Progress is much slower than I planned for. Isn't it always? But I have been having some health issues as well. I had to take rest at times when I would ordinarily tinker around. Nevertheless, panels are cut to size, driver cutout is in place. I am cutting up damping material now and I have already pre-drilled the panels (no space for extended glue setting, not enough clamps, so glue and screw it is). I am going for that IKEA assembly feeling. Hopefully even the damping will be on the panels when I screw it together (with a battery powered drill), it should be really fast.

What could possibly go wrong? 🤣🤣🤣🤣🤣

What could possibly go wrong? 🤣🤣🤣🤣🤣

That is exactly how I built my speakers for the most part because I didn't have enough and big enough clamps to hold everything down.so glue and screw it is

Hold it together with a few clamps, drill the holes, then glue&screw it. And while the glue hardens, you can continue working on the other speaker.

Your battery powered drill failing while you started glueing and screwing down one side. Happened to me: A few screws done. Lots more to do quickly before the glue becomes too hard so the wood doesn't sit together well anymore. My wrist hurt after those ten minutes of intense srewing it down by hand, haWhat could possibly go wrong? 🤣🤣

what speakers will you be putting in, and did you also use the BIB-excel-sheet?

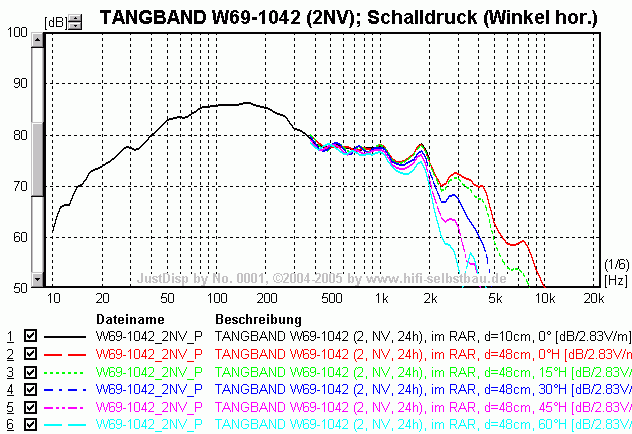

I am doing one BIB with a definite bass driver, the Tangband W69-1042. See the attached frequency response measurements from https://www.hifi-selbstbau.de

Whoops.

Anyway, it's already old, I think it's still in production but not fashionable anymore. I had a pair of sealed subs with them, tuned to approximately match room gain.

When I did my first BIB experiments, I put one in a box that was basically made from scrap wood I had and not particularly well tuned to it. I loved it, on the one hand neutral and dynamic, on the other a hint of bloom that kind of works well with my room and musical taste. Better than the much bigger BIB with a 12 inch driver I did after it. So I am going to revisit it with a BIB that is tuned much lower, closer to its full potential, and with a more adequate volume.

I did use the BIB calculator, but adjusted aspect ratio and volume to fit standard panels from my local building supply store.

If it performs as hoped, I might make another, or a double-driver version.

Anyway, it's already old, I think it's still in production but not fashionable anymore. I had a pair of sealed subs with them, tuned to approximately match room gain.

When I did my first BIB experiments, I put one in a box that was basically made from scrap wood I had and not particularly well tuned to it. I loved it, on the one hand neutral and dynamic, on the other a hint of bloom that kind of works well with my room and musical taste. Better than the much bigger BIB with a 12 inch driver I did after it. So I am going to revisit it with a BIB that is tuned much lower, closer to its full potential, and with a more adequate volume.

I did use the BIB calculator, but adjusted aspect ratio and volume to fit standard panels from my local building supply store.

If it performs as hoped, I might make another, or a double-driver version.

That’s why I’d bought two of the Rigid brand drill/impact driver kits when on sale at Home Depot a few years ago. With a total of 4 batteries and two chargers, you almost need to intentionally run out of juice.I had a failed battery powered drill during my last big build. My wrists hurt just thinking about it. 🫣

Like clamps, you just can’t have too many drills or routers.

Ha! I have a battery powered drill, two batteries and two chargers AND a cheap drill with a power cord! 🤣

I had a decent brand and two batteries before, but they slowly degraded and it was hard to pinpoint a moment in time that replacement was in order. Until it decided for itself. I have a cheap supermarket brand now. Knocks the socks off a Makita that costs 3 to 4 times as much. Don't know how, don't care. 🤣

I had a decent brand and two batteries before, but they slowly degraded and it was hard to pinpoint a moment in time that replacement was in order. Until it decided for itself. I have a cheap supermarket brand now. Knocks the socks off a Makita that costs 3 to 4 times as much. Don't know how, don't care. 🤣

Last edited:

Me too except big DeWalt commercial model some years earlier before they turned to %$#@! quality, though none of my power tools 'measure' up to my early '60s Sears Craftsman heavy duty corded drills that have only needed new brushes or even their somewhat cheaper made, so far only normal maintenance, '77 table planer, circular, table, radial arm, saws.

This is actually BIB related content. BIBs are tall cabinets. If you need to cut panels yourself, you're cutting metres instead of centimetres. You will be putting in lots of dowels per joint, instead of two. Of screwing lots vs a little. Tools really help.

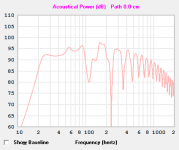

TB W69-1042J BIB 0.42 offset 4 ohms Rg/1pi

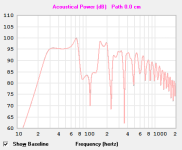

TB W69-1042J BIB 0.21 offset 4 ohms Rg/1pi

Minimal damping from the top down to just past the bottom of the driver; not too shabby for a ~8" dia. frame (Sd = 225 cm^2 calculated based on published specs)

TB W69-1042J BIB 0.21 offset 4 ohms Rg/1pi

Minimal damping from the top down to just past the bottom of the driver; not too shabby for a ~8" dia. frame (Sd = 225 cm^2 calculated based on published specs)

Attachments

Well I am not really that experienced and educated about woodworking skills, so basically it's not out of style with me. I just don't know. 🫣Speaking of which.......when did using glue blocks/strips, rope, etc, tie down straps to make glued together cabs go out of fashion?

Never, hahSpeaking of which.......when did using glue blocks/strips, rope, etc, tie down straps to make glued together cabs go out of fashion?

I even used some normal straps without a ratchet and just wound them tigther like a tourniquet. You get creative

Hmm, how do "small" BIBs perform when they are not near/close to the ceiling corner?

Let's say I'll build a BIB with a 4" FR driver, the excel sheet says the height would be ~125cm/49". Would the "room gain" still do as well as it does with "normal" sized BIBs that are much closer to the ceiling?

Or should I just put the BIBs on their head, make small inverted BIBs while moving the driver position closer to the fold...?

Let's say I'll build a BIB with a 4" FR driver, the excel sheet says the height would be ~125cm/49". Would the "room gain" still do as well as it does with "normal" sized BIBs that are much closer to the ceiling?

Or should I just put the BIBs on their head, make small inverted BIBs while moving the driver position closer to the fold...?

how do "small" BIBs perform when they are not near/close to the ceiling corner?

Lots (& lots) of ripple.

dave

Wow, my quick project from december finally had its final panel glued up today. Let's see if I can get it hooked up tonight!

It was a problematic build. Not enough time, not enough space indoors, it kept raining so I couldn't do it outside, it's too big for my car to take it to work. Water under the bridge. The last panel missing was the bottom. Sliding that in made a very satisfying difference in what kind of THUMP is heard when tapping the cone. I think this is going to work. 🤭

It was a problematic build. Not enough time, not enough space indoors, it kept raining so I couldn't do it outside, it's too big for my car to take it to work. Water under the bridge. The last panel missing was the bottom. Sliding that in made a very satisfying difference in what kind of THUMP is heard when tapping the cone. I think this is going to work. 🤭

Be sure to let us hear your impressions!

Some "news" from my BIBs: I swapped out the W8 2145's for the W8 1772 just because I find them more appealing visually.

And because I wanted to do something (idle hands are the devil's playground indeed) I put some more stuffing into the BIBs. To be precise I put additional ~600gram into the first fold, just below the drivers.

The bass was reduced significantly as far as I can tell, hm. I will listen to it some more, but most likely I'll take it back out. I do like it if things rumble

"Linear sound? Never heard of it! "

"

Some "news" from my BIBs: I swapped out the W8 2145's for the W8 1772 just because I find them more appealing visually.

And because I wanted to do something (idle hands are the devil's playground indeed) I put some more stuffing into the BIBs. To be precise I put additional ~600gram into the first fold, just below the drivers.

The bass was reduced significantly as far as I can tell, hm. I will listen to it some more, but most likely I'll take it back out. I do like it if things rumble

"Linear sound? Never heard of it!

- Home

- Loudspeakers

- Full Range

- Terry Cain's BIB -why does it work and does anyone have those Fostex Craft Handbooks?