The frame in question, I was getting the measurement of the spider landing:

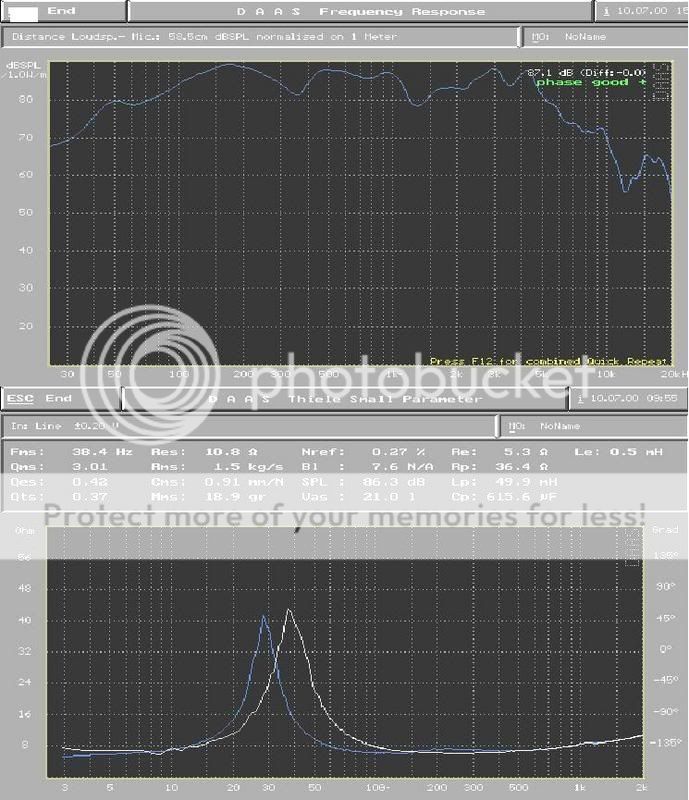

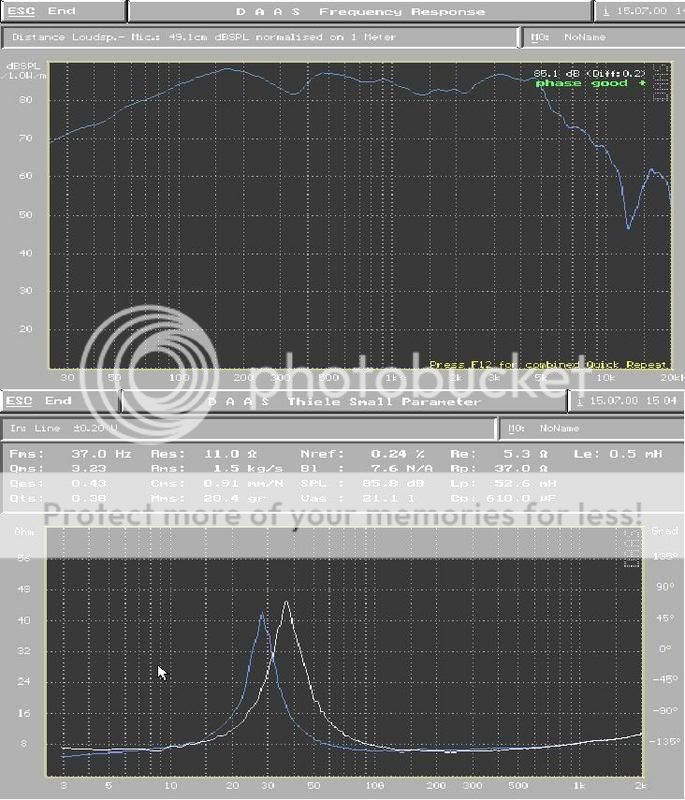

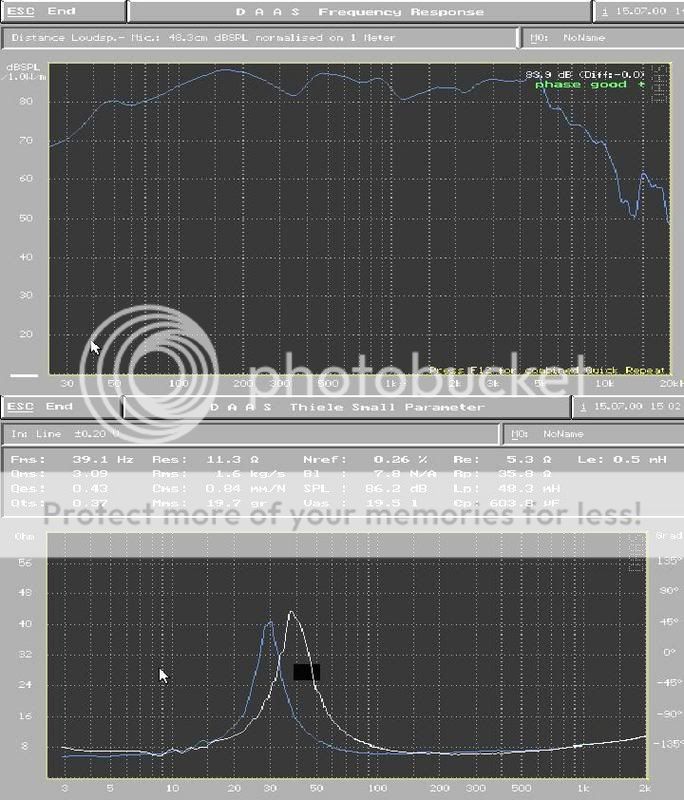

Treated paper cone top, wool cone bottom. I'm leaning towards the wool. This is for a 6.5" midwoofer I'll fill you in a bit more as things unfold. I'm looking at a 31mm tall coil 1.5” dia coil, 7mm tall gap, 126mm diameter magnet 40mm tall with a short path inside the magnet at the least and a phase plug in addition to venting under the spider. I was playing with an ~7mm of xmax underhung design as well but I favor this one. This BL curve should be a bit more symmetrical believe it or not, saturating a pole this far makes the magnetic strength in the gap increase as you head deeper into the motor. You would have to combat that by rounding over the ID of the top plate and that sounds like trouble waiting to happen.

If you are thinking: WTF is he thinking with such a large magnet?

I want to test to see if its the magnet quality, or the steel quality that is leading to the lower than predicted BL… Not to mention this much xmax chews up a lot of magnetic strength (neo mags cost a lot more or I would use them).

E/M target:

Re 5.38 ohms

Rms ~2 NS/m or less

Cms ~.82mm/N

Mms ~21g

Le ~.6-.9 depending on how close I can get an off the shelf copper short...

Sd ~126 cm^2

Pe ~200W (Possibly over inflated but… I think it might take it)

SPL ~88.4dB/w, 87.13 dB/w, 84dB/w (see below)

Now the BL is where I'm a bit shaky. If everything is perfect 10.6 is what I'll get... I'm expecting more along the lines of 9.3 being most likely, and if it is like something out of my worst nightmare... were talking about 6.5 Tm. If the BL does end up this low, it is the steel causing the problem and I will be left with a lower sensitivity midwoofer that actually likes to be sealed, unlike the other versions… It still looks rather nice though, although it is a bit power hungry.

I'm sure the suspension won't make it to 12mm so I won't even try calling it that... I guess we can hope and prey though… It never hurts to make the useable BL a little flatter and I don’t see this unit being used

I'm going to also look into the price for Kertonite treatment through about 80% the thickness of an aluminum cone... I have a felling it would do pretty well, it is at least worth looking at and if its comparable to anodizing it should carry high value (especially if ceramic-like performance results). http://www.azom.com/details.asp?ArticleID=1438

Anyways back to studying for my last final. I'll get some more info up after this quarter is over. I can't wait to be distracted by feedback

OlogyAudio said:If you are thinking: WTF is he thinking with such a large magnet?

That's exactly what I thought the first time I saw the W17RC38 from Silver Flute.

I should be done with the sample Tue if everything keeps on track and I'll see where this goes from there.

I'm trying the bottom cone (wool cone), that FR was with it using a dust cap so I'll see how it behaves with just the phase plug. It wouldn't be too hard to try some other different cones, just time consuming. I have high hopes for this variant though.

The dip at 350hz is an artifact of measurement by the way.

I'm trying the bottom cone (wool cone), that FR was with it using a dust cap so I'll see how it behaves with just the phase plug. It wouldn't be too hard to try some other different cones, just time consuming. I have high hopes for this variant though.

The dip at 350hz is an artifact of measurement by the way.

Not quite sure I am following this thread . . . Perhaps the "FR" in the title means something other than full-range. Almost one Le indicated in the design specifications. Measurement graphs provided show high frequency limits at 6 or 7 kHz. A bit short of what most would consider full range.

Is this going to be a woofer in a two-way system? If so, then if the off-axis response holds, this is not a bad frequency to cross to a dome tweeter. Most dome tweeters produce frequencies below 9 kHz in the decay region. The highest frequencies and lowest frequencies are smeared in time (with the low frequencies lagging). I have seen a couple of dome tweeters that did hold together (onset and decay responses) down to 6 kHz.

This is always assuming that the response graphs provided are high resolution and have not been excessively smoothed. I am a little skeptical of the smoothness in the stop band. Very rare to see this even with wool cones.

Best of luck to you with your project. I applaud your diy reach and your skill at mounting cones and voice coils. Just curious, do you have access to a manufacturer's assembly jigs?

Mark

Is this going to be a woofer in a two-way system? If so, then if the off-axis response holds, this is not a bad frequency to cross to a dome tweeter. Most dome tweeters produce frequencies below 9 kHz in the decay region. The highest frequencies and lowest frequencies are smeared in time (with the low frequencies lagging). I have seen a couple of dome tweeters that did hold together (onset and decay responses) down to 6 kHz.

This is always assuming that the response graphs provided are high resolution and have not been excessively smoothed. I am a little skeptical of the smoothness in the stop band. Very rare to see this even with wool cones.

Best of luck to you with your project. I applaud your diy reach and your skill at mounting cones and voice coils. Just curious, do you have access to a manufacturer's assembly jigs?

Mark

Sorry about the confusion I was asking which frequency response (FR) was preferred. This is intended to be used as a midwoofer in a 2 way. I’m not sure what the extent of the smoothing is but given that the upper frequencies are fairly stable looking I’m sure there is some. I decided to use the wool cone (bottom graph) since under 2khz it is substantially flatter so I’m hoping this will translate into less linear distortion. I would guess the crossover point will need to be under 2.2khz just from the graph but its hard to tell with incomplete information. The frequency response is also likely to change quite a bit from that graph just due to the addition of a phase plug.

I’m toying with the idea of using some never before used in speaker cones (to the best of my knowledge) advanced plastics/composites for the cones but I’m sure that will be quite a challenge to get a company to work with me on that one and not charge a few arms and legs more than I have…

The short path is under the top plate, on the outside of the voice coil windings and is 6mm thick… I’m not sure what that will do to the Le exactly (it would have more impact as a pole sleeve) but given that the pole was pretty close to saturated with this voice coil diameter I decided to opt with an extended pole and an extra thick external short path instead of a T pole and a 1-2mm thick short under the T and cap.

I can’t wait to see my baby monster assembled so I just had to post more pics.

I have access to a manufacturer though for assembling jigs I find that square wire works great as a spacing gauge (round works too with a few more inserted into the gap to help get the better concentricity tolerance needed). I find that a 0.25-0.30 mm radius between the coil or former and the steel for midranges yields good results and I’m a bit paranoid and step it up to .4mm with the larger subwoofer designs I’m working with.

I don’t have access to any powerful dynamic fluid and thermal modeling programs but I’d love to see exactly how cooling of the coil changes as the gap width changes… Anyone out there have something like this in their lab?

I’m toying with the idea of using some never before used in speaker cones (to the best of my knowledge) advanced plastics/composites for the cones but I’m sure that will be quite a challenge to get a company to work with me on that one and not charge a few arms and legs more than I have…

The short path is under the top plate, on the outside of the voice coil windings and is 6mm thick… I’m not sure what that will do to the Le exactly (it would have more impact as a pole sleeve) but given that the pole was pretty close to saturated with this voice coil diameter I decided to opt with an extended pole and an extra thick external short path instead of a T pole and a 1-2mm thick short under the T and cap.

I can’t wait to see my baby monster assembled so I just had to post more pics.

I have access to a manufacturer though for assembling jigs I find that square wire works great as a spacing gauge (round works too with a few more inserted into the gap to help get the better concentricity tolerance needed). I find that a 0.25-0.30 mm radius between the coil or former and the steel for midranges yields good results and I’m a bit paranoid and step it up to .4mm with the larger subwoofer designs I’m working with.

I don’t have access to any powerful dynamic fluid and thermal modeling programs but I’d love to see exactly how cooling of the coil changes as the gap width changes… Anyone out there have something like this in their lab?

OlogyAudio said:

I can't hold back anymore... No t/s or FR yet but hopefully tonight...

when you're done with these prototypes, I'll forward you my address

Are you thinking of releasing these drivers to the mass market any time soon? Target pricing?

Soon (2-3 months?), if I could get 100+ out of the door before they can be put together somehow (1 month-ish)

I will have to take a look at the FR and t/s first though to make sure there isn't anything wrong.

Being a student puts a damper on things a tad with so much going on right now.

Can I discuss pricing here? I have a feeling that would be more suited for a group buy link? I’m almost always on AIM SN: OlogyAudio

I will have to take a look at the FR and t/s first though to make sure there isn't anything wrong.

Being a student puts a damper on things a tad with so much going on right now.

Can I discuss pricing here? I have a feeling that would be more suited for a group buy link? I’m almost always on AIM SN: OlogyAudio

Aren't you the same kid that used to go by Audiophilenoob on this forum? Also looks like you used a few other names on other forums simultaneously, sometimes playing two people at once, having conversations with yourself and whatnot. Just seems really odd. I don't ask these questions simply to feed my own enjoyment of starting negative conversation on web forums, as I don't come here for that. I'm really just curious. It seems as though you've put painstaking effort into a large portion of this ridiculous foul play over the last few years or so. What were you trying to accomplish?

And out of curiosity, was this driver intended to be yet another revision of the magnificent end-all other loudspeaker transducers that never happened back in early '06, mentioned in threads like these?..

http://www.diyaudio.com/forums/showthread.php?s=&threadid=74170

http://forum.ecoustics.com/bbs/messages/4/181722.html

http://www.soundsolutionsaudio.com/forum/index.php?showtopic=5336#

http://forum.ecoustics.com/bbs/messages/4/184292.html

Weren't you Feandil on caraudioforum.com who kept attempting to trash Dan Wiggins early last year? That was hilarious! Thanks for all the laughs.

Ah, here it is.. Definitely one of the most interesting threads I've ever come across on any forum, although it did become a bit tiresome:

http://www.caraudioforum.com/vbb3/showthread.php?t=238440&page=5&pp=15

..Good stuff, I'll never forget that one.

Nice looking speakers!..

http://www.diyaudio.com/forums/showthread.php?postid=722164#post722164

Ever get those massive subwoofers figured out??

http://www.diyaudio.com/forums/showthread.php?s=&threadid=63831

Hrmm. I wonder why Zaph never responded?

http://www.diyaudio.com/forums/showthread.php?s=&threadid=102592

Apologies if this is old news to any of you, which it very well might be to some. Anyway, after roughly 5-10 minutes of searching around, I've observed that the following names appear to be the SAME individual, posing as different people all over the net:

OlogyAudio

Audiophilenoob

Feandil

Dylan Matlow

Matthew Rich

..I'm sure there's probably more out there somewhere, but I didn't bother to look. It's all just kinda sickening, really..and I wasn't about to waste anymore of my time on it. I simply stumbled upon this thread and saw OlogyAudio. Having never heard the name before, I wanted to find out more. Unfortunately, I quickly ended up finding out a lot more than I wanted. I honestly wish I wouldn't have read everything that I just spent the last half hour reading through. It's disturbing and irritating to know that this kind of activity exists within this community.

At the very least, I can only hope that this mendacious individual realizes the preposterousness and senselessness that he portrays of himself as he continues to instigate these episodes of his own utterly useless deceit, and discontinues the aforementioned acts as a result.

I applaud him for his few DIY attempts, or his deep interest in the subject, at the very least. However, I feel as though everything else he's brought to this community through the use of these forums is not only absolutely unecessary, but it also violates the trust of members participating in these communities, as these attempts and actions are definitely not committed with the least bit sincerity.

It would be nice to receive confirmation in regards to whether or not this individual has put a stop to his own actions, such as those implied in this post. However, I suppose that's not possible, at least during this point in time. If and once this person has indeed put a positive change toward his behavior and ways of thought, I truly hope that he will have the ability to continue sharing, practicing, discussing, and pursuing his interests in the audio/DIY community. Perhaps personally subjecting one's self to withdrawal from these forums for a period of time, as well as one last and final name change would be essential? Otherwise, people will see the names and continue to stumble upon this junk for years to come, just as I did.

And out of curiosity, was this driver intended to be yet another revision of the magnificent end-all other loudspeaker transducers that never happened back in early '06, mentioned in threads like these?..

http://www.diyaudio.com/forums/showthread.php?s=&threadid=74170

http://forum.ecoustics.com/bbs/messages/4/181722.html

http://www.soundsolutionsaudio.com/forum/index.php?showtopic=5336#

http://forum.ecoustics.com/bbs/messages/4/184292.html

Weren't you Feandil on caraudioforum.com who kept attempting to trash Dan Wiggins early last year? That was hilarious! Thanks for all the laughs.

Ah, here it is.. Definitely one of the most interesting threads I've ever come across on any forum, although it did become a bit tiresome:

http://www.caraudioforum.com/vbb3/showthread.php?t=238440&page=5&pp=15

..Good stuff, I'll never forget that one.

Nice looking speakers!..

http://www.diyaudio.com/forums/showthread.php?postid=722164#post722164

Ever get those massive subwoofers figured out??

http://www.diyaudio.com/forums/showthread.php?s=&threadid=63831

Hrmm. I wonder why Zaph never responded?

http://www.diyaudio.com/forums/showthread.php?s=&threadid=102592

Originally posted by Zaph

There was some discussion and a test unit was going to be sent to me, but it never happened.

At this point, I can say I'm not interested. I've got enough test drivers on my plate from real, established companies.

Apologies if this is old news to any of you, which it very well might be to some. Anyway, after roughly 5-10 minutes of searching around, I've observed that the following names appear to be the SAME individual, posing as different people all over the net:

OlogyAudio

Audiophilenoob

Feandil

Dylan Matlow

Matthew Rich

..I'm sure there's probably more out there somewhere, but I didn't bother to look. It's all just kinda sickening, really..and I wasn't about to waste anymore of my time on it. I simply stumbled upon this thread and saw OlogyAudio. Having never heard the name before, I wanted to find out more. Unfortunately, I quickly ended up finding out a lot more than I wanted. I honestly wish I wouldn't have read everything that I just spent the last half hour reading through. It's disturbing and irritating to know that this kind of activity exists within this community.

At the very least, I can only hope that this mendacious individual realizes the preposterousness and senselessness that he portrays of himself as he continues to instigate these episodes of his own utterly useless deceit, and discontinues the aforementioned acts as a result.

I applaud him for his few DIY attempts, or his deep interest in the subject, at the very least. However, I feel as though everything else he's brought to this community through the use of these forums is not only absolutely unecessary, but it also violates the trust of members participating in these communities, as these attempts and actions are definitely not committed with the least bit sincerity.

It would be nice to receive confirmation in regards to whether or not this individual has put a stop to his own actions, such as those implied in this post. However, I suppose that's not possible, at least during this point in time. If and once this person has indeed put a positive change toward his behavior and ways of thought, I truly hope that he will have the ability to continue sharing, practicing, discussing, and pursuing his interests in the audio/DIY community. Perhaps personally subjecting one's self to withdrawal from these forums for a period of time, as well as one last and final name change would be essential? Otherwise, people will see the names and continue to stumble upon this junk for years to come, just as I did.

Audiophilenoob and feandil are screen names for Matthew Rich who I'm not currently working with. I did get him to stay off the forums after one of the naster flame wars though. He has some great ideas but he just doesn't know when to stop sometimes.

That omega 6.5" driver has been revised and currently has a few technical difficulties in the implementation. I have a custom surround tool that can handle ~30mm of excursion but the compliance is a bit too stiff. Also a cone worthy of this unit proved to be a bit more costly and complicated to implement (Arnitel with fiber and glass microbeads in the mix, or a Dyneema fiber cone) so I'm starting with launching more feasible designs first.

I have some subwoofer designs coming down the pipe as well…

http://s8.photobucket.com/albums/a44/OlogyAudio/

Feel free to browse the pics…

I did get in touch with Zaph

In regards to:

I believe that my present and future actions are a more telling and honest method to show my true intent rather than scrapping the name Ology Audio simply because I associated with Matthew while I had this name. I'm not going to talk about the behind the scenes aspect related to some of these incidents since that is simply the wrong thing to do for all parties involved.

The Duke and Cornelius, NC IP addresses on the forums are from Matthew,

The Ohio State University, Columbus, and Shepherdsville/Lousiville Ky Ip addresses are all from me.

I'm doing my best to keep all of my discussions civilized. I do have to apologize for any past inappropriate behavior, if anyone sees something out of line in the future please let me know.

As for the public events, I do feel I have to defend Matt to some extent since he is a good guy at heart and really isn’t one to start fights. Matt just didn’t know when to shut his mouth when things got heated and then there was provocation escalating from both sides. It is best to keep the context of those situations in mind but the context is kind of hard to convey. We were 18-19 at the time, basically jumped in head first into the industry with just DIY experience, had expectations which weren't met, and had to learn how to design and source parts on our own with no guidance. The best way to look at it is extreme DIY that if it goes well can help everyone out. I intend to help expand the DIY community into DIY motor design and transducer design just like there are some individuals making DIY ESL and DIY ribbons. The saying: "If you want it done, you have to do it yourself" comes to mind… Matt has gone his own direction due to personal reasons though and isn't involved now.

I hope this clears the status of the situation up a little bit.

That omega 6.5" driver has been revised and currently has a few technical difficulties in the implementation. I have a custom surround tool that can handle ~30mm of excursion but the compliance is a bit too stiff. Also a cone worthy of this unit proved to be a bit more costly and complicated to implement (Arnitel with fiber and glass microbeads in the mix, or a Dyneema fiber cone) so I'm starting with launching more feasible designs first.

I have some subwoofer designs coming down the pipe as well…

http://s8.photobucket.com/albums/a44/OlogyAudio/

Feel free to browse the pics…

I did get in touch with Zaph

Hello,

I'm not as active on many forums anymore. I stop in here occasionally.

Normally, I don't test drivers that are not publicly available, though I've strayed from that rule in the past. But the bigger issue is that more recently, I don't feel an urge to test "boutique drivers" from smaller vendors. Bad results could resonate too loudly and affect sales of a company that is sensitive to bad press. Not that I care about that, but it's the part where the vendor gets defensive about their product that leaves a sour taste in my mouth. I'm not saying you're like that, but unfortunately I don't know you.

Likewise, good results could make the public want a driver they might not be able to get.

However, you seem to be working on this project from a DIY'er perspective. I'm not sure if you're potentially a vendor or just a DIY'er making drivers. Maybe we could work something out.

In regards to:

It would be nice to receive confirmation in regards to whether or not this individual has put a stop to his own actions, such as those implied in this post. However, I suppose that's not possible, at least during this point in time. If and once this person has indeed put a positive change toward his behavior and ways of thought, I truly hope that he will have the ability to continue sharing, practicing, discussing, and pursuing his interests in the audio/DIY community. Perhaps personally subjecting one's self to withdrawal from these forums for a period of time, as well as one last and final name change would be essential? Otherwise, people will see the names and continue to stumble upon this junk for years to come, just as I did.

I believe that my present and future actions are a more telling and honest method to show my true intent rather than scrapping the name Ology Audio simply because I associated with Matthew while I had this name. I'm not going to talk about the behind the scenes aspect related to some of these incidents since that is simply the wrong thing to do for all parties involved.

The Duke and Cornelius, NC IP addresses on the forums are from Matthew,

The Ohio State University, Columbus, and Shepherdsville/Lousiville Ky Ip addresses are all from me.

I'm doing my best to keep all of my discussions civilized. I do have to apologize for any past inappropriate behavior, if anyone sees something out of line in the future please let me know.

As for the public events, I do feel I have to defend Matt to some extent since he is a good guy at heart and really isn’t one to start fights. Matt just didn’t know when to shut his mouth when things got heated and then there was provocation escalating from both sides. It is best to keep the context of those situations in mind but the context is kind of hard to convey. We were 18-19 at the time, basically jumped in head first into the industry with just DIY experience, had expectations which weren't met, and had to learn how to design and source parts on our own with no guidance. The best way to look at it is extreme DIY that if it goes well can help everyone out. I intend to help expand the DIY community into DIY motor design and transducer design just like there are some individuals making DIY ESL and DIY ribbons. The saying: "If you want it done, you have to do it yourself" comes to mind… Matt has gone his own direction due to personal reasons though and isn't involved now.

I hope this clears the status of the situation up a little bit.

http://www.caraudioforum.com/vbb3/s...40&page=5&pp=15

Wow...

I didn't read that all untill now guess he did start a fight there and not thank Wiggens for teaching him a thing or 2 about thermodynamics...

guess he did start a fight there and not thank Wiggens for teaching him a thing or 2 about thermodynamics...

As for perf formers have their uses although not properly outlined in that thread! They allow for better air flow and if the radius of the perforation is equal to or smaller than the thickness of the former the surface area is equal to or greater than a solid former... also it is of lower mass (although lower strength)

So inevitably if you make it thicker to increase strength and make the perforations smaller and more densely populated you get more surface area, comparable strength, but the necessity for a larger gap.

Although there is a minimum radius for the perforation since as fluids are forced through micron channels there is substantial resistance to flow since the effects at the channel walls are rather curious.

Wow...

I didn't read that all untill now

As for perf formers have their uses although not properly outlined in that thread! They allow for better air flow and if the radius of the perforation is equal to or smaller than the thickness of the former the surface area is equal to or greater than a solid former... also it is of lower mass (although lower strength)

So inevitably if you make it thicker to increase strength and make the perforations smaller and more densely populated you get more surface area, comparable strength, but the necessity for a larger gap.

Although there is a minimum radius for the perforation since as fluids are forced through micron channels there is substantial resistance to flow since the effects at the channel walls are rather curious.

What's that last cone? Doesnt look like aluminum ... looks like some sort of coating. Your efforts look interesting, that wool cone and former look almost exactly like Al's Raw RA165 drivers.

BTW, I hope you don't go with a stright aluminum cone - I've never heard one I enjoy in the midrange. If you try some other unique cone composition though, I'll almost certainly buy a pair to try out.

BTW, I hope you don't go with a stright aluminum cone - I've never heard one I enjoy in the midrange. If you try some other unique cone composition though, I'll almost certainly buy a pair to try out.

The last cone is indeed a coating however it didn't help as much as I was hoping with the dip in the freq response. The wet look didn't do anything whatsoever. I can get red or black dyes added to that coating which won't really impact anything from a technical point of view.

I'm getting a high quality fiberglass cone made for this unit and am searching once more for a manufacturer that can handle a HSHMPE (dyneema or spectra brand) fiber cone but that is going to prove difficult.

I could see about a simple carbon fiber/paper or a hshmpe/paper mix which would be easier for the manufacture process but might help get rid of some of the rather large 4dB dip in the frequency response... If only that dip didn't exist this would be as good as I could manage at this fairly budget oriented price point... If I have to go with a HSHMPE cone or a Carbon Fiber cone or some other exotic material it would still have good value, just I couldn't quite consider it budget oriented anymore...

The dip at 350hz is a measurement error that shows up in everything...

I'm getting a high quality fiberglass cone made for this unit and am searching once more for a manufacturer that can handle a HSHMPE (dyneema or spectra brand) fiber cone but that is going to prove difficult.

I could see about a simple carbon fiber/paper or a hshmpe/paper mix which would be easier for the manufacture process but might help get rid of some of the rather large 4dB dip in the frequency response... If only that dip didn't exist this would be as good as I could manage at this fairly budget oriented price point... If I have to go with a HSHMPE cone or a Carbon Fiber cone or some other exotic material it would still have good value, just I couldn't quite consider it budget oriented anymore...

The dip at 350hz is a measurement error that shows up in everything...

OlogyAudio said:The last cone is indeed a coating however it didn't help as much as I was hoping with the dip in the freq response. The wet look didn't do anything whatsoever. I can get red or black dyes added to that coating which won't really impact anything from a technical point of view.

Not to mention it appears your sensitivity is dropping rapidly. The dip there isn't that big a deal since typical BSC will smooth it out somewhat.

Can you apply the coating just on the outside edge of the cone and soften the surround? Or is there a process to only embed fibers in the cone perimeter, and pair that with a softer surround?

I'm getting a high quality fiberglass cone made for this unit and am searching once more for a manufacturer that can handle a HSHMPE (dyneema or spectra brand) fiber cone but that is going to prove difficult.

I could see about a simple carbon fiber/paper or a hshmpe/paper mix which would be easier for the manufacture process but might help get rid of some of the rather large 4dB dip in the frequency response... If only that dip didn't exist this would be as good as I could manage at this fairly budget oriented price point... If I have to go with a HSHMPE cone or a Carbon Fiber cone or some other exotic material it would still have good value, just I couldn't quite consider it budget oriented anymore.

The only fiberglass cone mids I've heard have left a lot to be desired, but of course the exact makeup of the fiberglass is what's important. What's special about HSHMPE?

The dip at 350hz is a measurement error that shows up in everything...

Floor bounce maybe? Try raising your baffle a foot or two and see if the dip moves, or just set the baffle on top of a big stack of pillows

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- What do you want in a 6.5... Pick a FR any FR... A few targets inside