Hello, noob here.

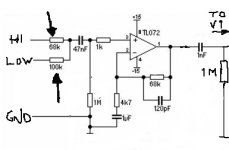

I am using 1/2 TL072 at a gain of 8 as a pre-preamp feeding a high gain tube pre, for the purpose of reducing noise floor hiss.

In an effort to reduce it further, it has been found the input resistors are contributing a good portion of noise, regardless of whether anything is plugged in or not.

Experimenting, reducing the parallel value of the 68k and 100k resistors, to ~10k, the hiss is greatly reduced.

What I don't understand, and could not find out by research, was how the parallel pair and the coupling cap suppress RFI, or if reduction would cause any performance issues. I wish to reduce the values to 6.8k and 10k, but don't know if the cap value should be adjusted as well.

I know there are quiter opamps, but I wish to order lower value, low noise resistors at the same time as the opamp. I am tempted to go with foil$ but my budget won't allow. Paralleling is another option which averages the thermal noise; thus suppressing the total when they add.

Also, would there be any advantage to using the other half as a buffer?

Any comments welcome. Thanks.

I am using 1/2 TL072 at a gain of 8 as a pre-preamp feeding a high gain tube pre, for the purpose of reducing noise floor hiss.

In an effort to reduce it further, it has been found the input resistors are contributing a good portion of noise, regardless of whether anything is plugged in or not.

Experimenting, reducing the parallel value of the 68k and 100k resistors, to ~10k, the hiss is greatly reduced.

What I don't understand, and could not find out by research, was how the parallel pair and the coupling cap suppress RFI, or if reduction would cause any performance issues. I wish to reduce the values to 6.8k and 10k, but don't know if the cap value should be adjusted as well.

I know there are quiter opamps, but I wish to order lower value, low noise resistors at the same time as the opamp. I am tempted to go with foil$ but my budget won't allow. Paralleling is another option which averages the thermal noise; thus suppressing the total when they add.

Also, would there be any advantage to using the other half as a buffer?

Any comments welcome. Thanks.

In an effort to reduce it further, it has been found the input resistors are contributing a good portion of noise, regardless of whether anything is plugged in or not.

Hi,

The 68K & 100K should't be contributing any noise on their OWN, if nothing is plugged in ! It's possible some RFI or other interference is being picked and is the cause ?

how the parallel pair and the coupling cap suppress RFI,

They don't.

or if reduction would cause any performance issues.

It shouldn't, but the gain will be less.

I wish to reduce the values to 6.8k and 10k, but don't know if the cap value should be adjusted as well.

I would to 470nf.

I know there are quiter opamps,

Use a low noise FET input OpAmp because in high impedance circuits they actually produce LESS noise

1% metal film resistors will be just fine

Paralleling is another option which averages the thermal noise; thus suppressing the total when they add.

It's the resistance that REALLY matters. Higher = more noise

Also, would there be any advantage to using the other half as a buffer?

Where ?

Thank you for the tips!

This shoud be checked. The problem seems to be the 100k only. The 68k is very close to its value and shorting that one does nothing; just touching the 100k definitely picks up some RFI and a little 60 cycle. I will switch the 100k with a low noise and see what happens. If nothing, then some shielding. The aluminum box is open during these experiments.The 68K & 100K should't be contributing any noise on their OWN, if nothing is plugged in ! It's possible some RFI or other interference is being picked and is the cause ?

Sounds like the pickups would be loaded down. Didn't consider that. Thanks.It [effects of reducing input resistor value]shouldn't, but the gain will be less.

Ok, got two different ones in the chamber, but where is the "high" impedence that you refer?Use a low noise FET input OpAmp because in high impedance circuits they actually produce LESS noise

I meant, in lieu of using a higher wattage rating, use multiple resisitors in parallel--whose total resistance is equal to the single component--as an alternative.It's the resistance that REALLY matters. Higher = more noise

A unity gain at the output of the first half, since there is some loading by the feedback circuit.Where ?[other half as buffer]

Just a couple of things to consider. Changing the value of the two "input" resistors will have minimal effect due to the 1 meg resistor being in series.

And the corner frequencies of the input and feedback circuits are kinda bass-ackward. Input Fc is about 3Hz, and feedback Fc is about 33Hz. In that configuration the opamp could be fed signals that the feedback network will never see, in other words, increased noise and distortion. Put a 33uF cap in place of the 1uF in the feedback path to fix it, the input Fc should be at least two or three times the feedback Fc for proper operation.

Mike

And the corner frequencies of the input and feedback circuits are kinda bass-ackward. Input Fc is about 3Hz, and feedback Fc is about 33Hz. In that configuration the opamp could be fed signals that the feedback network will never see, in other words, increased noise and distortion. Put a 33uF cap in place of the 1uF in the feedback path to fix it, the input Fc should be at least two or three times the feedback Fc for proper operation.

Mike

The 1 Meg is in parallel with the input transducer. The one feeding the non-inverting input is 1k.Just a couple of things to consider. Changing the value of the two "input" resistors will have minimal effect due to the 1 meg resistor being in series.

And the corner frequencies of the input and feedback circuits are kinda bass-ackward. Input Fc is about 3Hz, and feedback Fc is about 33Hz. In that configuration the opamp could be fed signals that the feedback network will never see, in other words, increased noise and distortion. Put a 33uF cap in place of the 1uF in the feedback path to fix it, the input Fc should be at least two or three times the feedback Fc for proper operation.

Feedback path filtering is not intuitive for me yet. However, I will make a note of this, since high gain designs can suffer from seemingly small details. It also makes perfect sense.

Thanks Mike!

No, the 1 Meg is in series with the input transducer. The inputs on that opamp are something like twelve gigaOhms, so the 1k resistor one the non-inverting input is, for all practicle purposes irrelevent in this regard, there's no current through that 1k resistor.The 1 Meg is in parallel with the input transducer. The one feeding the non-inverting input is 1k.

Mike

No, the 1 Meg is in series with the input transducer. The inputs on that opamp are something like twelve gigaOhms, so the 1k resistor one the non-inverting input is, for all practicle purposes irrelevent in this regard, there's no current through that 1k resistor.

Mike

Yes, it occurred to me afterward that's what you meant. Even that is voodoo for me at this time.

What I did is take on a rather complicated project for first time, without studying enough of the fundamentals.

At any rate, I tried closing the cover and got some howling. Snipped a few unnecessary leads on the "ghetto wiring", placed a flat copper shield over the opamp board, and there is no howling with the cover almost closed. The tube sockets are on the cover adjacent to the tube-preamp board.

The socket of V1, which is now the second stage, should also be shielded, along with its peripheral components on the tube-preamp board. It was found when the amp was all-tube, V2 was rather sensitive and benefited from shielding. I used an aluminum stomp-box housing upside down without the cover, and it worked good; mostly for the 60 cycle hum. But if it picks up that, it must also be prone to RFI.

Also, the feedback resistor commonly referred to as R1 (the smaller value) is currently a carbon slide pot. I think it should be gotten rid of. Touching the metal housing makes noise, and picks up some 60 cycle hum from the open toroid that has yet to acquire its metal can.

Some wiring should also be shielded, and the perf board also has unecessary lengths of lead ends in hopes to save the components for reuse after they are pulled.

The preamp is very sensitive. It should be completely encapsulated with mumetal or "mag shield" and copper which meets with my "overkill" tradition. 3/32" aluminum has its limitations.

Thank you for the clarification on the resistor relationship.

It's all good, we're all still learning, we all start at the bottom and work our way up, and nobody ever reaches the top.

One thing that might help is to make sure that your circuit paths don't create any large loop areas, for example, the leads on a 9 volt battery should be twisted together to keep stray inductance low and noise pick-up antenna effect minimal. This principle should be applied wherever possible within the whole circuit to keep noise and distortion low.

Mike

One thing that might help is to make sure that your circuit paths don't create any large loop areas, for example, the leads on a 9 volt battery should be twisted together to keep stray inductance low and noise pick-up antenna effect minimal. This principle should be applied wherever possible within the whole circuit to keep noise and distortion low.

Mike

just touching the 100k definitely picks up some RFI and a little 60 cycle.

It will when not connected. It's the 1Meg resistance that causes the issues you hear. The input impedance has to be 1Meg though to load the guitar coil correctly. The GC resistance should be in parallel with the 1Meg, as far as i'm aware, so the actual input resistance as seen my the OpAmp is around 10 times less. Well it would be without those extra resistors you put in series.

You don't need the 1k resistor.

But do NOT get hung up on resistor noise, in fact you can forget it, & about using resistors in parallel. Also 1/2 - 3/4 Wattage resistors should be fine.

Ok, got two different ones in the chamber, but where is the "high" impedence that you refer?

I overlooked the fact that you're already using an FET OpAmp = TL072. If it wasn't i was talking about changing it for one.

A unity gain at the output of the first half, since there is some loading by the feedback circuit.

You could do, but i don't think it will make any difference.

Touching the metal housing makes noise, and picks up some 60 cycle hum from the open toroid that has yet to acquire its metal can.

It will, so don't. You need to screen the whole circuit in a metal box & ground it via the signal ground. Also when the pot thread is screwed onto it the problem will disappear.

It's all good, we're all still learning, we all start at the bottom and work our way up, and nobody ever reaches the top.

One thing that might help is to make sure that your circuit paths don't create any large loop areas, for example, the leads on a 9 volt battery should be twisted together to keep stray inductance low and noise pick-up antenna effect minimal. This principle should be applied wherever possible within the whole circuit to keep noise and distortion low.

Yes, but I should have acquired some books on guitar preamps, and read a few more articles and forum posts. If I had, I would have not used the bootleg SLO-100 preamp board, since it's much easier to modify a turret board (Aiken's suggestion).

This amp is sensitive to loops and lead placement. I really should start setting the final harness and see what happens.

Everything is twisted or shielded. I would use twisted/shielded pair, but there is only one place that it can be used, and it's so far down the chain, it makes no difference. The second conductor could be grounded to improve the shielding. I heard of the technique used when the shield is ground and connected at both ends.

If it looks like I will stick with the opamp-preamp arrangement, then I will order a real board made for this kind of thing. ESP has one and is reasonably priced. It has sockets for two opamps, but I can use the second one for an FX loop recovery stage.

The carbon slider was replaced with a metal film but to no affect. Anyway, the board and most of the peripheral opamp components are antennas, for sure.

There are now "low noise" capacitors by Wima. What distributor has them, I don't know? I would use them around the opamp just for GP.

Thanks much for your suggestions and encouragement.

It will when not connected. It's the 1Meg resistance that causes the issues you hear. The input impedance has to be 1Meg though to load the guitar coil correctly. The GC resistance should be in parallel with the 1Meg, as far as i'm aware, so the actual input resistance as seen my the OpAmp is around 10 times less. Well it would be without those extra resistors you put in series.

You don't need the 1k resistor.

But do NOT get hung up on resistor noise, in fact you can forget it, & about using resistors in parallel. Also 1/2 - 3/4 Wattage resistors should be fine.

For $7 I will get two quieter ones anyway to experiment with. OPA2134 & LM4562. They have better specs as well. I did notice a ever-so-slight "emptiness" with the TL072 in front, compared with all-tube. I have very good ears.I overlooked the fact that you're already using an FET OpAmp = TL072. If it wasn't i was talking about changing it for one.

I believe that, too. A tube grid draws almost no current. The only "load" is the output coupling cap with a 1M grid leak.You could [use second half as buffer], but i don't think it will make any difference.

The only other thing I can think of is terminating the unused opamp. All the pins are open. I read that problems can result leaving them unconnected.

I have been putting off the purchase of Mag Shield from "Less EMF" because it was $57 shipped for a size worth paying the substantial shipping/handling fee. But it's perfect and can be trimmed with shears and soldered (supposedly without performance reduction). Once it's enclosed, it would be easy to test additional shielding materials, if they are necessary. I understand copper and steel have different EMF performance depending on the frequency.....You need to screen the whole circuit in a metal box & ground it via the signal ground. Also when the pot thread is screwed onto it the problem will disappear.

I need to contain the inductive field from the tranny as well. It is annoying and throws experimentation results off, too.

Thank you very much.

Yes, I saw that in only one DIY project somewhere. He also raise the non-inverting inut to 1/2 the positive rail, claiming the scheme not only preventa any interference with the active circuit, but prevents the unused amp from degrading in performance over time, in case it may be used in the future.About that 2nd opamp, if you have "extra" opamps that don't get used, you should connect the output to the inverting input for unity gain and ground the non-inverting input to minimize noise.

Mike

What I have never done is study the internal schematic of the typical opamp. This would help in understanding things like how the input circuit resistances are effectively paralleled or in series, as mentioned above.

Thank you.

You don;t need anything fancy to cover the open side of the chassis. In commercial amps we see aluminum foil and metal window screen. Peavey uses conductive paint.

There is no open part. It is a fully enclosed aluminum box with removable top. I put a temporary hinge on it since most of the time it would be open for testing, and closed on occasian for RFI and wiring scheme tests. That's how I proved the pre-preamp board needs at least a minimal shield over itself.

I have two circuits that are switchable on V4, the last stage with Cathode Follower. One switches a cathode bypass cap on/off, and the other does the bootstrap (according to Blencowe) which increases the output close to the mu of the tube.

I understand there is no way to get an amp that has even just one tube to be completely silent with gain, treble, mid and volume all set to ten (short of a noise gate near the end of the chain).

Yes, I saw a recommendation for amps with the traditional metal chassis, with aluminum under it to block RFI/EMI.

But aluminum in general has poor shielding qualities, whether for RFI or EMI from the tranny. Mine is inside the box because it's a torroid, but still is noisy. If there is one, it should have it's own shield, or if there are two in a stereo, for instance, if they are mounted back to back with the output wire sides facing each other, the fields cancel.

Thank you for your heads-up on the shielding.

Bit past their day now, but tobacco tins used to be great for building preamps in (either audio or RF), nice and easy to solder to and great screening.

They have been used for years for both valve and solid state.

Good idea. The "tin" is actually steel. They can be had in flea markets, yard sales, and surplus/used stores around here.

I stripped a 2000 vintage color projection TV that has an all-wood cabinet. Certain areas of the boards were enclosed with mumetal shields. If I lay down the caps, they coluld be used.

Interestingly, the are not totally solid on top. They have somewhat intricate cutout patterns that seem to be purposely designed. One consideration is probably ventilation.

Update

Well, it looks like the noob did it, with the help of everyone's suggestions.

Experimenting with shielding in various ways, proved it was not resistor noise or opamp noise. It was differential mode RFI from the power line.

I had a common mode power supply filter in there that had an X2 in front and another at the output, as it was designed for a 2 wire, ungrounded system.

I remembered a recommendation for solid state topology (somewhere), to use a Qualtek 851-03/004 which has the first cap up front and two caps bridged across the secondary which are grounded to the chassis in the center. http://www.qualtekusa.com/Catalog/EMI_Filters/pdf/85103004.pdf

Now when the cover is closed, the hiss diminishes greatly. It is quiet enough for bedroom levels. Complete silence will require some kind of noise gate, as all tubes, resistors, and silicon have some thermal hiss. But at least now the design won't have to be so complicated in order to make it transparent, since the degree of suppression required is much less than before.

Thank you again everybody.

Well, it looks like the noob did it, with the help of everyone's suggestions.

Experimenting with shielding in various ways, proved it was not resistor noise or opamp noise. It was differential mode RFI from the power line.

I had a common mode power supply filter in there that had an X2 in front and another at the output, as it was designed for a 2 wire, ungrounded system.

I remembered a recommendation for solid state topology (somewhere), to use a Qualtek 851-03/004 which has the first cap up front and two caps bridged across the secondary which are grounded to the chassis in the center. http://www.qualtekusa.com/Catalog/EMI_Filters/pdf/85103004.pdf

Now when the cover is closed, the hiss diminishes greatly. It is quiet enough for bedroom levels. Complete silence will require some kind of noise gate, as all tubes, resistors, and silicon have some thermal hiss. But at least now the design won't have to be so complicated in order to make it transparent, since the degree of suppression required is much less than before.

Thank you again everybody.

Last edited:

Originally Posted by ITPhoenix

proved it was not resistor noise or opamp noise.

Glad you got it sorted, & i was able to help some

Glad you got it sorted, & i was able to help some

Yes, I grounded the input and then the output of the opamp which resulted in zero noise. But reducing resistor values didn't seem like the answer.

Well, anyway the shielding was not producing the expected results. I started with a sheet steel sandwitch which worsened the situation, and even more so when they were grounded! Yet it improved when ungrounded and touched with my ungrounded finger. I presume that action imposed some RFI from my body onto the steel, and cancelling some of what was in the circuit.

It was as if something was being generated internally. That's when I gave the filter a shot.

I need to check what happens when only the mains hot and neutral are used.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Live Sound

- Instruments and Amps

- Guitar opamp Pre-amp input resistors