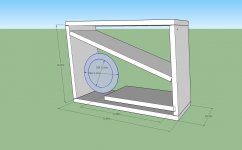

Wondering if making a short version of the Planet10 Tysen V2 would be a bad idea? (Sorry, my sketch is pretty rudimentary.)

Because of the odd space (I'll be putting them on a big 17" deep 'L' shaped corner cabinet), I have more depth to work with than height. In a thread Dave had mentioned a BR version in the works, but it sounds like it would be 40cm+ and I'm aiming for 30cm but 40cm deep.

I'd make them out of OSB to start, so if it is an epic fail, won't be too big of deal. I'll do an active crossover with a minidsp.

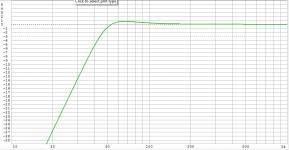

Fostex FF85wk in the top, but using winisd (though likely I'm doing it wrong) it looks like the Dayton Audio DCS165 will work best in the bottom. [Though a lot of the Peerless woofers also looked to work well in the small space and could probably fit two of the 830855 woofers push-push if I had a few more liters to work with.] The bottom would be about 7 liters tuned to 45Hz will give an F3 of about 44hz.

Because of the odd space (I'll be putting them on a big 17" deep 'L' shaped corner cabinet), I have more depth to work with than height. In a thread Dave had mentioned a BR version in the works, but it sounds like it would be 40cm+ and I'm aiming for 30cm but 40cm deep.

I'd make them out of OSB to start, so if it is an epic fail, won't be too big of deal. I'll do an active crossover with a minidsp.

Fostex FF85wk in the top, but using winisd (though likely I'm doing it wrong) it looks like the Dayton Audio DCS165 will work best in the bottom. [Though a lot of the Peerless woofers also looked to work well in the small space and could probably fit two of the 830855 woofers push-push if I had a few more liters to work with.] The bottom would be about 7 liters tuned to 45Hz will give an F3 of about 44hz.

Attachments

The Tysen being an MLTL IINM, there would be a modicum of flexibility in dimensions, however any changes to the net CSA, line length, driver offset from closed end, and terminus dimensions will affect tuning and performance, in a manner likely predictable by experienced designers.

That's not to say your proposal couldn't "work" in the strictest sense, but to make an assessment of the merits of the design from which such a morph was derived would be inappropriate.

I've never worked with OSB for anything other than shipping crates, and wonder if adequate joinery could be accomplished. Even particle board might be better?

That's not to say your proposal couldn't "work" in the strictest sense, but to make an assessment of the merits of the design from which such a morph was derived would be inappropriate.

I've never worked with OSB for anything other than shipping crates, and wonder if adequate joinery could be accomplished. Even particle board might be better?

Last edited:

The Tysen being an MLTL IINM, there would be a modicum of flexibility in dimensions, however any changes to the net CSA, line length, driver offset from closed end, and terminus dimensions will affect tuning and performance, in a manner likely predictable by experienced designers.

That's not to say your proposal couldn't "work" in the strictest sense, but to make an assessment of the merits of the design from which such a morph was derived would be inappropriate.

I've never worked with OSB for anything other than shipping crates, and wonder if adequate joinery could be accomplished. Even particle board might be better?

I was thinking of not using the MLTL part in the bottom, just a bass reflex enclosure in bottom. I was going to try and use the top TL part, but extend the length a little which might require (allow?) a bit lower crossover to the woofer. From looking at other threads, it sounded like the TL length was based on volume and 1/4 of the lowest wavelength, but was designed somewhat ad hoc to the particular needed cabinet size. I may have stretched it way too long.

I was thinking the OSB to do a quick mockup since it might not work. But as small as the speakers are going to be MDF may be a better option from the start.

I'm not so sure that much of Dave's design details could be categorized as ad hoc - you could discuss that with him via e-mail perhaps.

As with Scott L, he might have issues with judgement of the performance of an enclosure "inspired by" / "roughly based on" a design over which they may have spent much time modeling, prototyping and fine-tuning.

As with Scott L, he might have issues with judgement of the performance of an enclosure "inspired by" / "roughly based on" a design over which they may have spent much time modeling, prototyping and fine-tuning.

Sorry, maybe ad hoc wasn't the best wording, I just meant that he had mentioned in a few places that length wasn't super critical and was secondary to other cabinet dimensions.I'm not so sure that much of Dave's design details could be categorized as ad hoc - you could discuss that with him via e-mail perhaps.

As with Scott L, he might have issues with judgement of the performance of an enclosure "inspired by" / "roughly based on" a design over which they may have spent much time modeling, prototyping and fine-tuning.

Totally didn't mean to trivialize their expertise and hard work. My bad. Mostly just looking for feedback to see if I was headed down a reasonable path for a speaker for a oddly shaped space.

The original Tysen had a 7" sealed. Tysen V2 has 2 x 5 ¼" in an ML-TL (and has yet to be built).

Think of the above as concepts. A small FR as midTweeter with woofers crossed low (~150-400Hz). The FF85 is a midTweeter we like. Woofers, woofers, seas of woofers. Pick one you like, design a box for it, then graft on either a sealed box, or a midTL for the midTweeter (our preference).

If you want to do a passive XO, you have to take relative driver sensitivity into consideration.

dave

Think of the above as concepts. A small FR as midTweeter with woofers crossed low (~150-400Hz). The FF85 is a midTweeter we like. Woofers, woofers, seas of woofers. Pick one you like, design a box for it, then graft on either a sealed box, or a midTL for the midTweeter (our preference).

If you want to do a passive XO, you have to take relative driver sensitivity into consideration.

dave

zach- I can see now that my own earlier posts could certainly have been read as churlish - not my intent

During the past couple of years "we" have been working on a number of FAST systems with more than a few combination and number of drivers-sometimes based as much as what we have on hand as anything else - and as Dave notes above, the Tysen, or for that matter the Alpair12PW/A7 MTMs, Facets, and others should really be considered as templates for different topologies. From a personal point of view, I tend to gravitate to aesthetics with high WAF - not necessarily a constraint for everyone.

During the past couple of years "we" have been working on a number of FAST systems with more than a few combination and number of drivers-sometimes based as much as what we have on hand as anything else - and as Dave notes above, the Tysen, or for that matter the Alpair12PW/A7 MTMs, Facets, and others should really be considered as templates for different topologies. From a personal point of view, I tend to gravitate to aesthetics with high WAF - not necessarily a constraint for everyone.

From a personal point of view, I tend to gravitate to aesthetics with high WAF - not necessarily a constraint for everyone.

Hahaha...yep...WAF is a big driving force for me finding something squat

The speakers you guys are making look amazing, which was the impetus to use them for inspiration. If we move or readjust the living room I may have to take the ferry trip over and pick up a flatpak for a floorstander.

I've never worked with OSB for anything other than shipping crates, and wonder if adequate joinery could be accomplished. Even particle board might be better?

OSB can be used! I built the prototype for my Pappa's TL using OSB. Nasty, UGLY stuff, but you can make nice tight joints. It was very nice acoustically, however...

For those who might be tempted by the dark (cheap) side: I suppose it might be possible to coat it w/ Bondo & make it something like presentable, but the cost in time & materials to 'fix' the mess far out weigh other options. The wretched thing shot splinters at me every time I touched it.

Cheers, Jim

I'm a little embarrassed to admit I kinda like the look of OSB. Edges look like trash, but the finished side has a nice industrial look to it.

But turns out I found some knock down boxes that will be nearly the size I was planning, just a bit wider that planned on once I turn them on their sides.

But turns out I found some knock down boxes that will be nearly the size I was planning, just a bit wider that planned on once I turn them on their sides.

Speakers are coming together! (after a slowdown from a damaged in shipping knock-down box  , though that gave me time to play with the new miniDSP a bit)

, though that gave me time to play with the new miniDSP a bit)

As I was laying everything out and doing some test cuts with my ugly diy router jig in scrap, I started thinking I should have gone all the way and built them myself out of ply. But for a first build it was probably just as well...I'd have been more frustrated when my skills and tools went a little sideways (turns out while my miter saw will do 90degree full length, it doesn't accurately do 75degree on an 8in width). I'd have also counter sunk screws or used glue alone, since the cheap brad nailer I used sent a lot of them out the sides.

Will I need additional bracing in the bottom BR section (it's gonna eventually have a long slot port)? I'm gonna add a brace in the top ML part, but wondering if the bottom is small enough that I don't need to worry about it.

As I was laying everything out and doing some test cuts with my ugly diy router jig in scrap, I started thinking I should have gone all the way and built them myself out of ply. But for a first build it was probably just as well...I'd have been more frustrated when my skills and tools went a little sideways (turns out while my miter saw will do 90degree full length, it doesn't accurately do 75degree on an 8in width). I'd have also counter sunk screws or used glue alone, since the cheap brad nailer I used sent a lot of them out the sides.

Will I need additional bracing in the bottom BR section (it's gonna eventually have a long slot port)? I'm gonna add a brace in the top ML part, but wondering if the bottom is small enough that I don't need to worry about it.

Attachments

Thanks for the tip Dave. I cut it back before closing it up.

Actually, I got scared and just screwed it shut. I was stuffing the top and realized if it was this tough to adjust acousta-stuf with the side open, using tongs and a screwdriver through the vent and driver hole to adjust it later was gonna be a bear .

.

Actually, I got scared and just screwed it shut. I was stuffing the top and realized if it was this tough to adjust acousta-stuf with the side open, using tongs and a screwdriver through the vent and driver hole to adjust it later was gonna be a bear

All done and been playing for a week (well, almost a week).

I tried really hard to just let them break-in and not mess with them, but I failed...

I initially didn't stuff them enough, so I added more, especially near the terminus. Then I even lightly stuffed a folded up piece of denim insulation in the opening.

Adding the extra stuffing dramatically improved the midrange. They sounded a little hollow before.

I also initially set the crossover at 250hz, first order [miniDSP] (though played around with some other configurations). After a couple days, I lowered the crossover to 160hz (initially with LR24, then tried out Harsch but may not have implemented it correctly). After lowering the crossover, they really started singing.

I tried really hard to just let them break-in and not mess with them, but I failed...

I initially didn't stuff them enough, so I added more, especially near the terminus. Then I even lightly stuffed a folded up piece of denim insulation in the opening.

Adding the extra stuffing dramatically improved the midrange. They sounded a little hollow before.

I also initially set the crossover at 250hz, first order [miniDSP] (though played around with some other configurations). After a couple days, I lowered the crossover to 160hz (initially with LR24, then tried out Harsch but may not have implemented it correctly). After lowering the crossover, they really started singing.

Attachments

Well, I figure the bracing is probably enough, and glued it all up.

Went with two separate units so I could have some flexibility in placement and so I could make mid/tweet changes or woofer changes without being back to square one.

Went with two separate units so I could have some flexibility in placement and so I could make mid/tweet changes or woofer changes without being back to square one.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Shorty Tysen WAW / FAST Question