Finally my M2 project is ready, well almost. I’m very pleased with the result. A few things is still on the todo list.

M2Clone and PSU boards from Tea-Bag (http://www.diyaudio.com/forums/blogs/tea-bag/923-dual-rail-power-supply-power-amplifier.html, http://www.diyaudio.com/forums/blogs/tea-bag/203-m2clone-boards-120mm-ums-spacing.html ).

Caps: 8 x 15000uF

Enclosures from HIFI2000.it Dissipante 4U 300mm (little tight but should dissipate the heat. I let You know).

Components mostly from Tea-Bag’s BOM (resistors from Vishay RN60D-serie and two pairs of exotic Fukushimas)

300VA transformer from Toroidy.pl, dual 18V secondaries.

Schematics from firstwatt.com and tea-bags blog.

Bypass or no bypass capacitors(?), I went for the bypass alternative.

I went for Harris instead of IRFP9240 described by Tea-bag(http://www.diyaudio.com/forums/blogs/tea-bag/203-m2clone-boards-120mm-ums-spacing.html).

Inrush: thermistor CL-60

Filter on main: X2 0.47uF parallell(!) on power lines (230V)

It seams like color by numbers but it was not, but fun. After a lot of reading and couple months looking at the parts I tossed them in the case and whisked around with a solder iron. The M2 clone became ready for smoke test. No smoke, puh.

Observations:

After a couple of hours the heat sinks settled to 45-50°C, 20-25°C above ambient. The 300VA transformer working 200VA at nominal, perhaps little to high. The Fukushimas bias ing at 0.648V-0.662V with offset 2mV. The difference is probably because the Harris. The transformer buzzing a bit, ground-loops? Small speakers reveals a small 50/100/150Hz hum.

Sound:

After smoke test and soundest I decided to hook it up to the bigger speakers. I let it warm up with low volume for half an hour. I took a seat in the sofa and raised the volume to comfortable 60-70dB. Happyface!! The sound is amazing, detailed, clear but still the dash of softness I like. Amazing detailed base, mid and top and with natural attack. My ears agree with the distortion free clarity. My tube amp have a bigger voices at mid range so compared to M2clone it appears the voices is higher. I am convinced the tube amp is not the accurate reference but the one I can compare with.

In silent room the transformer is buzzing. To get rid of the hum and buzz I plan for a hole new set of cables with hopefully rigorous routing. The power cables now is in complete chaos and ground loop friendly. Is the transformer to small? Sensitive capacitors in PSU? The new power cables are going to be tined solid copper tightly twined firmly against chassi. If someone have recommendations for a remedy I receive them thankfully.

I miss the sound of my M2. It’s very addictive.

*DC-bocking, always(!) but no effect.

*Ground-star in chassi near main inlet, check.

*Thermistor between PSU-G and chassi, no effect.

*R10 5W in parallell with X2 0.1uF between PSU-G and chassi, no effect.

*Disconnect transformer ground, no effect

I have the same hum issue and have a whole thread on it. It looks like the signal transformer picks up hum from power transformer. I verified by moving the power trafo outside the case. Also measured EMI field with trafo inside vs outside.

I like the sound of my M2 except for the hum. I bought some mu-metal shielding good the signal trafos. Have not had a chance to try yet. I have similar 4U 300mm dissipante case as well. My power trafo also buzzes. When I switch to smps the hum goes away (same grounding scheme).

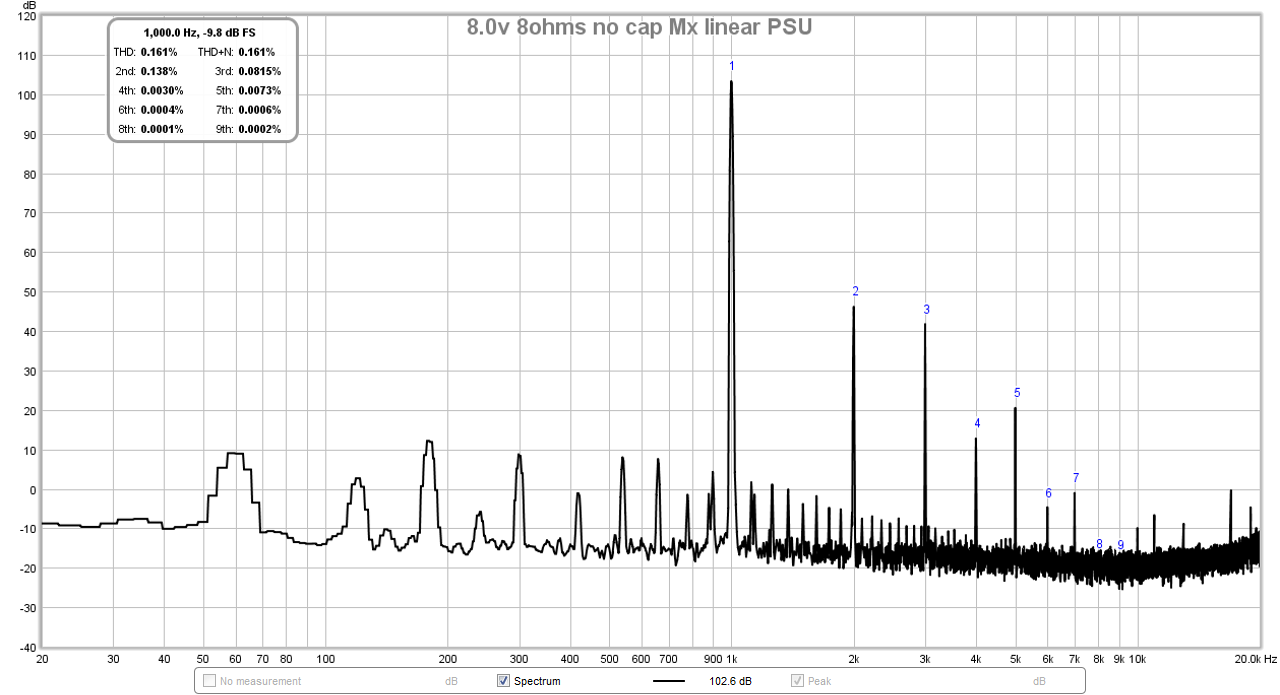

Strange Forest of Noise with Linear PSU

Here is linear trafo PSU for 8vrms into 8ohms:

Here is same thing with two 24v 5amp SMPS bricks in series and feeding same CRC filter bank:

Last edited:

@xrk971 I got a new transformer as replacement, 300VA. Toroidy.pl are great. I also switch the cable work to solid cables "bolted" to chassi bottom(ground) using only PSU from Tea-Bag. Now it is silent. I could still here a hum if I put my ear against the 15" but otherwise silent. I could upload some pictures but I think I'm not allowed, yet.

Cables: AlphaWire solid copper tinned with mPPP isolation and a thicker to ground star near power inlet.

Cables: AlphaWire solid copper tinned with mPPP isolation and a thicker to ground star near power inlet.

I could still here a hum if I put my ear against the 15" but otherwise silent.

I play M2 with triode preamplifier.

This one have gain low or high switch option.

Without to much gain from preamp my M2

is nice quiet on 12" inch full ranges and non use crossovers.

What is Gain Structure? - diyAudio

Kindest regards

@xrk971 I got a new transformer as replacement, 300VA. Toroidy.pl are great. I also switch the cable work to solid cables "bolted" to chassi bottom(ground) using only PSU from Tea-Bag. Now it is silent. I could still here a hum if I put my ear against the 15" but otherwise silent. I could upload some pictures but I think I'm not allowed, yet.

Cables: AlphaWire solid copper tinned with mPPP isolation and a thicker to ground star near power inlet.

Good to know but my issue with hum originates from EMI pickup by small signal transformer on the PCB. When I move the mains transformer out of the case it goes away.

Anyone have any tricks for creating a nice mu metal enclosure for the already-installed edcor? I have the plain 0.01x4x12" sheet material from McMaster, not adhesive backed. Looks like I could also slip a piece under the Edcor and maybe even on the backside of the PCB just for a belts and suspenders effect. Build a little hand brake? Use a sheetmetal bending software program? Wing it with some pliers and snips? New territory for me.

BK

BK

I don't think you'll be able to hear the difference between a pliers-and-snips version and a sheet-metal-brake version, but you'll certainly be able to see it. Whether or not that matters is something only you can answer.

If the answer is yes, there are lots of hobby machinists around in the Bay Area. Do some googling to find one of the clubs (I think the one I was in was called South Bay Metalworkers or something) and then ask if you can use someone's brake for 10 minutes.

If the answer is yes, there are lots of hobby machinists around in the Bay Area. Do some googling to find one of the clubs (I think the one I was in was called South Bay Metalworkers or something) and then ask if you can use someone's brake for 10 minutes.

I don't think you'll be able to hear the difference between a pliers-and-snips version and a sheet-metal-brake version, but you'll certainly be able to see it. Whether or not that matters is something only you can answer.

If the answer is yes, there are lots of hobby machinists around in the Bay Area. Do some googling to find one of the clubs (I think the one I was in was called South Bay Metalworkers or something) and then ask if you can use someone's brake for 10 minutes.

Great suggestion - thanks. Yes, looks are important for me. A nice little box out of sheet metal seems to take some skill and proper tools!

BK

Yes, I did not want to use IRFP9240 from Vishay, It did not sound as good as the Harris part.

I was not able to source any Harris IRFP240 parts.

Nelson I beleived use use Fairchild parts, but those are REALLY hard to get now Lots of fakes. Toshiba parts I believe are easier to find, but takes more tweaking (which I have not bothered with).

I was not able to source any Harris IRFP240 parts.

Nelson I beleived use use Fairchild parts, but those are REALLY hard to get now Lots of fakes. Toshiba parts I believe are easier to find, but takes more tweaking (which I have not bothered with).

Hi all!

I have a quick question

I my first build had some offset but I have ended up replacing the R7 with 56k amd needed up in a couple of tens mv

In the last build I have used R6 as 56k and ended up with an offset of +600 mv on each of the channels

A dumb question should I reduce the value of R7 or better increase the value of r6 to rove the positive offset?

Or in a ither way which resistor adds the positive and negative offset

I guess R7 adds to the positive offset, while R6 for the negative, right?

I have a quick question

I my first build had some offset but I have ended up replacing the R7 with 56k amd needed up in a couple of tens mv

In the last build I have used R6 as 56k and ended up with an offset of +600 mv on each of the channels

A dumb question should I reduce the value of R7 or better increase the value of r6 to rove the positive offset?

Or in a ither way which resistor adds the positive and negative offset

I guess R7 adds to the positive offset, while R6 for the negative, right?

Tea-Bag...I found your offering for the M-2 through the Pass Labs forum on DIYAudio.com. Is there a build guide?

I believe he still has a downloadable BOM

Also a special build section with descriptions and photos

FR

Tea-Bag...I found your offering for the M-2 through the Pass Labs forum on DIYAudio.com. Is there a build guide?

Here is the blog I wrote about it. It gives some guidance about the boards.

I do not offer step by step build guides in general.

M2Clone boards with 120mm UMS spacing - diyAudio

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Group Buys

- GB Pass M2 Clone Boards with 120mm UMS spacing by Tea-Bag