After some delays in my PC speaker conversion I am starting a project to build bookshelf speakers with a cardboard enclosure.

Much encouragement at this thread ( mine ).

Corrugated Cardboard tower desgin

Also, less energy is used to make cardboard, and it is bio-degradable, although I am not sure if making something as enduring a speaker should be.

Similar attempts:

YouTube

https://i.pinimg.com/736x/7c/db/79/7cdb7956943f7b5545f36490808e57e3.jpg

How to Make a Speaker Box From a Cardboard Box | Techwalla.com

YouTube

https://www.techwillsaveus.com/resources/build-diy-speakers-cardboard-box/

This last one looks very promising:

https://www.youtube.com/watch?v=Bt1W4CyPKs8

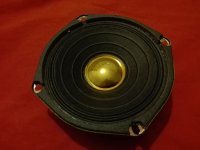

Any suggested designs? Will post pictures of the generic driver units.

Much encouragement at this thread ( mine ).

Corrugated Cardboard tower desgin

Also, less energy is used to make cardboard, and it is bio-degradable, although I am not sure if making something as enduring a speaker should be.

Similar attempts:

YouTube

https://i.pinimg.com/736x/7c/db/79/7cdb7956943f7b5545f36490808e57e3.jpg

How to Make a Speaker Box From a Cardboard Box | Techwalla.com

YouTube

https://www.techwillsaveus.com/resources/build-diy-speakers-cardboard-box/

This last one looks very promising:

https://www.youtube.com/watch?v=Bt1W4CyPKs8

Any suggested designs? Will post pictures of the generic driver units.

Last edited:

Check links in post 1. There are some cardboard speakers in there. Mostly foam core.

Foam Core Board Speaker Enclosures?

Foam Core Board Speaker Enclosures?

Check links in post 1. There are some cardboard speakers in there. Mostly foam core.

Foam Core Board Speaker Enclosures?

Thanks.

Look at Recommended Standard Bass Reflex Type Enclosure in this Fostex design:

http://loudspeakerfreaks.com/datasheets/fostex/fe126e_encl.pdf

http://loudspeakerfreaks.com/datasheets/fostex/fe126e_encl.pdf

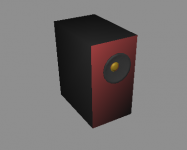

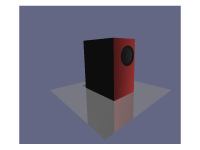

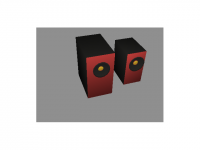

Computer Assisted Design completed

Preliminary design completed: 30 cm by 20 cm approx, and about 35 cm high. Finishing is important: I don't want it to look like a cardboard box, should look more like these:

Bifrost

(Results of a search)

Screen shots from Wings3d and G3D Viewer (with reflection).

Preliminary design completed: 30 cm by 20 cm approx, and about 35 cm high. Finishing is important: I don't want it to look like a cardboard box, should look more like these:

Bifrost

(Results of a search)

Screen shots from Wings3d and G3D Viewer (with reflection).

Attachments

Design Changes

Some design changes were made after cutting out some of the cardboard. By the way the stuff is quite strong, la belled as DOUBLEWALL by Viking Industries, NJ.

Existing bookshelf speakers vary in width from 13 cm to 20 cm, and are 24 cm to 30 cm high for the most part. Depth is between 24 and 40 cm, as long as it is not equal to the other sides, should be OK.

Depth is an important factor I previously overlooked: hold any speaker driver ( without the enclosure) against a wall, pointing outwards of course, and it does not sound as good as when it is some distance away from the wall.

Design changes shown: now the dimensions are 14W X 23-26H X 24D. Newer design is on the right.

Some design changes were made after cutting out some of the cardboard. By the way the stuff is quite strong, la belled as DOUBLEWALL by Viking Industries, NJ.

Existing bookshelf speakers vary in width from 13 cm to 20 cm, and are 24 cm to 30 cm high for the most part. Depth is between 24 and 40 cm, as long as it is not equal to the other sides, should be OK.

Depth is an important factor I previously overlooked: hold any speaker driver ( without the enclosure) against a wall, pointing outwards of course, and it does not sound as good as when it is some distance away from the wall.

Design changes shown: now the dimensions are 14W X 23-26H X 24D. Newer design is on the right.

Attachments

En-closure: to close the back ( radiation ) of a speaker

With six baffles ( the sides of a box...a parallelogram ) made with cardboard you are creating six + 1 ( the speaker itself ) radiating membranes.

The basic of en-closuring is that the material is not fono-transparent at all; it should be sound proof...and of course not vibrating when solicited.

With six baffles ( the sides of a box...a parallelogram ) made with cardboard you are creating six + 1 ( the speaker itself ) radiating membranes.

The basic of en-closuring is that the material is not fono-transparent at all; it should be sound proof...and of course not vibrating when solicited.

Yes indeed. I was thinking of this all through the design process. I had previously built corrugated card and also hardboard enclosure, but with improper sealing I cannot draw conclusions from them.

I imagined placing a sheet of cardboard that was folded many times, in a corrugated fashion, on each side of the box to dampen the vibrations. Alternatively a different material such as hardboard could be used. Its all in the building and listening.

The Wikipedia article on loudspeaker enclosures is worth quoting in part, and in its entirety makes for interesting reading.

Loudspeaker enclosure - Wikipedia

1) Mounting of the drivers

2) Preventing sound cancellation

3) Lowering the natural frequency and therefore changing the frequency response of the driver ( more bass)

(2) will be a problem in the cardboard box.

Some more info on speaker enclosures. Honeycombing is an option.

http://www.audioxpress.com/assets/upload/images/Klasco-AX-Sept12.pdf

I imagined placing a sheet of cardboard that was folded many times, in a corrugated fashion, on each side of the box to dampen the vibrations. Alternatively a different material such as hardboard could be used. Its all in the building and listening.

The Wikipedia article on loudspeaker enclosures is worth quoting in part, and in its entirety makes for interesting reading.

Loudspeaker enclosure - Wikipedia

A loudspeaker enclosure or loudspeaker cabinet is an enclosure (often box-shaped) in which speaker drivers (e.g., loudspeakers and tweeters) and associated electronic hardware, such as crossover circuits and, in some cases, power amplifiers, are mounted

It sounds better in a box, that I know, and at a certain distance from a rear wall, without a box.The primary role of the enclosure is to prevent sound waves generated by the rearward-facing surface of the diaphragm of an open speaker driver interacting with sound waves generated at the front of the speaker driver.

So the enclosure serves the following purposes:The enclosure also plays a role in managing vibration induced by the driver frame and moving airmass within the enclosure, as well as heat generated by driver voice coils and amplifiers (especially where woofers and subwoofers are concerned).

1) Mounting of the drivers

2) Preventing sound cancellation

3) Lowering the natural frequency and therefore changing the frequency response of the driver ( more bass)

(2) will be a problem in the cardboard box.

Some more info on speaker enclosures. Honeycombing is an option.

http://www.audioxpress.com/assets/upload/images/Klasco-AX-Sept12.pdf

Last edited:

Initial testing proved disappointing as it was not possible to seal the box adequately using tape. I am now gluing and sealing the sides of the box. On the plus side, the speaker was installed in the front rectangle of the box and placed over a proper MDF sealed enclosure, where a big improvement was heard, especially in bass. This speaker puts out some howling distortion, not the best of speakers, and may need a low bypass filter to clear up the noise, as well as some interior padding.

If a simple corrugated cardboard enclosure works well, then it opens a lot of possibilities and cost savings. If not... well back to the drawing board.

If a simple corrugated cardboard enclosure works well, then it opens a lot of possibilities and cost savings. If not... well back to the drawing board.

Sounds Terrible

Terrible. I installed the speaker in the box alright, but the problem is the speaker, it gives out a distorted sound, no matter where it is placed. The smaller full range I have sounds better, by itself, in open baffle mode, so that pretty much settles it.

Its a woofer (duh)

Apparently its a woofer (says so on the label) and I need a coil to keep out those bad mid to high frequencies, and that means a tweeter is needed as well. More complexities.

The lesson is:

Choose your drivers carefully and listen before you buy, or buy a reputable brand and check its reviews online. Or go for a full range.

What next:

Since the whole exercise was to check how a cardboard enclosure sounds, I will place my earlier full range speakers into a simple cardboard box from that a rechargeable light came in, and test.

All that work...

Terrible. I installed the speaker in the box alright, but the problem is the speaker, it gives out a distorted sound, no matter where it is placed. The smaller full range I have sounds better, by itself, in open baffle mode, so that pretty much settles it.

Its a woofer (duh)

Apparently its a woofer (says so on the label) and I need a coil to keep out those bad mid to high frequencies, and that means a tweeter is needed as well. More complexities.

The lesson is:

Choose your drivers carefully and listen before you buy, or buy a reputable brand and check its reviews online. Or go for a full range.

What next:

Since the whole exercise was to check how a cardboard enclosure sounds, I will place my earlier full range speakers into a simple cardboard box from that a rechargeable light came in, and test.

All that work...

Last edited:

I applaud you trying the unusual...

If you browse enough here and elsewhere, people make boxes of all sorts of materials, sometimes even MDF or plywood.

I've done some half-assed experiments, which pretty much describes all my DIY efforts, with plywood or similar. Just for fun. xrk971 here has had great success with foam core board.

Based on my ***/2 researches I would say that a heavy duty cardboard box will work decently for a smaller full range (auto two/three way for example) speaker. I had good results using a cat litter box. Sturdy cardboard and a built in carrying handle

I would say that a heavy duty cardboard box will work decently for a smaller full range (auto two/three way for example) speaker. I had good results using a cat litter box. Sturdy cardboard and a built in carrying handle

Not so well for a subwoofer (yes I tried it and what a mess.)

The important thing is, if you make a successful cardboard speaker:

1. Don't sit on it.

If you browse enough here and elsewhere, people make boxes of all sorts of materials, sometimes even MDF or plywood.

I've done some half-assed experiments, which pretty much describes all my DIY efforts, with plywood or similar. Just for fun. xrk971 here has had great success with foam core board.

Based on my ***/2 researches

Not so well for a subwoofer (yes I tried it and what a mess.)

The important thing is, if you make a successful cardboard speaker:

1. Don't sit on it.

Success thinking out of the box

I place my PC speaker driver - by the way it is a HYH unit, very similar to what is tested here:

YouTube

In the cardboard box in which I cut out a round hole, by hand, using a router.

It sounds good, press on the top and bottom of the box to fully seal it and the bass increases a bit more, press on the sides and that increase the bass some more. I could try some bracing to make it stiffer in the sides.

Next: secure the speakers, seal the enclosure and paint it to look like wood. Or granite. I also plan to add a cloth grille. It should look presentable, and I already know the sound is good - when you listen to a speaker and think "I could listen to this forever" you have a winner.

I place my PC speaker driver - by the way it is a HYH unit, very similar to what is tested here:

YouTube

In the cardboard box in which I cut out a round hole, by hand, using a router.

It sounds good, press on the top and bottom of the box to fully seal it and the bass increases a bit more, press on the sides and that increase the bass some more. I could try some bracing to make it stiffer in the sides.

Next: secure the speakers, seal the enclosure and paint it to look like wood. Or granite. I also plan to add a cloth grille. It should look presentable, and I already know the sound is good - when you listen to a speaker and think "I could listen to this forever" you have a winner.

Attachments

Cost savings...most of the cheap boxes that you can find around are made from thin chipboard with vinyl covering, a plastic baffle for the looks and cheap drivers arranged in a simple way ( some capacitor for the tweeter or even a fake piezo not connected ! ).

But they do work; going cheaper than that it is just frustating !

I found that eliminating the plastic baffle and securing the woofer tightly to the baffle and then reworking the crossover for letting the speaker to play as the norm, works.

But they do work; going cheaper than that it is just frustating !

I found that eliminating the plastic baffle and securing the woofer tightly to the baffle and then reworking the crossover for letting the speaker to play as the norm, works.

Familiar with these chipboard things, mini systems had these, but the worst is using plastic anywhere in a speaker. I am happy for the suppliers making lots of money from cheap speakers and giving DIYers a chance to prove their skills.

There are some cardboard speakers on the web: the sub here is impressive:

YouTube

Instructions:

How to Make a Speaker Box From a Cardboard Box | Techwalla.com

Coolest Gadgets:

Cardboard Box Speakers >> Coolest Gadgets

Ali Baba

Mobile Phone Foldable Cardboard Speaker - Buy Cardboard Speaker,Foldable Cardboard Speaker,Mobile Phone Foldable Cardboard Speaker Product on Alibaba.com

More instructions:

Build your own DIY Speakers out of their cardboard box - Technology Will Save Us

Nothing with a cloth grille yet, and wood like appearance, hopefully mine will be the first.

There are some cardboard speakers on the web: the sub here is impressive:

YouTube

Instructions:

How to Make a Speaker Box From a Cardboard Box | Techwalla.com

Coolest Gadgets:

Cardboard Box Speakers >> Coolest Gadgets

Ali Baba

Mobile Phone Foldable Cardboard Speaker - Buy Cardboard Speaker,Foldable Cardboard Speaker,Mobile Phone Foldable Cardboard Speaker Product on Alibaba.com

More instructions:

Build your own DIY Speakers out of their cardboard box - Technology Will Save Us

Nothing with a cloth grille yet, and wood like appearance, hopefully mine will be the first.

Last edited:

Wood look

Unlike my carpentry skills, I have some experience with "wood graining" but only at the amateur level. It is very easy to do wood colors with just a few coats of paint, or just get vinyl (contact paper) in a pattern you like. I guess you could put real wood veneer on cardboard but then it is rapidly getting into carpentry and real wood prices

Unlike my carpentry skills, I have some experience with "wood graining" but only at the amateur level. It is very easy to do wood colors with just a few coats of paint, or just get vinyl (contact paper) in a pattern you like. I guess you could put real wood veneer on cardboard but then it is rapidly getting into carpentry and real wood prices

I used an old plasmascreen box to make midbasshorns.

There is some vibration when playing, and resonans around 2-300 Hz which I hope I might get rid of with some bracing, but for now I am enjoying them from 150Hz to 600Hz.

I made them similar in profile to John Inslows 135Hz horn, but I am using the JA-8008 as my driver, not the b&c unit.

The rear chamber is a sonotube that fits against the flange of the driver, giving me a minimal chamber.

I taped it together first but the edges were rubbing against eachother making a buzzing sound, that was solved with silicone.

All braces and the connection to the baffle are glued with epoxy, the throat is very stiff.

There is some vibration when playing, and resonans around 2-300 Hz which I hope I might get rid of with some bracing, but for now I am enjoying them from 150Hz to 600Hz.

I made them similar in profile to John Inslows 135Hz horn, but I am using the JA-8008 as my driver, not the b&c unit.

The rear chamber is a sonotube that fits against the flange of the driver, giving me a minimal chamber.

I taped it together first but the edges were rubbing against eachother making a buzzing sound, that was solved with silicone.

All braces and the connection to the baffle are glued with epoxy, the throat is very stiff.

Attachments

So I ran across this site that has cardboard building tools and fasteners, might be useful in speaker building.

No connection with the company.

Makedo - Cardboard Construction – Makedo Cardboard Construction

David

No connection with the company.

Makedo - Cardboard Construction – Makedo Cardboard Construction

David

Unlike my carpentry skills, I have some experience with "wood graining" but only at the amateur level. It is very easy to do wood colors with just a few coats of paint, or just get vinyl (contact paper) in a pattern you like. I guess you could put real wood veneer on cardboard but then it is rapidly getting into carpentry and real wood prices

Here us example

How to Make Anything Look Like Real Wood

I would like to use something like this:

Woodgrain Card Stock Paper | Embossed, Pattern, Texture - LCI Paper

As an example of cardboard use:

A Cathedral:

A cardboard church! - Review of Cardboard Cathedral, Christchurch, New Zealand - TripAdvisor

A bike:

The Recycled Cardboard Bicycle [Video] - ChurchMag

And a train set:

YouTube

A Cathedral:

A cardboard church! - Review of Cardboard Cathedral, Christchurch, New Zealand - TripAdvisor

A bike:

The Recycled Cardboard Bicycle [Video] - ChurchMag

And a train set:

YouTube

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Corrugated Cardboard Bookshelf Speaker Project