Putting the Beta-8a drivers in a small vented box improved the mid bass punch and the addition of the horns was a large improvement in clarity and openness of the top end.

So to answer your question, adding the horns did the most for dynamics. The Beta-8a drivers in small boxes increased the dynamics of the mid bass.

So to answer your question, adding the horns did the most for dynamics. The Beta-8a drivers in small boxes increased the dynamics of the mid bass.

Yes, In the large open back boxes the bass started rolling off at 100Hz and never had a very tight sound. The small vented boxes go down to 70Hz. The crossover is setup with and additional 12dB high pass at 68Hz to keep the Beta-8a from over excursion at low frequencies. Effective crossover slope on the bottom of the Beta-8a is 36dB/octave with the subs set at 36dB/octave to match.

Question for ra7-

What microphone was used for the distortion measurements between horn systems and cone & dome systems?

I was using the Dayton Audio EMM-6 with the calibration file. It may loose its linearity at higher SPLs, but 100 db is easy.

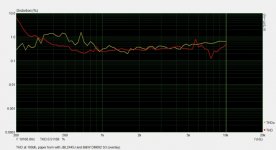

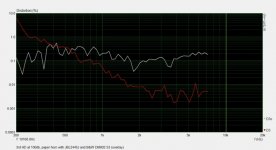

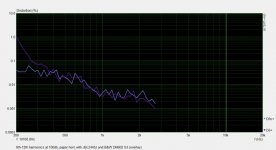

Anyway, attached are the measurements that compare the B&W to the 2445/tractrix combo. All measurements are outdoors at 2m and 100 db. They show the comparison for THD, 3rd and higher orders combined (6th to 12th). There is some difference in the 3rd harmonic distortion, but the clincher for me is the higher order comparison. Little to no difference at all.

You might want to check the DIY pages here:

DIY archive of Kimmo Saunisto

And especially this one:

KS-1804

He shows a lot of measurements, one of which is the STIpa.

I have moved away from the large horn/large format driver design. The large horn narrows in dispersion above 3 kHz, and it's very hard to mate a supertweeter because of the depth of the horn. Withing this 15" woofer/horn/CD design school, I think the sweet spot is a crossover at about 800 Hz to 1000 Hz to a 1" exit driver on a horn with wider dispersion than the larger horn needed to go lower. I recently received a SEOS-18 horn and even with my rudimentary first attempts at a crossover, it is already sounding quite good... a holographic, you are there sound.

Attachments

Yes, the EMM6 should be fine at 100dB. That's the same microphone I use.

The Beta-8a are in use more from a historical perspective than anything else. There has been a series of different designs that were using the Beta-8a and HiVi RT8 as the drivers. The current 1K horn was the largest I could turn on the the crappy Harbor Freight wood lathe I got from my dad.

The 1K horn crossed over at 2K mates nicely with the 8" driver.

I'm currently in the process of building a wood lathe that will be capable of turning horns up to 20" in diameter. Current plan is to work up to a 500Hz horn and pair them with some Electrovoice SP15 drivers that I re-coned keeping the original voice coil but changed to the EV 15B cone. The plan is to cross over the 15" driver 500Hz horn combo in the 900-1K region.

There may be a 12" driver and 800Hz horn combo as a stepping stone.

The Beta-8a are in use more from a historical perspective than anything else. There has been a series of different designs that were using the Beta-8a and HiVi RT8 as the drivers. The current 1K horn was the largest I could turn on the the crappy Harbor Freight wood lathe I got from my dad.

The 1K horn crossed over at 2K mates nicely with the 8" driver.

I'm currently in the process of building a wood lathe that will be capable of turning horns up to 20" in diameter. Current plan is to work up to a 500Hz horn and pair them with some Electrovoice SP15 drivers that I re-coned keeping the original voice coil but changed to the EV 15B cone. The plan is to cross over the 15" driver 500Hz horn combo in the 900-1K region.

There may be a 12" driver and 800Hz horn combo as a stepping stone.

An important point not addressed by your article though is changes in frequency response occuring over time due to the change in Re with VC heating. The small changes in sensitivity with Re you demonstrate would not be important if they were flat across the board, but in any practical speaker the result will actually be a change in frequency response as the sensitivity loss will be frequency dependent.

You're right, and it's pretty amazing how large the shifts are. I studied this exhaustively when designing the cooling system for the 12Pi hornsub.

I really intended the device to simply keep the voice coil temperature low enough to prevent the adhesive from failing. It was the most common failure mode, the adhesive fails and the voice coil unwinds, outer windings first.

But when I tested response, I found that the peaks increased at high power levels. I think this is a lot like putting series resistance in the line, sort of like what happens when using a current source as opposed to a voltage source. The impedance curve is reflected into the response curve.

For example, look at the measurements of the subwoofers tested at the link below. Compare their response charts at 100 watts with their response at full power. The change is quite noticeable.

I think prosound guys must deal with this all the time, but it was fascinating to me to see just how much response change there was from thermal effects. I was already aware of the shifts in T/S parameters, just going from say 1/10th watt (small signal) to 10 watts. This can make some cabinets go from slightly overdamped to slightly underdamped, making a shift in response. That part didn't surprise me. But what did was how much the response peaks changed with thermal stress.

The discrepancy in SPL with power could be a result of any number of things that vary nonlinearly with increased power. Measurement of impedance at the different power levels would be more revealing. Of course, the problem there is that nonlinear behavior will also affect the impedance and may have nothing to do with heating. For example, if the Q of a resonance changes with power level it would be reflected in the impedance even in the absence of heating.

Seems like a small box for a driver this size.With the changes made over the last few months the system is quite a bit more dynamic and open sounding.

At this point the subs are mounted on swings, the Beta-8a drivers are in 16L boxes tuned to 68Hz with ~75% fill of Bonded Logic Ultratouch cotton insulation, and the high end is handled by wood 1Khz .707 Cléac'h profile horns driven by Radian 475pb drivers.

The discrepancy in SPL with power could be a result of any number of things that vary nonlinearly with increased power. Measurement of impedance at the different power levels would be more revealing. Of course, the problem there is that nonlinear behavior will also affect the impedance and may have nothing to do with heating. For example, if the Q of a resonance changes with power level it would be reflected in the impedance even in the absence of heating.

I agree, that's reasonable. But we do not see this behavior in hornsubs with cooling plugs installed, or it is very mild. When we take them out, the peaking at high power levels significantly increases. Of course, the drivers run much hotter without cooling plugs, so they don't live as long either.

I would disagree that a woofer automatically suffers from thermal shifts first. It might be handling more power but it has a much larger thermal mass compared to a tweeter as well, as well as a much larger magnet for the heat to be radiated to.Consider that the woofer gets the largest part of energy from the spectrum and low frequencies require more energy to move the more moving mass of the woofer.

Power compression is the term for what happens when the voice coil gets warm and impedance rises. This usually happens to the woofer first, especially compression drivers due to theyr high sensitivity are attenuated by about 6-8 dB and will not get heated up so fast. Changes in impedance and sensitivity will make x-over drift and let the system loose balance to sound thin and agressive.

So it could easily be that the tweeter suffers thermal compression first (in 10's of seconds of prolonged loud music) followed by the woofer (after a few minutes) so that the tweeter sensitivity drops first, followed by the woofer, and the woofer may actually drop more in the long term in a 2 way system as you suggest, so they could potentially leapfrog each other.

Which one varies first and by how much is going to be highly system dependent though, remember my example was a 3 way, where the midrange driver is going to have a much longer thermal time constant than the tweeter, yet won't have the high power demands of the woofer, in this scenario I would expect to see the least thermal compression from the midrange driver, although again highly system dependent.

My main point stands - you have different drivers with thermal time constants that are up to an order of magnitude different and are handling power from different parts of the spectrum, if there is any significant heating of voice coils in any of them they simply will not track with each other at higher SPL's and the attenuation balance between the different drivers will shift around in a complex and music dependent fashion. This is a big problem and is more of a problem in low efficiency systems, generally.

That the frequency response of the individual drivers will change within their passbands with temperature as well is also a problem but I think the shifts between the dissimilar drivers used in a complete speaker is the bigger issue.

I would disagree that a woofer automatically suffers from thermal shifts first. It might be handling more power but it has a much larger thermal mass compared to a tweeter as well, as well as a much larger magnet for the heat to be radiated to.

The woofers voicecoil heats up very fast. transition to the magnet is slow because of air in the gap being a good insulator.

The tweeter gets much less current compared to the woofer. it can be less than 10% of all the energy coming to the crossover.

You can see as well that tweeters specified 10 Watts can be used together with a woofer with 100 Watts rms.

I have seen a couple of crossover designs that because of the powercompression the compression driver is a bit to low and when the box gets driven in real life, the balance is good. it is not uncommon with commercial designs to test the balance under normal use.

Shift of drivers impedance changes crossover frequencie and can missalign filters that are EQing out peaks or even phaseshifting elements.

JackNZ,

I won't say with complete knowledge on this subject but there are a few other parameters that you have to keep in mind with the heating and dissipation of the temperature rise. A dome tweeter is going to have a much smaller gauge wire than a woofer. In many short voicecoil woofers the gap distance from the wire to the magnetic steel structure can be very similar to the dome tweeters clearance though the overall gap can be very different. So the woofer voicecoil will have much more copper wire mass to absorb the heat before it needs to transfer the heat to the motor structure before damage or adhesive failure will occur. There is more to the heat transfer than just the transfer through the air through other transfer functions.

I won't say with complete knowledge on this subject but there are a few other parameters that you have to keep in mind with the heating and dissipation of the temperature rise. A dome tweeter is going to have a much smaller gauge wire than a woofer. In many short voicecoil woofers the gap distance from the wire to the magnetic steel structure can be very similar to the dome tweeters clearance though the overall gap can be very different. So the woofer voicecoil will have much more copper wire mass to absorb the heat before it needs to transfer the heat to the motor structure before damage or adhesive failure will occur. There is more to the heat transfer than just the transfer through the air through other transfer functions.

Again, there is a significantly larger part of the spectrum being sent down the lowpass than goes towards the upper way. And then if the tweeter is only 8 dB more in sensitivity, and most of the time it can be even more, then you just calculate how much the attenuation circuit lets through. There will be not enough current to heat up the tweeter.

The game changes when the amplifier gets overrun. But that is to be avoided anyway.

The game changes when the amplifier gets overrun. But that is to be avoided anyway.

This is dividing two ways?I've done a bit of measuring of the equal energy points in music. It really depends on the genre of music. Usually it's somewhat lower than the ~630Hz dividing line of pink noise.

I recall for three ways it was something like 300 and 3K.

It would probably be really rare for heat to be a major influencing factor of dynamics with the majority of home systems I would think.

Hi

Power compression is a somewhat “new” phenomena, it didn’t exist in the old days for the simple reason that before the voice coil was hot enough for that to be an issue, the glue had failed and the rubbing voice coil wires would have attracted your attention.

The issue is that about 230 degrees C the resistance of copper has doubled. This wasn’t a problem when the epoxy failed at 155C but is now where we have some VC adhesives which are rated to 300C or over.

If you model any speaker you have both a response and impedance curve for, you can arbitrarily stick in an R of your choosing to see how it affects the average level and response. The astute designer will assume some of this when choosing the system tuning too hint hint.

In the 80’s and early 90’s I worked for a NASA contractor but they allowed me to developed a Servomotor driven subwoofer that was eventually popular for large scale low frequency production. If you went to Disney the Mirage volcano or saw U-2, Michael Jackson, Garth Brooks or Def Leopard on tour, you probably heard these supplying the bass for the sound system.

The commutated motor allowed one to have an unlimited Xmax, only set by the radiator which made for a very powerful woofer but the motor was limited by the same thing, the highest temperature that could be tolerated. The rotor for these was a hollow formed out of the conductors of the type and type shown here;

http://www.kollmorgen.com/en-us/pro...tia/_literature/low_inertia_pmdc_catalog.pdf/

The limiting thing in the thermal circuit is that the air between the wire and the metal connected to the outside is a very poor path, a high resistance. The motors (once we were buying enough to have them made to order) had provision for air cooling and by forcing air through the magnetic gaps, one could raise the power handling by as much as 4.

At the same AES session I presented this;

AES E-Library The Elimination of Power Compression in Servo Drive Loudspeakers

A friend working at JBL did a presentation showing that if the trend of higher and higher temps continued, we could reach the point where increasing the input power actually reduces the sound level being produced.

For that paper, I used the TEF machine as a wide band level vs time recorder when investigating power compression. I also found the same trick worked for conventional loudspeakers too.

https://docs.google.com/viewer?url=www.google.com/patents/US4757547.pdf

A friend Steve (now director of R&D at 18 sound Go Steve!) had licensed the arrangement from the place I worked for and made a line of his own air cooled speakers.

Anyway, what you find is that each voice coil has a thermal mass and thermal resistance to the next link to the outside. How hot it gets how fast is set by those and how much power over time you put in.

A large coil can pass more power to the frame than a tiny one but it is usually on a much higher sensitivity driver, covering a range where there is little acoustic energy. So for a big woofer, you might find is takes seconds to heat up where a small coil is faster and looking in more detail here are several slopes involved.

For Thiele small parameter view, because the safe max VC temp is a strong governor of the electrical power handling, a thumb rule is that there is some shift beginning between about 1/8 and 1/10 rated power for a modern driver, beginning somewhat lower with some of the super power rated drivers.

If you have the nerve and desire, one can see where a speaker goes awry thermally and if careful, you won’t hurt it. An independent lab does this to our full range speakers at work to determine the linear rage of operation; this would be a worst case. Anyway it uses IEC 268-1 noise which is a standard musical emulation noise. A description of how is here;

Loudspeaker Toaster – An Abbreviated Power Test You Can Do at Home Synergetic Audio Concepts

Anyway, some thoughts on the thermal aspect of dynamics.

Best,

Tom Danley

Dynamics, it’s not just amplitude linearity on the long time scale (seconds), it’s also at least in part the difference between quiet and loud and how fast it can get between the two where you are listening.

Power compression is a somewhat “new” phenomena, it didn’t exist in the old days for the simple reason that before the voice coil was hot enough for that to be an issue, the glue had failed and the rubbing voice coil wires would have attracted your attention.

The issue is that about 230 degrees C the resistance of copper has doubled. This wasn’t a problem when the epoxy failed at 155C but is now where we have some VC adhesives which are rated to 300C or over.

If you model any speaker you have both a response and impedance curve for, you can arbitrarily stick in an R of your choosing to see how it affects the average level and response. The astute designer will assume some of this when choosing the system tuning too hint hint.

In the 80’s and early 90’s I worked for a NASA contractor but they allowed me to developed a Servomotor driven subwoofer that was eventually popular for large scale low frequency production. If you went to Disney the Mirage volcano or saw U-2, Michael Jackson, Garth Brooks or Def Leopard on tour, you probably heard these supplying the bass for the sound system.

The commutated motor allowed one to have an unlimited Xmax, only set by the radiator which made for a very powerful woofer but the motor was limited by the same thing, the highest temperature that could be tolerated. The rotor for these was a hollow formed out of the conductors of the type and type shown here;

http://www.kollmorgen.com/en-us/pro...tia/_literature/low_inertia_pmdc_catalog.pdf/

The limiting thing in the thermal circuit is that the air between the wire and the metal connected to the outside is a very poor path, a high resistance. The motors (once we were buying enough to have them made to order) had provision for air cooling and by forcing air through the magnetic gaps, one could raise the power handling by as much as 4.

At the same AES session I presented this;

AES E-Library The Elimination of Power Compression in Servo Drive Loudspeakers

A friend working at JBL did a presentation showing that if the trend of higher and higher temps continued, we could reach the point where increasing the input power actually reduces the sound level being produced.

For that paper, I used the TEF machine as a wide band level vs time recorder when investigating power compression. I also found the same trick worked for conventional loudspeakers too.

https://docs.google.com/viewer?url=www.google.com/patents/US4757547.pdf

A friend Steve (now director of R&D at 18 sound Go Steve!) had licensed the arrangement from the place I worked for and made a line of his own air cooled speakers.

Anyway, what you find is that each voice coil has a thermal mass and thermal resistance to the next link to the outside. How hot it gets how fast is set by those and how much power over time you put in.

A large coil can pass more power to the frame than a tiny one but it is usually on a much higher sensitivity driver, covering a range where there is little acoustic energy. So for a big woofer, you might find is takes seconds to heat up where a small coil is faster and looking in more detail here are several slopes involved.

For Thiele small parameter view, because the safe max VC temp is a strong governor of the electrical power handling, a thumb rule is that there is some shift beginning between about 1/8 and 1/10 rated power for a modern driver, beginning somewhat lower with some of the super power rated drivers.

If you have the nerve and desire, one can see where a speaker goes awry thermally and if careful, you won’t hurt it. An independent lab does this to our full range speakers at work to determine the linear rage of operation; this would be a worst case. Anyway it uses IEC 268-1 noise which is a standard musical emulation noise. A description of how is here;

Loudspeaker Toaster – An Abbreviated Power Test You Can Do at Home Synergetic Audio Concepts

Anyway, some thoughts on the thermal aspect of dynamics.

Best,

Tom Danley

Dynamics, it’s not just amplitude linearity on the long time scale (seconds), it’s also at least in part the difference between quiet and loud and how fast it can get between the two where you are listening.

Dynamics, it’s not just amplitude linearity on the long time scale (seconds), it’s also at least in part the difference between quiet and loud and how fast it can get between the two where you are listening.

Thanks Tom! As usual, an informative post. I think the operative phrase in that last statement you made is, "where you are listening."

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel