I'm curious about the effect of using multiple small ports vs 1 port of larger diameter. I'm trying to design a ported enclosure for a small portable speaker and in WinISD, in order to have a single port that will fit inside my box, I can use ~0.5 inch diameter, but the "vent mach" number is calculated as 0.13 which by my understanding is getting close to a value where turbulence might cause some unwanted noise.

I noticed that if I use 3 x 0.25" ports instead, the length is fine for the dimensions of my enclosure and the vent mach drops to 0.06. I've read a little bit here and understand that WinISD beta doesn't always calculate this value correctly for multiple ports or for small diameter ports. Just wondering:

1) Does this seem accurate? Would 3 small diameter ports really have an advantage over one larger port with respect to port air velocity or turbulence? (This is what vent mach refers to isn't it?)

2) Are there any other issues I'd encounter with this type of port design?

Thanks!

I noticed that if I use 3 x 0.25" ports instead, the length is fine for the dimensions of my enclosure and the vent mach drops to 0.06. I've read a little bit here and understand that WinISD beta doesn't always calculate this value correctly for multiple ports or for small diameter ports. Just wondering:

1) Does this seem accurate? Would 3 small diameter ports really have an advantage over one larger port with respect to port air velocity or turbulence? (This is what vent mach refers to isn't it?)

2) Are there any other issues I'd encounter with this type of port design?

Thanks!

Very small ports (fingerlike) don't behave the same way. You can use a small port with short lengths instead of a larger one and longer but you will use less power from port chuffing limit. Resistence from boundaries makes the ports smaller...

Read: Vent Tuning of Ported Systems by Troels Gravesen

The way small ports "in a net" work is different more like aperiodic().

Read: Vent Tuning of Ported Systems by Troels Gravesen

The way small ports "in a net" work is different more like aperiodic().

Very small ports (fingerlike) don't behave the same way. You can use a small port with short lengths instead of a larger one and longer but you will use less power from port chuffing limit. Resistence from boundaries makes the ports smaller...

Read: Vent Tuning of Ported Systems by Troels Gravesen

The way small ports "in a net" work is different more like aperiodic().

Thanks for the reference. I'll read it.

This actually really made me wonder if you drilled a net of holes into the back of an enclosure, if it would end up working as a port, or just a leaky box.

For example, you need a 1 inch by 6 inch port.. But instead you drill 8 holes 1in diameter into the back of your enclosure that is 3/4in thick (8 x 3/4 = 6 in).

For example, you need a 1 inch by 6 inch port.. But instead you drill 8 holes 1in diameter into the back of your enclosure that is 3/4in thick (8 x 3/4 = 6 in).

Baruch/Lang patent - -- the speaker became commercially available for awhile

Patent US2766839 - Loudspeaker system - Google Patents

Patent US2766839 - Loudspeaker system - Google Patents

This actually really made me wonder if you drilled a net of holes into the back of an enclosure, if it would end up working as a port, or just a leaky box.

For example, you need a 1 inch by 6 inch port.. But instead you drill 8 holes 1in diameter into the back of your enclosure that is 3/4in thick (8 x 3/4 = 6 in).

There is a continuum between a leak and a port. This 8 hole panel depth port would act like a port with the same total area and a length of 3/4". If you add up the circumference of all those ports, it will be greater than the circumference of a single round port, and thus the viscous losses will be higher in such a port. Losses don't generally do any good unless a port is tuned too high, and all they accomplish is that the port emits less sound...and puts less damping or control on the cone.

...or you get a more highly damped alignment. Not automatically a bad thing; depends how you categorise 'too high' & the design details. Dave does this with his Fonkens / other-Kens, which are generally considered good examples of the breed.

Small wrote off damped vents; they were in his doctoral thesis as I recall, but he omitted them from his published work. However, a goodly proportion of Onkens and their Ultraflex predecessors need some damping in the vents as they're frequently long enough to run into audible issues with their 1/2 wave harmonic structure. Same applies to some other classic BR designs, since the traditional way to do it was to pitch for maximum efficiency at resonance and then damp out what you didn't need via the old click-test, either by stapling damping over the rear of the driver and / or adding more in the box or vent. YMMV as ever of course.

Small wrote off damped vents; they were in his doctoral thesis as I recall, but he omitted them from his published work. However, a goodly proportion of Onkens and their Ultraflex predecessors need some damping in the vents as they're frequently long enough to run into audible issues with their 1/2 wave harmonic structure. Same applies to some other classic BR designs, since the traditional way to do it was to pitch for maximum efficiency at resonance and then damp out what you didn't need via the old click-test, either by stapling damping over the rear of the driver and / or adding more in the box or vent. YMMV as ever of course.

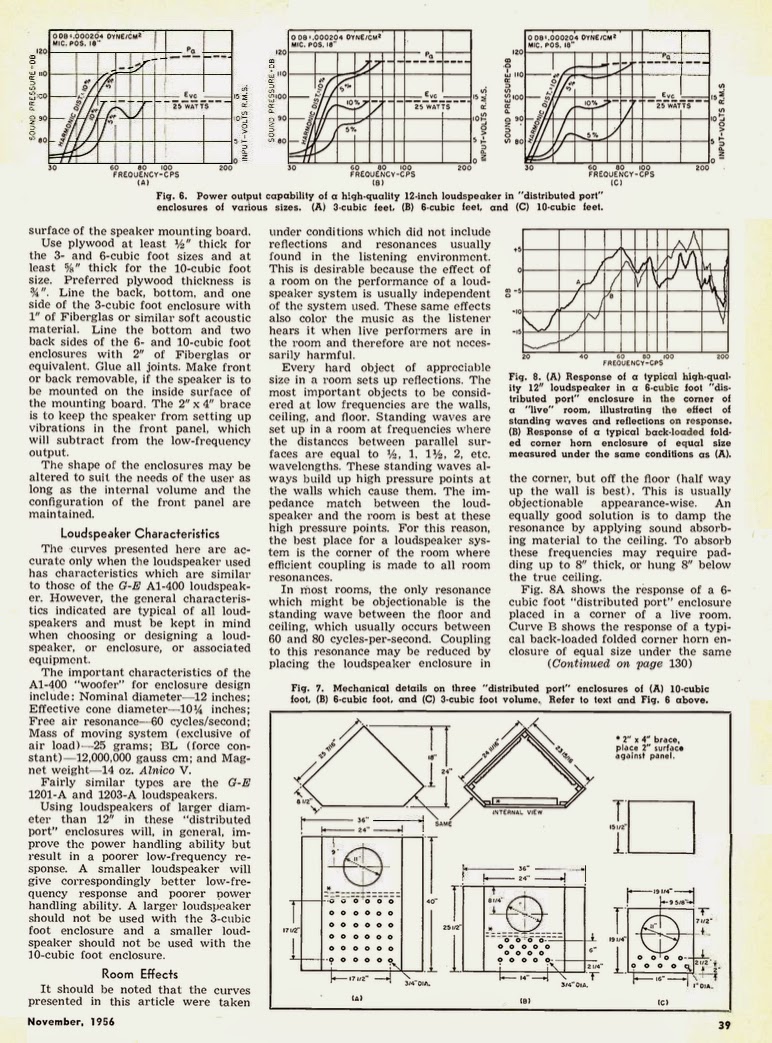

there was a time around the mid 1950's where distributed hole and slit vents were popular with a GE 12" article and think even EV made one. It was a time of mix and match driver and enclosure based on luck. Some drivers had high qts. Karlson's 12 inch model went to six spaced 1/8" high slits about 10 inches wide. With large ratios of Sd to Sv and diameter in the range of panel thickness or less, they can introduce high amounts (near 100%) of harmonic distortion if fed with sine wave in the box tuning area. With music produced by traditional instruments having mainly transient info , it doesn't seem much of an audible problem. I tried a 43 3/8" diameter hole distributed vent on a 1/2" panel in a 3.6 cubic foot reflex - small signal tuning was around 40Hz - with only 10 watts input at 40Hz to te Peavey 15, it made a nice breeze 7 feet or so away  - - under hard drive port rectification seems to happen, input impedance changes probably losing the lower peak characteristic of a reflex for a bit.

- - under hard drive port rectification seems to happen, input impedance changes probably losing the lower peak characteristic of a reflex for a bit.

Do you think this principle influenced Karlson with his holey K12?Baruch/Lang patent - -- the speaker became commercially available for awhile

Patent US2766839 - Loudspeaker system - Google Patents

possible - but by 1956, I there were other examples before that time - it was probably faster to cut the slits than drill a number of holes.

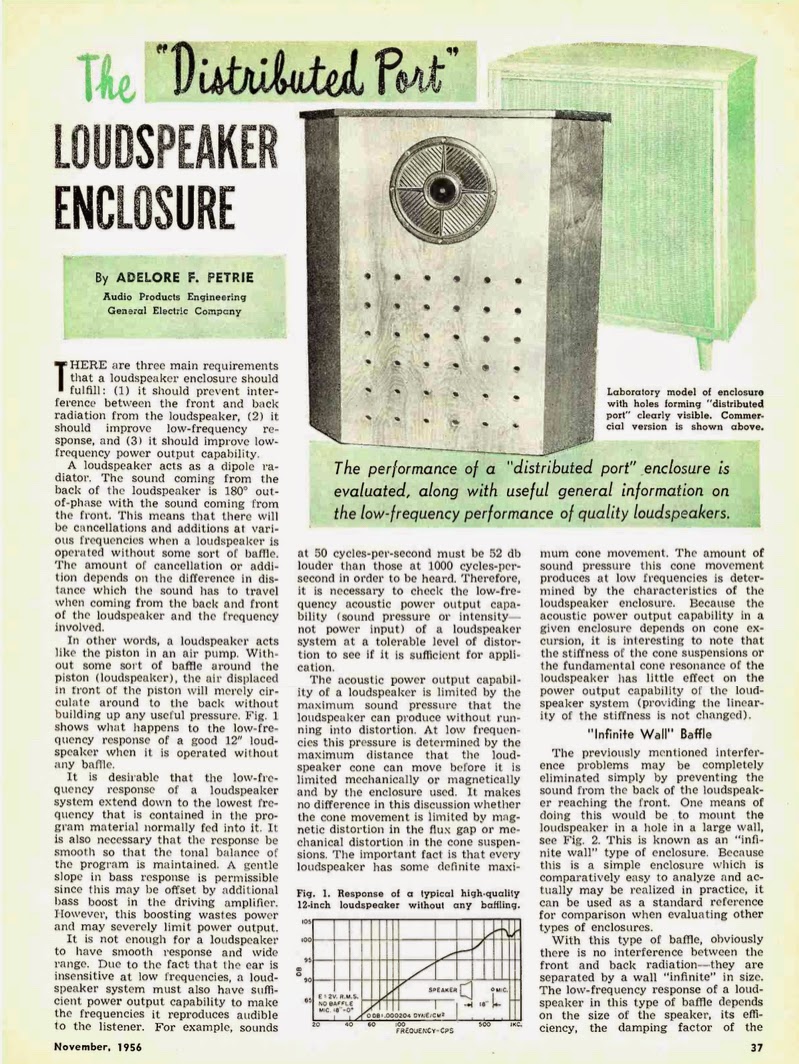

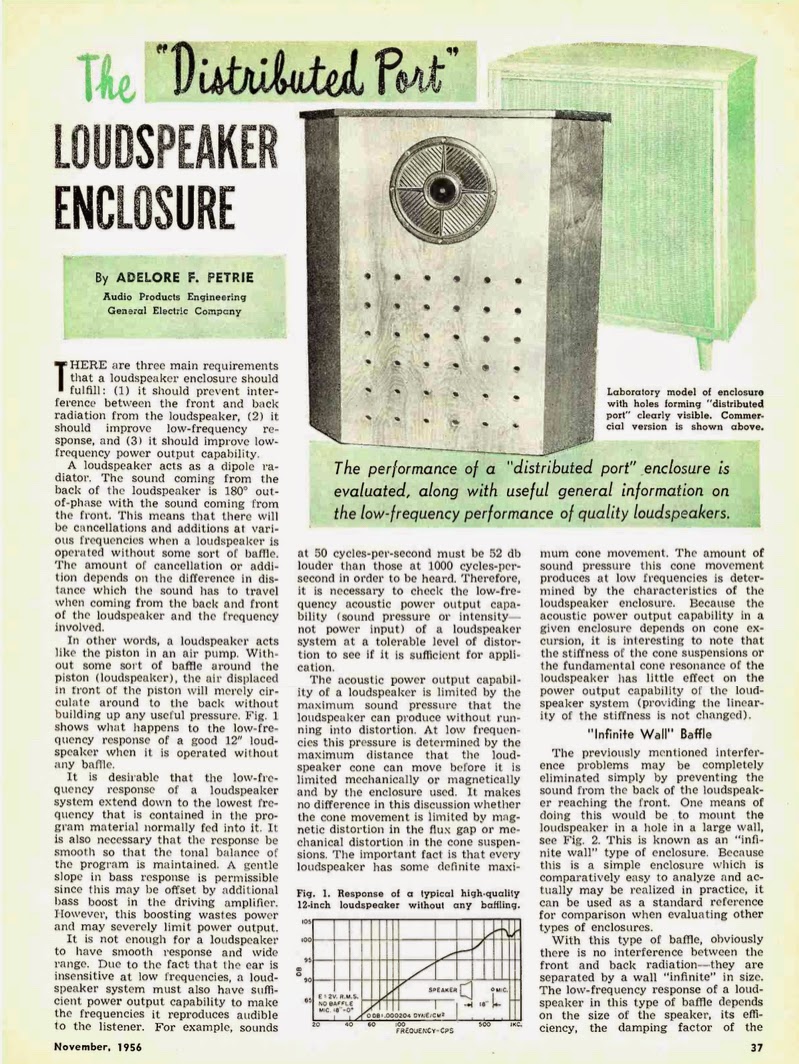

Here's the famous GE distributed port enclosure Mid-50's GE A1-400 speakers / GE A1-406 cabinets | Audiokarma Home Audio Stereo Discussion Forums

I made a 5 cubic foot reflex tuned with a few (I think 8) 3/4" holes with a weak motor Jensen/knight 12" whizzer cone speaker around 1966 - attempts to re-tune with less lossy vent per charts failed in comparison so it seemed useful at the time with a high qts driver.

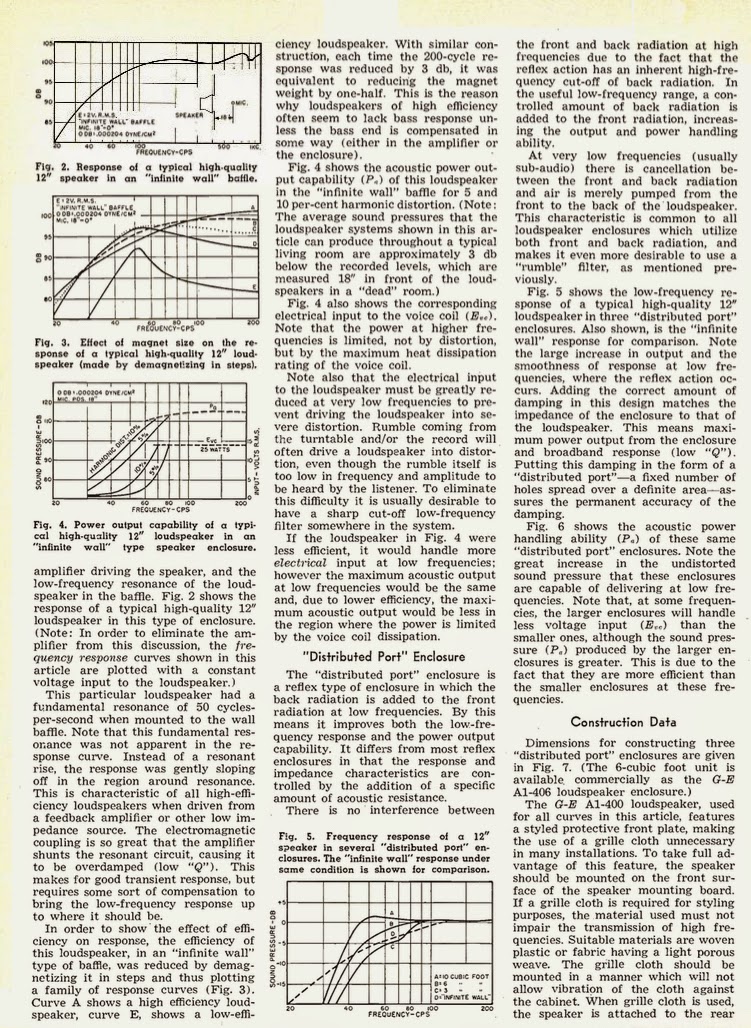

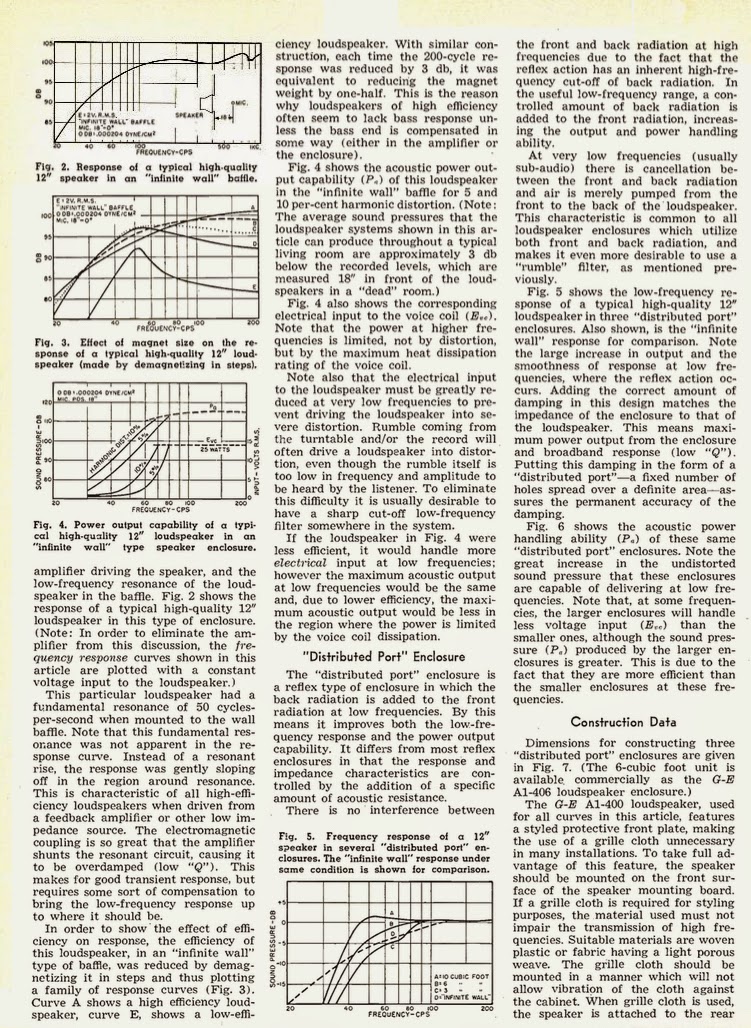

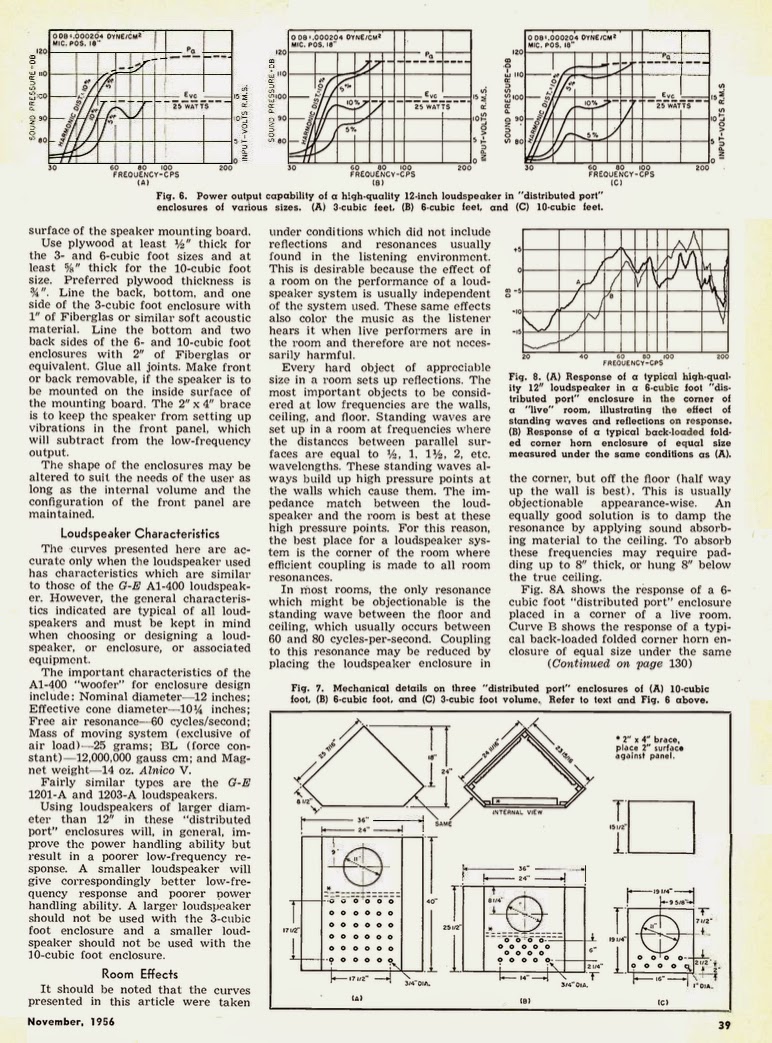

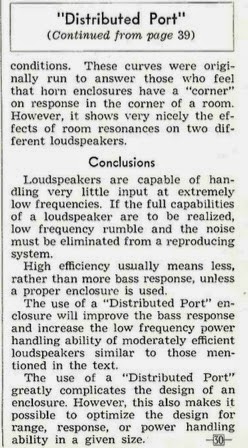

Article - probably suitable for 12lta

http://www.itishifi.com/2015/02/the-distributed-port-loudspeaker.html

btw - the article images if you copy and paste their url are large enough to read

Here's the famous GE distributed port enclosure Mid-50's GE A1-400 speakers / GE A1-406 cabinets | Audiokarma Home Audio Stereo Discussion Forums

I made a 5 cubic foot reflex tuned with a few (I think 8) 3/4" holes with a weak motor Jensen/knight 12" whizzer cone speaker around 1966 - attempts to re-tune with less lossy vent per charts failed in comparison so it seemed useful at the time with a high qts driver.

Article - probably suitable for 12lta

http://www.itishifi.com/2015/02/the-distributed-port-loudspeaker.html

btw - the article images if you copy and paste their url are large enough to read

Last edited:

I view these as a latter day lazy man's version of the '30s folded bass horn's slot vented 'compression' chamber: http://www.lansingheritage.org/images/altec/catalogs/1942/page09.jpg

GM

GM

And that makes me think of the Western Electric retro vintage.

They are lovely OB. Links to picture below.

retro vintage modern hi-fi: September 2009

retro vintage modern hi-fi: Western Electric

Of course it has nothing to do with the title of the thread. But they are nice and make me think of the simplicity (or not, maybe they were the Rolls-Royce of the time) involved.

They are lovely OB. Links to picture below.

retro vintage modern hi-fi: September 2009

retro vintage modern hi-fi: Western Electric

Of course it has nothing to do with the title of the thread. But they are nice and make me think of the simplicity (or not, maybe they were the Rolls-Royce of the time) involved.

Attachments

I view these as a latter day lazy man's version of the '30s folded bass horn's slot vented 'compression' chamber: http://www.lansingheritage.org/images/altec/catalogs/1942/page09.jpg

GM

Sounds favourite.

And that makes me think of the Western Electric retro vintage.

Wow! Wasn't aware of these, only their 594, etc., horns.

GM

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Porting for Small Enclosure