The recent threads related to driver mounting point out a question I've had for years. Many kit plans indicate a brace behind the driver which seems to provide some additional rigidity (see Dave's Planet10 site for numerous examples). I have never used such a mounting system for fear of warping the frame as Mark indicates.

Just how much tightly should these braces fit in order to provide the desired rigidity or "push-pull coupling" in the case of a bipole design? Recognizing that the driver WILL vibrate a bit, if there is insufficient pressure, the result may be a buzzing at higher levels / low frequency. If there is too much pressure, the frame will warp.

So what is the right answer (maybe in terms of mounting screw turns of fractions thereof)?

Thank you in advance for your kind patience.

Just how much tightly should these braces fit in order to provide the desired rigidity or "push-pull coupling" in the case of a bipole design? Recognizing that the driver WILL vibrate a bit, if there is insufficient pressure, the result may be a buzzing at higher levels / low frequency. If there is too much pressure, the frame will warp.

So what is the right answer (maybe in terms of mounting screw turns of fractions thereof)?

Thank you in advance for your kind patience.

I have always thought that braces that squeeze the driver frame were a bad idea. The idea, I think, is to make the baffle, driver and back panel one solid unit. Also, I think that there is a presumption that the basket will ring if something isn't done. This also leads to application of various materials to the basket legs, particularly with stamped baskets.

I consider two window braces immediately above and below the driver adequate to tie the structure together. As far as restraining any front/back movement of the driver basket, one needs only to consider the relative masses of the cone and the basket/magnet structure. At the power levels used here, that movement has to be miniscule.

Bob

I consider two window braces immediately above and below the driver adequate to tie the structure together. As far as restraining any front/back movement of the driver basket, one needs only to consider the relative masses of the cone and the basket/magnet structure. At the power levels used here, that movement has to be miniscule.

Bob

Hi Guys,

Re bracing. Dave and his team have allot of build experience so they are skilled at making a precise fit between a brace and the rear of a driver. From what I understand about their builds, its just enough for the driver to rest on the brace without applying a significant stress load.

It is very important NOT to apply any significant stress load to the back of the driver. I don't know any current driver maker that specifically designs their products to take a stress load applied to the rear of their units.

For those wanting to use bracing up to the rear of drive units, I recommend using some low to medium density foam in-between the driver's rear plate and the brace. This should help to give some support while keeping the fit tolerance wide enough so as not to stress the driver's frame.

Bob Brines's observation is correct. The operational power levels of Full-Range drivers (and most smaller woofs) isn't sufficient to physically move a mounted driver. For those guys mounting larger drivers, those with heavy double magnet systems, or larger subs, it then may become wise to physically support these drivers with bracing.

Cheers

Mark.

Re bracing. Dave and his team have allot of build experience so they are skilled at making a precise fit between a brace and the rear of a driver. From what I understand about their builds, its just enough for the driver to rest on the brace without applying a significant stress load.

It is very important NOT to apply any significant stress load to the back of the driver. I don't know any current driver maker that specifically designs their products to take a stress load applied to the rear of their units.

For those wanting to use bracing up to the rear of drive units, I recommend using some low to medium density foam in-between the driver's rear plate and the brace. This should help to give some support while keeping the fit tolerance wide enough so as not to stress the driver's frame.

Bob Brines's observation is correct. The operational power levels of Full-Range drivers (and most smaller woofs) isn't sufficient to physically move a mounted driver. For those guys mounting larger drivers, those with heavy double magnet systems, or larger subs, it then may become wise to physically support these drivers with bracing.

Cheers

Mark.

Last edited:

This will be my last comment on this subject so that I don't appear argumentative. I simply have a different outlook on the subject.

Mark, you are kind of making my point. If an elastomeric contact is used, there will be little or no energy transfer and precious little support.

Bob

Mark, you are kind of making my point. If an elastomeric contact is used, there will be little or no energy transfer and precious little support.

Bob

This will be my last comment on this subject so that I don't appear argumentative. I simply have a different outlook on the subject.

Mark, you are kind of making my point. If an elastomeric contact is used, there will be little or no energy transfer and precious little support.

Bob

Hi Bob, Guys

Your welcome. Please feel free to continue posting. You have considerable experience in audio. Along with other posts from experienced members, it much helps those members who want to learn more. To all experienced forum members, please post as often as possible as it helps newer and less experienced members with their ideas and projects.

Some members may have read some of the posts on the recently closed "Disabled" thread. Some of its content was shockingly bad and clearly broke the rules. That thread's starter tried to manipulate the outcome of the thread, doing his best to contrive a particular bias in its content. That type of behaviour won't be accepted on the Markaudio section of the forum. I'm happy to say the Markaudio section attracts genuine Diyaudio forum members who want to support each other and learn more. Posting differences of opinion, alternative approaches to theory and varying project build methods are all much welcomed on the Markaudio section provided they observe and demonstrate mutual respect.

Cheers

Mark.

Last edited:

Can someone help a noob here........how is this.....or is this any different than say spikes on a speaker or stand to the floor? Is this one more way of getting the speaker "connected" (or whatever the right verbiage would be), to the floor?

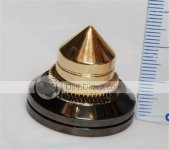

Hi 503Timber,

Ideally, its best to minimise the amount of contact surface area between the base of the box and the floor. If the contact surface area is large (the whole of the box base), there is some possibility of transmitting vibration or damping (carpets) in either direction which might affect the box's performance. While these effects are small in most cases, its still reasonable practice to isolate the speaker box using spikes or similarly designed feet. This practice can also be applied to the rest of your audio equipment (amp, CD player etc.). For those using turn-tables, its usually essential to isolate this equipment due to its pick-up sensitivity.

Thx

Mark.

Attachments

Last edited:

Thank you for the information and clarification. It sounds like the better solution is just a firm but not tight driver mount and a lot of internal box bracing.

Hi silver,

Glad to help. Yes, just firm enough to secure the driver, no need to apply allot of muscle.

Re bracing, there are 2 schools of thought, one being bracing reduces un-wanted resonances, the other is to make boxes without bracing as some builders like a box to have some resonance. I've heard Pencil 10 and 12 boxes with and without bracing. Depending on the material used (MDF, solid wood or ply), I found both braced and non-braced boxes very pleasing.

As a guide:

1 - Most small boxes (up to 12 litres) won't need any or very little bracing. Larger boxes may benefit from bracing.

2 - MDF is the least structured material so bracing will likely be more useful. Ply and solid woods tend to be more structured, as such their rigidity may be sufficient to do without bracing (depending on box size).

3 - Thinner box material will likely require bracing (less than 18-mm). Conversely, thicker materials may not need any bracing.

An example could be: A 10 litre (internal) vented box using 20-mm MDF, 18-mm solid wood or 18-mm ply may not need bracing. Taking the same basic box design to 14 litres (internal), adding some cross bracing might be become desirable.

My advice is to experiment. Where possible, start with no bracing and gradually add some until you get a sound that suits your ears.

Cheers

Mark.

Last edited:

The recent threads related to driver mounting point out a question I've had for years. Many kit plans indicate a brace behind the driver which seems to provide some additional rigidity (see Dave's Planet10 site for numerous examples). I have never used such a mounting system for fear of warping the frame as Mark indicates.

Bill,

The use of the holey driver brace derives from the active vibration cancelation possible with a push-push pair of drivers. And that follows (at least partially) from a speaker designer who designed his basket and polepiece such that it was possible to run a lag bolt thru the polepiece into the cabinet.

There is a very specific purpose to these braces in our designs. The baffle is typically the weakest (and most audiable) panel in the loudspeaker (because you've cut a big hole in it). The driver brace is aimed at directly transfering some of the drivers reactionary energy to the back of the box (some will be dissipated inside the box from the holey brace itself. This allows driver energy to be shared between the baffle & the back (generally the 2nd least audible panel after the bottom). Given that it takes a certain threshold to get a resonance going, the goal in spreading the energy around is to decrease the likelihood of reaching the threshold. We have found this to improve DDR (downward dynamic range).

As Mark has already indicated, the fit needs to be tight, but not so tight as to stress the basket. To get this perfect requires some practise and test fitting during assembly. The bracing can often take as much or more time to do as the entire box (ie in the pensils).

We usually use something stiff in the case of a brace that is just a bit deep. Paper or a sliver of wood. If you use foam you need to make sure that under full compression the foam is not too thick.

dave

Can someone help a noob here........how is this.....or is this any different than say spikes on a speaker or stand to the floor? Is this one more way of getting the speaker "connected" (or whatever the right verbiage would be), to the floor?

If you read enough articles and post on spikes, you will find two camps. One says that the spikes decouple the speaker from the floor. The other says that the spikes couple the speaker to the floor. I personally take no comfort with either. That said, I put spike on all of my floor-standers and speaker stands. Why? Most speakers, including my personal speakers, wind up on carpeted floors. A tall, thin speaker is pretty wobbly on a plush carpet. The spikes go down to the floor and provide stability.

BTW, my stereo listening room is downstairs on a concrete slab. My HT room is upstairs in a stick frame house. I can't tell that the spikes have any sonic effect in either, but then again, the rooms are so different that a comparison is hard in the best of cases.

Bob

Like so...

This is a 16" frame, Altec 4168b. The foam is approximately 1/4" thick when compressed.

As was mentioned, none of the smaller full-rangers I've used needed a "cradle", as such. I would think that it could be beneficial, though, but to what amount of improvement?

This is a 16" frame, Altec 4168b. The foam is approximately 1/4" thick when compressed.

As was mentioned, none of the smaller full-rangers I've used needed a "cradle", as such. I would think that it could be beneficial, though, but to what amount of improvement?

off topic

Hi,

sorry to interrupt, but I see another MarkAudio thread as "closed" after MarkAudio posted and leaving no opportunity to reply. In both this thread and that other thread, MarkAudio has the apparent ability to delete or censor posts.

Does MarkAudio have these rights that are denied to Members?

Is this the case for all "manufacturer threads"

Hi,

sorry to interrupt, but I see another MarkAudio thread as "closed" after MarkAudio posted and leaving no opportunity to reply. In both this thread and that other thread, MarkAudio has the apparent ability to delete or censor posts.

Does MarkAudio have these rights that are denied to Members?

Is this the case for all "manufacturer threads"

Last edited:

Hi,

sorry to interrupt, but I see another MarkAudio thread as "closed" after MarkAudio posted and leaving no opportunity to reply. In both this thread and that other thread, MarkAudio has the apparent ability to delete or censor posts.

Does MarkAudio have these rights that are denied to Members?

Is this the case for all "manufacturer threads"

Hi Andrew,

Yes, this is the commercial part of Diyaudio.com

Each section is managed/moderated by its business (Vendors, Manufacturers).

Some threads concentrate on specific technical advice. If they get too long or go off topic, it becomes difficult for those members who ask the early questions to find the answers they need.

If you have any more to add, please feel free to send my a private message. I'll be glad to open up the thread to you or post your comments if they specifically relate to the original purpose of the thread.

Thanks

Mark.

To follow up on an earlier post of Bob's re "spikes" / coupling etc - this is certainly one of those areas were multiple points of view abound - my own position of avoiding them is based on the personal experience of damaging both carpeted and solid wood floors on different occasions. Some enclosures are heavy or awkward enough that adjusting positions can be very difficult, and in the case of fitting the divoted pads under spikes on hardwood floors, it can definitely be a 2 person job.

I've had some of the more slender spikes that easily pierce carpet and under-padding at were soft enough to deform on the tip when hitting a concrete basement floor or the nail/screw head on wood subfloor. They were fine going in, but bent into a small bit of a fish-hook and tore carpet when pulled out.

All that said, the important question should be do they "work" - well they can certainly take the wobble out, but I've yet to hear a demonstrable sonic improvement solely attributable to them. To reference Bob again - that test is harder than it sounds - you either rely on sonic memory , or need 2 otherwise identical pairs of speakers for comparison - not all of us do .

Re driver mount/bracing - I'll concede that smaller full-range/wide-band drivers of all makes, and certainly all of Mark's I've seen to date with the composite resin baskets probably work quite well without the nested support/magnet bracing, which is certainly tricky to get "just right". However, I'm still of the opinion that the enclosure itself should be as well braced against panel flex and towards minimizing / dispersing resonant energy as Dave described. There's more than one way to skin that cat.

I've had some of the more slender spikes that easily pierce carpet and under-padding at were soft enough to deform on the tip when hitting a concrete basement floor or the nail/screw head on wood subfloor. They were fine going in, but bent into a small bit of a fish-hook and tore carpet when pulled out.

All that said, the important question should be do they "work" - well they can certainly take the wobble out, but I've yet to hear a demonstrable sonic improvement solely attributable to them. To reference Bob again - that test is harder than it sounds - you either rely on sonic memory , or need 2 otherwise identical pairs of speakers for comparison - not all of us do .

Re driver mount/bracing - I'll concede that smaller full-range/wide-band drivers of all makes, and certainly all of Mark's I've seen to date with the composite resin baskets probably work quite well without the nested support/magnet bracing, which is certainly tricky to get "just right". However, I'm still of the opinion that the enclosure itself should be as well braced against panel flex and towards minimizing / dispersing resonant energy as Dave described. There's more than one way to skin that cat.

When i did my Mar-Kel70 speakers i fit the drivers and the brace and left the top piece open. Then i took thin pieces of paper sticking them in between the driver and the brace until i couldn't add any more. I could then move the paper but if i let go of it, it would still stay in place. So the driver had contact, but it wasn't stressing the frame.

When i did my Mar-Kel70 speakers i fit the drivers and the brace and left the top piece open. Then i took thin pieces of paper sticking them in between the driver and the brace until i couldn't add any more. I could then move the paper but if i let go of it, it would still stay in place. So the driver had contact, but it wasn't stressing the frame.

Hi Rull,

Good practical work. Thanks for making this effort.

Cheers

Mark.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Driver mount back pressure