200Hz

Bjorn Kolbrek's midrange horn is quite relevant to this, and a very interesting read :

Exponential Midrange 2

Bjorn Kolbrek's midrange horn is quite relevant to this, and a very interesting read :

Exponential Midrange 2

I read Poohs comments and I must have regressed about a month. Don't worry Pooh, this is just a hobby (though I've been known to help schools and churches). Indecisive is just a state of mind.. I think.

IslandPink,

I just fail to see the thinking of pushing any compression driver down so low that you need a 200hz horn mouth size to achieve that. If your going to use something like a 15" cone driver below why wouldn't you use that up to its sweet spot in the 600hz range and call it a day. If you do that a much smaller midrange horn would work well and be so much smaller, the integration would be much better between the two sections.

I just fail to see the thinking of pushing any compression driver down so low that you need a 200hz horn mouth size to achieve that. If your going to use something like a 15" cone driver below why wouldn't you use that up to its sweet spot in the 600hz range and call it a day. If you do that a much smaller midrange horn would work well and be so much smaller, the integration would be much better between the two sections.

If by that you mean the independence of H and V (and hence a continually changing aspect ratio) isn't bad if the source is transitioned well that way, then that's good.

I've always felt it best to do aspect transitions either very early or very late, now I'd like to do one in the middle.

Well, done right, this occurs inside the horn, then the mouth only radiates whatever radial pattern it's designed for throughout its gain BW. This is to a great extent what makes the old multi-cells so highly prized among the audio cognoscenti.

'Sounds' then like you need to figure out how to 'streamline' an Altec Mantaray diffraction horn. I tried and failed, with heavy mouth damping and throat plug only giving me a hint of what might be, but didn't have a computer and TTBOMK, advanced pressure wave in a bounded space simming capability was nothing more than an engineer's wet dream, so maybe now with such programs combined with relatively inexpensive 3D model making, someone can do it without needing a wind tunnel, etc..

GM

Is there not a really great 2" or larger CD that can cross low and perform stellar in the 300-500hz range all the way up to the 17-20,000hz range on one reasonably sized horn? Then bring the GPA Classic 416 in a sealed cab aka Gary D, and work it from 70hz on up to 300+ to 500Hz? Seems like it would be more of a simple solution in keeping with a two way design.. For more sens two 416's could be used side by side?, below the larger CD and then dial in some IB subs or sealed for 70hz on down etc.. Seeings how most here interested in the system created by Lynne and Gary are using just a few watts there has to be a really decent CD that can handle going pretty low and take us on up to the limits of most of our hearing here.. I'm working with 6watts at the most myself with my SEP amp, so it's not like most are going to try pumping 100watts into a CD that's crossed low etc.. Dunno just trying to keep the KISS principle happening in my thoughts towards this type of build using a 15 and a CD as a two way fed by the left and right channel of one SEP valve amp, (minus the subs etc).

Last edited:

BMS 4592 coax ?

"theoretically" this answers your quest:

BMS 4592ND IS A HIGH POWER DUAL VOICE COIL 2" COAXIAL HIGH-MID FREQUENCY COMPRESSION DRIVER

EXTENDED FREQUENCY RANGE FROM 300HZ TO 22KHZ

But if it seems too good to be true, it probably is. A horn large enough to handle the lowest of this range, would without doubt, suffer from severe beaming at the highest part of the range.

BMS 4592ND Neodymium Coaxial High frequency Compression Driver - BMS 4592ND - BMS 4592ND lightweight neodymium 2" coaxial high frequency compression driver. BMS neodymium 4592ND dual voice 2" coaxial high frequency compression drivers are available h

Is there not a really great 2" or larger CD that can cross low and perform stellar in the 300-500hz range all the way up to the 17-20,000hz range on one reasonably sized horn? Then bring the GPA Classic 416 in a sealed cab aka Gary D, and work it from 70hz on up to 300+ to 500Hz? Seems like it would be more of a simple solution in keeping with a two way design.. For more sens two 416's could be used side by side?, below the larger CD and then dial in some IB subs or sealed for 70hz on down etc.. Seeings how most here interested in the system created by Lynne and Gary are using just a few watts there has to be a really decent CD that can handle going pretty low and take us on up to the limits of most of our hearing here.. I'm working with 6watts at the most myself with my SEP amp, so it's not like most are going to try pumping 100watts into a CD that's crossed low etc.. Dunno just trying to keep the KISS principle happening in my thoughts towards this type of build using a 15 and a CD as a two way fed by the left and right channel of one SEP valve amp, (minus the subs etc).

"theoretically" this answers your quest:

BMS 4592ND IS A HIGH POWER DUAL VOICE COIL 2" COAXIAL HIGH-MID FREQUENCY COMPRESSION DRIVER

EXTENDED FREQUENCY RANGE FROM 300HZ TO 22KHZ

But if it seems too good to be true, it probably is. A horn large enough to handle the lowest of this range, would without doubt, suffer from severe beaming at the highest part of the range.

BMS 4592ND Neodymium Coaxial High frequency Compression Driver - BMS 4592ND - BMS 4592ND lightweight neodymium 2" coaxial high frequency compression driver. BMS neodymium 4592ND dual voice 2" coaxial high frequency compression drivers are available h

Probably should go with a large format TAD driver with a 4" diaphragm and a much larger horn than the horn they use. A flare rate of 180 cycles in a tractrix is around 28" in diameter and with the round over of the horns they use it would likely be much larger. I have seen response graph of the smaller 3" Radian and it doesn't look like something I'd use in the treble in a large horn that will beam. The TAD has the extra slit in the phase plug and will deliver the treble but at the expense of beaming. Yhe 4" TAD will work down to 300 cycles though with little 45 or 2A3 single ended amps. What Gary has done crossing over higher with the smaller horn won't be as beamy and is much more practical for most people and rooms. If you want to horn load lower simply do it right and build a midbass horn.

Is there not a really great 2" or larger CD that can cross low and perform stellar in the 300-500hz range all the way up to the 17-20,000hz range on one reasonably sized horn? Then bring the GPA Classic 416 in a sealed cab aka Gary D, and work it from 70hz on up to 300+ to 500Hz? Seems like it would be more of a simple solution in keeping with a two way design.. For more sens two 416's could be used side by side?, below the larger CD and then dial in some IB subs or sealed for 70hz on down etc.. Seeings how most here interested in the system created by Lynne and Gary are using just a few watts there has to be a really decent CD that can handle going pretty low and take us on up to the limits of most of our hearing here.. I'm working with 6watts at the most myself with my SEP amp, so it's not like most are going to try pumping 100watts into a CD that's crossed low etc.. Dunno just trying to keep the KISS principle happening in my thoughts towards this type of build using a 15 and a CD as a two way fed by the left and right channel of one SEP valve amp, (minus the subs etc).

Is there not a really great 2" or larger CD that can cross low and perform stellar in the 300-500hz range all the way up to the 17-20,000hz range on one reasonably sized horn?

The physics is against us since ideally we need around a 200 Hz Fs driver with a ~0.02 Qes and 0.137" dia. throat to have good linear output to 20 kHz at a relatively high efficiency and since even the most powerful field coils can't generate this much motor strength and the horn's path-length would be so ridiculously long to get to 200 Hz........this is why horns are gain BW limited to ~three octaves.

GM

Thanks Scott L, POOH, and GM!

So it would seem with a 15" two way you're pretty much forced to use the 15" up fairly high to bring in a CD, tweet,ribbon etc etc to keep it a two way. And hence why people get interested in 3 ways, 4 ways, 5+ ways etc.. I think I get it now, but I could also live with and would prefer the two way 15'' even if somewhat compromised to how it could be taken further using a 15'' etc. One day a modernized and tweaked M-19 will be singing me some tunes or a version thereof etc..

So it would seem with a 15" two way you're pretty much forced to use the 15" up fairly high to bring in a CD, tweet,ribbon etc etc to keep it a two way. And hence why people get interested in 3 ways, 4 ways, 5+ ways etc.. I think I get it now, but I could also live with and would prefer the two way 15'' even if somewhat compromised to how it could be taken further using a 15'' etc. One day a modernized and tweaked M-19 will be singing me some tunes or a version thereof etc..

Last edited:

Thanks Scott L, POOH, and GM!

So it would seem with a 15" two way you're pretty much forced to use the 15" up fairly high to bring in a CD, tweet,ribbon etc etc to keep it a two way. And hence why people get interested in 3 ways, 4 ways, 5+ ways etc.. I think I get it now, but I could also live with and would prefer the two way 15'' even if somewhat compromised to how it could be taken further using a 15'' etc. One day a modernized and tweaked M-19 will be singing me some tunes or a version thereof etc..

The classic approach that has been around for decades is a 15 crossed over at 800 (some times 500 but 800 tends to be better) to a medium format (3" diaphragm 1.3 to 1.5" exit) compression driver in a radial horn. It's a compromise but can be pretty sweet if pulled off right. The system that Gary built in this thread is an attempt to get that right. The best thing to do is go ahead and get started on a two way with off the shelf parts and improve the system as you seem fit for your own personal satisfaction.

Hi,

The last few pages are full of interesting stuff

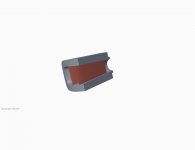

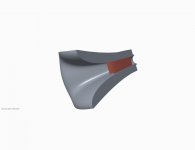

I have had a pair of TH-4001 on loan for some time and i like them. They are of course not perfect but are a good match on many of the parameters that i seek. Eventually they will have to be returned and i need something else. The drivers I have are the TD-4001 and they will stay. I could just make a pair of clones and be happy, but why stop there. The TH-4001 does have some issues that can be addressed, i think that a smoother throat transition would be beneficial, as would a larger mouth round-over. A larger mouth to avoid pattern flip would also be beneficial i think. I will not use the horn below 600Hz so a 300Hz horn will be fine.

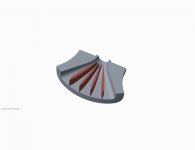

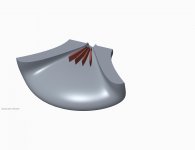

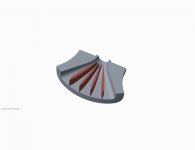

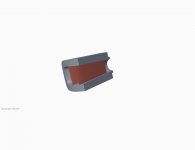

INITIAL SECTION

- A smooth horizontal transition from the CD exit angle to the final coverage angle.

- A vertical section that just follows CD exit angle.

- Smooth fins to aid horizontal treble dispersion and give the actual expansion rate.

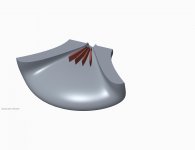

It can look something like this:

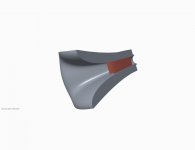

The complete horn can look like below and would end up being a bit over 80cm wide, 40cm high and about 50cm deep. It can be CNC:d in two equal parts that are glued together. This model is actually a 320Hz exponential horn but deviates a bit from that for the last rounding of the mouth.

Comments?

BR,

Anders

The last few pages are full of interesting stuff

I have had a pair of TH-4001 on loan for some time and i like them. They are of course not perfect but are a good match on many of the parameters that i seek. Eventually they will have to be returned and i need something else. The drivers I have are the TD-4001 and they will stay. I could just make a pair of clones and be happy, but why stop there. The TH-4001 does have some issues that can be addressed, i think that a smoother throat transition would be beneficial, as would a larger mouth round-over. A larger mouth to avoid pattern flip would also be beneficial i think. I will not use the horn below 600Hz so a 300Hz horn will be fine.

INITIAL SECTION

- A smooth horizontal transition from the CD exit angle to the final coverage angle.

- A vertical section that just follows CD exit angle.

- Smooth fins to aid horizontal treble dispersion and give the actual expansion rate.

It can look something like this:

The complete horn can look like below and would end up being a bit over 80cm wide, 40cm high and about 50cm deep. It can be CNC:d in two equal parts that are glued together. This model is actually a 320Hz exponential horn but deviates a bit from that for the last rounding of the mouth.

Comments?

BR,

Anders

Bappe,

Just to give you a bit of background on all the classic radial horns like the Altec and others. The pattern makers and designers who originally developed those horns didn't have nice PC computers to help to develop those shapes. What they settled on was a simple shape change that did most of what they wanted. The first 1/4 of the horn was shape change from the round entrance to a square shape done in an exponential expansion. From this section the radial flare was added with whatever angle the side walls were chosen for horizontal dispersion. This is what causes the dip in the flare when you look at it. to keep the exponential expansion the same as the throat the side walls dictated that dip to keep the cross-section following the chosen expansion rate. There is really a discontinuity in the joining of those two section but because the mathematics got rather tricky it was ignored, this is what gave us the classic radial horn. If you want to fix this and get rid of that dip you have to have a curving side wall and set some limits in the shape change as you make the transition from the initial round entrance hole. This is what gave rise to the JMLC horns from what I have looked at. This was not an easy thing to create before the advent of pc cad software. I can tell you it was some serious calculus to do this with nothing but paper and pencil. I developed some elliptical radial horns in about 1976 but never commercialized those and didn't patent that idea. Gedlee had the same basic idea and hence his patented horn shape changes. I guess history tells the story. Earl has gone with the direction of the symmetrical waveguide though I still think with what we know today about the end termination of a horn flare a true radial horn is a real option and that is what I would do if I was creating a new two way system today.

Just to give you a bit of background on all the classic radial horns like the Altec and others. The pattern makers and designers who originally developed those horns didn't have nice PC computers to help to develop those shapes. What they settled on was a simple shape change that did most of what they wanted. The first 1/4 of the horn was shape change from the round entrance to a square shape done in an exponential expansion. From this section the radial flare was added with whatever angle the side walls were chosen for horizontal dispersion. This is what causes the dip in the flare when you look at it. to keep the exponential expansion the same as the throat the side walls dictated that dip to keep the cross-section following the chosen expansion rate. There is really a discontinuity in the joining of those two section but because the mathematics got rather tricky it was ignored, this is what gave us the classic radial horn. If you want to fix this and get rid of that dip you have to have a curving side wall and set some limits in the shape change as you make the transition from the initial round entrance hole. This is what gave rise to the JMLC horns from what I have looked at. This was not an easy thing to create before the advent of pc cad software. I can tell you it was some serious calculus to do this with nothing but paper and pencil. I developed some elliptical radial horns in about 1976 but never commercialized those and didn't patent that idea. Gedlee had the same basic idea and hence his patented horn shape changes. I guess history tells the story. Earl has gone with the direction of the symmetrical waveguide though I still think with what we know today about the end termination of a horn flare a true radial horn is a real option and that is what I would do if I was creating a new two way system today.

I know what you mean about 300Hz and up to maybe 17kHz in one driver.

That is my goal too.

For me, it does not need to be a CD or especially loud.

That is my holy grail.

Just get the TAD large format drivers and some horns at least this size.

You might like it, I feel it is a a big step back from using multi horns - say one to cover each decade. 60-600, 600-6000, 6000 up

The large wooden horn shown below would do 300-350 cycles with the TAD large format up but was about 2 feet deeper for the 2" throat. I have some radial horns that are 34" wide and 12" tall and two feet deep that have a 220 Hz flare and they will only load the driver to 500-600 cycles.

What you imagine doing and getting good results ? Likely not - the big multicells sound no better, a big radial like the EV "Great White Whales" might be alright for you? I couldn't get good sound crossed below 600 Hz with them.

An externally hosted image should be here but it was not working when we last tested it.

Kindhornman,

Thanks for the input, have done quite a few horns without PC over the years but mostly for bass and Lowthers What i am trying to do here is basically a radial with a twist. The first part that includes the fins are well over 1/4 wave length and have "correct" expansion. The second stage is more of a wave guide than a horn really, as the old radials, only smoother. I also think that the old style alnico drivers with long throat sections are less suitable for a "modern" horn like the JMLC. I have tried the TD-4001 in such horns and it does not work.

What i am trying to do here is basically a radial with a twist. The first part that includes the fins are well over 1/4 wave length and have "correct" expansion. The second stage is more of a wave guide than a horn really, as the old radials, only smoother. I also think that the old style alnico drivers with long throat sections are less suitable for a "modern" horn like the JMLC. I have tried the TD-4001 in such horns and it does not work.

I want the heart of the system to be a classic two-way, and the 4001 in a good horn could do the trick i think.

//Anders

Thanks for the input, have done quite a few horns without PC over the years but mostly for bass and Lowthers

I want the heart of the system to be a classic two-way, and the 4001 in a good horn could do the trick i think.

//Anders

Bappe,

I haven't had the pleasure to work with the 4001 driver, I used the TAD 2001 and the ET703 on the last horn system I created. I never had any real interest in any of the 2" exit drivers I would use a cone driven mid for that range, I haven't been a fan of the large exit compression drivers even in the long ago past when I worked with PA back in the 70's. Even then we didn't use anything with a throat larger than a 1.4" Altec. The TAD drivers are just somewhat updated JBL designs with Be diaphragms. The cost is just way to high today, I could buy them for 1/10 the cost back when I worked with them.

I haven't had the pleasure to work with the 4001 driver, I used the TAD 2001 and the ET703 on the last horn system I created. I never had any real interest in any of the 2" exit drivers I would use a cone driven mid for that range, I haven't been a fan of the large exit compression drivers even in the long ago past when I worked with PA back in the 70's. Even then we didn't use anything with a throat larger than a 1.4" Altec. The TAD drivers are just somewhat updated JBL designs with Be diaphragms. The cost is just way to high today, I could buy them for 1/10 the cost back when I worked with them.

600 Hz might be the "sweet spot". I was able to use mine down to 500, but that was with using a steep x-over (48db/oct, Marchand).

NICE. Those horns can really give the goosebumps with a good driver

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel