utilisation to other (larger) mids though, needs to be crossed higher; may be a problem with a TL bass due to the rippled higher end response they produce (?). Also virtually impossible to obtain, if anyone knows of how to get them let me know . May be nice crossed to a ribbon tweeter.

. May be nice crossed to a ribbon tweeter.

Monacor SPH-165KEP, I like the look of the response of this driver, with it falling at higher frequencies and no emphasis around 5-6k. Probably difficult to mount and would likely look out of place aesthestically though.

Peerless 832873, good extension and overall quite flat. Flattened edges on basket could blend in well with rounded cabinet sides. Does rise in the top end though, not heard any subjective opinions.

Audax HM100Z0, really nice response and excellent subjective opinions. Very different utilisation to other (larger) mids though, needs to be crossed higher; may be a problem with a TL bass due to the rippled higher end response they produce (?). Also virtually impossible to obtain, if anyone knows of how to get them let me know

Ok, I thought about starting a new thread since this has changed quite a lot since my initial idea. Anyhow, I now have drivers and have been running tests for some time. I managed to get Audax HM100Z0 drivers and am using the Hi-Vi RT2E-A planar tweeter with them.

I am getting a very good overall sound even in the crude test setup. A 12db LR crossover is being used and the two channels of my amp are bi-amping the setup (meaning mono sound until I redo my burnt out chipamp ). There are problems with the sound though which I think (hope) are purely down to the very poor cabinet the mid is in. It is a cabinet from an old mini hi-fi, about the right volume but thin walls, no bracing, a ported design etc. It has little going for it really, I have completely stuffed it but am still getting lots of resonances. Are these likely to be purely cabinet based? The propsed cabinet is the polar opposite, thick walls, laminate construction, internal diffusion patterns, rounded baffle. But how likely is this to completely clear up the sound?

). There are problems with the sound though which I think (hope) are purely down to the very poor cabinet the mid is in. It is a cabinet from an old mini hi-fi, about the right volume but thin walls, no bracing, a ported design etc. It has little going for it really, I have completely stuffed it but am still getting lots of resonances. Are these likely to be purely cabinet based? The propsed cabinet is the polar opposite, thick walls, laminate construction, internal diffusion patterns, rounded baffle. But how likely is this to completely clear up the sound?

Also the speaker is running down low, it will be crossed 24db at about 420Hz, this should also help dramatically? Obviously a lot of midbass is missing as it is, making electric guitars etc sound thin, but it should also help the upper response by not letting it run down to its resonance?

I am getting a very good overall sound even in the crude test setup. A 12db LR crossover is being used and the two channels of my amp are bi-amping the setup (meaning mono sound until I redo my burnt out chipamp

). There are problems with the sound though which I think (hope) are purely down to the very poor cabinet the mid is in. It is a cabinet from an old mini hi-fi, about the right volume but thin walls, no bracing, a ported design etc. It has little going for it really, I have completely stuffed it but am still getting lots of resonances. Are these likely to be purely cabinet based? The propsed cabinet is the polar opposite, thick walls, laminate construction, internal diffusion patterns, rounded baffle. But how likely is this to completely clear up the sound?

). There are problems with the sound though which I think (hope) are purely down to the very poor cabinet the mid is in. It is a cabinet from an old mini hi-fi, about the right volume but thin walls, no bracing, a ported design etc. It has little going for it really, I have completely stuffed it but am still getting lots of resonances. Are these likely to be purely cabinet based? The propsed cabinet is the polar opposite, thick walls, laminate construction, internal diffusion patterns, rounded baffle. But how likely is this to completely clear up the sound? Also the speaker is running down low, it will be crossed 24db at about 420Hz, this should also help dramatically? Obviously a lot of midbass is missing as it is, making electric guitars etc sound thin, but it should also help the upper response by not letting it run down to its resonance?

Attachments

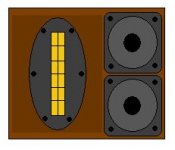

Ok, I think I will do an open back mid enclosure after some reading. I still plan a laminated enclosure and it will have the random internal cuts. Any ideas about how large an "enclosure" of this type needs to be? If the walls are quite close together how far back might it need to reach or is it fairly unimportant? I am not decided on baffle layout but probably won't be able to do the nice fully rounded enclosure. I plan just a rounding at the front. I have drawn some baffle layouts, the darker brown is where the rounding would be. Any ideas, the edge models them similarly. The side by side arrangement means I can make the bass units taller reducing the depth needed to make up thier volume, but it looks the worst imo

Attachments

perhaps as a final bid to make it as ugly as possible, or mabye a refinement, how about something like this (assuming I can get more mids)  . The tweeter would be set into a waveguide cut in the wood itself("easy" with the laminate design), in order to achieve better time alignment. Are there specific dimensions for a waveguide that must be adhered to, Hi-Vi do a version of this tweeter with one and it just looks like an angled cut either side. Twin mids make for higher sensitivity (rather decent at 96db), but could they cause problems of lobing etc in the range of 400-4500hz? Is the spacing to the tweeter now too much? Will this design impact imaging quality? I want to get building these enclosures, but being so critical to the overall sound I want to do it right too!

. The tweeter would be set into a waveguide cut in the wood itself("easy" with the laminate design), in order to achieve better time alignment. Are there specific dimensions for a waveguide that must be adhered to, Hi-Vi do a version of this tweeter with one and it just looks like an angled cut either side. Twin mids make for higher sensitivity (rather decent at 96db), but could they cause problems of lobing etc in the range of 400-4500hz? Is the spacing to the tweeter now too much? Will this design impact imaging quality? I want to get building these enclosures, but being so critical to the overall sound I want to do it right too!

Attachments

That is the ideal way, but i'm not sure about easy. It'd still be a few weeks work to make any enclosure of this laminate style. I like the idea of that recessed tweeter enclosure, has a studio monitor quality to it, purely functional. Not sure I can do it though, strength of the walls could become an issue too. Braces can be added easily by leaving wood on the layers (in arch or triangle shapes optimally I guess), but if I use a normal baffle (which may be nescecary for the unusual recess of those mids) the overall structure won't be very self supporting, relies too much on joints. I'm going to have to go ahead with something though, see how much of a disaster it turns out

Might be worth a go, or I may just take the plunge with it  . I put that enclosure into the Edge and it looks decent. One advantage is it produces a baffle roll off about where I want to cross to the woofer, so step compensation is as easy as adjusting the woofers level (I believe?). Also the overall response is +/-1db with no big peaks or dips; does anyone know if it takes lobing etc into account when modelling with 2 drivers? Setting a close mic distance and moving it around it seems to show more change than usual. I may soon have some ugly speakers on my hands, but so long as they sound wonderful i'm sure I'll grow to love them

. I put that enclosure into the Edge and it looks decent. One advantage is it produces a baffle roll off about where I want to cross to the woofer, so step compensation is as easy as adjusting the woofers level (I believe?). Also the overall response is +/-1db with no big peaks or dips; does anyone know if it takes lobing etc into account when modelling with 2 drivers? Setting a close mic distance and moving it around it seems to show more change than usual. I may soon have some ugly speakers on my hands, but so long as they sound wonderful i'm sure I'll grow to love them

. I put that enclosure into the Edge and it looks decent. One advantage is it produces a baffle roll off about where I want to cross to the woofer, so step compensation is as easy as adjusting the woofers level (I believe?). Also the overall response is +/-1db with no big peaks or dips; does anyone know if it takes lobing etc into account when modelling with 2 drivers? Setting a close mic distance and moving it around it seems to show more change than usual. I may soon have some ugly speakers on my hands, but so long as they sound wonderful i'm sure I'll grow to love them

. I put that enclosure into the Edge and it looks decent. One advantage is it produces a baffle roll off about where I want to cross to the woofer, so step compensation is as easy as adjusting the woofers level (I believe?). Also the overall response is +/-1db with no big peaks or dips; does anyone know if it takes lobing etc into account when modelling with 2 drivers? Setting a close mic distance and moving it around it seems to show more change than usual. I may soon have some ugly speakers on my hands, but so long as they sound wonderful i'm sure I'll grow to love them With a waveguide, what maths might be involved? The parameter I can find is the depth of the guide (ie, how far the tweeter needs to be recessed to time align with the mids). Beyond that i'm not too sure. I'd like the tweeter to be close to the mids as much as possible, but that suggests a sharper transition. I wouldn't want the guide to have an influence on the sound itself, an increase in sensitivity is fine though. Should the guide be curved or just a straight cut or is it unimportant? Crossover frequency will be around 4.2-4.5khz.

I decided to make some test boxes  . Got another set of mids to do this with (the higher sensitivity was too tempting!). A 6L sealed box is behind the mids, the tweeter is on the "wing" of the baffle. The distance between the centre of all drivers is equal at 125mm. Not so worried about having a waveguide now and have updated my ideas on the actual box construction.

. Got another set of mids to do this with (the higher sensitivity was too tempting!). A 6L sealed box is behind the mids, the tweeter is on the "wing" of the baffle. The distance between the centre of all drivers is equal at 125mm. Not so worried about having a waveguide now and have updated my ideas on the actual box construction.

I'm not noticing any massive problems. No obvious comb filtering effect (is it actually that obvious anyhow?). The imaging is still great (may try flipping these over to put the tweeters on the outside edge, just for the sake of it!). Level of the mids has stayed the same as it should, now twice the sensitivity but being delivered half the power as a 16ohm configuration.

My box construction idea is to have a box inside a box with sand between them. I reckon this should kill a majority of resonances? Lots of space behind the tweeter (since its flat) to fill in and i'd move the whole thing over to leave a gap at the edge of the mids to fill too. The top and bottom will have only a small seperation of sand but hopefully the overall effect will be enough. The mids enclosure will stay sealed and will be a box, but with the laminated construction within it. This will be a curved construction, becoming thinner toward the back and with the "ripples" cut in each layer. Combined with acoustic foam and wadding I should be able to achieve a good amount of diffusion and absorbtion so as to stop too much coming back through the light cone(s). Hopefully a picture tells a thousand words; even a really bad one (see attachment )

)

I'm not noticing any massive problems. No obvious comb filtering effect (is it actually that obvious anyhow?). The imaging is still great (may try flipping these over to put the tweeters on the outside edge, just for the sake of it!). Level of the mids has stayed the same as it should, now twice the sensitivity but being delivered half the power as a 16ohm configuration.

My box construction idea is to have a box inside a box with sand between them. I reckon this should kill a majority of resonances? Lots of space behind the tweeter (since its flat) to fill in and i'd move the whole thing over to leave a gap at the edge of the mids to fill too. The top and bottom will have only a small seperation of sand but hopefully the overall effect will be enough. The mids enclosure will stay sealed and will be a box, but with the laminated construction within it. This will be a curved construction, becoming thinner toward the back and with the "ripples" cut in each layer. Combined with acoustic foam and wadding I should be able to achieve a good amount of diffusion and absorbtion so as to stop too much coming back through the light cone(s). Hopefully a picture tells a thousand words; even a really bad one (see attachment

An externally hosted image should be here but it was not working when we last tested it.

Attachments

Cabinet suggestions

Your project sounds very interesting. You might want to consider the use of felt for lining the inside of your cabinets. It is very effective at preventing random reflections through the cone.

Also, MDF is not an ideal material as many people will make you think. Just being "dead" does not ensure good sound quality. Many people have reported that the result is also "dead sounding".

You should consider a very high quality birch plywood, for it has many excellent characteristics. It is difficult, however, to sand the exposed edges of it in your laminated layout. You may want to consider applying a thin layer of some nice wood over top of your wood laminations.

Good luck!

Your project sounds very interesting. You might want to consider the use of felt for lining the inside of your cabinets. It is very effective at preventing random reflections through the cone.

Also, MDF is not an ideal material as many people will make you think. Just being "dead" does not ensure good sound quality. Many people have reported that the result is also "dead sounding".

You should consider a very high quality birch plywood, for it has many excellent characteristics. It is difficult, however, to sand the exposed edges of it in your laminated layout. You may want to consider applying a thin layer of some nice wood over top of your wood laminations.

Good luck!

Thanks for your response! Felt sounds good, I suppose I can get it from hobby/craft shops? Probably most effective in the higher frequencies, these go up to 4.2-4.5khz so it should help.

Do you think that this heavy sand filled enclosure will create too much of a "dead" sound? Baltic birch is nice, but I don't know where I can get it round here (it'd need to be cut for me too, which the local DIY stores do). In this well reinforced design with the extra weight either will surely perform similarly (ie, the enclosure is constructed as such to remove the artifacts of the construction material)? I really dislike sound that resonates or suddenly "shouts" at certain frequencies, and believe the main cause is cabinet resonances.

The laminates on the inside of the mid box I'm thinking about using real wood. Thick beams, and cutting them with the jigsaw to give the desired shaping. The great thickness will save time in not having to cut so many layers and the beams are already cut to a specific profile so I need not cut lots of square pieces to be shaped. See here, the internal sides are made from beams:

http://www.diyaudio.com/forums/showthread.php?postid=1456506#post1456506

The exposed edge won't really exist in my revised design, the outside will be a humble, perhaps boring, box

Do you think that this heavy sand filled enclosure will create too much of a "dead" sound? Baltic birch is nice, but I don't know where I can get it round here (it'd need to be cut for me too, which the local DIY stores do). In this well reinforced design with the extra weight either will surely perform similarly (ie, the enclosure is constructed as such to remove the artifacts of the construction material)? I really dislike sound that resonates or suddenly "shouts" at certain frequencies, and believe the main cause is cabinet resonances.

The laminates on the inside of the mid box I'm thinking about using real wood. Thick beams, and cutting them with the jigsaw to give the desired shaping. The great thickness will save time in not having to cut so many layers and the beams are already cut to a specific profile so I need not cut lots of square pieces to be shaped. See here, the internal sides are made from beams:

http://www.diyaudio.com/forums/showthread.php?postid=1456506#post1456506

The exposed edge won't really exist in my revised design, the outside will be a humble, perhaps boring, box

I don't think that felt is a particularly good material for cabinet lining, while it is better than most foams, and better than not lining at all, with the testing I did I found natural fiber materials which are a little less dense than felt to be more effective, also, most felt is relatively thin and I would recommend something at least an inch thick.

I do agree that Baltic Birch is a nice wood to use for building cabinets and while MDF is popular, some people that have done a lot of testing of different materials, have found that it is not very good in that application. Using layers of two or more different materials is generally superior to using one material.

I do agree that Baltic Birch is a nice wood to use for building cabinets and while MDF is popular, some people that have done a lot of testing of different materials, have found that it is not very good in that application. Using layers of two or more different materials is generally superior to using one material.

Which natural fibre materials would you reccomend? I have lambswool, but doubt it's nearly dense enough for lower frequency absorption. These cabs go down to around 400Hz and I want to stop the majority of sound reflecting back through the cone. I think to do this I'd need a heavy fill of dense material at the back; hoping the narrowing toward the rear of this enclosure will help "trap" sound (B&W Nautilus tube style I guess  ). Dense studio foam must be effective for overall absorption, but a mixture of materials will surely yeild the best results, easy to experiment with anyhow.

). Dense studio foam must be effective for overall absorption, but a mixture of materials will surely yeild the best results, easy to experiment with anyhow.

I'd like to use good plywood as I prefer using it (especially if I need to cut it) but expect MDF will be the only affordable option. The mids internal box will use natural wood backed on to the MDF (or ply) so hopefully that will yeild some of that extra strength you mentioned. I could add some of my offcut plywood to the outer boxes too to get that extra rigidity again, though resonances through the sand should be very minimal.

I'll listen some more to these test boxes before getting some real construction underway. A nice finish will probably be the most difficult part

I'd like to use good plywood as I prefer using it (especially if I need to cut it) but expect MDF will be the only affordable option. The mids internal box will use natural wood backed on to the MDF (or ply) so hopefully that will yeild some of that extra strength you mentioned. I could add some of my offcut plywood to the outer boxes too to get that extra rigidity again, though resonances through the sand should be very minimal.

I'll listen some more to these test boxes before getting some real construction underway. A nice finish will probably be the most difficult part

If you're going to fill the between areas with sand, then the mid enclosure can be almost anything that will support the load: the sand is going to do a fine job damping whatever energy is left, which above 400Hz, won't be a lot anyway. Just use MDF and add some crossbracing. Ditto for the outside enclosure in terms of material and strength.

I'd be far more concerned with dealing with the rear wave of the driver. Read the link and hunt out what you can get locally.

http://www.bobgolds.com/AbsorptionCoefficients.htm

Some polyfill closest to the rear of the driver and recycled cotton waste or wool fibre for the last half of the depth is likely a good bet. If you need to keep the layers seperate because the mass of the rear damping falls forward, or you need to move them, staple some openish weave fabric between the laters and around the rear of the driver. Good internal bracing holds the stuffing in place well.

This is what I'll be doing for my mid/top box (2xJBL 2123 + CD/horn), also with a 30mm sand layer between the front and sides and the internal enclosure.

I'd be far more concerned with dealing with the rear wave of the driver. Read the link and hunt out what you can get locally.

http://www.bobgolds.com/AbsorptionCoefficients.htm

Some polyfill closest to the rear of the driver and recycled cotton waste or wool fibre for the last half of the depth is likely a good bet. If you need to keep the layers seperate because the mass of the rear damping falls forward, or you need to move them, staple some openish weave fabric between the laters and around the rear of the driver. Good internal bracing holds the stuffing in place well.

This is what I'll be doing for my mid/top box (2xJBL 2123 + CD/horn), also with a 30mm sand layer between the front and sides and the internal enclosure.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Mid-top for three way