my last speaker (jordan MLTL)

Vent out the bottom, 31". I took a look again & remembered that I installed the vent tube on a 3/4" wood "plate" that's screwed in place, so that I can change the vent length by removing the plate.

GM said:OK, you chose a length in-between the short and tall versions, so I'm curious what vent size/length you used. Or did you build the 31" version with the vent extending out the bottom?

Vent out the bottom, 31". I took a look again & remembered that I installed the vent tube on a 3/4" wood "plate" that's screwed in place, so that I can change the vent length by removing the plate.

An externally hosted image should be here but it was not working when we last tested it.

johninCR said:I need to throw my 2 cents in as well. GM is a great asset to these forums. His knowledge, experience, and willingness to share are greatly appreciated by those with sense enough to listen.

Well said. Seconded.

dave

fred76 said:

Hi GM,

You were very clear. I understand what you are saying wrt proper horn's expansion = higher gain and BW... Nagaoka was actually besides the point (different by having Right Angled bends and such), I only cited it coz it also had sharp bends. I think the way I posted my orignal query wasn't really clear. Coming from another country my (english) syntax takes on another meaning most often than not. Sorry about that.

My question was really in reference to the the zine review that Dave Panet10 posted some pages back:

*taken from review*

http://www.6moons.com/audioreviews/gemmeaudio/108_2.html

GemmeAudio touts its enclosure for having NO sharp bends. So I was thinking if sharp bends really affect performance even if the horn is properly designed with folds having proper expansion etc.

Anyways, just a while ago I remember reading a post of yours in the BiB thread, busting the myth that sharp bends/points are a bad idea:

http://www.diyaudio.com/forums/showthread.php?postid=894001#post894001

http://www.diyaudio.com/forums/showthread.php?postid=893467#post893467

I guess that somewhat sheds some light on my orignal question. A smooth CNC'd horn path really looks neat though. Thank you.

regards,

fred

Greets!

OK, obviously I know English isn't your native tongue, but your writing is better than many Americans (sad to say), so I can only take it at face value (IOW you mean what you write, whether it be a fact and/or innuendo, personal or otherwise) until I can elicit further clarifications, if any.

Anyway, I'm still not sure you're understanding what I've tried to explain WRT horn bends. Horn bend geometry is frequency dependent, so if the bend is acoustically large enough for the desired HF response to pass without causing a discontinuity (reflection) back to the throat or lose too much energy due to friction/refraction, then it doesn't matter how 'tight' it physically looks. As the frequency decreases, its shape becomes increasingly irrelevant because the WL size/horn Vb ratio becomes so great that its acoustic power isn't measurably reduced by tight bends and/or discontinuities in the expansion. FWIW I find this easier to understand by visualizing different size bubbles passing through different bend geometries with the understanding that any impediment to its passage is amplified by the fact that it's oscillating at ~770 mph/f.

From this we see that the bend's spiral geometry must increase with increasing frequency since acoustic energy is falling at 1/f and why W.E.'s early cinema horn's 10 kHz upper limit requires such a large 'Scorpion tail': http://www.audioanthology.com/images/15a r.jpg

Another thing that has to be considered for max gain/BW is the distances between the bends when other than a spiral expansion is used.

GM

Hi GM,

Thanks for elucidating further. I get what you mean now that horn bends are freq dependent, and the higher the freq the more criticial it is not to have friction/refraction that would cause reflections back to the throat...

some more WE type spiral horns:

http://www.gokudo.co.jp/News/n2006Qtr2/jeju 354_2.jpg

http://www.gokudo.co.jp/News/n2006Qtr2/jeju 392_thumb_2.jpg

regards,

fred

Thanks for elucidating further. I get what you mean now that horn bends are freq dependent, and the higher the freq the more criticial it is not to have friction/refraction that would cause reflections back to the throat...

some more WE type spiral horns:

http://www.gokudo.co.jp/News/n2006Qtr2/jeju 354_2.jpg

http://www.gokudo.co.jp/News/n2006Qtr2/jeju 392_thumb_2.jpg

regards,

fred

With reguard to some horns possibly being stepped resonant tubes I recall way back in the dim past when I was interested in Megaphone type exhasts, a sort of conical horn, on cars that an engineer whose name I can't recall but it sounded possibly Polish, had a theory on stepped pipes rather than megaphones so maybe this is a corollary to horn theory. Mike.

jamikl

jamikl

planet10 said:

Well said. Seconded.

dave

Greets!

Thanks guys, I appreciate it!

GM

Re: my last speaker (jordan MLTL)

Greets!

Ah, the layout I prefer from a technical POV since I haven't actually auditioned any of my Jordan designs. Do you use any EQ or just listen off axis as TJ recommends?

GM

cheesehead said:

Vent out the bottom, 31".

Greets!

Ah, the layout I prefer from a technical POV since I haven't actually auditioned any of my Jordan designs. Do you use any EQ or just listen off axis as TJ recommends?

GM

fred76 said:Thanks for elucidating further.

some more WE type spiral horns......

Greets!

You're welcome!

Oh wow! I didn't think any of the ultra rare 13As had survived! Cool! An excellent example of how to do a complex wide BW horn folding!

GM

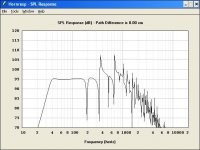

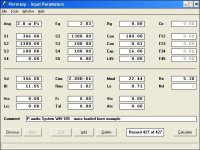

Hornresp MLH Design

David McBean has added mass-loaded horn modeling to the latest version of Hornresp. We began corresponding about two or three weeks ago, when I suggested the mass-loading feature, and he decided to take a look at the possibilities of mass-loading. He has been able to achieve some excellent-looking results from a mass-loaded BLH using the new version of his program, which can model mass-loaded horns as well as horns that have mouth constrictions. The ability to simulate conical segments with a negative flare has also been added while preserving the ability to model mass-loaded designs.

In my experimentation, mass loading appears to increase the apparent length of the horn, though efficiency is slightly reduced when compared to a horn that is not mass-loaded.

The version you're looking for is 16.40.

Provided are a few of the images that David sent me when he informed me that mass-loading capability would be added to Hornresp.

David McBean has added mass-loaded horn modeling to the latest version of Hornresp. We began corresponding about two or three weeks ago, when I suggested the mass-loading feature, and he decided to take a look at the possibilities of mass-loading. He has been able to achieve some excellent-looking results from a mass-loaded BLH using the new version of his program, which can model mass-loaded horns as well as horns that have mouth constrictions. The ability to simulate conical segments with a negative flare has also been added while preserving the ability to model mass-loaded designs.

In my experimentation, mass loading appears to increase the apparent length of the horn, though efficiency is slightly reduced when compared to a horn that is not mass-loaded.

The version you're looking for is 16.40.

Provided are a few of the images that David sent me when he informed me that mass-loading capability would be added to Hornresp.

Attachments

Re: Hornresp MLH Design

Greets!

Cool! Yes, that's exactly what it does. Common real world examples are the reverse megaphone exhaust systems that are de riguer in motorcycle design and the SuperTrapp adjustable tuning systems. For HIFI apps the benefits are obvious, but smoothest response requires the driver be placed along its path rather than end loaded, so is this an option? Ditto the tapped horn?

GM

Greets!

Cool! Yes, that's exactly what it does. Common real world examples are the reverse megaphone exhaust systems that are de riguer in motorcycle design and the SuperTrapp adjustable tuning systems. For HIFI apps the benefits are obvious, but smoothest response requires the driver be placed along its path rather than end loaded, so is this an option? Ditto the tapped horn?

GM

A very useful addition.

FWIW,you can sim a mass-loaded horn with any driver offset you like in Martin's BLH Sections worksheet, although you need divide the path into sections & enter the length & CSA at that point by hand. OTOH, unfortunately none of those sheets can sim a tapped horn, as Martin has little interest in them so it's great that Hornresp is becoming so flexible. Cracking little programme and big kudos to David for all the work he's put into it.

FWIW,you can sim a mass-loaded horn with any driver offset you like in Martin's BLH Sections worksheet, although you need divide the path into sections & enter the length & CSA at that point by hand. OTOH, unfortunately none of those sheets can sim a tapped horn, as Martin has little interest in them so it's great that Hornresp is becoming so flexible. Cracking little programme and big kudos to David for all the work he's put into it.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Mass loaded horn?