Besides Jan isn't talking to me...ES

??? Ed, I even took a picture of you last time we met!

jan

??? Ed, I even took a picture of you last time we met!

jan

Just checking!

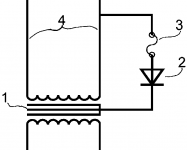

Attached is a picture that might explain why one should use radial capacitors for power supply filtering not axial ones.

Attachments

Oh, Please, John, L.C. had just sell in 3 days his last amps circuit 10 X times the number of sold Blowtorch.

Just a DIY project, with no aircraft or spatial b.ls...t.

L.C.?

se

I would like to point something out to Gapapag, something of interest

Mr Curl, my professional life circulated more or less around (certified) aircraft grade aluminium for real (engineering) needs.

I would not object to posts like this.

The point of this discussion

Steve gave already some simple clear answers ref. Buzzwords.

George

Well, a good finish is also important for HI END AUDIO needs, even if you would be happy with something cheaper.

Graining, bead blasting and anodizing isn't very expensive. Not much more than powder coating.

se

I don't know the 'particulars' about the Blowtorch case, all I know is what I was told, perhaps a decade or more ago. I left it to Bob Crump, (now deceased) and his pick of machinists in Houston, Texas. I mostly worried about the thickness being enough to get rid of any external interference, and that it did not RING! I feel the same way about phonograph turntable platters.

must be the longest thread i ever tried to go through...

I must say, after all the bashing John Curl had to endure it is admirable he

took it so calm....

After all, it turned out that he propable is not even responsible

for the flashy stuff, lousy connectors a.s.o.

All the best to you John

I must say, after all the bashing John Curl had to endure it is admirable he

took it so calm....

After all, it turned out that he propable is not even responsible

for the flashy stuff, lousy connectors a.s.o.

All the best to you John

So what? Why all this fuzz if someone chooses otherwise???Graining, bead blasting and anodizing isn't very expensive. Not much more than powder coating.

se

I really do not understand....

But I like your hairstyle

So what? Why all this fuzz if someone chooses otherwise???

I could care less if someone chooses otherwise. I was responding to John's "...even if you would be happy with something cheaper." Simply pointing out that graining, bead blasting and anodizing isn't terribly expensive to begin with.

But I like your hairstyle

Thanks! I really like its low maintenance.

se

US6181124 Eddy current reducing system

Eddy currents are produced by a changing magnetic field acting upon free electric charges in the ferromagnetic core. When the free electric charges are removed from the core eddy currents will be reduced. When an excess of free electric charges are added to the core , the magnetic field energy is spread over many more electric charges. Then the magnitude of movement of each electric charge will be reduced and the eddy currents will be reduced. The reduction of eddy currents will reduce heat and the energy losses related there to. This has applications on all alternating current inductive devices.

Attachments

I really do not see the point of that patent, the only way to reduce eddy currents is to have thinner laminations or a non-conductive core.

tvi

I read the patent

Eddy current reducing system

I would expect him to use well known formulae and arrange for proper testing

Hysteresis losses are a function of frequency.

Eddy current losses are a function of frequency squared.

Both are depending on core construction and are independent of load.

Copper losses are a function of load current squared and are independent of core construction.

He claims an eddy current reducing system, assuming that eddy currents behave the way he thinks. He backs up his claim with some really inadequate measurements.

I can assure you that eddy currents induced in a good conducting mass of metal can not be “grounded” by grounding the metal mass in one, two, three points. They are localized currents. This is reliably verified and quantified with specialized equipment (NDT eddy current testers).

True, size and way of eddy current circulation is affected by frequency, but they are still localized, to the extend that they can not be routed to or siphoned by electrical connections.

I really do not see the point of that patent, the only way to reduce eddy currents is to have thinner laminations or a non-conductive core.

wrinkle

His patent would be of great importance to the industry, as it would potentially eliminate the need for laminated construction in some trafos, motors, generators and would give him a lot of money, only if it “worked”.

George

Last edited:

After all, for the flashy stuff

Stupid question 1 : How many (serial) preamp models, with cases out of a solid chunk of easy to machine aluminum, were there at the time of BT No2 ('97)?

Stupid question 2 : How many now (+ power amps/phono stages/DAC's) ?

(aviation/military not acceptable)

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II