It would be interesting to see Stephens Tru-Sonic revived; the old-timers I've met told me that they were the best-sounding drivers and loudspeakers of the early and mid-Fifties. My understanding is that Stephens was part of the Wente and Thuras team at ERPI in the late Thirties, and was the inventor of the multicell horn.

Stephens seems to have been running his own company at the time. It looks like he did some OEM work for W.E., and he worked on the muticell horn for the the Shearer system under John K. Hilliard. He designed and built the horn, probably on a licence from W.E., since Wente holds the patent.

Wente and Thuras worked at the Bell Labs, not at ERPI, which was a separate company. BTL/WE developed and produced the equipment, ERPI installed and maintained it in the theatres.

-Bjørn

Lyon,

Extrapolating from what you are saying I will add in that JBL and Altec at the time just acted as if the crossover components were completely interchangeable, that is what you are seeing. As long as the value was electrical component met a minimum standard like it was plus or minus 10% it was the same and would sound the same. We all know now that isn't true and I bet they more than likely did also, but just ignored it as they could get away with that. The same guys designing those great drivers of the time we just as capable as anyone at designing better crossovers. As you say Heyser was in California and there were just to many others who knew what was going on. When you control the market for the products why change was the thinking.

Peter Snell was doing exactly the same thing and his standards regarding matching crossovers and drivers are said to be the highest in the industry. I heard from reliable source that it was incredibly tight . Yet , he mixed mylar and electrolityc caps only with regards to value . I found early Model K where

in one speaker there was a mix of bipolar and mylar caps in tweeters hf filter and in the another only electrolityc bipolar caps.. granted he used cheap drivers with poor tolerances and had to select them but still those old vifa woofers have tone which I miss in modern drivers.

Hi Bud, Do you mean they used air core inductors? The old drivers I thought were forgiving of this basic approach. Particularly when horn loaded. Pio caps and air core inductors in 12dB primitive style sound pretty good, but hoping to learn more from Lynn.

martin

Well, I use (electrical) 2nd-order crossovers a lot myself, as a reasonable subjective compromise between group-delay error, out-of-band attenuation, and immunity to driver impedance variation.

The Altec A5 crossovers I saw were the "constant-power" type, with the same-value L's and C's for the high and low-pass sections, a 10-watt L-pad attenuator for the HF driver. That was it. There was nothing else in the cast-aluminum can except for lamp-cord type wire going to the binding posts.

Rather unexpectedly, Paul Klipsch was doing some unexpected things with autoformers as far back as 1959, and in following Klipschorns, La Scala's, Cornwalls, and Heresies, you see asymmetric 1st, 2nd, and 3rd-order networks, along with autoformers. But PWK's drivers were not easy to work with, with some pretty rough responses (particularly at the top of the range of the folded bass horn), so I can see why he and his staff were forced to be creative.

Speaking from personal experience, the one thing horns have taught me is they are much less tolerant of out-of-band operation (compared to direct-radiators). I don't understand how anyone is getting them to work satisfactorily with 1st-order highpass filters, whether active or passive.

The sound gets much grainier and harsher if the compression driver gets too much energy in the horn-cutoff region. I was surprised that differences between 2nd, 3rd, and 4th-order highpass filtering were as strikingly audible as they turned out to be. (Mylar diaphragms seem to be a lot more tolerant of out-of-band operation, which probably accounts for their popularity in small-format compression drivers.)

Bjorn, thanks for the additional information about the history and people of Western Electric, ERPI, and Altec; always appreciated.

Last edited:

Lynn,

I think you would be very surprised at the actual acoustical output of the surrounds on these compression drivers and that also really goes for direct radiators also. I tried to mention this to one of the other designers on another forum and was told that he only cared about sound in the far field but there is a large contribution to noise in some drivers from the surrounds. Compression drivers are most definitely not immune to this factor, the surround can be a very large area compared to the diaphragm surface area and many times this area is out of phase to the diaphragms output. I would say that the mylar surrounds are probably much more well damped than say a metallic surround, with or without diamond shaped reliefs that themselves can cause even more breakup modes in the surrounds signature sound output. When doing speaker development one thing I have been taught is to not overlook the surround. We not only look at the response at 1 meter but also at very short distances and it is amazing when using a 1/4" mic to actually analyze the output of the different sections of the cone, you can definitely look at the acoustical signature of the surrounds when working this close to a particular area, I am talking about almost touching the surface but far enough away not to get hit by the moving parts.

I think you would be very surprised at the actual acoustical output of the surrounds on these compression drivers and that also really goes for direct radiators also. I tried to mention this to one of the other designers on another forum and was told that he only cared about sound in the far field but there is a large contribution to noise in some drivers from the surrounds. Compression drivers are most definitely not immune to this factor, the surround can be a very large area compared to the diaphragm surface area and many times this area is out of phase to the diaphragms output. I would say that the mylar surrounds are probably much more well damped than say a metallic surround, with or without diamond shaped reliefs that themselves can cause even more breakup modes in the surrounds signature sound output. When doing speaker development one thing I have been taught is to not overlook the surround. We not only look at the response at 1 meter but also at very short distances and it is amazing when using a 1/4" mic to actually analyze the output of the different sections of the cone, you can definitely look at the acoustical signature of the surrounds when working this close to a particular area, I am talking about almost touching the surface but far enough away not to get hit by the moving parts.

Lynn and I have spoken about this subject and my take on it is that it's not the quality of the crossover parts that is the problem, but the design of the circuit. They were mostly just bog standard 2nd order crossovers with no regard for actual impedance or the acoustical targets. The results were not worthy of the drivers. A good crossover is more than just textbook values.

FWIW, the UK Westrex drivers were better (IMO) than the same vintage Altec. Rare finds, tho, at least on this side of the pond.

FWIW, the UK Westrex drivers were better (IMO) than the same vintage Altec. Rare finds, tho, at least on this side of the pond.

Lynn and I have spoken about this subject and my take on it is that it's not the quality of the crossover parts that is the problem, but the design of the circuit. They were mostly just bog standard 2nd order crossovers with no regard for actual impedance or the acoustical targets. The results were not worthy of the drivers. A good crossover is more than just textbook values.

…

"A good crossover is more than just textbook values"

It sounds so true and so familiar. Though I have zero experience with speaker drivers and crossovers, from my experience in electronics, including RF filters, it sounds very true.

Peter Snell was doing exactly the same thing and his standards regarding matching crossovers and drivers are said to be the highest in the industry. I heard from reliable source that it was incredibly tight . Yet , he mixed mylar and electrolityc caps only with regards to value . I found early Model K where

in one speaker there was a mix of bipolar and mylar caps in tweeters hf filter and in the another only electrolityc bipolar caps.. granted he used cheap drivers with poor tolerances and had to select them but still those old vifa woofers have tone which I miss in modern drivers.

Back in the Seventies, I would give the nod to licensed BBC monitors and the studio-grade KEF products. Although you'd see things like electrolytic caps for the larger values, they were selected to 1% precision, and the final product matched against the approved prototype.

We did this at Audionics too ... in fact, we have been the only US manufacturer foolish enough to apply for a BBC license. It took the BBC about 9 months to answer ... no. That didn't stop other US manufacturers from making LS3/5 copies, and selling them as minimonitors.

One little tip I picked up from Laurie Fincham when I visited KEF was phase-matching each production loudspeaker against the original prototype by placing the two speakers side-by-side, reversing the phase of one of them, and measuring the combined pair with a spectrum analyzer. If the null was 20 dB or more across the entire spectrum, it would pass QC as a match. For this to happen, you had to trim the driver levels (which usually vary by 1~2 dB in production) and have caps pre-matched within 1% tolerance. Since we and the Brits were using notch filters as a matter of routine, tight tolerances were pretty much required for the response-shaping portion of the crossover.

This is what we and the high-end Brit manufacturers were doing in the mid-to-late Seventies. At the time, many US manufacturers thought a "crossover" was a series cap to protect to protect the mid and tweeter (look at the crossover for the JBL L100 if you don't believe me, or many of the "East Coast sound" loudspeakers).

The US manufacturers started using more sophisticated crossovers in the Eighties, but I didn't follow the market closely since I spent the Eighties out of the hifi business ... Audionics had burned me out on hifi. I didn't re-enter until 1989, and things had changed a lot during that time. I never did understand why Wilson Audio became so popular during that time; they weren't flat, there was no diffraction control, and the drivers, particularly the dreadful Focal tweeter, were not that good.

Last edited:

As for Wilson, they appeal to the "appearance" first crowd. Although, they recently started the to transition to soft dome tweeters, and now are much less annoying to listen to.

Only took them twenty years to discover soft-domes. Progress.

I think they are just shying away from a problem they cannot solve by moving to soft domes.It appears Tannoy was way ahead of it's time.

As for Wilson, they appeal to the "appearance" first crowd. Although, they recently started the to transition to soft dome tweeters, and now are much less annoying to listen to.

Lynn,

I was looking at pictures of the AZURAHORN AH-425, and They appear to terminate at the mouth at between 90 and 120 degrees.

I understand that a Le Cléac’h Horn should have a mouth rollback of about 360 degrees.

What did this compromise entail?

I was looking at the frequency response and impedance plots on this site and it looks like there is some ripple in the 1k and below measurements.

https://sites.google.com/site/drivervault/driver-measurements/horns-and-waveguides/azura-425hz-horn

Doug

I was looking at pictures of the AZURAHORN AH-425, and They appear to terminate at the mouth at between 90 and 120 degrees.

I understand that a Le Cléac’h Horn should have a mouth rollback of about 360 degrees.

What did this compromise entail?

I was looking at the frequency response and impedance plots on this site and it looks like there is some ripple in the 1k and below measurements.

https://sites.google.com/site/drivervault/driver-measurements/horns-and-waveguides/azura-425hz-horn

Doug

Autotech alternative ?

The Autotech JMLC horns have mouth termination not fare from 180 degrees. I have the 325 and the 1000 horns. The FR is smooter in the mids tha Azura horn. Does anyone considered them as an alternative to the Azuras? Lynn have you looked or tried them ?

Chris

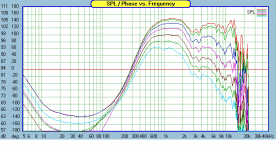

Ps first graph is for Azura 425

The Autotech JMLC horns have mouth termination not fare from 180 degrees. I have the 325 and the 1000 horns. The FR is smooter in the mids tha Azura horn. Does anyone considered them as an alternative to the Azuras? Lynn have you looked or tried them ?

Chris

Ps first graph is for Azura 425

Attachments

Radian Beryllium domes

Hi

i talked the other day to a very nice guy at radian who told me that they are ramping up production for the Beryllium domes for their drivers which means that the 745 neo is now available w/ truextent diaphragm from materion through usspeaker .

i was also told that all other CD's will be available w/ the new Be diaphragm .

i will have to try them and see what the fuss about BE is about .

Hi

i talked the other day to a very nice guy at radian who told me that they are ramping up production for the Beryllium domes for their drivers which means that the 745 neo is now available w/ truextent diaphragm from materion through usspeaker .

i was also told that all other CD's will be available w/ the new Be diaphragm .

i will have to try them and see what the fuss about BE is about .

The DriverVault notch between 3 and 4 kHz is a driver artifact, as far as I can tell. The width and depth of this notch was not the same between the two 288's tested by DriverVault, leading me to surmise that either the centering of the diaphragm, or differences in radiation from the tangential surrounds, is responsible.

The notch is not present with the Radian 745Neo driver, with very smooth response between 700 Hz and 10 kHz. Radians use a stretched Mylar surround instead of the Altec/GPA stamped tangential aluminum surround, as well as a different phase plug. (My understanding is the Radian 745Neo has a more sophisticated phase plug than the 745 ceramic, which gives smoother response in the 1~5 kHz region, as well as a little bit higher efficiency.) The potential downside of a stretched Mylar surround is a higher Fs for the compression driver, which limits the lowest frequency that can be safely used with low distortion.

The question with any LeCleac'h horn is the match between the exit angle of the compression driver, and entrance angle of the horn. These should be as close as possible, and if there's a mismatch, it's better that the exit angle of the compression driver is a bit narrower than the horn entrance.

If compression drivers and horns are mixed-n-matched without attention to exit angle, the response variations might be the result of mismatch, instead of anything the horn is doing. Similarly, it's a good idea to see how much difference there is between different samples of compression drivers ... if there is, that points to potential problems with the diaphragms.

The notch is not present with the Radian 745Neo driver, with very smooth response between 700 Hz and 10 kHz. Radians use a stretched Mylar surround instead of the Altec/GPA stamped tangential aluminum surround, as well as a different phase plug. (My understanding is the Radian 745Neo has a more sophisticated phase plug than the 745 ceramic, which gives smoother response in the 1~5 kHz region, as well as a little bit higher efficiency.) The potential downside of a stretched Mylar surround is a higher Fs for the compression driver, which limits the lowest frequency that can be safely used with low distortion.

The question with any LeCleac'h horn is the match between the exit angle of the compression driver, and entrance angle of the horn. These should be as close as possible, and if there's a mismatch, it's better that the exit angle of the compression driver is a bit narrower than the horn entrance.

If compression drivers and horns are mixed-n-matched without attention to exit angle, the response variations might be the result of mismatch, instead of anything the horn is doing. Similarly, it's a good idea to see how much difference there is between different samples of compression drivers ... if there is, that points to potential problems with the diaphragms.

Last edited:

krzys,

I like the Auto-Tech horns, but I can't find what T value Auto-Tech used.

I was looking at the JMLC-400 as being more equivalent in size to the AH-425.

Doug

Dough, I can not find the reference but as I remember T is 0.8. Maybe JZagaja or JMLC can chime in and confirm. They have designed those horns together.

I like those horns very much, they measure and sound very well, much better than my previous Tractrix 400 Stereorlab horns. They are BIG!

Dough, I can not find the reference but as I remember T is 0.8. Maybe JZagaja or JMLC can chime in and confirm. They have designed those horns together.

I like those horns very much, they measure and sound very well, much better than my previous Tractrix 400 Stereorlab horns. They are BIG!

The entrance angle would be of interest also: zero degree, eight degrees, or what?

I agree about the sonic (and measured) differences between LeCleac'h and Tractrix horns. In addition to lower (nearly absent) horn coloration, the LeCleac'h profile has a very deep "3D" presentation, which they share with the big Altec 1505 and 1005 multicell horns.

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel