The five electrolytic caps (under the metal dome) on my dad's AB763 are fifty years old, leaking & smoking--they need replacement.

Which make/model of electrolytic capacitors should I replace them with? Or does it matter? I am guessing it matters. 20MFD 500VDC x 3 , 70MFD @ 350VDC x 2 are currently in it.

Which make/model of electrolytic capacitors should I replace them with? Or does it matter? I am guessing it matters. 20MFD 500VDC x 3 , 70MFD @ 350VDC x 2 are currently in it.

Which make/model of electrolytic capacitors should I replace them with? Or does it matter? I am guessing it matters.

No, not at all - the values aren't very critical either.

The problem is likely to be finding suitable replacements, not having a plethora of choices

Some people are inclined to use a high quality cap like a sprague. A inexpensive chinese unit will work but may not be the right choice for a collectable nice amp like that.

If it was mine I would not be afraid to use a inexpensive unit if I had the correct ones laying around. But, if it was a customer's I would have them step up for the good ones. Come-backs suck!

try these http://thetubestore.com/sprague.html

If it was mine I would not be afraid to use a inexpensive unit if I had the correct ones laying around. But, if it was a customer's I would have them step up for the good ones. Come-backs suck!

try these http://thetubestore.com/sprague.html

Last edited:

With all due respect to Sprague, they are no longer any better than others in the industry.

In fact, if you cut open the current production Sprague Atoms they are nothing more than a tiny component inside a needlessly big can.

Best bang for the buck these days in guitar amp caps are F&T.

They make a great 22uf/500V as well as 80uf/450V

You might end up a tiny stiffer in the supply but from a cost effectiveness standpoint,

Spragues = $55.00-$65.00 for all 5 caps

F & T = $30.00-$35.00 for all 5 caps

Exact values will be difficult to locate since even sprague vendors do not seem to stock the original values anymore.

In fact, if you cut open the current production Sprague Atoms they are nothing more than a tiny component inside a needlessly big can.

Best bang for the buck these days in guitar amp caps are F&T.

They make a great 22uf/500V as well as 80uf/450V

You might end up a tiny stiffer in the supply but from a cost effectiveness standpoint,

Spragues = $55.00-$65.00 for all 5 caps

F & T = $30.00-$35.00 for all 5 caps

Exact values will be difficult to locate since even sprague vendors do not seem to stock the original values anymore.

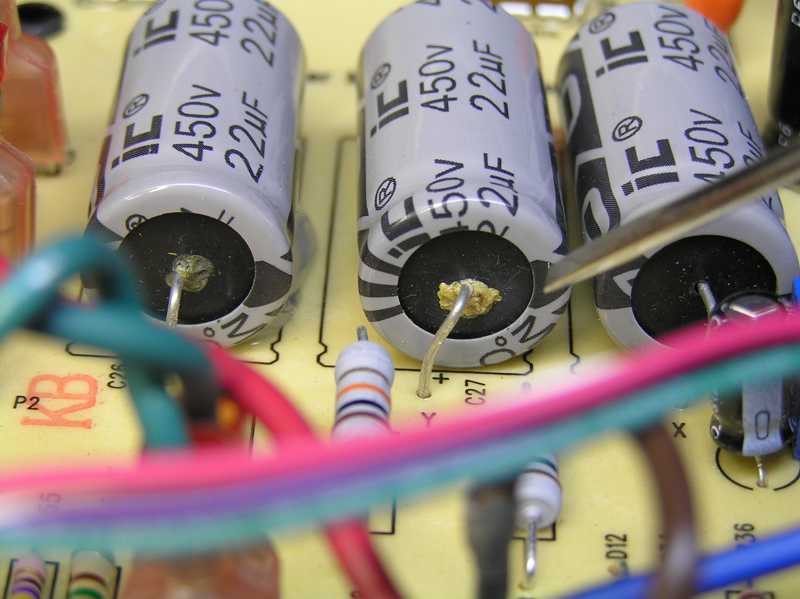

I like IC- Illinois Capacitor, but I'm not sure it makes much difference. I'd stay very close to factory values.

I have used IC's on several occasions and had no complaints at all with them.

They are in most cases even lower cost than F&T.

That Said,

not long ago they were pretty much thought of as junk after a couple bad runs that landed in Fender Blues Deluxes or Blues Juniors, I forget which.

Lots of pictures on the web of failed ones from back than.

Thanks for all the replies. I ended up going with a set of F&T's.

I installed them correctly and checked all my solder joints. The amp won't turn on. The power light doesn't turn on and the fuse is good. It's getting AC voltage at the input--I measured that. The three smaller caps get charged up with like 7-17 volts and the 2 bigger ones I've seen at a few volts--after turning off.

I don't know what was damaged the last time it was turned out (it was smoking from the bad caps).. I figured it would be working again after replacing the caps.. sigh.

Well thanks again for the help.

I installed them correctly and checked all my solder joints. The amp won't turn on. The power light doesn't turn on and the fuse is good. It's getting AC voltage at the input--I measured that. The three smaller caps get charged up with like 7-17 volts and the 2 bigger ones I've seen at a few volts--after turning off.

I don't know what was damaged the last time it was turned out (it was smoking from the bad caps).. I figured it would be working again after replacing the caps.. sigh.

Well thanks again for the help.

Well, it's a very straightforward circuit.

Problems are not just "bad parts", that's only half of the picture.

You must check *connections* too.

Getting 120 or 240V "at the input" is just the beginning.

1) with the amp unplugged, switch it on and measure continuity across hot and neutral plug pins.

Switch it off and on to check power switch.

2) now plug it into the wall socket, turn it on.

**CAREFULLY** measure voltage across transformer primary (those wires are soldered somewhere, either switch or fuse), does wall voltage reach the transformer?

3) then **CAREFULLY** measure voltage across secondaries, both 6.3 V filaments and HV secondaries. What do you get there?

4) follow 6.3V wiring towards tube filaments and pilot light, does 6.3V reach them?

And so on and on.

Good luck.

Problems are not just "bad parts", that's only half of the picture.

You must check *connections* too.

Getting 120 or 240V "at the input" is just the beginning.

1) with the amp unplugged, switch it on and measure continuity across hot and neutral plug pins.

Switch it off and on to check power switch.

2) now plug it into the wall socket, turn it on.

**CAREFULLY** measure voltage across transformer primary (those wires are soldered somewhere, either switch or fuse), does wall voltage reach the transformer?

3) then **CAREFULLY** measure voltage across secondaries, both 6.3 V filaments and HV secondaries. What do you get there?

4) follow 6.3V wiring towards tube filaments and pilot light, does 6.3V reach them?

And so on and on.

Good luck.

If it used to power up, and now after a cap swap it no longer does, then the first suspect must be your work. I assume you pulled the board out, or at least freed it, so I'd wager some connection is mising or loose, probably a wire that leaves the board. Or you have pushed one of the wires of the mains circuitry onto the wrong push post.

Hrm, all I did is remove the aluminum cover over the caps.. then desolder each cap and soldered a new one in its place with correct polarity. I just soldered to the existing joints.. was very simple task and all the wires are connected still. I also did continuity checks on each solder joint and components connected to those joints.

Ok, so I determined it was a bad fuse holder that kept me from getting voltage to the circuit. (Did a continuity check and was infinite resistance--even when I wiggled the leads to it and pressed them in.)

I tried to temporarily solder the leads to the fuse directly but the fuse didn't have the right metal to take on solder. (The fuse is good btw, I did a continuity test.)

So I risked it and connected the wires directly together. Then I plugged it in and the power light came on then after a couple seconds it went out--I figured the cord came loose from the wall. I then plugged it back in and the power light came on for another second then a big spark came from the wall with black powder smoke and the circuit breaker broke connection.

Go figures, it would short .. I'll never risk not having a fuse again.

So I have no idea what's wrong now. When it was initially smoking with the bad caps it did not blow the fuse.

I guess I can buy a NOS fuse folder for around $9 off ebay.. I'll start there.. and buy a few fuses.

I tried to temporarily solder the leads to the fuse directly but the fuse didn't have the right metal to take on solder. (The fuse is good btw, I did a continuity test.)

So I risked it and connected the wires directly together. Then I plugged it in and the power light came on then after a couple seconds it went out--I figured the cord came loose from the wall. I then plugged it back in and the power light came on for another second then a big spark came from the wall with black powder smoke and the circuit breaker broke connection.

Go figures, it would short .. I'll never risk not having a fuse again.

So I have no idea what's wrong now. When it was initially smoking with the bad caps it did not blow the fuse.

I guess I can buy a NOS fuse folder for around $9 off ebay.. I'll start there.. and buy a few fuses.

Last edited:

My BF checked all the diodes in the rectifier and said they were working properly (current flowing only in one direction). He thinks it's probably a bad transformer. If this is the case, I don't know why it didn't blow the fuse initially, when the old caps started smoking.

Does anyone have the schematic for AB763? I've tried to find it to no avail.

A simple google finds multiple sites with it.

Attachments

So I risked it and connected the wires directly together. Then I plugged it in and the power light came on then after a couple seconds it went out--I figured the cord came loose from the wall. I then plugged it back in and the power light came on for another second then a big spark came from the wall with black powder smoke and the circuit breaker broke connection.

PLEASE do yourself a favor and send that amp to a Tech.

Besides the obvious safety problems, it will end up being *cheaper*.

Obviously you should have followed your gut and not jumped the fuse, I would chalk that up as a learning expierience, a line you don't cross ever again. You need to correct the safety feature of your amp first and then I think befor I went and ordered a transformer I would disconnect the secondaries (Heater and HT) and see if the fuse blows, if it doesn't may not be your transformer. If you have any reservations you should follow JMFahey's recommendation.

Last edited:

Transformers usually don't just go bad. There has got to be a cause.

I would step back for a moment, leave the power disconnected, and run a few tests with a multimeter. Are any resistors blown? Etc. You don't want to risk making another mistake and completely blowing up the wall.

Buy and oscilloscope and learn how to use it if you plan to do much more diagnostic work. These are extremely useful.

I would step back for a moment, leave the power disconnected, and run a few tests with a multimeter. Are any resistors blown? Etc. You don't want to risk making another mistake and completely blowing up the wall.

Buy and oscilloscope and learn how to use it if you plan to do much more diagnostic work. These are extremely useful.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Live Sound

- Instruments and Amps

- Which Brand Electrolytic Caps for Fender AB763?