panomaniac said:

Yep, we hoped there would be good sonic synergy between the bamboo and the hemp cones. Thus the "Little Grass Shack" appellation.

how could I have missed that ? any brownies left over?

The Bamboo plywood is a beautiful material, but not cheap. About $170 US per sheet for 3/4" thickness. The 6 Moons photo came out better than mine and does the color justice to some extent. The color is a rich honey brown, matte finish. Everyone loved the way they looked. I highly recommend the bamboo ply, if you can get it. No need for veneer or paint, it's beautiful on its own with a simple finish.

more than just visually gorgeous, after a couple of FE127 PAWO enclosures, I'm convinced there's some tone magic happening that's particularly synergistic with full range drivers

Taking full advantage of the exposed edge grain of the block core, and efficient yield on the cutting plan does make for a more interesting project as well

Oddly enough, I got no questions about the all the strange dots on the driver. Go figure.....

If this was VSAC, you might get some inquiries, but I guess the attendees here already knew everything (they were willing to accept)

Hi panomaniac! and DavidD

That is a very sweet design IMO I like the fact that near wall placement was one of the considerations and the 8" hemp driver is a unit that I have been looking at. Also the Audio Nirvana Super 8 has my interest - and MJK's OB.

I like the fact that near wall placement was one of the considerations and the 8" hemp driver is a unit that I have been looking at. Also the Audio Nirvana Super 8 has my interest - and MJK's OB.

Sigh - so many speakers - so little time (and space - and $$$)

But I think I have a way figured out! Bamboo - at $170.00 per sheet - I'm planting the front and back yard full of it!! Oh wait - we have a drought going on right now - hmmm - that will have to wait - darn!

Oh wait - we have a drought going on right now - hmmm - that will have to wait - darn!

That is a very sweet design IMO

Sigh - so many speakers - so little time (and space - and $$$)

But I think I have a way figured out! Bamboo - at $170.00 per sheet - I'm planting the front and back yard full of it!!

Oh wait - we have a drought going on right now - hmmm - that will have to wait - darn!

Oh wait - we have a drought going on right now - hmmm - that will have to wait - darn!

c2cthomas said:But I think I have a way figured out! Bamboo - at $170.00 per sheet

That is actually a REALLY cheap price for bamboo ply.

dave

bamboo ply

FWIW, I just googled bamboo ply and got to Plyboo, a manufacturer. They sent me to the only distributor in my region. They quoted me a price of $220 per 3/4" x 4' x 8' sheet. Shipping to me an additional $120 via truck for a few sheets...

t

chrisb,

How did you find the bamboo as to workability?

t

FWIW, I just googled bamboo ply and got to Plyboo, a manufacturer. They sent me to the only distributor in my region. They quoted me a price of $220 per 3/4" x 4' x 8' sheet. Shipping to me an additional $120 via truck for a few sheets...

t

chrisb,

How did you find the bamboo as to workability?

t

chrisB

I had about a patch of about 10 sq meters I had to clear out of my yard when I lived in Sacramento CA. Almost impossible to kill that stuff off!! But for that price (and $170 per sheet of 3/4 inch is low - more like $190 to $230 from what I've seen) I'm ready to become a bamboo King!! Just need to figure out how to make it grow in squares!

I had about a patch of about 10 sq meters I had to clear out of my yard when I lived in Sacramento CA. Almost impossible to kill that stuff off!! But for that price (and $170 per sheet of 3/4 inch is low - more like $190 to $230 from what I've seen) I'm ready to become a bamboo King!! Just need to figure out how to make it grow in squares!

WIKI?

I think the time is drawing near for a wiki to contain a summary of information contained here. I've collected what I think are the gems from the first ~150 or so posts and I'm up to 6 pages (in 8 point typeset!). It isn't edited but would definitely benefit from doing so.

I see many questions being asked multiple times...and amiably responded to...Thanks Bud!

Do we want a wiki?

I think the time is drawing near for a wiki to contain a summary of information contained here. I've collected what I think are the gems from the first ~150 or so posts and I'm up to 6 pages (in 8 point typeset!). It isn't edited but would definitely benefit from doing so.

I see many questions being asked multiple times...and amiably responded to...Thanks Bud!

Do we want a wiki?

Re: WIKI?

certainly- at least lookin' at my last question- few posts ago.............

Ed LaFontaine said:........

Do we want a wiki?

certainly- at least lookin' at my last question- few posts ago.............

Re: bamboo ply

Pricing does seem to vary quite a bit, depending no doubt on your location in the distribution network. Although bamboo grows very fast and has high ecological appeal, and is currently quite in vogue for flooring, there is still limited harvesting and manufacturing for full sized sheet goods. It's also quite more time intensive a production process than regular veneer cored plywoods.

Very dense for a "plywood", with a lot of resin glue content, so super sharp tooling is mandatory, and steady feed rates (e.g. slower than you'd use for MDF) highly recommended. It will hold a very sharp beveled edge better than HDF - as I've got the scars to verify.

Panels or cut parts can warp quite readily with varying humidity - so glue it up as quick as you can. I did experience some minor chip-out on gross grain dadoes of the exposed block cores, but those were easily remedied by the gap filling properties of moisture cured polyurethane glue ( Gorilla, etc) .

Purists will blanch, but since I'm a bit lazy, my finishing generally consists of few coats of sprayed satin sheen nitrocellulose lacquer (adds just enough amber sheen to pop some colour and bring out depth of grain)

t-head said:FWIW, I just googled bamboo ply and got to Plyboo, a manufacturer. They sent me to the only distributor in my region. They quoted me a price of $220 per 3/4" x 4' x 8' sheet. Shipping to me an additional $120 via truck for a few sheets...

t

chrisb,

How did you find the bamboo as to workability?

t

Pricing does seem to vary quite a bit, depending no doubt on your location in the distribution network. Although bamboo grows very fast and has high ecological appeal, and is currently quite in vogue for flooring, there is still limited harvesting and manufacturing for full sized sheet goods. It's also quite more time intensive a production process than regular veneer cored plywoods.

Very dense for a "plywood", with a lot of resin glue content, so super sharp tooling is mandatory, and steady feed rates (e.g. slower than you'd use for MDF) highly recommended. It will hold a very sharp beveled edge better than HDF - as I've got the scars to verify.

Panels or cut parts can warp quite readily with varying humidity - so glue it up as quick as you can. I did experience some minor chip-out on gross grain dadoes of the exposed block cores, but those were easily remedied by the gap filling properties of moisture cured polyurethane glue ( Gorilla, etc) .

Purists will blanch, but since I'm a bit lazy, my finishing generally consists of few coats of sprayed satin sheen nitrocellulose lacquer (adds just enough amber sheen to pop some colour and bring out depth of grain)

Well now that I have hi-jacked this thread with bamboo ply, here goes.

The Bamboo ply we used was bought in the Seattle area. I expected over $200 a sheet, but the guys told me more like $160.

Bamboo works well, it's stiff and dense. It's also somewhat brittle, so you have to be careful not to chip it when drilling and routing. I have made amplifier face plates out of laminated bamboo, it works much the same.

Finishing is pretty easy, sanding and oil or varnish. It's not as porous as you would think.

The high price of the bamboo ply is because it is so complicated to make and quantities are still small. Lets hope that in the future that will change.

EDIT: See Chris's post above.

The Bamboo ply we used was bought in the Seattle area. I expected over $200 a sheet, but the guys told me more like $160.

Bamboo works well, it's stiff and dense. It's also somewhat brittle, so you have to be careful not to chip it when drilling and routing. I have made amplifier face plates out of laminated bamboo, it works much the same.

Finishing is pretty easy, sanding and oil or varnish. It's not as porous as you would think.

The high price of the bamboo ply is because it is so complicated to make and quantities are still small. Lets hope that in the future that will change.

EDIT: See Chris's post above.

Re: WIKI?

Wiki would be good. I'm also going to be putting up a page on my website, but that will be more oriented towards sales of drivers.

dave

Ed LaFontaine said:I think the time is drawing near for a wiki to contain a summary of information contained here. I've collected what I think are the gems from the first ~150 or so posts and I'm up to 6 pages (in 8 point typeset!). It isn't edited but would definitely benefit from doing so.

Wiki would be good. I'm also going to be putting up a page on my website, but that will be more oriented towards sales of drivers.

dave

Ok, after trying out several options, including airbrush paints, I went ahead with doing 2 midwoofer cones with the Testors Model Master custom lacquer system paint #28015 flat black. It seemed to go on easy enough, dried quickly, but seemed fine with the speedball pen. I had to use a flat tipped pen to do the inside cone and phase plug and essentially do not much more than dots, since they were so small (1" dia. phase plug).

I still did not find the Microscale gloss coat, but they did have some Gloss Top Coat in their airbrush paints area. It is called Createx Airbrush Colors Gloss Top Coat and here is a link.

Createx Airbrush Colors Gloss Top Coat

In addition it says it "meets ASTM D-4236 standards Protective Top coat which dries to a clear gloss finish" on the bottle.

Does anyone think this will work in place of the Microscale? These are aluminum cones and I believe they only need one coat over just the patterned area.

I still did not find the Microscale gloss coat, but they did have some Gloss Top Coat in their airbrush paints area. It is called Createx Airbrush Colors Gloss Top Coat and here is a link.

Createx Airbrush Colors Gloss Top Coat

In addition it says it "meets ASTM D-4236 standards Protective Top coat which dries to a clear gloss finish" on the bottle.

Does anyone think this will work in place of the Microscale? These are aluminum cones and I believe they only need one coat over just the patterned area.

Ed,

I have been letting others think about this. I wonder if anyone but you has attempted it. My attempts always drool off into some minutely trivial point, since I have zero objectivity on this or most other subjects.

If you want me to I will look your text over for anything I can find . However, the short Wiki post you made many moons ago, indicated to me that you has the fundamental concepts down solid.

Please Wiki us, I really do think others should create this.

Bud

I have been letting others think about this. I wonder if anyone but you has attempted it. My attempts always drool off into some minutely trivial point, since I have zero objectivity on this or most other subjects.

If you want me to I will look your text over for anything I can find . However, the short Wiki post you made many moons ago, indicated to me that you has the fundamental concepts down solid.

Please Wiki us, I really do think others should create this.

Bud

dlneubec.

I wouldn't put any gloss coat on. Mount the drivers, both left and right channel and listen to complex music.

You will be listening for two things.

First is a point where the sound goes from spacious and clear to corrupted for just a split second and then recovers. This indicates the need for a single 50% cut coat over the blocks. If the corrupted sound is longer than just small moments then a complete cone coating is needed. Since these are aluminum and already coated, I doubt you will find either case to be true.

The second possibility is a thin, sharp sound at the top of energy spikes. This is where the sound is warm and thick with information and suddenly is thin and spiky. This is not an EnABL problem, though you are hearing it because of EnABL. This is actually a deficiency of electrons for small signal wide band dynamics. Electron Pools or poured ground planes in your equipment will take care of this problem.

So, don't do anymore than you have, but do be ready to coat the patterns on the phase plugs with gloss. The reference sound for phase plug problems is a distinct time misalignment induced IM distortion in alto range voices, especially female voices.

Bud

I wouldn't put any gloss coat on. Mount the drivers, both left and right channel and listen to complex music.

You will be listening for two things.

First is a point where the sound goes from spacious and clear to corrupted for just a split second and then recovers. This indicates the need for a single 50% cut coat over the blocks. If the corrupted sound is longer than just small moments then a complete cone coating is needed. Since these are aluminum and already coated, I doubt you will find either case to be true.

The second possibility is a thin, sharp sound at the top of energy spikes. This is where the sound is warm and thick with information and suddenly is thin and spiky. This is not an EnABL problem, though you are hearing it because of EnABL. This is actually a deficiency of electrons for small signal wide band dynamics. Electron Pools or poured ground planes in your equipment will take care of this problem.

So, don't do anymore than you have, but do be ready to coat the patterns on the phase plugs with gloss. The reference sound for phase plug problems is a distinct time misalignment induced IM distortion in alto range voices, especially female voices.

Bud

Hi Bud,

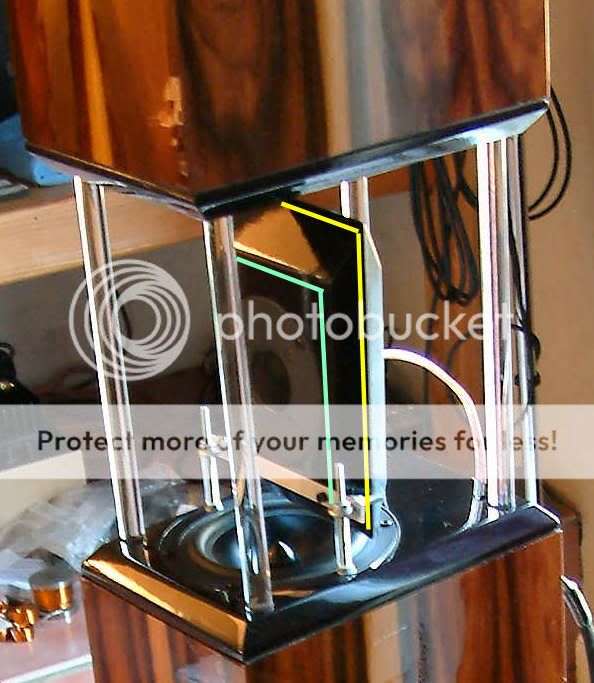

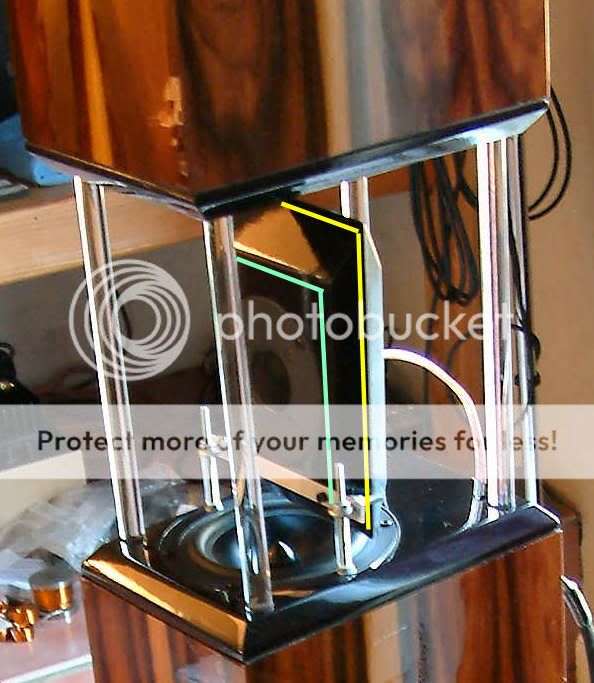

I've completed the 4 midwoofers, but have not had a chance to do any serious listening. I'm contemplating the tweeter baffle and whether it should be treated and where. Take a look at the attached photo. Would you apply the pattern around the flat front part of the tweeter baffle just before the chamfers (green lines) and/or after the chamfers (yellow lines)?

I've completed the 4 midwoofers, but have not had a chance to do any serious listening. I'm contemplating the tweeter baffle and whether it should be treated and where. Take a look at the attached photo. Would you apply the pattern around the flat front part of the tweeter baffle just before the chamfers (green lines) and/or after the chamfers (yellow lines)?

Hi Dan.

The blue line is correct. The yellow line is unneeded. Instead, I would put another complete set of block rings, on the slanted end pieces, just before they bend over onto the vertical surfaces of the tweeter bezel.

This will make a ring around the top and bottom pyramids and keep the mid range energy from ringing either radially or around the perimeter, at the junction of top and bottom pyramids with the tweeter bezel.

You can also treat the backside face of the tweeter mounting bezel to good effect.

I would not do any more than you will have finished at that point, except treating the tweeter dome, until you have listened for a few days. This is important, because you must acclimate yourself to the lack of ringing induced noise coming from your drivers. Dave, from Planet 10, calls this the "Hall of Mirrors" effect. Once you are used to listening as deeply as these patterns should allow you to, then you can begin to look for the remaining corruptions and get rid of them.

Bud

The blue line is correct. The yellow line is unneeded. Instead, I would put another complete set of block rings, on the slanted end pieces, just before they bend over onto the vertical surfaces of the tweeter bezel.

This will make a ring around the top and bottom pyramids and keep the mid range energy from ringing either radially or around the perimeter, at the junction of top and bottom pyramids with the tweeter bezel.

You can also treat the backside face of the tweeter mounting bezel to good effect.

I would not do any more than you will have finished at that point, except treating the tweeter dome, until you have listened for a few days. This is important, because you must acclimate yourself to the lack of ringing induced noise coming from your drivers. Dave, from Planet 10, calls this the "Hall of Mirrors" effect. Once you are used to listening as deeply as these patterns should allow you to, then you can begin to look for the remaining corruptions and get rid of them.

Bud

BudP said:the "Hall of Mirrors" effect.

Look at the image here...

http://www.flickr.com/photos/neocles/1558619578/in/pool-49502971711@N01

now by analogy the image after EnALe would be something like below.

dave

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- EnABL Processes