Aengus said:ust waiting for Dave's drawings.

Still not finished, but close enuff to start experimenting with...

dave

Attachments

Woah, that was fast. Thank you, Dave - this looks great.

What is it that's not finished - it looks pretty complete to me?

Regards.

Aengus

Still not finished, but close enuff to start experimenting with...

What is it that's not finished - it looks pretty complete to me?

Regards.

Aengus

Aengus said:SCD said:

SCD, what was the source for this? I was thinking that BB 1/8" would work fine for the outer curve, but the inner curve is likely to be pretty sharp. Lee Valley sells some very flexible stuff, but it's expensive and comes (from them) only in 2' x 2' sheets IIRC.

How flexible was the stuff you saw?

Regards.

Aengus

"Rubberply" either Reimer or PJ White in Victoria. I'd best not quote a price, since as an industrial customer, our quantity discount pricing is part of our profit margin

The material we use is 5-6mm thickness - 2 layers of Luan on synthetic(?) elastic core. For curved reception wall cases, 2 or 3 layers bonded with yellow PVA or 2-part epoxy glue (i.e. NOT white PVA or "Welbond") over a 3/4" plywood frame is pretty damn stiff. There are a couple of down sides - most notably that a finish layer of anything thinner than GP grade P-lam or 2 ply wood veneer will telegraph surface imperfections - it's also only slightly less fugly than OSB in its raw state - don't even think about "just paint" finish.

Aengus said:Woah, that was fast. Thank you, Dave - this looks great.

What is it that's not finished - it looks pretty complete to me?

Regards.

Aengus

some dimensions missing on the draft I saw.

Long Harvey, is that like John Holmes?

"This is 12", but I can't use it as a rule"

Re some of the queries -no, I haven't really considered a tiltback to the design -yet. But that's really one of the imponderables to a large extent -there's too many variables to consider. That's why Dave & I want these to be open-source to a large extent, like the Frugelhorn. There'll be long path versions of Iris and Bruce too, though they will likely need to be somewhat enlarged over the BVR types.

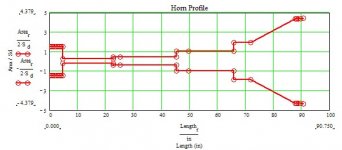

The design isn't completely done yet for this one -I want to do some detail work, though the response isn't looking bad at all as-is. BTW: the slope at the front and the strike plates can be angled, or stepped using multiple layers of boards a la Fostex / Nagaoka. I think Dave's been hanging fire because of this, but I haven't had tme to do any real design work at all for about a week now. Hopefully I'll be able to get some in tomorrow -I want to work via the impedence trace & impulse responses somewhat.

Once these are done, I'll start to look properly at dissimilar mouth-sizes for double horns -something GM and I have discussed, but which I haven't got around to doing anything about yet. All credit, as ever, to Dave for his CAD magic & enthusiasm.

The design isn't completely done yet for this one -I want to do some detail work, though the response isn't looking bad at all as-is. BTW: the slope at the front and the strike plates can be angled, or stepped using multiple layers of boards a la Fostex / Nagaoka. I think Dave's been hanging fire because of this, but I haven't had tme to do any real design work at all for about a week now. Hopefully I'll be able to get some in tomorrow -I want to work via the impedence trace & impulse responses somewhat.

Once these are done, I'll start to look properly at dissimilar mouth-sizes for double horns -something GM and I have discussed, but which I haven't got around to doing anything about yet. All credit, as ever, to Dave for his CAD magic & enthusiasm.

chrisb said:

Thank you. As to pricing, I accept that I'll get penalized for small quantity buying.

I wasn't thinking of a paint finish; for the outer curved wall, I was thinking either natural-finish on birch ply (so the outer layer would be 1/8" birch ply if it will take the bend), or possibly a thin layer of aluminum. The inside tightly-curved wall may pose a challenge for the 1/8" BB, and I'm not sure I want aluminum on the inside of the horn, so that's more of a challenge.

An alternative to all these strategies, of course, is to cold-mould it with cedar strips and epoxy. Hmmm...

I think they can all be inferred, though. I'll look again, but at this point what I'm probably going to do is to lay out half (top or bottom) and play with drawing curves for the outermost section of the horn.

Entertainment for the weekend, indeed.

Regards.

Aengus

"Rubberply" either Reimer or PJ White in Victoria. I'd best not quote a price, since as an industrial customer, our quantity discount pricing is part of our profit margin

The material we use is 5-6mm thickness - 2 layers of Luan on synthetic(?) elastic core. For curved reception wall cases, 2 or 3 layers bonded with yellow PVA or 2-part epoxy glue (i.e. NOT white PVA or "Welbond") over a 3/4" plywood frame is pretty damn stiff. There are a couple of down sides - most notably that a finish layer of anything thinner than GP grade P-lam or 2 ply wood veneer will telegraph surface imperfections - it's also only slightly less fugly than OSB in its raw state - don't even think about "just paint" finish.

Thank you. As to pricing, I accept that I'll get penalized for small quantity buying.

I wasn't thinking of a paint finish; for the outer curved wall, I was thinking either natural-finish on birch ply (so the outer layer would be 1/8" birch ply if it will take the bend), or possibly a thin layer of aluminum. The inside tightly-curved wall may pose a challenge for the 1/8" BB, and I'm not sure I want aluminum on the inside of the horn, so that's more of a challenge.

An alternative to all these strategies, of course, is to cold-mould it with cedar strips and epoxy. Hmmm...

some dimensions missing on the draft I saw.

I think they can all be inferred, though. I'll look again, but at this point what I'm probably going to do is to lay out half (top or bottom) and play with drawing curves for the outermost section of the horn.

Entertainment for the weekend, indeed.

Regards.

Aengus

Scottmoose said:Interesting. OK guys,

The time has come, the Moose said,

To talk of many things,

Of short double horns, and large filter chambers,

But mostly of long path double horns with small chambers for the FE126E and FE108ESigma.

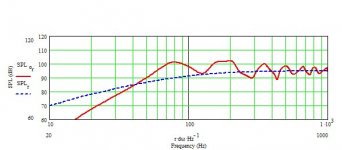

The Harvey, Iris & Bruce BVR designs appear to have gone down well generally, but it was always the intent to bring some sister models forward, with a long pathlength and small chamber. You didn't really expect them to be regular though did you? No? Oh good. Just got the first pass CAD drawings back from Dave & they have potential: see attached FR plot. They use the Nagaoka stepped expansion a la Fostex horns, for ease of construction, and to help cram the longest possible line into the box. Also, the best of my knowledge, while there are several MathCad designed horns out there, no-one's done a stepped horn from scratch in the worksheets before. Red rag to a bull.Besides, horns or notif you've heard a good stepped design, you'll know just how well they can work.

Same height as Harvey, a little narrower, and a little deeper. Plans should appear soon once we've made a few refinements. All credit to Dave for his CAD magic and his patience in being able to interpret my terrible hand-drawings and insane notation.

Haven't decided on a name for this one yet. Possibly Loreena (after Loreena McKennitt).

Scott

Scott, looking at your worksheet plot, it looks pretty good. However, what are you doing to avoid baffle step problems. From the look of the graph, you will still need a BSC. What formula did you use to derive your horn shape? Are you using exponential or are you using something more esoteric like Tractrix? I am quite intrigued by your designs and would love to know how you arrived at them. Thanks!

Tom

Aengus said:chrisb said:

Thank you. As to pricing, I accept that I'll get penalized for small quantity buying.

I wasn't thinking of a paint finish; for the outer curved wall, I was thinking either natural-finish on birch ply (so the outer layer would be 1/8" birch ply if it will take the bend), or possibly a thin layer of aluminum. The inside tightly-curved wall may pose a challenge for the 1/8" BB, and I'm not sure I want aluminum on the inside of the horn, so that's more of a challenge.

An alternative to all these strategies, of course, is to cold-mould it with cedar strips and epoxy. Hmmm...

Try "TruePly" 2layer veneer - also available from PJ White. (ask for Liz - maybe she can work you a discount) The thick wood backer is more than capable of covering small flaws in the core, and still quite flexible. I personally use the iron-on method (yellow glue, 15min standing time, and linen setting on dedicated clothes iron)

I think they can all be inferred, though. I'll look again, but at this point what I'm probably going to do is to lay out half (top or bottom) and play with drawing curves for the outermost section of the horn.

Entertainment for the weekend, indeed.

Regards.

Aengus

Give Dave a few more days (and buy him a Turkish coffee), he'll have a fully dimensioned set of drawings completed.

chrisb said:ive Dave a few more days

The next 4 days don't count... i'll be on a "visit relatives for christmas" trip.

dave

Harderror said:Scott, looking at your worksheet plot, it looks pretty good. However, what are you doing to avoid baffle step problems. From the look of the graph, you will still need a BSC. What formula did you use to derive your horn shape? Are you using exponential or are you using something more esoteric like Tractrix? I am quite intrigued by your designs and would love to know how you arrived at them. Thanks! Tom

In re the baffle step, nothing. Like most horns, they simply don't need it. That's why it's extremely rare to find a horn with a circuit in place.

With regard to the horn profile, it usually depends what sort of design I'm working on. With the BVR enclosures, I initially calculate the Vb and alignment I'm after, the size throat and horn mouth which will match said alignment, and then adjust the vent / horn profile for the lowest distortion. I usually start with a ~exponential flare and adjust from there. Usually ends up with that, or somewhere between that and a tractrix. For longer horns, I now usually start with a ~hyperbolic profile and work from there. The stepped designs, which work in a different way to horns usually favour length over all other factors -they're not too fussy about flare for obvious reasons!

Regards

Scott

Dave,

Do you have the detail plan for Bruce 1.1? Got the one you posted but as you said, there are still some missing parts and measurement. Really would like to build one and try them.

Have made the jump and bought a pair of Audio Nirvana 8 (my first introduction to full range) and built their BR cab. I am itching to try out some other cab that will allow me to reuse for other type of FR drivers later (like Fostex)

Do you have the detail plan for Bruce 1.1? Got the one you posted but as you said, there are still some missing parts and measurement. Really would like to build one and try them.

Have made the jump and bought a pair of Audio Nirvana 8 (my first introduction to full range) and built their BR cab. I am itching to try out some other cab that will allow me to reuse for other type of FR drivers later (like Fostex)

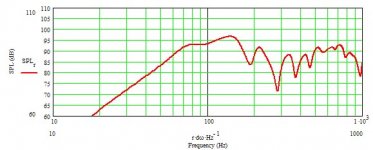

Scott, I am working a horn for my AN Super 8. I pretty much stick to the base formula for horn dimensions and CC dimensions with some mild tweaking. Ok, So here is my design (As you can see it is stepped, like the fostex, up until the end). As hard as I try I don't get mathcad to give me the graphs with the depth of bass that you are showing for your an 10 and fostex 106. The question is: are you getting the response because you are rolling in the TL response or does it have to do with something else that I m missing. As you see, I have the 3db shelf to fight the baffle step, but, the bass heads down hill at 80 Hz. This of course is a 1/32 compromised design. My guess is that put into a corner I will get the 37 Hz that it is designed for. On a wall, I will get probably 40-45. What do you think?

Tom

Tom

Attachments

fe108ez

Good morning from the land of ice and snow!

Have fe108ez drivers coming in the mail. I would like to build the 1st version 126e style horn. Don't really like multiple fold Fostex type horns. To use the original 126e style double horn, any recommended changes to the compression chamber[smaller?] and size of exit slot?can the original cc be tuned by adding mass inside to tune for the fe108ez?

doggie

Good morning from the land of ice and snow!

Have fe108ez drivers coming in the mail. I would like to build the 1st version 126e style horn. Don't really like multiple fold Fostex type horns. To use the original 126e style double horn, any recommended changes to the compression chamber[smaller?] and size of exit slot?can the original cc be tuned by adding mass inside to tune for the fe108ez?

doggie

hwong said:Do you have the detail plan for Bruce 1.1?

Coming. All the power outages have put a crimp in productivity on my 'puter. 1st we were out for a week. Power is now out again, after hurricance force gusts (180 km/hr) ripped out a lot of trees by there roots (2 50m 100 year old trees on my front lawn, just missing the house)

Patience required.

dave

- Home

- Loudspeakers

- Full Range

- Spawn of Frugel-Horn