Graham Maynard said:That 21" Beyma is more for enclosure mounting with its suspension stiffness.

Two 15" could give same area with twice sensitivity, though with a dedicated amp must be impressive.

Cheers ........ Graham.

It does a heck of a job - This 21" has a serious Xmax and a fairly high QTS and decent sensitivity at 40 cycles mounted on a board without EQ - It may seem strange but I used a 21 to make the system more compact over other systems that would require many more woofers to move this much air this low. It goes easily an octave lower than the five tens in less space, two 15's would have had to be folded (I don't like) to be this compact. This has no wings or folds- less coloration IMO

I will build your T circuit if I dig up a big enough transformer Thanks!

Re: Re: Re: Re: Good Articles

Don't think so - the material of the former isn't responsible for LOW / HIGH Qms – at least if proper implemented by the speaker manufacturer.

Its suspension and surround losses that mainly cause low Qms / high rms.

The Vifa 10BG with aluminium former versus the Vifa XT18WO09-08 with Kapton former are a good example:

the VIVA XT18WO09-08 with Kapton former:

http://www.tymphany.com/files/products/pdf/XT18WO09-08.pdf

Qms = 5,87

Rms = 0,49 kg/s

VIFA 10BG120 with aluminium former:

Qms = 4,6

Rms = 0.36 kg/s (which is even LOWER )

http://www.lautsprechershop.de/pdf/vifa/lautsprecher/10bg120.pdf

Obviously eddy currents in an aluminium former can be handled down to negligible amounts.

Greetings

nickmckinney said:

In non ferrofluid drivers the low Qms is coming from an aluminum voice coil former of which I never heard or measured a difference. Very little of the suspension comes into play for the Qms (actually the correct spec for this effect is the Rms)

Don't think so - the material of the former isn't responsible for LOW / HIGH Qms – at least if proper implemented by the speaker manufacturer.

Its suspension and surround losses that mainly cause low Qms / high rms.

The Vifa 10BG with aluminium former versus the Vifa XT18WO09-08 with Kapton former are a good example:

the VIVA XT18WO09-08 with Kapton former:

http://www.tymphany.com/files/products/pdf/XT18WO09-08.pdf

Qms = 5,87

Rms = 0,49 kg/s

VIFA 10BG120 with aluminium former:

Qms = 4,6

Rms = 0.36 kg/s (which is even LOWER )

http://www.lautsprechershop.de/pdf/vifa/lautsprecher/10bg120.pdf

Obviously eddy currents in an aluminium former can be handled down to negligible amounts.

Greetings

mige0 said:

Its suspension and surround losses that mainly cause low Qms / high rms.

And of course the losses due to pressure air flow through the tight voice coil gap caused by the membrane-dust-cap-air-pump.

? How could I forget ?

These mechanical losses should increase with bigger voice coils as the "piston" area = dust cap area increases and thus the air volume pushed through the gap.

This model assumes ventilation holes behind the VC or an open suspension and does not apply in exactly the same way to ancient designs where the spider usually is completely sealed as is the magnet not vented and almost no air circulation happens .

All in all it depends on how the manufacturer balances between mechanical losses and extended and program dependant membrane-dust-cap-air-pump-VC-cooling

mige0 said:

The benefits of doing AC rather than DC is that you can use a simple soundcard with its very good resolution by simply replacing the mic by the shunt – symmetric inputs assumed.

We would like to inject a well defined power for a well defined time– so you will have to calculate the output voltage by measuring the speakers impedance - at ambient temperature - at 10kHz / 100Hz first.

No cabinet, no baffle, speaker positioned vertical in a room.

Doors and windows closed

Any – its not just to do a fun competition (burning down VC's would serve that better) – its for having data available to compare.

I would hold against a two decade old 12" Dynaudio 30W54 having an outer magnet and 54mm VC and a Dynaudio 17W75 having an inner magnet and a 75mm VC.

Both speakers are well documented and represent the top engineering at their time.

Lets see how much progress was made in the meantime.

nickmckinney - still interested in the thermal response competition I suggested ??

To make it a little bit more juicy for you I bet a bottle of Champaign that whatever you measure from your current designs against one of the two Dymaudios I mentioned

- DONT be better / lower twice = in terms of 1kWs resistance difference

- DONT be better / quicker twice = in terms of temperature decay

Greetings

Michael

Re: Re: Re: Re: Re: Good Articles

Sorry, but when you try arguing with a guy who has building drivers for many years, you are going to lose most of the time.

When a voice coil former is made from metal (a conductor), it will act as a shorted turn (unless there is a deliberate gap made in the former). This shorted turn provides mechanical damping to motion of the cone and will thereby affect the Qms.

When the voice coil former is not acting like a shorted turn, then you are correct that suspension and surround losses are the dominant factor.

mige0 said:Don't think so - the material of the former isn't responsible for LOW / HIGH Qms – at least if proper implemented by the speaker manufacturer.

Its suspension and surround losses that mainly cause low Qms / high rms.

Sorry, but when you try arguing with a guy who has building drivers for many years, you are going to lose most of the time.

When a voice coil former is made from metal (a conductor), it will act as a shorted turn (unless there is a deliberate gap made in the former). This shorted turn provides mechanical damping to motion of the cone and will thereby affect the Qms.

When the voice coil former is not acting like a shorted turn, then you are correct that suspension and surround losses are the dominant factor.

Re: Re: Re: Re: Re: Re: Good Articles

BS - You don't think I tested Kapton only vs Kapton/Aluminum formers for my drivers? When we first started selling them we offered them both ways, low Qms and high Qms. Only difference was the former material that was in the gap.

I like mine slightly chilled, I own a set of those drivers, my first DIY design. I still use them in my office.

BTW - Like I said before again and again - someone else has to do the tests. Lynn and a few others are getting drivers shortly, they can comment on what they find.

Finally someone that has a grasp of what really happens inside the driver.

Only issue the former always has a gap so its not a shorted turn, in this case it would be called an "eddy brake" or similiar. This same concept is used in other damping designs outside of speakers. If you can find an old set of Rockford Fosgate with the compression rings, you can see what a solid turn will do (its like hitting a brick wall)

BTW - I started in the speaker world rebuilding drivers, about 20-40 a day with other people on a team. I rebuilt probably about 2000-4000 of other people's drivers before I designed my own. I have seen about everything (and copied the best ideas for my own)

mige0 said:Don't think so - the material of the former isn't responsible for LOW / HIGH Qms – at least if proper implemented by the speaker manufacturer.

Its suspension and surround losses that mainly cause low Qms / high rms.

BS - You don't think I tested Kapton only vs Kapton/Aluminum formers for my drivers? When we first started selling them we offered them both ways, low Qms and high Qms. Only difference was the former material that was in the gap.

mige0 said:nickmckinney - still interested in the thermal response competition I suggested ??

To make it a little bit more juicy for you I bet a bottle of Champaign that whatever you measure from your current designs against one of the two Dymaudios I mentioned

- DONT be better / lower twice = in terms of 1kWs resistance difference

- DONT be better / quicker twice = in terms of temperature decay

I like mine slightly chilled, I own a set of those drivers, my first DIY design. I still use them in my office.

BTW - Like I said before again and again - someone else has to do the tests. Lynn and a few others are getting drivers shortly, they can comment on what they find.

Charles Hansen said:Sorry, but when you try arguing with a guy who has building drivers for many years, you are going to lose most of the time.

When a voice coil former is made from metal (a conductor), it will act as a shorted turn (unless there is a deliberate gap made in the former). This shorted turn provides mechanical damping to motion of the cone and will thereby affect the Qms.

When the voice coil former is not acting like a shorted turn, then you are correct that suspension and surround losses are the dominant factor.

Finally someone that has a grasp of what really happens inside the driver.

Only issue the former always has a gap so its not a shorted turn, in this case it would be called an "eddy brake" or similiar. This same concept is used in other damping designs outside of speakers. If you can find an old set of Rockford Fosgate with the compression rings, you can see what a solid turn will do (its like hitting a brick wall)

BTW - I started in the speaker world rebuilding drivers, about 20-40 a day with other people on a team. I rebuilt probably about 2000-4000 of other people's drivers before I designed my own. I have seen about everything (and copied the best ideas for my own)

Charles Hansen said:

Sorry, but when you try arguing with a guy who has building drivers for many years, you are going to lose most of the time.

When a voice coil former is made from metal (a conductor), it will act as a shorted turn (unless there is a deliberate gap made in the former). This shorted turn provides mechanical damping to motion of the cone and will thereby affect the Qms.

When the voice coil former is not acting like a shorted turn, then you are correct that suspension and surround losses are the dominant factor.

Concerning gaps in metal formers to prevent from eddy currents:

Yeah, - I know– you know - Vifa knows

- but – are you sure nickmckinney knew?

Well - most certainly he did – I guess (hope) - now for sure.

Greetings

Michael

Bs - Btw

BS again? – ts, ts ..

BTW ...

You miss a really good chance – and a bottle Champaign.

The chance to provide hard data as the MANUFACTURER about what you claim to be the superiority of your design.

Anyway, either you don't know how to take measurements (embarrassing, embarrassing ) OR you are afraid to proof your own words.

) OR you are afraid to proof your own words.

Regarding third party measurement - I guess we both don't have any problem with delivering trustworthy data (plus / minus some tolerance) as anybody here can do a proof and display different findings.

Beside our little combating it may be a real challenge to lower thermal transient response significantly for ANY manufacturer and to put things into (measured) perspective should be worth the effort.

Not seen that much data about yet.

To some degree I guess that what Lynn has in mind about the effortless dynamic presentation from PA speakers may be based on exactly that – different thermal response due to the generally bigger VC's compared to home speakers.

Greetings

Michael

nickmckinney said:

BTW - Like I said before again and again - someone else has to do the tests. Lynn and a few others are getting driver

BS again? – ts, ts ..

BTW ...

You miss a really good chance – and a bottle Champaign.

The chance to provide hard data as the MANUFACTURER about what you claim to be the superiority of your design.

Anyway, either you don't know how to take measurements (embarrassing, embarrassing

Regarding third party measurement - I guess we both don't have any problem with delivering trustworthy data (plus / minus some tolerance) as anybody here can do a proof and display different findings.

Beside our little combating it may be a real challenge to lower thermal transient response significantly for ANY manufacturer and to put things into (measured) perspective should be worth the effort.

Not seen that much data about yet.

To some degree I guess that what Lynn has in mind about the effortless dynamic presentation from PA speakers may be based on exactly that – different thermal response due to the generally bigger VC's compared to home speakers.

Greetings

Michael

Re: Bs - Btw

The problem with us providing any data is that we can't directly compare it to anything, or more realistically people in general cant' compare it to anything. Finding any other companies who have adequate data on power compression is difficult to begin with. Finding one that will give their specifications on how they come up with the numbers so someone can duplicate the measurements is impossible. We can publish our own data and state how the results are measured, but without other manufacturers measuring in the same way for comparison sake the data alone doesn't do much good. It's like saying vehicle A is 300hp and vehicle B is 600HP, which is faster? Without knowing vehicle A is a corvette and vehicle B is a dump truck you can't make a valid comparison.

We can do in house measurements of our drivers vs other manufacturers, but we can't very well publish the results of their info for comparison. Then figure in the fact that the industry is so full of marketing lies and garbage, that people can skew any tests to make the results look how they want. No matter how reliable our tests are, people won't believe them anyway. This is why an impartial 3rd party is the key to the whole thing. Not being associated with either company, the full comparison can be published and their is no "hidden agenda" so people can make reliable conclusions for the results.

John

mige0 said:

You miss a really good chance – and a bottle Champaign.

The chance to provide hard data as the MANUFACTURER about what you claim to be the superiority of your design.

Anyway, either you don't know how to take measurements (embarrassing, embarrassing) OR you are afraid to proof your own words.

Regarding third party measurement - I guess we both don't have any problem with delivering trustworthy data (plus / minus some tolerance) as anybody here can do a proof and display different findings.

The problem with us providing any data is that we can't directly compare it to anything, or more realistically people in general cant' compare it to anything. Finding any other companies who have adequate data on power compression is difficult to begin with. Finding one that will give their specifications on how they come up with the numbers so someone can duplicate the measurements is impossible. We can publish our own data and state how the results are measured, but without other manufacturers measuring in the same way for comparison sake the data alone doesn't do much good. It's like saying vehicle A is 300hp and vehicle B is 600HP, which is faster? Without knowing vehicle A is a corvette and vehicle B is a dump truck you can't make a valid comparison.

We can do in house measurements of our drivers vs other manufacturers, but we can't very well publish the results of their info for comparison. Then figure in the fact that the industry is so full of marketing lies and garbage, that people can skew any tests to make the results look how they want. No matter how reliable our tests are, people won't believe them anyway. This is why an impartial 3rd party is the key to the whole thing. Not being associated with either company, the full comparison can be published and their is no "hidden agenda" so people can make reliable conclusions for the results.

John

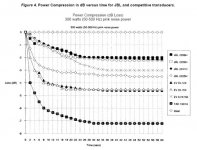

Why not do something like this. If JBL can publish this information about their competitors?? It's a simple test in principle, 300 watts of Pink Noise from 50-500 with SPL measured at time intervals. Total time 60 seconds, wouldn't want to be anywhere nearby when they were running that one

Rob

Rob

Attachments

Re: Re: Bs - Btw

John, good points, I agree with to some extent.

On the other hand :

- I proposed a measurement procedure that reveals way more than usual compression figures. The procedure is public and fully transparent to everyone. It displays results as plot that is easy and intuitively to understand / interpret

- I am pretty sure if your design is way superior as claimed, it does not take much discussion about how to interpret things - but I doubt – and have presented some quick calculations - that this is not likely to happen as long no better VC wire material is used

- measurement isn't beyond the skills and equipment of may here so I am confident that over time we will see data from a wide spectrum of competitors

- a neutral third party would always be good to have – but who is NEUTRAL = having NO "hidden agenda"? - Only the public proof here is kinda real proof – not something done by "specialists" with Ray Ban sunglasses you have to believe to

- Only the public proof here is kinda real proof – not something done by "specialists" with Ray Ban sunglasses you have to believe to

Its up to you to take the chance I offer or to put us off with some strong words and some limp hand waving only .

Greetings

Michael

John_E_Janowitz said:

The problem with us providing any data is that we can't directly compare it to anything, or more realistically people in general cant' compare it to anything. Finding any other companies who have adequate data on power compression is difficult to begin with. Finding one that will give their specifications on how they come up with the numbers so someone can duplicate the measurements is impossible. We can publish our own data and state how the results are measured, but without other manufacturers measuring in the same way for comparison sake the data alone doesn't do much good. It's like saying vehicle A is 300hp and vehicle B is 600HP, which is faster? Without knowing vehicle A is a corvette and vehicle B is a dump truck you can't make a valid comparison.

We can do in house measurements of our drivers vs other manufacturers, but we can't very well publish the results of their info for comparison. Then figure in the fact that the industry is so full of marketing lies and garbage, that people can skew any tests to make the results look how they want. No matter how reliable our tests are, people won't believe them anyway. This is why an impartial 3rd party is the key to the whole thing. Not being associated with either company, the full comparison can be published and their is no "hidden agenda" so people can make reliable conclusions for the results.

John

John, good points, I agree with to some extent.

On the other hand :

- I proposed a measurement procedure that reveals way more than usual compression figures. The procedure is public and fully transparent to everyone. It displays results as plot that is easy and intuitively to understand / interpret

- I am pretty sure if your design is way superior as claimed, it does not take much discussion about how to interpret things - but I doubt – and have presented some quick calculations - that this is not likely to happen as long no better VC wire material is used

- measurement isn't beyond the skills and equipment of may here so I am confident that over time we will see data from a wide spectrum of competitors

- a neutral third party would always be good to have – but who is NEUTRAL = having NO "hidden agenda"?

Its up to you to take the chance I offer or to put us off with some strong words and some limp hand waving only .

Greetings

Michael

Robh3606 said:Why not do something like this. If JBL can publish this information about their competitors?? It's a simple test in principle, 300 watts of Pink Noise from 50-500 with SPL measured at time intervals. Total time 60 seconds, wouldn't want to be anywhere nearby when they were running that one

Rob

Excelent starter – thanks, Rob.

What we don't see in the diagram is

- how fast do the speakers recover

- to what extend its cooling mechanism is program (= membrane excursion) dependant

300W for 60 sec is 18 times the energy injection I propose. It might be a good test if you want to compare reliability rather than sound quality – and having some fun burning down a competitors VC.

For many interesting speakers its way too much - limiting this procedure significantly in usability not to speak that you hardly can do that somewhere at home.

Greetings

Michael

Hi mige0,

You might want to have a read at what others thought of Lambda speaker driver before thinking that nickmckinney don't know anything.

http://www.htguide.com/forum/showpost.php4?p=398872&postcount=68

Sam

You might want to have a read at what others thought of Lambda speaker driver before thinking that nickmckinney don't know anything.

http://www.htguide.com/forum/showpost.php4?p=398872&postcount=68

Sam

Regarding power compression, I too think that it is an important aspect of a loudspeaker system, but I am not sure that the JBL test gets at all of the problems.

I also think that some "common" if not standard method is needed for comparison purposes.

I used pink noise and plotted the spectrum as a function of time which showed how the individual drivers and the crossover was compressing and how the frequency response changing. This test showed signifcant differences in systems since it shows far more than simply plotting the dB Loss over time. Power compression is at least as important for the HF device as it is for the LF one and the JBL test completely ignores this.

Personally, I'd steer clear of a stated power levels and worry about a stated SPL levels. Its the SPL that we care about not how much power the system can handle. Power ratings are mostly for pro apps where driver burn out is an issue. For us this is not the issue, but audible FR changes at useful (but high) SPL levels is.

I also think that some "common" if not standard method is needed for comparison purposes.

I used pink noise and plotted the spectrum as a function of time which showed how the individual drivers and the crossover was compressing and how the frequency response changing. This test showed signifcant differences in systems since it shows far more than simply plotting the dB Loss over time. Power compression is at least as important for the HF device as it is for the LF one and the JBL test completely ignores this.

Personally, I'd steer clear of a stated power levels and worry about a stated SPL levels. Its the SPL that we care about not how much power the system can handle. Power ratings are mostly for pro apps where driver burn out is an issue. For us this is not the issue, but audible FR changes at useful (but high) SPL levels is.

mige0 said:Concerning gaps in metal formers to prevent from eddy currents:

Yeah, - I know– you know - Vifa knows

- but – are you sure nickmckinney knew?

Michael, your arrogant tone matches your ignorance. I am surprised to find that Nick even bothers to take the time to answer your posts.

In case you missed it, he *corrected* my misinformation.

My post was only partially correct. Go back and re-read Nick's reply.

And keep doing that until you understand what Nick said.

Then, when you finally get it, I would recommend coming back here with your tail between your legs and offer an apology.

Re: Bs - Btw

Are you trying to be a troll or just act like an annoying fool that knows little about speaker driver design but talks like he is the expert on it?

I gave an offer for any third party to test my designs against any other and report the results. If you think this gets done overnight with reputable people that you all respect then you are sadly mistaken.

Lynn himself has stated that he will test the ceramic magnet TD drivers against Alnico Altecs in this very thread. Why don't you take a chill pill and wait for the results?

BTW - That is not the only comparison in the works, and when more results come back with closer to the tests that *you* are looking for I will be sending a PM with my address for delivery of that champagne.

mige0 said:Anyway, either you don't know how to take measurements (embarrassing, embarrassing) OR you are afraid to proof your own words.

Are you trying to be a troll or just act like an annoying fool that knows little about speaker driver design but talks like he is the expert on it?

I gave an offer for any third party to test my designs against any other and report the results. If you think this gets done overnight with reputable people that you all respect then you are sadly mistaken.

Lynn himself has stated that he will test the ceramic magnet TD drivers against Alnico Altecs in this very thread. Why don't you take a chill pill and wait for the results?

BTW - That is not the only comparison in the works, and when more results come back with closer to the tests that *you* are looking for I will be sending a PM with my address for delivery of that champagne.

SunRa said:This complex conic horn looks a bit like Dr's Geddes waveguides, isn't it? Magnetar, can't wait to see your new loudspeakers!

An externally hosted image should be here but it was not working when we last tested it.

It measures much better on axis based from what I have seen posted here from gedlleel. It also has better pattern control vertically (for my room) The profile is 90 by 60. I bought mine for 60.00 for the pair off ebay but have since found Renkus Heinz (the original Emilar people) sells them through their parts department. They have them for small and large format drivers in a variety of profiles. Mine are 1200 flare small format. The construction quality is superb.

For home hifi satisfaction I feel these are much better then the 'Azura' or round tractrix horns

Order Horns from parts

Measurement echnique for in Depth Investigation of Thermal Transient Response of Sp

"Measurement Technique for in Depth Investigation of Thermal Transient Response of Speakers" seems to be an explosive topic.

To allow for cooling down I will take a short vacation – seems I have injected more energy than some people in this thread can handle.

Earl, thanks for your statement at # 3984 – spot on – and exactly what I wanted to draw peoples attention to when I brought up that topic .

nickmckinney, no measurement competition between you and me – no champagne. - but you always can send me one in case you loose the third party testing.

Sam, don't get me wrong - in fact I find the AE-speakers very appealing.

Scroll down a few thousand postings and you will find my strong bias towards phase plug designs. There are strong PROS (less coughing / less program dependant thermal response...) especially for OB designs, but nevertheless some CONS (slower PC decay / faster heat up / higher equilibrium resitance) with that approach

Charles, study the datasheets I presented for proof or find some others.

Before arguing with me - argue with the manufactures that in fact WERE able to implement metal VC formers well.

"Then, when you finally get it, I would recommend coming back here..."

Lynn, apologise for having occupied your thread too much

Greetings

Michael.

"Measurement Technique for in Depth Investigation of Thermal Transient Response of Speakers" seems to be an explosive topic.

To allow for cooling down I will take a short vacation – seems I have injected more energy than some people in this thread can handle.

Earl, thanks for your statement at # 3984 – spot on – and exactly what I wanted to draw peoples attention to when I brought up that topic .

nickmckinney, no measurement competition between you and me – no champagne. - but you always can send me one in case you loose the third party testing.

Sam, don't get me wrong - in fact I find the AE-speakers very appealing.

Scroll down a few thousand postings and you will find my strong bias towards phase plug designs. There are strong PROS (less coughing / less program dependant thermal response...) especially for OB designs, but nevertheless some CONS (slower PC decay / faster heat up / higher equilibrium resitance) with that approach

Charles, study the datasheets I presented for proof or find some others.

Before arguing with me - argue with the manufactures that in fact WERE able to implement metal VC formers well.

"Then, when you finally get it, I would recommend coming back here..."

Lynn, apologise for having occupied your thread too much

Greetings

Michael.

Re: Measurement echnique for in Depth Investigation of Thermal Transient Response of

I happen to agree with you. It seems the singers of AE speakers have not really compared them to real drivers. I have never tried them and probably never will

mige0 said:"Measurement Technique for in Depth Investigation of Thermal Transient Response of Speakers" seems to be an explosive topic.

To allow for cooling down I will take a short vacation – seems I have injected more energy than some people in this thread can handle.

Greetings

Michael.

I happen to agree with you. It seems the singers of AE speakers have not really compared them to real drivers. I have never tried them and probably never will

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel