I hate askin the UN for help but I'm desperate. These speakers are taking forever. First I listened to Planet10 and Bill Fitzgerald debate MDF or ply. Then finding a design I had a chance of pulling off. This will be my first home speaker. Then the problem of finding Baltic birch. I found a great deal on 1/2" Baltic in a town 40 miles away, I got three 5X5 sheets and a table saw.

Then hurricane Dennis came and I had to put the birch ply on my windows ! Geez, what next ? o.d.t.a.a.

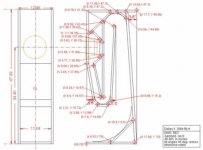

Because Ron Clark's Dallas II plans call for .700" ply and my wood was .500" I did some redesigning to keep the cross section of the sound path the same area. I thought a double thickness baffle would help the sound. I also thought the center fold should be doubled since it was 27" long and only supported by the sides.

...now the big mistake...

I used Gorilla glue to laminate two 27"pieces . The glue expanded and there are gaps around the edges. I had enough wood left over to remake the baffles and the lamination worked well with the yellow glue. I don't have enough birch left to redo the 27" pieces so I am now trying to fill the gaps with yellow wood glue (pva?)

Would I be better off continuing to do this or should I just use 3/4 MDF for this one piece ?

Then hurricane Dennis came and I had to put the birch ply on my windows ! Geez, what next ? o.d.t.a.a.

Because Ron Clark's Dallas II plans call for .700" ply and my wood was .500" I did some redesigning to keep the cross section of the sound path the same area. I thought a double thickness baffle would help the sound. I also thought the center fold should be doubled since it was 27" long and only supported by the sides.

...now the big mistake...

I used Gorilla glue to laminate two 27"pieces . The glue expanded and there are gaps around the edges. I had enough wood left over to remake the baffles and the lamination worked well with the yellow glue. I don't have enough birch left to redo the 27" pieces so I am now trying to fill the gaps with yellow wood glue (pva?)

Would I be better off continuing to do this or should I just use 3/4 MDF for this one piece ?

Attachments

The UN simply doesn't have time to handle all speaker-related issues brought to its attention, but I will make an exception in this case.

In my experience with speaker building, I screw up a lot. So while I am not the person to ask questions of concerning good planning and execution, I may be able to advise with fixing things that didn't quite work out as planned.

I always use a little caulk to fill unplanned gaps. Some say rope caulk works well, but I like the lazy way with the stuff that doesn't require a caulk gun, but oozes out of a pressurized can with just the push of a finger.

I'd stay away from filling gaps with wood glue, but only because its messy and I don't think it will fill the gaps quite as well as caulk.

Good luck with your project!

Kofi

In my experience with speaker building, I screw up a lot. So while I am not the person to ask questions of concerning good planning and execution, I may be able to advise with fixing things that didn't quite work out as planned.

I always use a little caulk to fill unplanned gaps. Some say rope caulk works well, but I like the lazy way with the stuff that doesn't require a caulk gun, but oozes out of a pressurized can with just the push of a finger.

I'd stay away from filling gaps with wood glue, but only because its messy and I don't think it will fill the gaps quite as well as caulk.

Good luck with your project!

Kofi

...............er.....................so were not talking the bathroom stuff ?oozes out of a pressurized can with just the push of a finger

Oh yea, and a few more questions may I ask you or the security council ? I have some 1/4 Luan plywood I was going to use to cover my plies. When I cut it the cut edge frays pretty badly. Is there anything I can do to get a smoother cut ?

I'm thinking of making the top of the speaker flip up to reveal a secret felt lined compartment. Will I pay a sonic penalty for doing this ?

Attachments

Hi!

I, too have made many mistakes on building cabinets. For general guide, see the link :

http://www.woodzone.com/tips/10_plywood_cutting_tips.htm

PS : Masking tape is very useful when cutting ply.

Happy cutting....

I, too have made many mistakes on building cabinets. For general guide, see the link :

http://www.woodzone.com/tips/10_plywood_cutting_tips.htm

PS : Masking tape is very useful when cutting ply.

Happy cutting....

..............er.....................so were not talking the bathroom stuff ?

The bathroom stuff should work fine. Your local Home Depot, Lowes, et. al. should carry it. Its a small can that is aerosol operated. The caulk comes out like shaving cream.

Mmmmmm.... Cream....

Kofi

Hi MikeFarad , oface..... Thanx for the advice.

Although I was able to get some clean cuts on the 1/4" Luan it just wans't getting the effect I wanted. It would have stained very differently than the birch. I got some 1/2" quarter-round and will cover my plies with that.

Progress is slow. Being a pool tech in the middle of summer I'm bussier than a one legged man in a bum kicking contest.

Has anyone looked at my first attachment ? Is anyone else planning to build one of these ?

Although I was able to get some clean cuts on the 1/4" Luan it just wans't getting the effect I wanted. It would have stained very differently than the birch. I got some 1/2" quarter-round and will cover my plies with that.

Progress is slow. Being a pool tech in the middle of summer I'm bussier than a one legged man in a bum kicking contest.

Has anyone looked at my first attachment ? Is anyone else planning to build one of these ?

An externally hosted image should be here but it was not working when we last tested it.

Just wanted to share,,, I made some more progress. I was slowed by Hurricane Katrina. Does anyone have any suggestions as to bracing ? Any other suggestions ?

How does it look so far ?

Koffi - I think it's about time you setup a commitee on abuse of the public by the audiophile press

Hey squalor - I like the cut of your jib me lad

Must been damn difficult with all of those angulations. Well done.

What the hell are these anyway? Your own design? What drivers are you planning on putting in there?

Just a tip in terms of applying ply externaly as a covering. Try cutting it slightly ( 2 / 3 mm per side) oversized, fixing the ply covering in place, and then using a router with a bearing guide flush trim bit to get it to the correct size.

As long as you have a reasonably sharp bit and the right RPM set it should give a cleaner finish than any saw.

As for bracing - I would imagine that none would be necessary here - I may be wrong!

Hey squalor - I like the cut of your jib me lad

Must been damn difficult with all of those angulations. Well done.

What the hell are these anyway? Your own design? What drivers are you planning on putting in there?

Just a tip in terms of applying ply externaly as a covering. Try cutting it slightly ( 2 / 3 mm per side) oversized, fixing the ply covering in place, and then using a router with a bearing guide flush trim bit to get it to the correct size.

As long as you have a reasonably sharp bit and the right RPM set it should give a cleaner finish than any saw.

As for bracing - I would imagine that none would be necessary here - I may be wrong!

What the hell are these anyway? Your own design? What drivers are you planning on putting in there?

These are Dallas II designed by Ron. Most of the angles are 45. They are designed to use the Fostex FE206E but with some modifications (suggested by GM i think) they can use the 208 sigma. I have 206e that may be getting a phase plug and other tricks but thats for later. First I need to finish these cabinets. I bought MinWax stain and a gallon of MinWax fast dry gloss poly

Kofi, the caulk I had worked great. Dried harder than I thought it would- it's the paint-able kind. I'm thinking of using it on all the non-visible seams.

Also, I plan to use Cat5 for speaker wire from binding posts to driver terminals but only one length, not three braided together. Power will be a 50W HT receiver until I build the Mauro 40W chip amp. I hope one run wont affect damping factor too much, I hear arguments either way as to what sounds the best.

I have some floor spikes/tip toes. Johnincr says spikes are the devils workshop but others like them so I may add a piece of MDF under the cab so if I unscrewed the spikes it would have something to sit on.

I'm glad the people here talked me out of using MDF. The Baltic Birch is wonderful. It came from trees with names.

These are Dallas II designed by Ron. Most of the angles are 45. They are designed to use the Fostex FE206E but with some modifications (suggested by GM i think) they can use the 208 sigma. I have 206e that may be getting a phase plug and other tricks but thats for later. First I need to finish these cabinets. I bought MinWax stain and a gallon of MinWax fast dry gloss poly

Kofi, the caulk I had worked great. Dried harder than I thought it would- it's the paint-able kind. I'm thinking of using it on all the non-visible seams.

Also, I plan to use Cat5 for speaker wire from binding posts to driver terminals but only one length, not three braided together. Power will be a 50W HT receiver until I build the Mauro 40W chip amp. I hope one run wont affect damping factor too much, I hear arguments either way as to what sounds the best.

I have some floor spikes/tip toes. Johnincr says spikes are the devils workshop but others like them so I may add a piece of MDF under the cab so if I unscrewed the spikes it would have something to sit on.

I'm glad the people here talked me out of using MDF. The Baltic Birch is wonderful. It came from trees with names.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Kofi Annan aides Dallas victims of squalor