Why is this in Full-Range?

Because I may run this without a woofer.

Oswald Mill is not conical even though it looks that way. Each leaf is curved inside to form a flare.

According to their site their Imperia and AC1 modesl use conical horns:

The 100hz and 300hz wooden conical horns are made from a choice of solid Pennsylvania walnut, cherry, ash, or chestnut.

The midrange utilizes a very special vintage compression driver made by RCA for actual movie theaters, mounted to our conical 300hz horn, crafted from the same hardwoods...

with wood mabey? Cheapest solution.

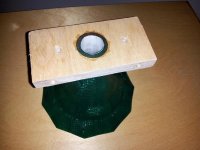

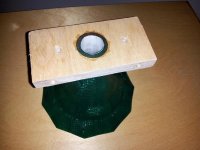

I get that part. My interest is in getting the clearance to firmly mount/bolt in the driver, and also , a more complicated thought , I don't currently have a wood shop I can just walk into and run off a new rev., so I always consider building things so there's flexibility to try other stuff, in this case , drivers.Going through the work of building the horn and being locked into the first driver I choose to do it with seems an unnecessary limitation.

The trouble is I haven't figured out a solution I'm completely happy with . . . .yet. Looking at your pic though , maybe that box structure could have spring clips or bands that come over the rear of the driver to lock it in. Centering the driver would then be the only issue, not too difficult to deal with.

The OMAs are pretty conical. Im not saying conical sucks so much that you should go to OB instead (the least efficient of everything) but im just saying exponential is the best

Let me simplify it by my hand drawing. Lets assume a very linear ultimate bandwidth driver will be loaded into a non-suitable short horn. There you can see the differences pretty well:

The expo will give you an 12dB boost from certain horn-length dependent frequency on, with a soft decline. Stronger than 12 is possible by using compression (throat significant smaller than diaphragm). While the compression ratio (usually 1:4) defines the boost, the diaphragm size defines the frequency-height where that happens.

Together with those 2 elements of horn and compression/dia and the certain rolloff that the driver comes with (lower energy at lower frequencies) you can design a pretty flat linear overall performance.

Following the same rules, the conical works a little different. It starts loading a little bit higher, slightly more than 12dB, but declines also faster. Worst of all are the notches in high frequencies due to phase interferences along the throat. All that leaves you with a very efficient, but tiny bandwidth, usually like a steep mountain. As you go off axis, the notches usually increase on conicals.

OMAs claim of CSD because the horn is straight is an absolute marketing BS which belongs to the snake-oil box, sorry. Just the opposite is the case.

Truth is likely, OMA has chosen a visually impressive design to create a nobel piece of interior decoration. Which definately is a great success, a stand alone feature, and fits the current move to industrial-loft fashion and vintage. But, its not a good performing thing.

Conical may work on an 8" fullrange driver (with no compression 1:1) that naturally beams in high frequencies and as such bypasses the horn straight through, using the horn as a low-mid lift to match its highs. This ive seen working pretty well.

Let me simplify it by my hand drawing. Lets assume a very linear ultimate bandwidth driver will be loaded into a non-suitable short horn. There you can see the differences pretty well:

The expo will give you an 12dB boost from certain horn-length dependent frequency on, with a soft decline. Stronger than 12 is possible by using compression (throat significant smaller than diaphragm). While the compression ratio (usually 1:4) defines the boost, the diaphragm size defines the frequency-height where that happens.

Together with those 2 elements of horn and compression/dia and the certain rolloff that the driver comes with (lower energy at lower frequencies) you can design a pretty flat linear overall performance.

Following the same rules, the conical works a little different. It starts loading a little bit higher, slightly more than 12dB, but declines also faster. Worst of all are the notches in high frequencies due to phase interferences along the throat. All that leaves you with a very efficient, but tiny bandwidth, usually like a steep mountain. As you go off axis, the notches usually increase on conicals.

OMAs claim of CSD because the horn is straight is an absolute marketing BS which belongs to the snake-oil box, sorry. Just the opposite is the case.

Truth is likely, OMA has chosen a visually impressive design to create a nobel piece of interior decoration. Which definately is a great success, a stand alone feature, and fits the current move to industrial-loft fashion and vintage. But, its not a good performing thing.

Conical may work on an 8" fullrange driver (with no compression 1:1) that naturally beams in high frequencies and as such bypasses the horn straight through, using the horn as a low-mid lift to match its highs. This ive seen working pretty well.

Looking at B&C/Radian compression drivers the mounting flanges c-c are the same.I get that part. My interest is in getting the clearance to firmly mount/bolt in the driver, and also , a more complicated thought , I don't currently have a wood shop I can just walk into and run off a new rev., so I always consider building things so there's flexibility to try other stuff, in this case , drivers.Going through the work of building the horn and being locked into the first driver I choose to do it with seems an unnecessary limitation.

The trouble is I haven't figured out a solution I'm completely happy with . . . .yet. Looking at your pic though , maybe that box structure could have spring clips or bands that come over the rear of the driver to lock it in. Centering the driver would then be the only issue, not too difficult to deal with.

...but im just saying exponential is the best

Ther eis no best, only best for the application.

dave

Because I may run this without a woofer.

Given a horn is only good for 3-4 octaves, and what you seem to be looking to build will have a very limited LF response, you will likely end up with something that sounds like an AM radio if you don’t have help below (and maybe above).

dave

Exponential might be tough to build

Im considering. I like the look of OMA, but want expo/tractrix shape.

I think making an octagonal horn of eight stripes will give an grammophone like vintage look. For the ease of built a flexible plastic-aluminum composite like Dubond is great to shape. Then stabilize mechanically the back afterwards.

The front could be laminated with printed wood foil for the look...

I think making an octagonal horn of eight stripes will give an grammophone like vintage look. For the ease of built a flexible plastic-aluminum composite like Dubond is great to shape. Then stabilize mechanically the back afterwards.

The front could be laminated with printed wood foil for the look...

The OMAs are pretty conical. Im not saying conical sucks so much that you should go to OB instead (the least efficient of everything) but im just saying exponential is the best

Let me simplify it by my hand drawing. Lets assume a very linear ultimate bandwidth driver will be loaded into a non-suitable short horn. There you can see the differences pretty well:

The expo will give you an 12dB boost from certain horn-length dependent frequency on, with a soft decline. Stronger than 12 is possible by using compression (throat significant smaller than diaphragm). While the compression ratio (usually 1:4) defines the boost, the diaphragm size defines the frequency-height where that happens.

Together with those 2 elements of horn and compression/dia and the certain rolloff that the driver comes with (lower energy at lower frequencies) you can design a pretty flat linear overall performance.

Following the same rules, the conical works a little different. It starts loading a little bit higher, slightly more than 12dB, but declines also faster. Worst of all are the notches in high frequencies due to phase interferences along the throat. All that leaves you with a very efficient, but tiny bandwidth, usually like a steep mountain. As you go off axis, the notches usually increase on conicals.

OMAs claim of CSD because the horn is straight is an absolute marketing BS which belongs to the snake-oil box, sorry. Just the opposite is the case.

Truth is likely, OMA has chosen a visually impressive design to create a nobel piece of interior decoration. Which definately is a great success, a stand alone feature, and fits the current move to industrial-loft fashion and vintage. But, its not a good performing thing.

Conical may work on an 8" fullrange driver (with no compression 1:1) that naturally beams in high frequencies and as such bypasses the horn straight through, using the horn as a low-mid lift to match its highs. This ive seen working pretty well.

I guess it's all how you choose to see it. Glass half empty , half full sort of thing.

There are others who would describe it by saying that the conical needs to be larger than it's curved counterparts because of it's LF loading (or lack of it) below cutoff, making it a poor choice for commercial designs. The same people also say that it sounds very clear and natural within the band it's used for.

I also have a question here. Can't the Synergy horn be seen as a stepped conical with the extra drivers to compensate for the LF characteristics of a single driver conical?

Im considering. I like the look of OMA, but want expo/tractrix shape.

I think making an octagonal horn of eight stripes will give an grammophone like vintage look. For the ease of built a flexible plastic-aluminum composite like Dubond is great to shape. Then stabilize mechanically the back afterwards.

The front could be laminated with printed wood foil for the look...

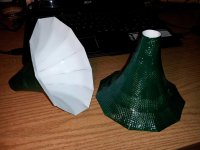

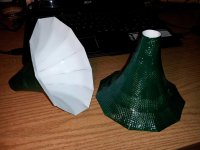

Somewhere, out on the web, one of our members describes how to make a petal horn of whatever contour you prefer out of paper mâché.

dave

I think Dave is referring in the above comment to the only place that I know used to host a fine little utility called "tractrix12.exe" and it sadly seems to now be completely MIA. It would calculate n-segment petal Tractrix horns. Can't retrieve it from the Wayback machine either.

Anyone know if it's hosted elsewhere or has a copy? I lost mine.

Anyway, I used it to make an 11-segment 700Hz petal horn a few years back. I drafted the output in Illustrator, printed it on thick paper, cut out all segments precisely with a sharp Xacto knife and reinforced with fiberglass tape and PVA glue, crude but worked. Cost is low, but takes some time.

Anyone know if it's hosted elsewhere or has a copy? I lost mine.

Anyway, I used it to make an 11-segment 700Hz petal horn a few years back. I drafted the output in Illustrator, printed it on thick paper, cut out all segments precisely with a sharp Xacto knife and reinforced with fiberglass tape and PVA glue, crude but worked. Cost is low, but takes some time.

I think Dave is referring in the above comment to the only place that I know used to host a fine little utility called "tractrix12.exe" and it sadly seems to now be completely MIA. It would calculate n-segment petal Tractrix horns. Can't retrieve it from the Wayback machine either.

Found it: doityourselfaudio: 140Hz Petal Horns

dave

Couldn't find the program there, but did here: Calculating 7 section tractrix horn – help!

http://www.revintage.se/tractrix12.exe

GM

http://www.revintage.se/tractrix12.exe

GM

I like the look of OMA, but want expo/tractrix shape. I think making an octagonal horn of eight stripes will give an grammophone like vintage look.

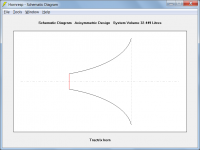

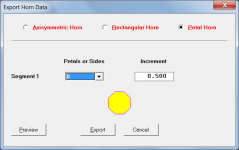

I read somewhere that David Macbean's hornresp. also has an export function for faceted horns.

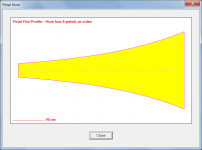

Example of an eight-sided tractrix horn. The side panel dimensions are given in the attached exported Tractrix.txt horn data file.

See the 'Export Horn Data' section in the Hornresp Help file for further details.

Attachments

I was not thinking of that one, but thanks for the link, also very cool! I had Inlowsound in mind.

Couldn't find the program there, but did here: Calculating 7 section tractrix horn – help!

http://www.revintage.se/tractrix12.exe

GM

I scoured the web for about 20min looking for it, but looks like you out-Googled me. Thanks, it's a neat little program that I may yet use again.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Horn Drivers