My latest projector project is an early Davis Powerbeam, which is optically identical to the standard DIY design, so easy to work on and modify.

I bought it cheap as a non-worker, and quickly discovered that the electronic ballast was presenting a dead short across the mains - everything else is OK.

Once I'd removed the ballast from its case and potting compound (an interesting job), I was expecting to find something fairly simple, similar to an SMPS or inverter, but this thing's stuffed with SMDs and LSIs - pretty complex!

I don't think there's much chance of saving it (big black hole in PCB ), but it did set me wondering how these things work, and even if it's possible to build a (simpler) replcement.

), but it did set me wondering how these things work, and even if it's possible to build a (simpler) replcement.

Can anyone help please?

Cheers,

Dave.

I bought it cheap as a non-worker, and quickly discovered that the electronic ballast was presenting a dead short across the mains - everything else is OK.

Once I'd removed the ballast from its case and potting compound (an interesting job), I was expecting to find something fairly simple, similar to an SMPS or inverter, but this thing's stuffed with SMDs and LSIs - pretty complex!

I don't think there's much chance of saving it (big black hole in PCB

Can anyone help please?

Cheers,

Dave.

just a fancy switching power supply

HID ballasts have many variations that all try to do the same thing: Deliver enough startup voltage to get an arc established, then deliver enough current to get the arc chamber solid elements and electrodes hot enough to operate, and then finally to deliver enough power to keep a sustained arc running without melting the electrodes. The magnetic versions may need an ignitor to make the initial high voltage pulse, and a capacitor to do some phase compensation for the inductive load.

The electronic ballasts do all of that using a microprocessor to deliver all of those requirements. Typically, they rectify and filter the line power to get a stable DC supply. Then they use a pulse width modulation scheme to generate high frequency (10KHz to 40KHz) variable duty cycle square waves. That lets them use fairly cheap MOSFETs as switching devices and much smaller inductors than a magnetic ballast. They can also do a much better job of regulation, so you tend to get a bit more light out of the same lamp. Easy to add over-power protection, short circuit detection, automatic restart, hour counter with replacement warning, etc. You could (or at least I could ) design & build one, but it would cost thousands of dollars worth of engineering time. Much cheaper to just buy one!

) design & build one, but it would cost thousands of dollars worth of engineering time. Much cheaper to just buy one!

HID ballasts have many variations that all try to do the same thing: Deliver enough startup voltage to get an arc established, then deliver enough current to get the arc chamber solid elements and electrodes hot enough to operate, and then finally to deliver enough power to keep a sustained arc running without melting the electrodes. The magnetic versions may need an ignitor to make the initial high voltage pulse, and a capacitor to do some phase compensation for the inductive load.

The electronic ballasts do all of that using a microprocessor to deliver all of those requirements. Typically, they rectify and filter the line power to get a stable DC supply. Then they use a pulse width modulation scheme to generate high frequency (10KHz to 40KHz) variable duty cycle square waves. That lets them use fairly cheap MOSFETs as switching devices and much smaller inductors than a magnetic ballast. They can also do a much better job of regulation, so you tend to get a bit more light out of the same lamp. Easy to add over-power protection, short circuit detection, automatic restart, hour counter with replacement warning, etc. You could (or at least I could

and is it true that it's the electronic ballasts that still hold a charge after you unplug it?

just asking,

my brother came to visit me and he's an electrician on a nuclear powered LA class submarine and he checked out my 400W magnetic ballast and ushio, when i unplugged it and went to put it away, he said the capacitor might still hold a charge and i should wait or by a voltage tester and check it.

which one holds a charge?

just asking,

my brother came to visit me and he's an electrician on a nuclear powered LA class submarine and he checked out my 400W magnetic ballast and ushio, when i unplugged it and went to put it away, he said the capacitor might still hold a charge and i should wait or by a voltage tester and check it.

which one holds a charge?

either one can zap you

The magnetic ballasts use an AC capacitor to phase shift the power load, so there could be some charge left on it if you shut down the ballast at the right part of a cycle. (But mine came with a bleeder resistor across it to discharge it in a few seconds.)

The electronic ballasts will use a capacitor or two internally to smooth out the rectified 120 (or 100) Hz AC power in. I don't think they would have much voltage on the outputs after you turn the power off, because the switching MOSFETS would be shut off. They might also include bleeder resistors, too.

But in general, he is absolutely right: Never trust any power equipment (especially computer UPS boxes) to be safe after you shut off the power. TVs are notorious for zapping the %$#@& out of you with 10000 to 25000 volts left stored in the picture tube. Stuff also gets wired backwards sometimes, so the power switch interrupts the neutral side of the circuit, leaving the circuit connected to the hot side. That's why you always pull out the plug, and then use just one hand inside the power circuit area of a box until you are sure it is safe. Little multimeters are very cheap at any Radio Shack.

The magnetic ballasts use an AC capacitor to phase shift the power load, so there could be some charge left on it if you shut down the ballast at the right part of a cycle. (But mine came with a bleeder resistor across it to discharge it in a few seconds.)

The electronic ballasts will use a capacitor or two internally to smooth out the rectified 120 (or 100) Hz AC power in. I don't think they would have much voltage on the outputs after you turn the power off, because the switching MOSFETS would be shut off. They might also include bleeder resistors, too.

But in general, he is absolutely right: Never trust any power equipment (especially computer UPS boxes) to be safe after you shut off the power. TVs are notorious for zapping the %$#@& out of you with 10000 to 25000 volts left stored in the picture tube. Stuff also gets wired backwards sometimes, so the power switch interrupts the neutral side of the circuit, leaving the circuit connected to the hot side. That's why you always pull out the plug, and then use just one hand inside the power circuit area of a box until you are sure it is safe. Little multimeters are very cheap at any Radio Shack.

damn, i hate getting out smarted by my little brother,

but then again the u.s. navy did spend over a million dollars training him so i gues that's to be expected.

his nuclear propulsion school has a 70 percent failure rate. and since it's top secret he could not even take books home with him. they made him study for 7 hrs straight every day.

but then again the u.s. navy did spend over a million dollars training him so i gues that's to be expected.

his nuclear propulsion school has a 70 percent failure rate. and since it's top secret he could not even take books home with him. they made him study for 7 hrs straight every day.

Electronics ballasts work like this:

AC bulb ballast:

a hybrid IC, or module contains a microprocessor and oscillators, The sequence is this: The pulse start ignition inverter fires up, sending a 2kv pulse to the secondaries of the output trans, when the SMPS senses current draw, the pulser shuts off, and the H-bridge that drives the output transformer takes over, and the bulb is lit. uPC sends a bulb ignition success command back to the main control unit (the projo).

DC bulb ballast:

This type has a large inductor instead of a transformer, and is drivin by a power MOSFET (think of a buck-boost converter setup). The controller sends an ignition pulse, jumps a spark gap and leaks into the inductor, jumps an arc in the bulb, and the bulb will ignite. current sensor picks up the surge, and shuts off the ignition oscillator.

AC bulbs ballasts are more reliable than DC, because the spark gap wears in DC ballasts, and knocked out tons of LP420 systems.

I repair ballasts alot of times, so I know this.

AC bulb ballast:

a hybrid IC, or module contains a microprocessor and oscillators, The sequence is this: The pulse start ignition inverter fires up, sending a 2kv pulse to the secondaries of the output trans, when the SMPS senses current draw, the pulser shuts off, and the H-bridge that drives the output transformer takes over, and the bulb is lit. uPC sends a bulb ignition success command back to the main control unit (the projo).

DC bulb ballast:

This type has a large inductor instead of a transformer, and is drivin by a power MOSFET (think of a buck-boost converter setup). The controller sends an ignition pulse, jumps a spark gap and leaks into the inductor, jumps an arc in the bulb, and the bulb will ignite. current sensor picks up the surge, and shuts off the ignition oscillator.

AC bulbs ballasts are more reliable than DC, because the spark gap wears in DC ballasts, and knocked out tons of LP420 systems.

I repair ballasts alot of times, so I know this.

Disabling the ballast detecting circuit

I got several DAVIS Powerbeam V and VI that were being thrown away by my university.

I´m interested in modifying them to use an alternative and cheaper lightsource but have a problem of bypassing the ballast detection circuit (the electronics that senses the lamp is Ok). Without a lamp, the projector refuses to start.

I have studied some of the electronics for the Ignitor for the Metal Halide lamp but was unable to find any electronics to measure the status of the lamp. Now i suspect that the OSRAM PSU (the large black box) senses the load on the connector for the Ignitor-board.

When i measured the (AC) voltage on this connector (black and white lead) i noticed it went up to about 320 volts and when dropped down to zero.

I also tried connecting a load (high-ohm resistor) on the lamp-connector and then the projector started, but it made a lot of noise from the connector so i cut the power immediatly!

Has anyone succeded in disabling the ballast detection circuit in this projector?

Where can i find a schematic for the OSRAM PSU and/or the Ignitronic ignitor?

I got several DAVIS Powerbeam V and VI that were being thrown away by my university.

I´m interested in modifying them to use an alternative and cheaper lightsource but have a problem of bypassing the ballast detection circuit (the electronics that senses the lamp is Ok). Without a lamp, the projector refuses to start.

I have studied some of the electronics for the Ignitor for the Metal Halide lamp but was unable to find any electronics to measure the status of the lamp. Now i suspect that the OSRAM PSU (the large black box) senses the load on the connector for the Ignitor-board.

When i measured the (AC) voltage on this connector (black and white lead) i noticed it went up to about 320 volts and when dropped down to zero.

I also tried connecting a load (high-ohm resistor) on the lamp-connector and then the projector started, but it made a lot of noise from the connector so i cut the power immediatly!

Has anyone succeded in disabling the ballast detection circuit in this projector?

Where can i find a schematic for the OSRAM PSU and/or the Ignitronic ignitor?

Sharp PG-M20X ballast problem

I believe I have a projector ballast issue. My lamp had under 800 hours on it and wouldn't light up. Bought a new lamp (figuring the used projector lamp timer may have been reset) and the new lamp starts to light up but stops, same as the old.

I believe I have a projector ballast issue. My lamp had under 800 hours on it and wouldn't light up. Bought a new lamp (figuring the used projector lamp timer may have been reset) and the new lamp starts to light up but stops, same as the old.

mbates14 says he repairs ballasts. Where can I get those services?

I cannot affort to put another $250 into this projector when I'm not 100% sure it's the ballast. I have the service manual but don't have an O-scope to check out the supposed 180Hz signal into the ballast to be sure it's not an issue with the $500 formatter board. It's a Hitachi media electronics Co. Ltd ps-234 (parts # RDENCA005WJZZ model PS-234A-LS-200 output 210W 20818 A US (K) SWPL-SW made in japan 5A73381).

Any info regarding the "worn spark gap" component would be a great help

Or a cross reference to a compatible lamp power supply, perhaps from osram.com, where another thread says was the ballast of older sharp projectors.

http://www.hitachi-media-el.co.jp/products/pws_e.html doesn't have that specific PS-234 mentioned so it may be custom application for Sharp.

ANy help or info is greatly appreciated.

-Justin

I believe I have a projector ballast issue. My lamp had under 800 hours on it and wouldn't light up. Bought a new lamp (figuring the used projector lamp timer may have been reset) and the new lamp starts to light up but stops, same as the old.

I believe I have a projector ballast issue. My lamp had under 800 hours on it and wouldn't light up. Bought a new lamp (figuring the used projector lamp timer may have been reset) and the new lamp starts to light up but stops, same as the old. mbates14 says he repairs ballasts. Where can I get those services?

I cannot affort to put another $250 into this projector when I'm not 100% sure it's the ballast. I have the service manual but don't have an O-scope to check out the supposed 180Hz signal into the ballast to be sure it's not an issue with the $500 formatter board. It's a Hitachi media electronics Co. Ltd ps-234 (parts # RDENCA005WJZZ model PS-234A-LS-200 output 210W 20818 A US (K) SWPL-SW made in japan 5A73381).

Any info regarding the "worn spark gap" component would be a great help

Or a cross reference to a compatible lamp power supply, perhaps from osram.com, where another thread says was the ballast of older sharp projectors.

http://www.hitachi-media-el.co.jp/products/pws_e.html doesn't have that specific PS-234 mentioned so it may be custom application for Sharp.

ANy help or info is greatly appreciated.

-Justin

http://www.projectorcentral.com/Sharp_PG_Series-Notevision_PG-M20X.htm

is it?

is shp lamp?

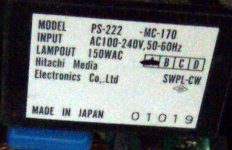

I have some ballasts, like this:

do you have some oic of your ballast?

is it?

is shp lamp?

I have some ballasts, like this:

do you have some oic of your ballast?

Attachments

210W SHP lamp

It's actually a Hitachi Media Electronics Co Ltd ballast (http://www.hitachi-media-el.co.jp/products/pws_e.html), must be custom made for Sharp. There's a crappy small pic on that website, I didn't take any pics when I had the unit out. Part number RDENCA005WJZZ model PS-234A-LS-200 [PS-234].

It looks somewhat similar but it has 4 control wires (lampen, gnd, lamplit, eco), not just an on/off/gnd control input. SO I don't think yours would work. I might be willing to try, do you have any connectors for that input? of course, then I'd need an adapter to my cable too. Hmmm.

Get this, I got a new bulb off ebay, new lamp did same thing old lamp did, got bright a bit (I could see from rear) but then didn't light up completely, so one would assume the ballast. When I was getting to the ballast inside the projector Removing the one flat brown cable/ribbon form the pc board to the formatter board, the one side plastic tab broke off that keeps the ribbon retaining flap down. Crap. But I super glued it like a surgon, and then applied a tiny bit of hot glue to help brace it a bit, connector seemed good as new. But now the lamps didn't brightly light anymore. In fact, I'm not sure it had still did that before the damage. Anyway, sent it into Sharp and the estimate I just recieved yesterday a quote for $606 !!! $125 for RPR-SR labor and $407 for a new lamp?!?!?!?! With the coding of CD for conceled damage, wich is somewhat accurate. That was a new lamp and I bet they just replaced the ballast!!! Can't wait to call them up on Monday. GRRRRRRRRRR!

Do you know of any similar ballasts with 4 control wires?

It's actually a Hitachi Media Electronics Co Ltd ballast (http://www.hitachi-media-el.co.jp/products/pws_e.html), must be custom made for Sharp. There's a crappy small pic on that website, I didn't take any pics when I had the unit out. Part number RDENCA005WJZZ model PS-234A-LS-200 [PS-234].

It looks somewhat similar but it has 4 control wires (lampen, gnd, lamplit, eco), not just an on/off/gnd control input. SO I don't think yours would work. I might be willing to try, do you have any connectors for that input? of course, then I'd need an adapter to my cable too. Hmmm.

Get this, I got a new bulb off ebay, new lamp did same thing old lamp did, got bright a bit (I could see from rear) but then didn't light up completely, so one would assume the ballast. When I was getting to the ballast inside the projector Removing the one flat brown cable/ribbon form the pc board to the formatter board, the one side plastic tab broke off that keeps the ribbon retaining flap down. Crap. But I super glued it like a surgon, and then applied a tiny bit of hot glue to help brace it a bit, connector seemed good as new. But now the lamps didn't brightly light anymore. In fact, I'm not sure it had still did that before the damage. Anyway, sent it into Sharp and the estimate I just recieved yesterday a quote for $606 !!! $125 for RPR-SR labor and $407 for a new lamp?!?!?!?! With the coding of CD for conceled damage, wich is somewhat accurate. That was a new lamp and I bet they just replaced the ballast!!! Can't wait to call them up on Monday. GRRRRRRRRRR!

Do you know of any similar ballasts with 4 control wires?

DIY electronic ballast for four 15W fluorescent lamps, just in case someone is interested... (I know, the lamps used in projectors are somewhat harder to drive)

http://www.diyaudio.com/forums/showthread.php?s=&threadid=91948

http://www.diyaudio.com/forums/showthread.php?s=&threadid=91948

old old and dead thread... sorry. As far as wattage goes, it really doesnt matter if you have a schematic you can adjust the resistor dividers in the run and ignition feedback circuits. inside an electronic ballast is a feedback comparator that is used to read the amount of current drawn from the lamp at all times. 250 watt lamps have specific current and voltage ratings and the ballast is designed around that...

Using a 150watt lamp, these change. ignition voltage could be the same, but the run current is definately not the same. simple ohms law would state that if you go from 250 watts down to 150watts, your loosing 100watts of power. So therefore, at 65V run voltage, at 250 watts, your pulling 3.85amps of current through the ballast, that circuit monitors this to confirm the bulb is lit continuously. youll drop to 2.31 amps for 150 watts, significantly lower. This can cause an issue, becuase it could be below its lamp lit threshold settings in the feedback circuit, so the ballast would think the lamp is dying and WILL shut down. depends on the circuitry.

this is why you must use lamps rated for ballasts.

Using a 150watt lamp, these change. ignition voltage could be the same, but the run current is definately not the same. simple ohms law would state that if you go from 250 watts down to 150watts, your loosing 100watts of power. So therefore, at 65V run voltage, at 250 watts, your pulling 3.85amps of current through the ballast, that circuit monitors this to confirm the bulb is lit continuously. youll drop to 2.31 amps for 150 watts, significantly lower. This can cause an issue, becuase it could be below its lamp lit threshold settings in the feedback circuit, so the ballast would think the lamp is dying and WILL shut down. depends on the circuitry.

this is why you must use lamps rated for ballasts.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- The Moving Image

- Lighting and OHP

- Electronic ballasts - how do they work?