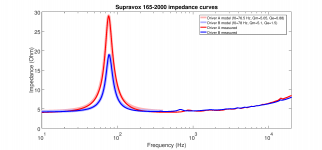

I've got a brand-new pair of Supravox 165-2000 drivers. I have measured the impedance curves after breaking in the drivers over night. The curves of the two units are rather different from each other (see attached figure). The TSP derived from the curves shows that unit "A" is similar to the manufacturer specs, whereas unit "B" has a much higher Qes (and hence also higher Qts).

In addition, the impedance wiggles at frequencies above the main resonance peak are quite a bit different between the two drivers.

These are expensive drivers and I wouldn't expect such variations.

Any ideas what might be going on with these drivers?

In addition, the impedance wiggles at frequencies above the main resonance peak are quite a bit different between the two drivers.

These are expensive drivers and I wouldn't expect such variations.

Any ideas what might be going on with these drivers?

Attachments

Hmm, being AlNiCo, a weak motor could very well be the problem in a small production run where they may be mixing different batches. Way back when, this was a real problem with high performance slot car motors, so we had to waste a some experimenting to find the optimum magnetizing settings, which could be so far from not just the recommended norm, but our 'norm' that there no way to come up with an acceptable 'fudge factor'.

Anyway, hope somebody can think of an easier, cheaper fix.

GM

Anyway, hope somebody can think of an easier, cheaper fix.

GM

In addition, the impedance wiggles at frequencies above the main resonance peak are quite a bit different between the two drivers.

These are expensive drivers and I wouldn't expect such variations.

Any ideas what might be going on with these drivers?

These 'wiggles' are resonances from the cone. They should indeed be identical otherwise the drivers will sound different. It could be a hint of a mechanical problem. Did you use a very high excursion while breaking the drivers in?

These 'wiggles' are resonances from the cone. They should indeed be identical otherwise the drivers will sound different. It could be a hint of a mechanical problem.

Yes, could be cone resonances. Or the spider. Or the surround. Or even the voice coil former. Or just about anything. Whatever it is, I'd also expect the wiggles to be similar for both drivers.

I contacted Supravox, and they seem to be rather helpful so far. They say that "the small variation on the700-900 impedance plot bump is normal, it's due to the very light cone and production variations."

Supravox also suggested to take a near-field measurement to see what the acoustic response is around the resonance frequency of the driver. The results seem to confirm the overly high Q at resonance, and show lower efficiency above resonance. Sounds like an issue with the motor unit to me. Let's see what Supravox says next week, when they're back in the office.

Did you use a very high excursion while breaking the drivers in?

No. The cone excursion was way below Xmax. I took a measurement before break in, and it was virtually identical to what I measured after break in.

Yes, could be cone resonances. Or the spider. Or the surround. Or even the voice coil former. Or just about anything. Whatever it is, I'd also expect the wiggles to be similar for both drivers.

The voice coil former can't be or is at least very unlikely, the cylindrical form makes it practically immune to movement-direction/-length resonance. If it would be across and vibrate that much, the coil windings won't stay on, it would crack the glue. The spider and surround could be but that would mean they actually are different and you do not have two matching drivers. That would be a completely catastrophic result for the series production quality. The same goes for the cone, it would mean they changed production materials without noting and - worse - mixing up the batches. That is pretty serious, I mean, that's a very strong resonance, you can tell that even without the frequency response measurement.

I contacted Supravox, and they seem to be rather helpful so far. They say that "the small variation on the700-900 impedance plot bump is normal, it's due to the very light cone and production variations."

That's BS! A light cone is no reason for the resonance to shift unless the production constantcy is very inconsistent or there are mechanical changes of the cone. Production variations? Yes, but that would mean they are doing a really bad job at assembling the drivers. Either way, that doesn't shed any good light on the driver.

Supravox also suggested to take a near-field measurement to see what the acoustic response is around the resonance frequency of the driver. The results seem to confirm the overly high Q at resonance, and show lower efficiency above resonance. Sounds like an issue with the motor unit to me. Let's see what Supravox says next week, when they're back in the office.

AlNiCo magnet and motor-strength-problems are (unfortunately) something that often goes hand-in-hand, together with the higher Q the lower efficiency above resonance is a very strong suggestion for such problems.

No. The cone excursion was way below Xmax. I took a measurement before break in, and it was virtually identical to what I measured after break in.

I asked that to exclude mechanical wear and tear as a reason for the shifting upper resonance.

What GM said, except I don't think it is alnico specific - I've measured this with ferrite magnet drivers. I assumed they didn't fully 'zap' the magnet.

Midrange (cone driver) horns; low relevance of magnet strength and Qts

Regarding "the very light cone and production variations" I think they simply mean that a hand-applied process on a lightweight cone will introduce more variance than for a heavy cone. That is: on a 500g subwoofer, 0.5g of additional glue won't be noticed.

Midrange (cone driver) horns; low relevance of magnet strength and Qts

Regarding "the very light cone and production variations" I think they simply mean that a hand-applied process on a lightweight cone will introduce more variance than for a heavy cone. That is: on a 500g subwoofer, 0.5g of additional glue won't be noticed.

Interesting! Haven't measured but a few powerful ferrite motors and then only Altec, but at least the 100+ thousand ferrite slot car magnets were so incredibly consistent that we quit measuring them other than making sure the equipment was up to spec.

Then again, in retrospect this was during the 'space race' years, so maybe it was primarily due to the manufacturer's QA program, which no doubt was extremely high [for all involved in government contracts].

Regardless, as easy, relatively cheap as it is nowadays, shame on any modern manufacturer that doesn't do at least a random quantity of impedance/frequency response plots per product run and every 'custom' to confirm it meets a +/- 10% [max?] spec.

Agreed, I learned the expensive way that even modest cone tweaking/damping on ~75 gr. 15" [mid] bass horn drivers can make/'break' its usable HF BW if not done properly .

.

GM

Then again, in retrospect this was during the 'space race' years, so maybe it was primarily due to the manufacturer's QA program, which no doubt was extremely high [for all involved in government contracts].

Regardless, as easy, relatively cheap as it is nowadays, shame on any modern manufacturer that doesn't do at least a random quantity of impedance/frequency response plots per product run and every 'custom' to confirm it meets a +/- 10% [max?] spec.

Agreed, I learned the expensive way that even modest cone tweaking/damping on ~75 gr. 15" [mid] bass horn drivers can make/'break' its usable HF BW if not done properly

GM

Supravox were very helpful so far. They offered to send my drivers to them, and they'll return a pair of matched drivers to me.

Well... there you go. Manufacturer response isn’t any better than that.

Could be a slight difference between the two voice coil's winding.

That would be awkward. With Qes ~ 1/(Bl)², the winding lengths would differ by some 30% (Qes = 0.88 vs 1.5). I'd think that event the crappiest manufacturer should be able to do better than this.

The Re are virtuelly identical.Need to look at both the Re values, Qes alone can't tell much.

On my Beyma 5MP60/N the VC was fully loose, after the replacement at my expense the treble has become very strong and with an audible sound of plastic from the polypropylene cone. ((Could be a slight difference between the two voice coil's winding.

The Re are virtuelly identical.

I see, i probably believe both your drivers are different manufacturing batches.

I myself encounter this after my supplier send me 2 spools of enameled wire at different time.

But is good that they are taking back and replace for you.

On my Beyma 5MP60/N the VC was fully loose, after the replacement at my expense the treble has become very strong and with an audible sound of plastic from the polypropylene cone. ((

That is the worst situation to get into. Ideally is to change both drivers.

Update: Supravox inspected the drivers and found the voice coil misaligned in one of the drivers. They promised to replace both drivers with new units that conform to the published specs, but I have not received them yet. I have asked a few times for the shipping date, but never received a clear answer to that. Hmmmm.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Supravox 165-2000 parameter inconsistencies