Chris,

I am in the process of getting a used(new) pair of A 10.3 Gold hence don't think that might be an option. But will have the large in mind .

.

Audiopath,

thanks for your input. I'm almost finalising the MA drivers but otherwise this did seem attractive .

.

chrisb,

you said it! I did contact Stefan, very nice guy. However it does seem a bit far away and I am open minded to the FR path so eager to see how it goes. I mean if I find bass lacking I'll add subs later.

I did contact Stefan, very nice guy. However it does seem a bit far away and I am open minded to the FR path so eager to see how it goes. I mean if I find bass lacking I'll add subs later.

To update I'm looking to buy some baltic birch in London. There are a lot of merchants nearby and the prices were ~£65+VAT for 8'x4' 15mm board. Unless anyone knows better options. The drivers are pretty much finalised:MA M10.3.

The drivers are pretty much finalised:MA M10.3.

Sadat

I am in the process of getting a used(new) pair of A 10.3 Gold hence don't think that might be an option. But will have the large in mind

Sadat,

Try the "standard" Tabaq build and see where that leads?

Regards

Chris

Audiopath,

thanks for your input. I'm almost finalising the MA drivers but otherwise this did seem attractive

My suggestions are none of the above. A pair of Seas FA22RCZ 8 inch fullrange drivers. These use a very simple correction network designed by Seas & can work well in a sealed cabinet 50 to 60 litres. Then get some bass traps behind your speakers ASAP.

chrisb,

you said it!

Lots of excellent designs around for the Alpairs and Pluvias - from Scott Lindgren's Pensils and FHXL, to Bob Brines' M10A10 - which I've heard, to the TABAQ, which I've not.

To repeat what I've said many times, if the whole world of FR / single driver systems is new to you, it's easy for the combination of analysis paralysis and sticker shock to keep you from making that first (mis) step.

It could be well worth the phone-call and perhaps shoe-leather / petrol to contact someone line Stefan at www.kjfaudio.com and see if he can find a system near enough for your travel convenience to audition first. But be careful, once you stumble down that rabbit hole, it can take a while to find your way out. For some of us, over a decade and half later, we still feel the gravitational pull.

yes, I know - mixed metaphors.

To update I'm looking to buy some baltic birch in London. There are a lot of merchants nearby and the prices were ~£65+VAT for 8'x4' 15mm board. Unless anyone knows better options.

Sadat

Sadat,

Good to see things moving forward from your side. Have no idea on UK Baltic birch prices though.

You good with the saw? Got the cutting of the pieces figured out?

Also please note, the Alpair 10.3 has a thick frame and for best sonic results, you should flush-mount it to the front baffle. In that case, you'll be left with only ~5"mm of ply behind the driver frame to screw them in - too less for a driver the size of the MA 10.3. One idea is to add an extra 6mm layer to the front baffle; that ways you still get 10mm+ after the driver rebate.

Also it's important that you do a 45 degree chamfer (or a similar round-over) on the backside of the driver mounting hole.

Good to see things moving forward from your side. Have no idea on UK Baltic birch prices though.

You good with the saw? Got the cutting of the pieces figured out?

Also please note, the Alpair 10.3 has a thick frame and for best sonic results, you should flush-mount it to the front baffle. In that case, you'll be left with only ~5"mm of ply behind the driver frame to screw them in - too less for a driver the size of the MA 10.3. One idea is to add an extra 6mm layer to the front baffle; that ways you still get 10mm+ after the driver rebate.

Also it's important that you do a 45 degree chamfer (or a similar round-over) on the backside of the driver mounting hole.

Last edited:

Ask Stefan how he approaches that issue. I use 18mm ply for the front baffles at least, and as Zia notes, these drivers need both a rebate for mounting flush - I don't use the extra rings if they're still supplied- and scalloped chamfers on the rear side of mounting hole.

I very much like the supplied screws - really more like a sheet metal thread thasn a tapered woodscrew, so careful pilot holes and pre-tapping in the plywood is important. By scalloping the chamfer to leave full thickness "pads" for the six mounting screws, I'm convinced that the approx 8mm of remaining plywood core is sufficient.

Whatever screws you use - do not overtighten them - the composite resin frames will crack

I very much like the supplied screws - really more like a sheet metal thread thasn a tapered woodscrew, so careful pilot holes and pre-tapping in the plywood is important. By scalloping the chamfer to leave full thickness "pads" for the six mounting screws, I'm convinced that the approx 8mm of remaining plywood core is sufficient.

Whatever screws you use - do not overtighten them - the composite resin frames will crack

Thanks both for your input.

I have a jigsaw from bosch and somewhat steady hands so I think I would somehow manage straight cuts. It won't be pitch perfect as with circular saws or using a CNC machine but it will have to make do.

I thought flush mount was for aesthetics only? I was planning on mounting them just straight on the front baffle the usual way. I can understand the 45° chamfer, and will try to implement it. I will also keep the over tightening advice in mind.

I thought which ever design I go for, I will eventually need the material so that's why I just ordered the drivers (used and hopefully in good condition) and looking to get the plywood next.

I was reading through this thread where zman introduces the four designs which is exactly the designs I'm looking at.

My primary choice is Bob's MLTL (I'm pretty sure all the designs from other designers are great!). He seems to have actual measurements after building the design and the response looks great. He's a bit hard to get a hold of, I'm thinking whether to just buy the plans first or wait for him to get back to m?

Sadat

I have a jigsaw from bosch and somewhat steady hands so I think I would somehow manage straight cuts. It won't be pitch perfect as with circular saws or using a CNC machine but it will have to make do.

I thought flush mount was for aesthetics only? I was planning on mounting them just straight on the front baffle the usual way. I can understand the 45° chamfer, and will try to implement it. I will also keep the over tightening advice in mind.

I thought which ever design I go for, I will eventually need the material so that's why I just ordered the drivers (used and hopefully in good condition) and looking to get the plywood next.

I was reading through this thread where zman introduces the four designs which is exactly the designs I'm looking at.

My primary choice is Bob's MLTL (I'm pretty sure all the designs from other designers are great!). He seems to have actual measurements after building the design and the response looks great. He's a bit hard to get a hold of, I'm thinking whether to just buy the plans first or wait for him to get back to m?

Sadat

Hi Sadat,

It is possible that Bob is not as regular as he used to be on the diyAudio forums; if not already, maybe send him an e-mail and tell him about your driver of choice and build plans.

I am not sure of the jigsaw will yield best results with ply-wood. If you can get hold of someone with a circular saw, and willing to size up the board for you, then better. Before buying the ply, my advise would be that you make a long cut on a test piece with your jigsaw and see how it comes out. The 45 degree chamfer can be implemented by hand with a rasp.

It is possible that Bob is not as regular as he used to be on the diyAudio forums; if not already, maybe send him an e-mail and tell him about your driver of choice and build plans.

I am not sure of the jigsaw will yield best results with ply-wood. If you can get hold of someone with a circular saw, and willing to size up the board for you, then better. Before buying the ply, my advise would be that you make a long cut on a test piece with your jigsaw and see how it comes out. The 45 degree chamfer can be implemented by hand with a rasp.

sadat - I believe that Bob is trying to ease into a very well deserved retirement, and may not be as active on the forums as was the case in his youthful 60s - so if you're looking for much more feedback from him than just the cabinet plans, pack your patience in your back pocket.

zman,

My present situation dictates that it is very hard to gain access to a circular saw, but I did work with plywood and jigsaw before. The results are fine, it chips a bit if you go too fast but otherwise acceptable.

chrisb,

he just got back to me. but i can surely understand.

but i can surely understand.

now just waiting to get the materials and start the process. any idea on plywood finishing though guys?

My present situation dictates that it is very hard to gain access to a circular saw, but I did work with plywood and jigsaw before. The results are fine, it chips a bit if you go too fast but otherwise acceptable.

chrisb,

he just got back to me.

now just waiting to get the materials and start the process. any idea on plywood finishing though guys?

zman,

My present situation dictates that it is very hard to gain access to a circular saw, but I did work with plywood and jigsaw before. The results are fine, it chips a bit if you go too fast but otherwise acceptable.

Ok, good to know that you already have some experience with power tools.

now just waiting to get the materials and start the process. any idea on plywood finishing though guys?

Many options exist... some folks go for a clear coat on the plywood without any stain or veneer. Others use exquisite veneers (depending on the wood and the quality of the veneers, they can cost quite a bit!). While there are other folks who fancy paint jobs and nice gloss finishes (not easy).

Easiest is to put some nice wall paper on them.

So what are you looking for?

Though the FH Mk3 is a different in design and aesthetics vs what you are planning to build, the following thread showcases the creativity of DIY builders and the various finishes they chose - should be able to provide some food for thought:

http://www.diyaudio.com/forums/full-range/199849-frugel-horn-mk3-picture-gallery.html

http://www.diyaudio.com/forums/full-range/199849-frugel-horn-mk3-picture-gallery.html

When cleanly cut on table saw - or cleaned up with flush trim router and/or random orbit sander - to at least 220G- the exposed edge of voidless BB or equivalent plywood can look quite nice with clear coats. Indeed it's frequently specified exactly that way by some architects and interior designers. It's the acceptance of stains or darker top coats that makes life interesting for the finisher.

Morning,

yeah I have seen some enclosures with chamfered edges and finished up, it does look nice when properly done. Might actually need to get myself a router (more costs ). I might apply some stain but for now I'm more curios about the thickness. I want to buy the plywood today, the merchant offers B,S, B/BB, BB in order of quality with B being the highest.

). I might apply some stain but for now I'm more curios about the thickness. I want to buy the plywood today, the merchant offers B,S, B/BB, BB in order of quality with B being the highest.

Bob recommended me to go for 12mm Plywood instead of 18mm MDF, I was actually planning for 18mm ply. But I guess I should go for 12mm if it saves weight, effort and cost? Also I assume a single sheet of 8x4ft should suffice for the two enclosures right. (I am yet to receive the plans but just want to order the ply as it will take ~3 days to arrive.)

yeah I have seen some enclosures with chamfered edges and finished up, it does look nice when properly done. Might actually need to get myself a router (more costs

Bob recommended me to go for 12mm Plywood instead of 18mm MDF, I was actually planning for 18mm ply. But I guess I should go for 12mm if it saves weight, effort and cost? Also I assume a single sheet of 8x4ft should suffice for the two enclosures right. (I am yet to receive the plans but just want to order the ply as it will take ~3 days to arrive.)

Sadat,

Good morning!

I think what Bob meant was that 12mm ply would be as good or better than 18mm MDF.

Thicker ply may or may not add any benefits for this particular design. How much is the difference of cost between 15mm and 12mm?

Also, did Bob tell you that 1 sheet of 8"x4" is enough for the build or you are assuming that? It is very much possible that one sheet will be enough, but just checking.

Good morning!

I think what Bob meant was that 12mm ply would be as good or better than 18mm MDF.

Thicker ply may or may not add any benefits for this particular design. How much is the difference of cost between 15mm and 12mm?

Also, did Bob tell you that 1 sheet of 8"x4" is enough for the build or you are assuming that? It is very much possible that one sheet will be enough, but just checking.

Last edited:

ok, its a bit hard to find 15mm as most of the merchant does 12mm or 18mm. The difference in cost is: 12mm (~£55) and 18mm (~£80). 15mm (if available ~£70)

edit: actually I was more like asking if it would be enough, I am waiting for the plan so more like assuming atm?!

Ok, understand.

One option (safest) is wait for the plans.

Another option can be make more of an educated guess - go to Bob's website and have a look at the external dimensions of the cab and do quick calculation if one 8"x4" covers both cabinets. Since you will be using 12mm, I am assuming that there will be some internal bracing involved too.

Short answer is: No

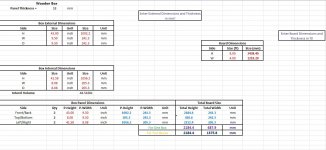

I did a draft calculation with excel for the box(see attached image). I took the dimensions from Bob's site and did some rough calculations. I would be able to squeeze in if I lay the panels out more efficiently but then I need extra wood for the base plate where the enclosures will stand and the front baffle oval piece thing, if I want to flush mount the drivers. But anyways I can always buy a sheet, start and then buy more if I need later, I think some merchants sell smaller dimensions as well.

I am not sure about bracing but I think I will put some. Would I not need it incase of 18mm?

Sorry if I am asking too many questions though (peace )!

)!

I did a draft calculation with excel for the box(see attached image). I took the dimensions from Bob's site and did some rough calculations. I would be able to squeeze in if I lay the panels out more efficiently but then I need extra wood for the base plate where the enclosures will stand and the front baffle oval piece thing, if I want to flush mount the drivers. But anyways I can always buy a sheet, start and then buy more if I need later, I think some merchants sell smaller dimensions as well.

I am not sure about bracing but I think I will put some. Would I not need it incase of 18mm?

Sorry if I am asking too many questions though (peace

Attachments

Sorry if I am asking too many questions though (peace)!

No worries, ask away.

Bracing would be probably necessary even with 18mm ply. If I recall correctly, Bob uses Window braces. You might have to double up on part of the baffle where the driver is going to sit, not sure. That you'll know when Mr. Brines sends you the plans.

On this side of the pond, the higher grading usually refers to the face veneers, in terms of number of allowable pin-knot holes, larger patched knots, or mineral stains. If your plans are to veneer, or get carried away and attempt a nice paint finish, those minor aesthetic flaws would be moot.

I have been communicating with Sadat by private email, but since my name has come up here, I think I need to make a few comments.

I have been building speakers for decades and have used any number of material types. In my middle period, I used 3/4" MDF laminated to 1/4" HardiBacker with Liquid Nails. Very dead cabinets. Very heavy. Incredible amount of dust. I am now using 12mm Baltic (Russian) birch. I will never again use MDF for anything.

12mm BB is stiffer and lighter that 3/4" MDF -- both good things sonically. 12mm BB is adequately stiff to be used in any speaker where unbraced panels are no more the 12" wide. You can use 15mm or 18mm BB if you feel the need or if bracing is going to be a problem, but 12mm BB is heavy enough. I know of a commercial builder who does PA subwoofers in 12mm BB. Bracing is the key.

I did a pair of subs 2ft^3 subs in 24mm BB -- actually doubled 12mm. The cabinets weigh 65lb, and I can no longer carry them without removing the drivers.

Bob

I have been building speakers for decades and have used any number of material types. In my middle period, I used 3/4" MDF laminated to 1/4" HardiBacker with Liquid Nails. Very dead cabinets. Very heavy. Incredible amount of dust. I am now using 12mm Baltic (Russian) birch. I will never again use MDF for anything.

12mm BB is stiffer and lighter that 3/4" MDF -- both good things sonically. 12mm BB is adequately stiff to be used in any speaker where unbraced panels are no more the 12" wide. You can use 15mm or 18mm BB if you feel the need or if bracing is going to be a problem, but 12mm BB is heavy enough. I know of a commercial builder who does PA subwoofers in 12mm BB. Bracing is the key.

I did a pair of subs 2ft^3 subs in 24mm BB -- actually doubled 12mm. The cabinets weigh 65lb, and I can no longer carry them without removing the drivers.

Bob

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- First full range build - Fostex ff165wk