The Beyma coaxes seem to be very good as well.

Beyma 15XA38ND - Audio Voice Acoustics

As I said, the Beymas keeps sounding like a dream to my taste.They are, by far, simply the best home speaker systems I have heard. Ever. Regardless of price, size or type .I have not yet finished the big boxes I have planned for them. That have to wait for warmer weather since I have to do the carpentry work on my patio and it's still freezing winter here. But even in small temporary 100 liter sealed boxes they sound fantastic, albeit helped a little with a Behringer active sub. I'll make the bigger 400 liter boxes sealed as well. I prefer that to ported ones. I like that tight, precise bass better than the ´loose´ bass from ported boxed. Just a matter of taste, I guess. Anyway, I hope I can ditch the subwoofer when finishing the larger boxes.

I have regularly been comparing the Beymas to some well reputed vintage, newly reconed 15" Tannoy coax units that a friend of mine owns. Those Tannoys got me hooked on big coax speakers. But compared to the Beymas they lose big time on all parameters. With the Tannoys, you hear the speakers playing musik. And they do play really great. But you still hear the speakers. With the Beymas, you only hear the music. No colorations or limitations. They are no less than flawless IMO. The only 'unnatural' thing about them is the fact that they can, in fact, play acoustic piano music louder than an actual piano. They can even play a snare drum louder than the real thing, with no audible loss of dynamic whack. **** High Fidelity - this is Real ******* Dynamic Fidelity!

Beyma 15XA38ND - Audio Voice Acoustics

As I said, the Beymas keeps sounding like a dream to my taste.They are, by far, simply the best home speaker systems I have heard. Ever. Regardless of price, size or type .I have not yet finished the big boxes I have planned for them. That have to wait for warmer weather since I have to do the carpentry work on my patio and it's still freezing winter here. But even in small temporary 100 liter sealed boxes they sound fantastic, albeit helped a little with a Behringer active sub. I'll make the bigger 400 liter boxes sealed as well. I prefer that to ported ones. I like that tight, precise bass better than the ´loose´ bass from ported boxed. Just a matter of taste, I guess. Anyway, I hope I can ditch the subwoofer when finishing the larger boxes.

I have regularly been comparing the Beymas to some well reputed vintage, newly reconed 15" Tannoy coax units that a friend of mine owns. Those Tannoys got me hooked on big coax speakers. But compared to the Beymas they lose big time on all parameters. With the Tannoys, you hear the speakers playing musik. And they do play really great. But you still hear the speakers. With the Beymas, you only hear the music. No colorations or limitations. They are no less than flawless IMO. The only 'unnatural' thing about them is the fact that they can, in fact, play acoustic piano music louder than an actual piano. They can even play a snare drum louder than the real thing, with no audible loss of dynamic whack. **** High Fidelity - this is Real ******* Dynamic Fidelity!

Lynn,

I thought that co-ax systems were ruled-out completely very early-on in this thread for various reasons - impossible to refine to the level you desired due to the known compromises of the woofer being the horn IIRC. Some excellent drivers were considered at the time but ruled-out.

What has changed? Is it because the application is not 2-channel music-only?

Thnx,

-- Mark

The 12" or 15" coaxial driver is only for the Center speaker, which in turn will only be used for home theater. No fancy triode amplifier, or Burr-Brown PCM1704 converter, as the signal source ... just whatever mundane opamps and converters that are inside the Marantz AV8003/MM8003 combo.

That said, I don't want it to be trash ... been down that road already, no need to go there again. The existing Dynaudio CSX is a pretty decent center speaker, but the side-by-side MTM driver layout impairs dialog clarity.

Thus, coax, which sounds pretty much the same wherever you sit, and has way more dynamic range than 4" to 6" fullrange drivers. Not a fan of whizzer cones, no matter whether it is Zu (Eminence), Lowther, AER, or Feastrex.

The gotcha with coax is getting reasonably smooth response from the bass driver ... if the response isn't smooth, not interested. Also not interested in vintage or unobtanium drivers. There are great unobtanium drivers out there, particularly some of the old-school fullrangers or coaxes, but I don't want to design a modern crossover for a rare driver that commands a high price on the used market.

I am just barely well-known enough in audio circles that a modern, LTO-designed crossover would have a material impact on the collector market, driving up prices and increasing scarcity. I was told by Madisound that the demand for the Vifa 5.5" midbass used in the Ariel actually kept the driver in production for a number of years. Don't know if that's true or not, although it's kind of flattering, but then again, I've never received a dime's worth of royalties from the Ariel project, so I have no way of verifying the story.

This is the real reason I avoid vintage drivers, unless I can sweet-talk a manufacturer into making new versions. Back when I was writing for Ed Dell's Glass Audio magazine, I was able to persuade JJ into manufacturing a new version of the 7119, which became the JJ ECC99, and has become a fairly successful seller for JJ Electronics. Likewise for the AH425 Azurahorn and Acoustic Elegance LO15 driver.

Last edited:

The Beyma coaxes seem to be very good as well.

Neo magnets which should catch Lynn's attention!

Just received a detailed and helpful letter from one of the coax-experienced posters here: the essence is to keep it small, like 10 inches, for best intelligibility over a broad area, along with a favorable comment about the Tannoy DC12i, designed for in-wall soffit mounting. The box of the DC12i is big enough that it's obviously intended for high-end projection setups, not plasma screens.

Will look again at the smaller Radian 5210, with a crossover in the 1.5 to 2 kHz region, priced at $279 at US Speakers. Intelligibility combined with peak-free response (which immediately disqualifies whizzer-cone drivers) are the design goals; musicality would be a nice plus, but I think smooth response, a good crossover, and a low-diffraction box (large-radius corners) should take care of that.

Will look again at the smaller Radian 5210, with a crossover in the 1.5 to 2 kHz region, priced at $279 at US Speakers. Intelligibility combined with peak-free response (which immediately disqualifies whizzer-cone drivers) are the design goals; musicality would be a nice plus, but I think smooth response, a good crossover, and a low-diffraction box (large-radius corners) should take care of that.

Last edited:

Just a little "picture" showing the size of such Coax drivers  - I cross mine at approx 1.3khz if my memory serves me right.. About 950hz is recommended. Tried and didn't like it..

- I cross mine at approx 1.3khz if my memory serves me right.. About 950hz is recommended. Tried and didn't like it..

Here is my 15" next to a SS revelator 18w8531

My old Oris Reference Ultra with AER md3 fullrange drivers and 15" Neodym BD woofer in the background..

The coaxes are better in every single way I must admit, but not so sensitive.

Here is my 15" next to a SS revelator 18w8531

My old Oris Reference Ultra with AER md3 fullrange drivers and 15" Neodym BD woofer in the background..

The coaxes are better in every single way I must admit, but not so sensitive.

Last edited:

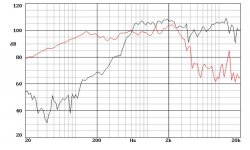

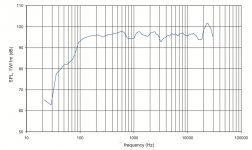

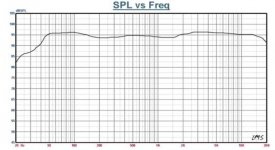

Here's the published frequency responses of the Beyma 15XA38Nd (left), along with the Tannoy DC12i (middle). Both are a lot rougher than I'm used to working with, which leaves me curious what the unsmoothed response of the Radian 5210 (right) looks like.

Attachments

Last edited:

I was looking at at coaxoals and noticed hoe many times the compression driver shows a pretty large rise in 3rd harmonic distortion in the higher frequencies. Is this due to the fact that the moving woofer cone is acting as its horn. The individual compression driver specs do not show this rise on standard horns.

Here is a Tannoy recommended to me. I believe they are tthe same but cannot promise it.

http://www.fullcompass.com/common/files/13992-cms1201dc_data_sheet.pdf

Here is a Tannoy recommended to me. I believe they are tthe same but cannot promise it.

http://www.fullcompass.com/common/files/13992-cms1201dc_data_sheet.pdf

The guys at No Frills Audio use modified Beyma coax drivers

Cavemanklanen | NO-FRILLS-AUDIO by P.C.B

They have replaced the HF membrane and added damping both on LF membrane and other components. They really like the Beyma drivers

Cavemanklanen | NO-FRILLS-AUDIO by P.C.B

They have replaced the HF membrane and added damping both on LF membrane and other components. They really like the Beyma drivers

. . . rise in 3rd harmonic distortion in the higher frequencies. Is this due to the fact that the moving woofer cone is acting as its horn.

I doubt that woofer motion is in play for published specs (it sure would be for music). Response is probably measured with a swept tone - woofer motion should be extremely small by the time the tweeter output appears in the measurements.

The possibly more audible problem is the unavoidable diffraction at at least 3 places:

where horn meets cone (even without woofer in motion), typically followed by a ring of glue and dustcap, and ending with the lousy woofer-as-waveguide edge termination.

Although always a good idea, nicely radiused cabinet edges might be like lipstick on a pig by this point.

I suppose the woofer-waveguide termination could be mitigated somewhat by covering the edge (including the surround) and front panel with dense foam.

-- Mark

Last edited:

I suppose the woofer-waveguide termination could be mitigated somewhat by covering the edge (including the surround) and front panel with dense foam.

-- Mark

- or by creating a flower petal-like edge to the throat to distribute the reflections over a band of frequencies rather than be specific to a single frequency. I believe something like this was at play in the design of the tops of the smoke stacks/funnels on the old Mississippi riverboats, presumably to smear the tuning.

The possibly more audible problem is the unavoidable diffraction at at least 3 places:

where horn meets cone (even without woofer in motion), typically followed by a ring of glue and dustcap, and ending with the lousy woofer-as-waveguide edge termination.

Just wondering :

has anyone made direct listening comparisons between the same horn, but one with smooth horn mouth edge, like LeCleac'h, avoiding diffraction, and one with edges, or abrupt ending of the horn mouth, causing diffraction ?

Lynn,

Sorry that my power supply for my router went dead and I'm still waiting on a new unit so I can get back on my own computer.

From what I understand but would have to confirm, Radian, Emilar and Rankus-Heinz were all the same few people in the beginning. Radian has always been owned by Richard Contramose from what I know but I don't think that he had much of anything to do with the basic design of any of the compression drivers. There was a time when I think you could almost interchange all the soft parts between the different brands. It has been a war of personalities between these three companies and I think that Radian has probably been the most successful of the three over time.

As to the 8" and 10" coaxial designs they have all used the cone as the waveguide. I have never seen a Radian with a separate horn like an Altec, that isn't something that they ever did to my knowledge. I think I still have a pair somewhere of the 8" that actually has a paper cone rather than the polypropylene cone material that they are again using exclusively. The paper sounded better but they only did this for a short time. Since my friend worked there at the time I could get custom products from them to my own specifications. I know at one time with the earlier small format compression drivers that there was resonant problem about 16Khz if I remember the frequency correctly and this was a mechanical design flaw and not anything inherent in the design, but they never got a real handle on the problem. Some of the newer designs are supposed to be better in that the magnetic energy is better now. In the beginning they did not use the correct steel in the motor assembly, it was not low carbon steel, but it looked nice.

The problem with Radian is that the behind the scenes personnel keeps changing and even when they get someone in that knows what they are doing they are overridden by the owner and what could be great doesn't happen. My friend says that one of the compression drivers he likes now is actually still using a ceramic magnet and not the newer Neo magnet assembly. I would have to ask him the model numbers of what he likes today. If you really want to ask questions I will ask him if I can give you his contact information.

Steven

Sorry that my power supply for my router went dead and I'm still waiting on a new unit so I can get back on my own computer.

From what I understand but would have to confirm, Radian, Emilar and Rankus-Heinz were all the same few people in the beginning. Radian has always been owned by Richard Contramose from what I know but I don't think that he had much of anything to do with the basic design of any of the compression drivers. There was a time when I think you could almost interchange all the soft parts between the different brands. It has been a war of personalities between these three companies and I think that Radian has probably been the most successful of the three over time.

As to the 8" and 10" coaxial designs they have all used the cone as the waveguide. I have never seen a Radian with a separate horn like an Altec, that isn't something that they ever did to my knowledge. I think I still have a pair somewhere of the 8" that actually has a paper cone rather than the polypropylene cone material that they are again using exclusively. The paper sounded better but they only did this for a short time. Since my friend worked there at the time I could get custom products from them to my own specifications. I know at one time with the earlier small format compression drivers that there was resonant problem about 16Khz if I remember the frequency correctly and this was a mechanical design flaw and not anything inherent in the design, but they never got a real handle on the problem. Some of the newer designs are supposed to be better in that the magnetic energy is better now. In the beginning they did not use the correct steel in the motor assembly, it was not low carbon steel, but it looked nice.

The problem with Radian is that the behind the scenes personnel keeps changing and even when they get someone in that knows what they are doing they are overridden by the owner and what could be great doesn't happen. My friend says that one of the compression drivers he likes now is actually still using a ceramic magnet and not the newer Neo magnet assembly. I would have to ask him the model numbers of what he likes today. If you really want to ask questions I will ask him if I can give you his contact information.

Steven

Thanks for the info, Kindhornman!!!

Radian must be doing something right with the 745Neo; it's the best I've heard a compression driver sound, along with the best measurements. It's not that common in loudspeaker design for the sonics and measurements to match up. From 700 Hz to 10 kHz, frequency response is flat to +/-1 dB with no smoothing or crossover equalization. Things get goofy above 10 kHz, but that's to be expected from a large-format driver. Despite rough appearance above 10 kHz, it does not sound dull, coarse, or edgy at the high end, and below that, it sounds as smooth and resolved as an electrostat. Radian has a winner here.

Here are some questions for your friend: I've signed up as a beta-test customer for the Radian 745Neo with beryllium diaphragm. Does your friend think the 745Neo with Be diaphragm is going to be out this year, or should I just go ahead and order the standard 745Neo with aluminum diaphragm?

I'm also curious if Beryllium is going to be available for either the 10" 5210 or the 12" 5312Neo coaxial drivers. I'm guessing the 5312 and 5215 diaphragms are the same 3" size used by the 636, 745, and 835 compression drivers, so if it's available for these drivers, it should be available (by special order) for the 5312 and 5215 coaxial drivers as well.

Here's a couple of papers from Materion: comparing tuning forks, which they brought to the 2012 RMAF so you could hear for yourself what titanium, aluminum, and beryllium sound like, and a comparison of aluminum and beryllium diaphragms in the Radian 950Pb compression driver.

The most important takeaway from the two papers isn't the improvement at high frequencies, which we all expect, but the significant improvement in self-damping, as seen in the decay characteristics in both the tuning forks and the diaphragms. This is a big deal.

Adding damping goo to a diaphragm decreases efficiency and tends to dull the sound, but better self-damping from the material itself is another thing altogether. Note also that titanium has the worst self-damping of all three metals ... and this is what's used in the majority of PA and movie theater speakers today.

Radian must be doing something right with the 745Neo; it's the best I've heard a compression driver sound, along with the best measurements. It's not that common in loudspeaker design for the sonics and measurements to match up. From 700 Hz to 10 kHz, frequency response is flat to +/-1 dB with no smoothing or crossover equalization. Things get goofy above 10 kHz, but that's to be expected from a large-format driver. Despite rough appearance above 10 kHz, it does not sound dull, coarse, or edgy at the high end, and below that, it sounds as smooth and resolved as an electrostat. Radian has a winner here.

Here are some questions for your friend: I've signed up as a beta-test customer for the Radian 745Neo with beryllium diaphragm. Does your friend think the 745Neo with Be diaphragm is going to be out this year, or should I just go ahead and order the standard 745Neo with aluminum diaphragm?

I'm also curious if Beryllium is going to be available for either the 10" 5210 or the 12" 5312Neo coaxial drivers. I'm guessing the 5312 and 5215 diaphragms are the same 3" size used by the 636, 745, and 835 compression drivers, so if it's available for these drivers, it should be available (by special order) for the 5312 and 5215 coaxial drivers as well.

Here's a couple of papers from Materion: comparing tuning forks, which they brought to the 2012 RMAF so you could hear for yourself what titanium, aluminum, and beryllium sound like, and a comparison of aluminum and beryllium diaphragms in the Radian 950Pb compression driver.

The most important takeaway from the two papers isn't the improvement at high frequencies, which we all expect, but the significant improvement in self-damping, as seen in the decay characteristics in both the tuning forks and the diaphragms. This is a big deal.

Adding damping goo to a diaphragm decreases efficiency and tends to dull the sound, but better self-damping from the material itself is another thing altogether. Note also that titanium has the worst self-damping of all three metals ... and this is what's used in the majority of PA and movie theater speakers today.

Last edited:

Lynn,

I will have to ask my friend about the beryllium for those Radians but in the old coaxial designs it was the same diaphragms as in the separate compression drivers so I would think they would be interchangeable. I could also ask the person that I am dealing with at Materion as I am waiting for my own domes from them right now. They would know when this is going to happen but may not want to divulge that information. That will be one expensive replacement diaphragm I'm sure. I wonder if it will still be a Mylar surround in that configuration? I would think they will need new tooling for the bonding fixtures as the new diaphragm will be much thinner than the aluminum they will be replacing. I know that Earl Geddes says there is no real difference between the materials but I don't agree with that. The mass reduction alone should increase the upper frequency response and move the resonant frequency from where it is. Only time will tell. I'll talk to my friend and see what he has to say.

ps. I am in complete agreement on the titanium material. Some of the worst dome tweeters I have ever tested have used this material and they were some expensive well known dome tweeters. The resonant breakup modes are right in the pass band and they just self resonate like no tomorrow and don't want to stop. I won't mention the name of the company I tested as they are well thought of by to many people here. I always wondered why titanium gave me ear fatigue until I saw what these things were doing. The high frequency output was all noise and not related to the musical waveform. I would expect the same situation in a compression driver. Aluminum is actually preferable to the titanium.

I will have to ask my friend about the beryllium for those Radians but in the old coaxial designs it was the same diaphragms as in the separate compression drivers so I would think they would be interchangeable. I could also ask the person that I am dealing with at Materion as I am waiting for my own domes from them right now. They would know when this is going to happen but may not want to divulge that information. That will be one expensive replacement diaphragm I'm sure. I wonder if it will still be a Mylar surround in that configuration? I would think they will need new tooling for the bonding fixtures as the new diaphragm will be much thinner than the aluminum they will be replacing. I know that Earl Geddes says there is no real difference between the materials but I don't agree with that. The mass reduction alone should increase the upper frequency response and move the resonant frequency from where it is. Only time will tell. I'll talk to my friend and see what he has to say.

ps. I am in complete agreement on the titanium material. Some of the worst dome tweeters I have ever tested have used this material and they were some expensive well known dome tweeters. The resonant breakup modes are right in the pass band and they just self resonate like no tomorrow and don't want to stop. I won't mention the name of the company I tested as they are well thought of by to many people here. I always wondered why titanium gave me ear fatigue until I saw what these things were doing. The high frequency output was all noise and not related to the musical waveform. I would expect the same situation in a compression driver. Aluminum is actually preferable to the titanium.

Last edited:

Well, I heard the difference between the tuning forks at the 2012 RMAF and it was really obvious. The beryllium tuning fork (which is a slightly different color than aluminum) had a sharp initial ping but quieted down surprisingly quickly. It didn't sound dull like I thought it might, it just quieted down quickly. Aluminum sounded just like other tuning forks. Titanium sounded pretty ugly, with harsh overtones. Pretty much the same difference you hear between different diaphragms, really, but it was a useful ear-training aid just to remind you that yes, materials are audible.

This doesn't surprise me. Human evolution has made us really, really good at acoustically detecting what materials are made of, and musicians have taking advantage of this for millenia. Better to work with this, and select materials that sound good right from the outset, rather than attempt tricks with equalization to conceal the inherent sound of the material.

Put another way, first impressions count. If the first thing you think when you hear something is "harsh", well, that's what tends to stay with you. I use massed choral to get a quick first impression of a driver, and notice the interior emotional state that the music creates. Is it beautiful? Annoying? Tense? Confused? Is there a "look-at-me" quality to it? This quick impression has a lot to do with diaphragm materials, reflections in the horn, and in the lower registers, box and vent modes.

This doesn't surprise me. Human evolution has made us really, really good at acoustically detecting what materials are made of, and musicians have taking advantage of this for millenia. Better to work with this, and select materials that sound good right from the outset, rather than attempt tricks with equalization to conceal the inherent sound of the material.

Put another way, first impressions count. If the first thing you think when you hear something is "harsh", well, that's what tends to stay with you. I use massed choral to get a quick first impression of a driver, and notice the interior emotional state that the music creates. Is it beautiful? Annoying? Tense? Confused? Is there a "look-at-me" quality to it? This quick impression has a lot to do with diaphragm materials, reflections in the horn, and in the lower registers, box and vent modes.

Last edited:

Lynn,

My big concern with using the large format compression driver on the coax is the beaming at rather low frequency due to the throat configuration and the large exit size before you get to the flare of the cone. That is one of the main reasons that I never liked using the large format compression drivers, you just can't get a very wide dispersion with those large diameter throats and the long conic section from the end of the phase plug and the end of the driver exit. I just haven't seen much success in that regards from my years around pro audio gear. I have settled on midrange cone driven horns for that very reason. Most large format compression drivers in the past from JBL just didn't cut it on the bottom end and the beaming above about 6Khz was something you couldn't do anything about really. I am not one for conic horns and though I agree with many things that Earl says about waveguides I also disagree with some of the ideas that he has. If I was a bit farther along I would send a pair of cone drivers for you to test to see what you think. Perhaps in the not to distant future I will do that.

Steven

My big concern with using the large format compression driver on the coax is the beaming at rather low frequency due to the throat configuration and the large exit size before you get to the flare of the cone. That is one of the main reasons that I never liked using the large format compression drivers, you just can't get a very wide dispersion with those large diameter throats and the long conic section from the end of the phase plug and the end of the driver exit. I just haven't seen much success in that regards from my years around pro audio gear. I have settled on midrange cone driven horns for that very reason. Most large format compression drivers in the past from JBL just didn't cut it on the bottom end and the beaming above about 6Khz was something you couldn't do anything about really. I am not one for conic horns and though I agree with many things that Earl says about waveguides I also disagree with some of the ideas that he has. If I was a bit farther along I would send a pair of cone drivers for you to test to see what you think. Perhaps in the not to distant future I will do that.

Steven

That's where the combination of LeCleac'h and large-format compression driver is rather special. Instead of the annoying braying sound of a big PA system, it actually sounds rather intimate and delicate.

The sound seems to come from inside the room instead of the loudspeaker; I've never heard this from conicals, controlled-directivity horns, tractrix, or conventional exponential horns. A few ... very few direct-radiator speakers with extremely low diffraction can do this, along with a handful of exotics. The AH425 does it effortlessly, with every disc I play, so I have to give credit to Bjorn Kolbrek for really getting diffraction and internal reflection down to an absolute minimum. To realize the full performance of the horn, though, exit angles of the compression driver and the entrance angle of the horn have to match.

Other listeners to LeCleac'h horns, including JMMLC himself, know what I'm talking about. The very low diffraction of the LeCleac'h, particularly if it is optimized for best-possible impulse response, sounds different than other horns, particularly the spatial impression, where the instruments seem to be located in the room, and the overall impression is of delicacy instead of crudeness. PA systems, from what I can tell, are optimized for a given SPL for each seat in a large auditorium or outdoors, and not much else. The sound is crude and harsh ... look in the time domain, and it isn't pretty.

The AH425 is pretty much the opposite end of the pole. The directivity pattern has soft edges, impulse response is as good as direct-radiators, and there's no requirement for in-band equalization. The loading on the compression driver is very close to a plane-wave tube, and it measures similarly.

The subjective aspect is what surprised me with the first round of prototypes for the LTO. I knew the measurements would be there, but what would that mean subjectively?

Well, a surprisingly delicate in-the-room presentation, with a sense of unlimited headroom if a transient came along. None of the stress-and-strain of a small-format driver being asked to go too low, and none of the floodlight-in-the-face sensation of some other high-efficiency speakers. The image floats in the room, free of the loudspeakers, and the overall spatial impression is much larger than the listening room (going back 20 to 50 feet, depending on the recording). This is very different than most commercial high-efficiency loudspeakers I've heard, where the sound is pinned to the loudspeaker, and kind of grows and shrinks, depending on volume.

Although the AH425 certainly favors the sweet spot, it does it in the same way as a direct-radiator speaker ... that's just where you hear the most resolution and most thrilling sound. Off-axis just sounds a little less exciting, with a bit less snap and pop to the sound. It does not sound like other horns; the closest parallel would be the large multicells, which have a more diffuse sound.

The sound seems to come from inside the room instead of the loudspeaker; I've never heard this from conicals, controlled-directivity horns, tractrix, or conventional exponential horns. A few ... very few direct-radiator speakers with extremely low diffraction can do this, along with a handful of exotics. The AH425 does it effortlessly, with every disc I play, so I have to give credit to Bjorn Kolbrek for really getting diffraction and internal reflection down to an absolute minimum. To realize the full performance of the horn, though, exit angles of the compression driver and the entrance angle of the horn have to match.

Other listeners to LeCleac'h horns, including JMMLC himself, know what I'm talking about. The very low diffraction of the LeCleac'h, particularly if it is optimized for best-possible impulse response, sounds different than other horns, particularly the spatial impression, where the instruments seem to be located in the room, and the overall impression is of delicacy instead of crudeness. PA systems, from what I can tell, are optimized for a given SPL for each seat in a large auditorium or outdoors, and not much else. The sound is crude and harsh ... look in the time domain, and it isn't pretty.

The AH425 is pretty much the opposite end of the pole. The directivity pattern has soft edges, impulse response is as good as direct-radiators, and there's no requirement for in-band equalization. The loading on the compression driver is very close to a plane-wave tube, and it measures similarly.

The subjective aspect is what surprised me with the first round of prototypes for the LTO. I knew the measurements would be there, but what would that mean subjectively?

Well, a surprisingly delicate in-the-room presentation, with a sense of unlimited headroom if a transient came along. None of the stress-and-strain of a small-format driver being asked to go too low, and none of the floodlight-in-the-face sensation of some other high-efficiency speakers. The image floats in the room, free of the loudspeakers, and the overall spatial impression is much larger than the listening room (going back 20 to 50 feet, depending on the recording). This is very different than most commercial high-efficiency loudspeakers I've heard, where the sound is pinned to the loudspeaker, and kind of grows and shrinks, depending on volume.

Although the AH425 certainly favors the sweet spot, it does it in the same way as a direct-radiator speaker ... that's just where you hear the most resolution and most thrilling sound. Off-axis just sounds a little less exciting, with a bit less snap and pop to the sound. It does not sound like other horns; the closest parallel would be the large multicells, which have a more diffuse sound.

Last edited:

I know that Earl Geddes says there is no real difference between the materials but I don't agree with that.

I don't think that I ever said that, at any rate, reading here, I would not agree. Of course there are differences in materials, you can measure them. The question is that if the drivers are EQ'd properly are these differences audibly significant? That I have some doubts about. On the margins one might be able to detect the differences, but I would not attribute a huge difference in perception to the diaphragm material alone (again once EQ'd to be comparable, not just swap diaphragms and listen, that will always be detectable.)

From the measurements we can see that the differences are in the very upper registers which are not a huge influence on the overall impression.

Your comment that the HF's are all "noise" was very curious as I have never seen this in anything that I have measured. It is hard to envision any mechanism that would cause such an effect.

Earl,

This is one of the areas that we seem to disagree. The problem with the titanium domes that I have looked into is that the dome itself with the material is in a resonant state. It does not need a signal to be excited, it is a purely mechanical resonance and you can never eq this phenomena out of the device. No amount of electrical damping or eq can remove a mechanical resonance from a device, you can't do that.

I don't want to look for your exact quote but I do remember you saying that most if not all compression drivers are now commodity devices and they can be interchanged at will with just a little eq at most to make them all the same. I don't believe this and I would say that many people would say from personal experience that this just isn't so. There are mechanical as well as acoustical reasons that they do not all sound the same. It could be something as simple as the suspension material in the diaphragm that will change the character of the device. the difference between a metal surround and Mylar can be heard. The damping qualities of the different materials can be very different in the time domain.

I don't have any real experience with the LeCleac'h horns but they sure do look interesting. This is something I contemplated many years ago but never went down that road. I would think that some of the newer compression drivers with very short throat sections could help solve some of the on axis problems that have plagued waveguides for years. It appears that some of these devices end almost at the very tip of the phase plug.

This is one of the areas that we seem to disagree. The problem with the titanium domes that I have looked into is that the dome itself with the material is in a resonant state. It does not need a signal to be excited, it is a purely mechanical resonance and you can never eq this phenomena out of the device. No amount of electrical damping or eq can remove a mechanical resonance from a device, you can't do that.

I don't want to look for your exact quote but I do remember you saying that most if not all compression drivers are now commodity devices and they can be interchanged at will with just a little eq at most to make them all the same. I don't believe this and I would say that many people would say from personal experience that this just isn't so. There are mechanical as well as acoustical reasons that they do not all sound the same. It could be something as simple as the suspension material in the diaphragm that will change the character of the device. the difference between a metal surround and Mylar can be heard. The damping qualities of the different materials can be very different in the time domain.

I don't have any real experience with the LeCleac'h horns but they sure do look interesting. This is something I contemplated many years ago but never went down that road. I would think that some of the newer compression drivers with very short throat sections could help solve some of the on axis problems that have plagued waveguides for years. It appears that some of these devices end almost at the very tip of the phase plug.

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel