I agree. That being said, I don't think the enable pattern is supposed to dampen anything.

It makes the cabinet less... lossy???

How and why, who knows? I admit the science is beyond me.

I'm adding it here because I can and I can't see it doing any harm. I'll do before and after on the exterior of the cabinets once they are done but then again, that will be subjective.

I tried to take a crack at the physics-based reason behind why the dots reduce pressure losses on the BIB EnABLE thread. I used the golf ball dimple analogy and simple scaling arguments to show similar flow regimes between the two systems. Some people don't think there is "flow" of fluid in a speaker but I would ask them why the Mach number is used at speaker ports. It is oscillatory flow. It is like people who say AC current isn't current because it doesn't move anywhere like DC...

I tried to take a crack at the physics-based reason behind why the dots reduce pressure losses on the BIB EnABLE thread. I used the golf ball dimple analogy and simple scaling arguments to show similar flow regimes between the two systems. Some people don't think there is "flow" of fluid in a speaker but I would ask them why the Mach number is used at speaker ports. It is oscillatory flow. It is like people who say AC current isn't current because it doesn't move anywhere like DC...

I get what you are saying but the pure math behind it goes over my head

(as I originally posted the article about the golf ball in Race-Car Engineering.)

I intuit more than I understand at this level.

The question, a question that I have is: why not dimples? Would be real easy to make a die and bash it into the wood.

Sorry for the OT

and now back to our regularly scheduled program-

I see this possibly having some effect on a driver cone that needs to be light fast and can't be damped otherwise. Just like the rings on some larger drivers or the star pattern on the Manger driver. But for everything else in the speaker, there are better methods to kill boundary layer and material resonances.

Frankly, I think it would be a pity to spoil the look of those fine old planks by plastering them in small ugly squares of plaster.

Frankly, I think it would be a pity to spoil the look of those fine old planks by plastering them in small ugly squares of plaster.

The final photos of my FIB build and a sound clip are in the foam core thread.

http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures-120.html

http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures-120.html

Wow... those look great xrk971. Congrats!

As for the plaster rectangles, those are for the inside of the baffles...

Outside, I will try tape first and then maybe some sort of discrete application of paint, varnish, I don't know... we'll see.

Progress on my end.

-andré-

As for the plaster rectangles, those are for the inside of the baffles...

Outside, I will try tape first and then maybe some sort of discrete application of paint, varnish, I don't know... we'll see.

Progress on my end.

An externally hosted image should be here but it was not working when we last tested it.

-andré-

Thanks B00B00. Will you apply anything on top of plaster and wood to seal it and make sure it doesn't flake off or does it stick pretty well?

Oh it sticks all right... had to vigourously scrape with a putty knife and then sand to remove the offending rectangles. Fine instruments are often finished on the insides and it can apparently affect the sonic qualities of the instrument so I might put a light coat of polyurethane... it might seal the wood and keep it from expanding and contracting (or slow the process down). That being said, I get the impression it might make the inside of the cabinet livelier and that... I'm not sure I want.

Made a Mini BiB in foam board...

How should I describe the sound then?

WOW, I'm stuck, feel a new addiction coming.

Of course they do not rattle any windows, but there are enough bass so that's really fun to listen to Vicious Delicious by Infected Mushroom.

But they need not be ashamed when they play Ohio by Over The Rhine or Joy to my soul by Oslo Gospel Choir.

A bigger one is on the way

This one uses Aura NS3-193-8A1 and Vifa DQ25SC16 that is not connected right now.

\M

How should I describe the sound then?

WOW, I'm stuck, feel a new addiction coming.

Of course they do not rattle any windows, but there are enough bass so that's really fun to listen to Vicious Delicious by Infected Mushroom.

But they need not be ashamed when they play Ohio by Over The Rhine or Joy to my soul by Oslo Gospel Choir.

A bigger one is on the way

This one uses Aura NS3-193-8A1 and Vifa DQ25SC16 that is not connected right now.

\M

Fantastic job Mag.  They look great and I bet they sound even better. Did you have to play with the stuffing much? I went through many iterations on stuffing levels and densities before I had a sound that I was happy with. Looks like you did the standard fill from the sharp corner to the bottom turn?

They look great and I bet they sound even better. Did you have to play with the stuffing much? I went through many iterations on stuffing levels and densities before I had a sound that I was happy with. Looks like you did the standard fill from the sharp corner to the bottom turn?

They look great and I bet they sound even better. Did you have to play with the stuffing much? I went through many iterations on stuffing levels and densities before I had a sound that I was happy with. Looks like you did the standard fill from the sharp corner to the bottom turn?

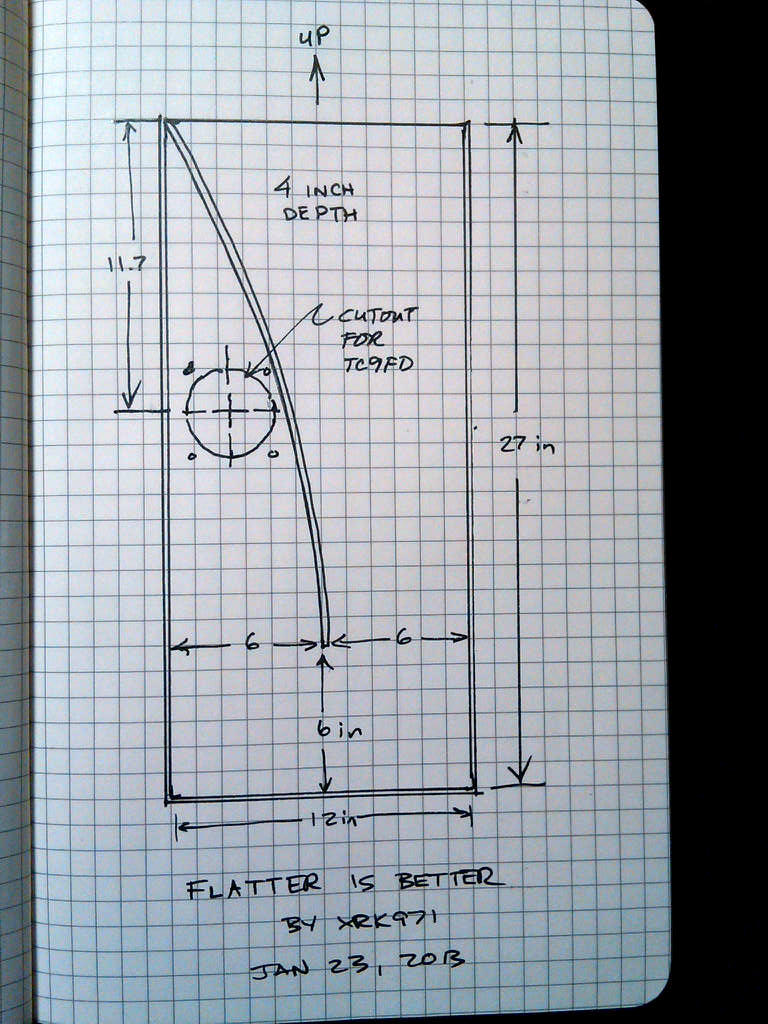

They look great and I bet they sound even better. Did you have to play with the stuffing much? I went through many iterations on stuffing levels and densities before I had a sound that I was happy with. Looks like you did the standard fill from the sharp corner to the bottom turn?Flatter is Better Plan for Vifa TC9FD driver. What is not shown are numerous vertical braces every 2 to 3 inches, braces would be aligned parallel to direction of flow (diagonal in the corners). Probably 25 to 30 2 in wide x 4 in tall pieces of 3/16 in thick foam core braces glued with hot melt to back panel and then with PVA to front baffle. Use 90 deg square guide to ensure braces are vertical and square when fastening to back panel with hot melt glue. I would put stuffing in closed end and loosely up the 180 deg turn. Adjust to taste. I think that there may be extensive bass with this design and it may require more stuffing than usual.

For those wishing to build this out of wood. You can still use plywood (I would use 1/4 in thick to keep it light so it can be hung on wall). Use the foam core just for the internal diagonal as it is easy to curve by scoring lines on the concave side.

I finished the FIB last night. I had to go to Dollar Tree to get just one sheet of foamcore to finish. Next thing I know I'm coming out the door with 10 sheets and 5 bags of glue sticks ($15!).

SurfaceTension,

Great! So you went with the design above? I actually ended up with the inverted V for my FIB. Curious how it sounds and looks? Pictures please I have yet to buy stuffing. I look around the house for old pillows that we don't use - just make sure to ask the boss before you can cut up her pillows!

I have yet to buy stuffing. I look around the house for old pillows that we don't use - just make sure to ask the boss before you can cut up her pillows!

Your dollar tree sells glue sticks? Where?

X

Great! So you went with the design above? I actually ended up with the inverted V for my FIB. Curious how it sounds and looks? Pictures please

Your dollar tree sells glue sticks? Where?

X

Last edited:

xrk,

Sorry, stupid day job gets in the way of my fun!

As with the cornu a bit of experimentation is needed with stuffing. Not sure I've got it right yet. I'm going to take them to my buddies place this weekend so I can compare directly with the 20" cornu. At first they seemed to have that midrange shout but with addition of Sonic Barrier behind the driver and more stuffing seems to mellow out. So far they seem to require quite a bit more stufffing than the cornu, good bass response, audible to 40hz range (according to my Bink test cd) nice at 50hz signal. I need to figure out measuring soon. I can play test tones but no way to measure. The man cave is getting a bit crowded at this point and placement is not optimal. At present I have them setting on the floor against the wall, no wall hangers mounted yet. Primitive evaluation. Overall from a musical standpoint I am very encouraged and will continue to work with the stuffing, placement and mounting hardware. I've sampled through some of my favorite music test cds and am encouraged with the results, just feel I haven't quite arrived yet.

And yes, my local Dollar Tree carries glue sticks now, 20 sticks 1$, nice!

I'll report back when I have some more time to listen and tune. Thanks for the plan xrk.

Sorry, stupid day job gets in the way of my fun!

As with the cornu a bit of experimentation is needed with stuffing. Not sure I've got it right yet. I'm going to take them to my buddies place this weekend so I can compare directly with the 20" cornu. At first they seemed to have that midrange shout but with addition of Sonic Barrier behind the driver and more stuffing seems to mellow out. So far they seem to require quite a bit more stufffing than the cornu, good bass response, audible to 40hz range (according to my Bink test cd) nice at 50hz signal. I need to figure out measuring soon. I can play test tones but no way to measure. The man cave is getting a bit crowded at this point and placement is not optimal. At present I have them setting on the floor against the wall, no wall hangers mounted yet. Primitive evaluation. Overall from a musical standpoint I am very encouraged and will continue to work with the stuffing, placement and mounting hardware. I've sampled through some of my favorite music test cds and am encouraged with the results, just feel I haven't quite arrived yet.

And yes, my local Dollar Tree carries glue sticks now, 20 sticks 1$, nice!

I'll report back when I have some more time to listen and tune. Thanks for the plan xrk.

Increasing net Vb = increasing acoustic efficiency, so wider and/or deeper will lower F3, etc. and Fb[p] will lower due to increasing port/terminus end correction for a given acoustic path-length and why I always recommend making a cab as large as practical for the intended app to reduce distortion and maximize tuning flexibility.

GM

GM

Last edited:

I need to figure out measuring soon. I can play test tones but no way to measure.

I'll report back when I have some more time to listen and tune. Thanks for the plan xrk.

Buy a Panasonic wm61a mic capsule from Digikey ($2 ea). Look up circuit schematic on web for wm61a and measurement - wire 3.5 mm plug from cheap old set of headphones to mic. Plug into mic input of pc and use Holmimpulse software and you are in business. Panasonic mic is being discontinued and replaced by another brand - wm61a has calibrated file for Holmimpulse, but is basically flat response from 20 Hz to 20 kHz.

The FIB took a lot of messing around with the stuffing. It took me at least 7 iterations to get it right. It helps to have measurement to see where problem is and to balance left and right.

Glad you are happy with plan and found it fun.

- Home

- Loudspeakers

- Full Range

- Terry Cain's BIB -why does it work and does anyone have those Fostex Craft Handbooks?