Yes, the PS95-8 has been tested with this speaker and sounds quite nice. It has a little more shall we say, “excitement” in the higher registers. It is a drop in replacement with the current crossover with just minor tweak to the value of R1 attenuation resistor.

Have not tried Dynavox, ever.

Earlier in this thread I discuss using the PS95 with the SB23 woofer and listened to them as an OB combo for several weeks.

https://www.diyaudio.com/forums/ful...5-8-fast-waw-ref-monitor-181.html#post5893670

Have not tried Dynavox, ever.

Earlier in this thread I discuss using the PS95 with the SB23 woofer and listened to them as an OB combo for several weeks.

https://www.diyaudio.com/forums/ful...5-8-fast-waw-ref-monitor-181.html#post5893670

SB Acoustics SB10PGC21-4 3" Full Range

SB Acoustics SB10PGC21-4 3" Full Range

looks like a candidate. I know, the rising response... But I have tried suspending a modeling clay 1" ball right in front of the dustcap and it flattens out the rising response. This work only to a certain extent but may be just what this driver needs.

SB Acoustics SB10PGC21-4 3" Full Range

looks like a candidate. I know, the rising response... But I have tried suspending a modeling clay 1" ball right in front of the dustcap and it flattens out the rising response. This work only to a certain extent but may be just what this driver needs.

Interesting driver - the peak is only on-axis. If you listen slightly off axis, it is actually very flat. I think it would sound quite nice. This is a new driver for me, so might have to try this one day soon. It is 4 ohms though so the XO would require approximately a 120uF capacitor to keep at 900Hz XO frequency. This is too big for a film cap, so probably a BP 100uF and 22uF film cap bypass could work.

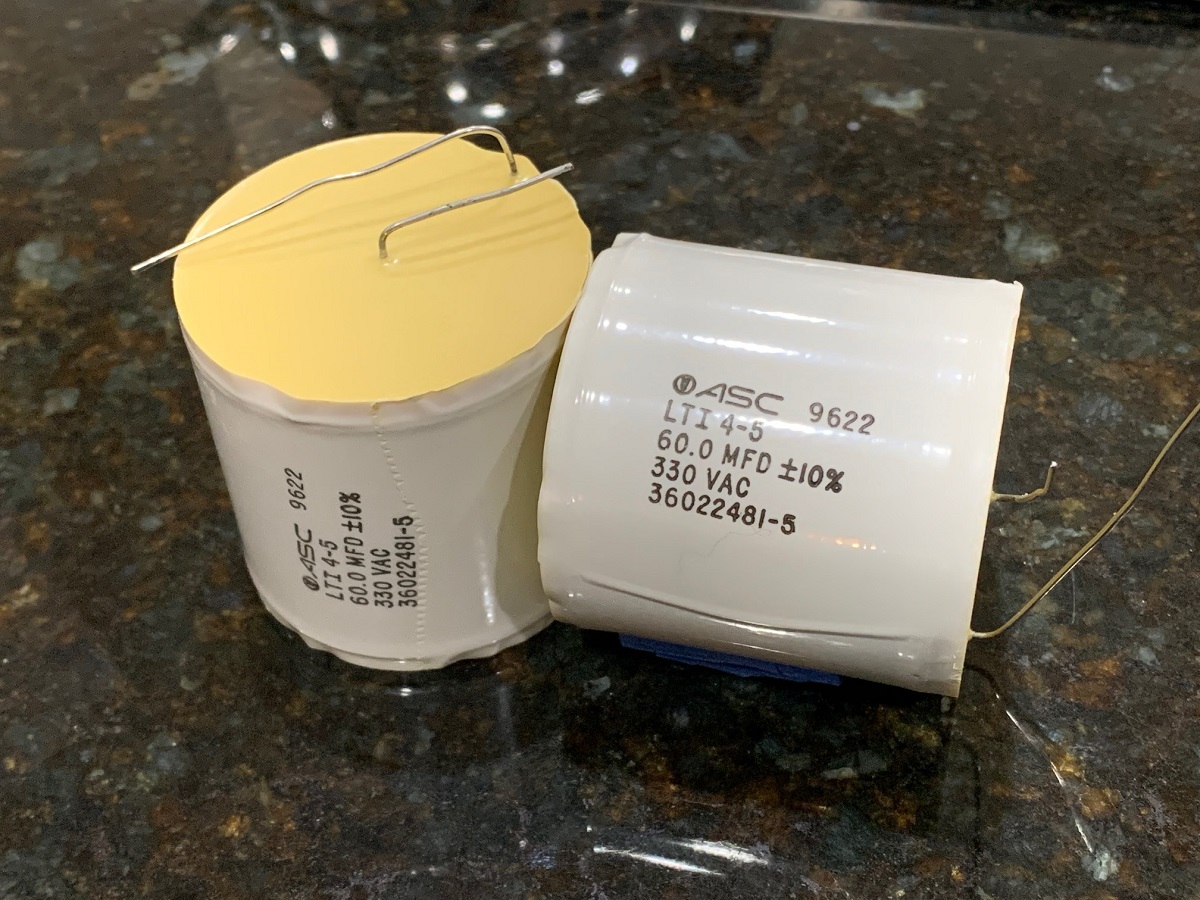

I just got a nice box of goodies from Vunce: a pair of the big fat 60uF ASC film cap, and the magical unicorn Miflex KPCU-01 paper-PP-oil 0.1uF bypass caps that Maty has been raving about. Thanks, Vunce!

Can't wait to try them out in the XO. But first have to do some other work on deadline before I can play with my speakers.

These look way cool! The Miflex exude quality - never had a cap this cool looking before!

The ASC's are about 2.5in in diameter - they are huge!

Can't wait to try them out in the XO. But first have to do some other work on deadline before I can play with my speakers.

These look way cool! The Miflex exude quality - never had a cap this cool looking before!

The ASC's are about 2.5in in diameter - they are huge!

Attachments

Interesting driver - the peak is only on-axis. If you listen slightly off axis, it is actually very flat. I think it would sound quite nice. This is a new driver for me, so might have to try this one day soon. It is 4 ohms though so the XO would require approximately a 120uF capacitor to keep at 900Hz XO frequency. This is too big for a film cap, so probably a BP 100uF and 22uF film cap bypass could work.

Or.... use two drivers to bring it to 8 Ohms, and set the top driver OB, as in the Nola Brio. That could be cool....

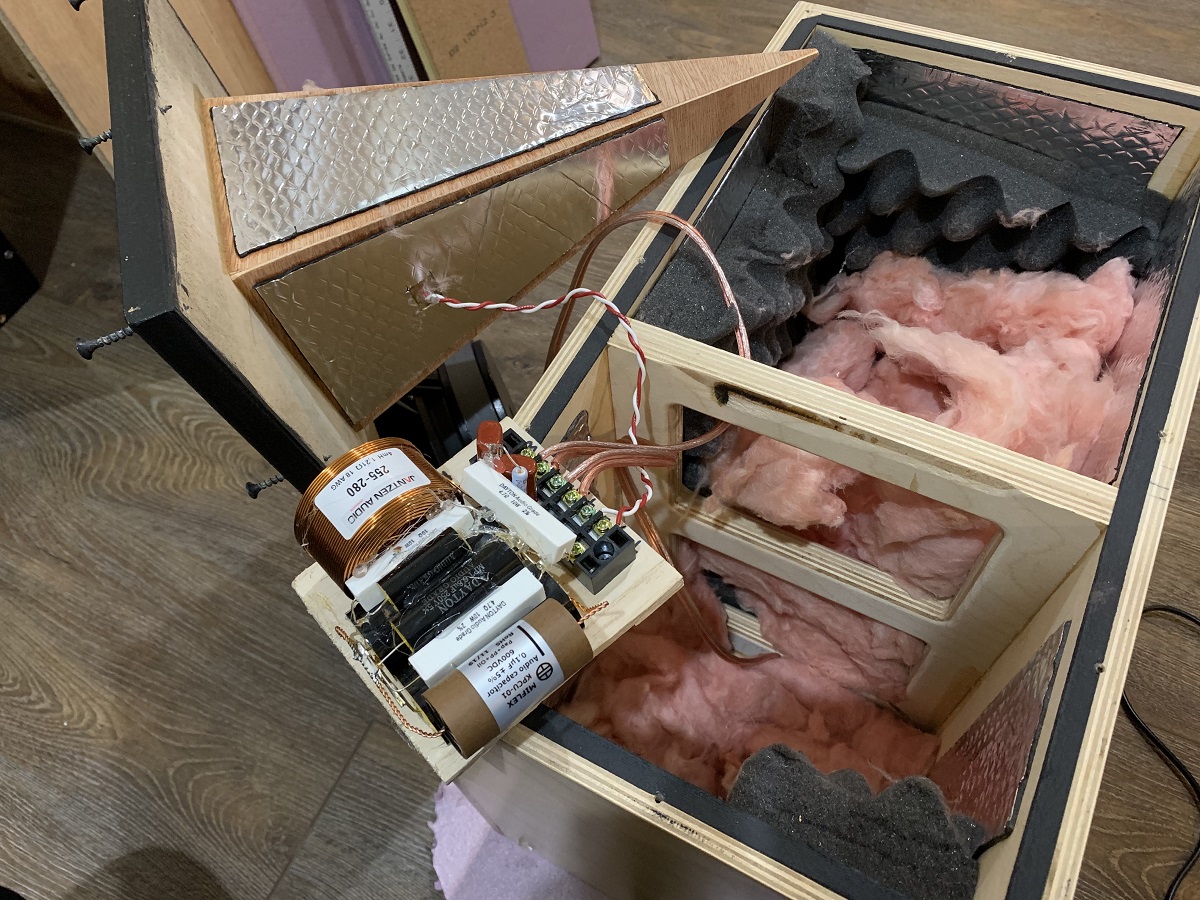

The Miflex copper foil/paper/polyethylene/oil KPCU-01 bypass cap (0.1uF) is now installed in the 10F/RS225F XO (this is my original, pre-PCB XO). Listened to a few songs and I think I hear a difference. Vocals are warmer and more resolving, imaging feels very precise. Nice caps. I have to thank Vunce for giving me a great upgrade to the sound.

Attachments

With very good recordings and high DR the difference is amazing. Acoustic and electrified instruments with voices without Autotune. Of course, if you listen to studio recordings like Billie Elish...

Album list - Dynamic Range Database: Billie Eilish

Next, tweeter resistors.

Album list - Dynamic Range Database: Billie Eilish

Next, tweeter resistors.

I have heard Mills resistors are very good for XO's - are they non-inductive? The basic Dayton Audio "Audio Grade" 2% tolerance cement filled resistors I have been using are supposedly non-inductive. I should measure one on my LCR meter and crack it open to see what is inside. I have used little green ceramic Vishay and they turned out to increase THD when used as source resistors on an amp. The best source resistors I have so far are KOA Speer BPR's. I might have to try getting a bunch in typical values needed for XO's.

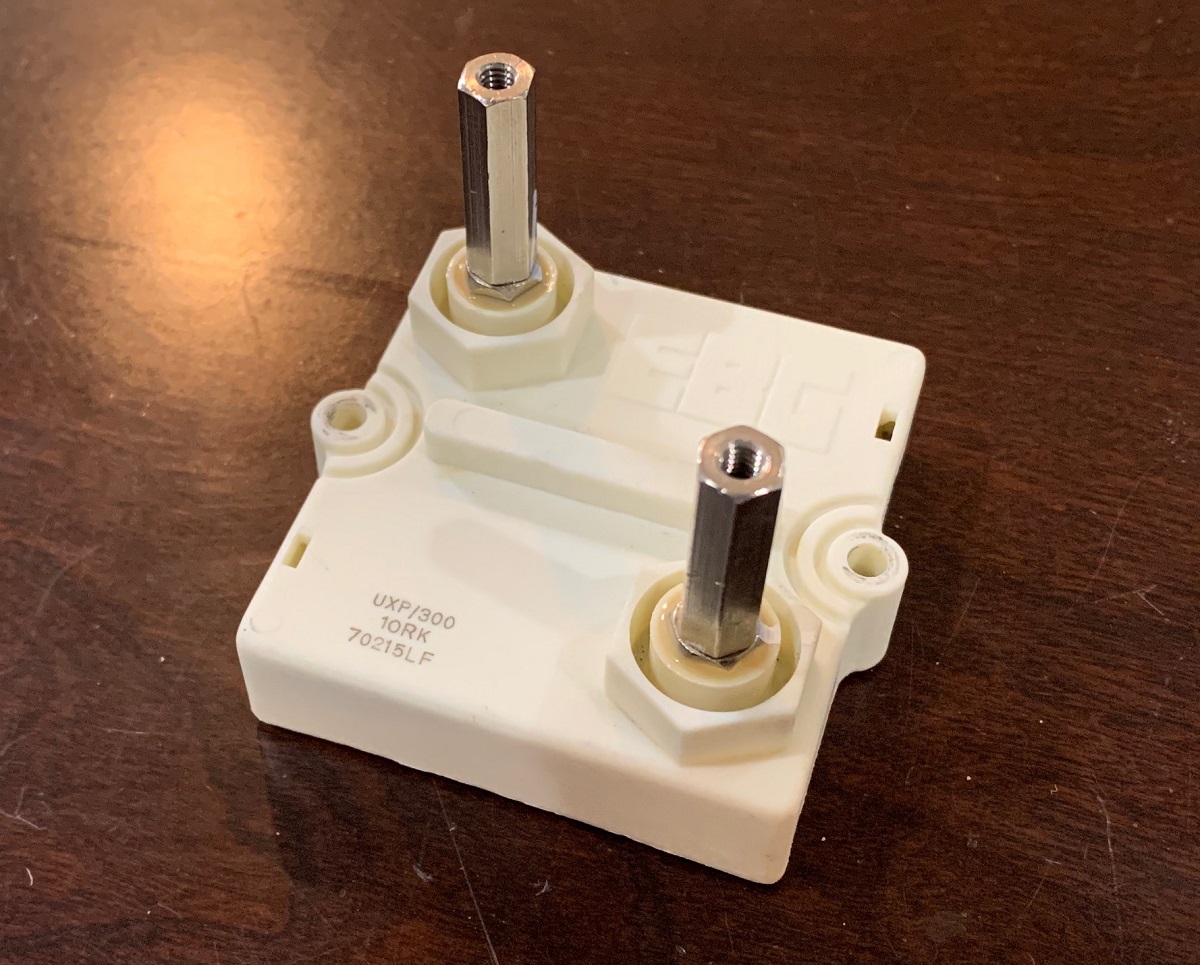

So I sacrifieced a Dayton audio grade 10R 10W 2% XO resistor to the vise and see that the inside is a wirewound element. It measures below 0.050mH with the DATS LCR so technically, it is "non-inductive" and does not show up at the rather high 50uH level associated with practical speaker crossovers. I do know that wirewound resistors tend to be higher distortion than metal thin film or carbon film or carbon composition. I should compare this 10R Dayton with my reference ultra low distortion 300W EBG UXP/300 10RK resistor someday. But I think in terms of speaker distortion at the usual -50dB levels, this type of resistor is not going to matter. For a driver like the Purifi 6.5in midbass woofer that I will be getting (a reported -75dB aucoustic THD at 2.83v), perhaps the best resistors will ne needed to achieve the lowest possible THD?

Here is the teardown of the Dayton "Audio Grade" 10ohm 10W 2% resistor (which measured in at 4% tolerance, btw):

Here is what an ultralow distortion 10R 300W resistor looks like (normally bolted to a heatpipe CPU cooler with a fan):

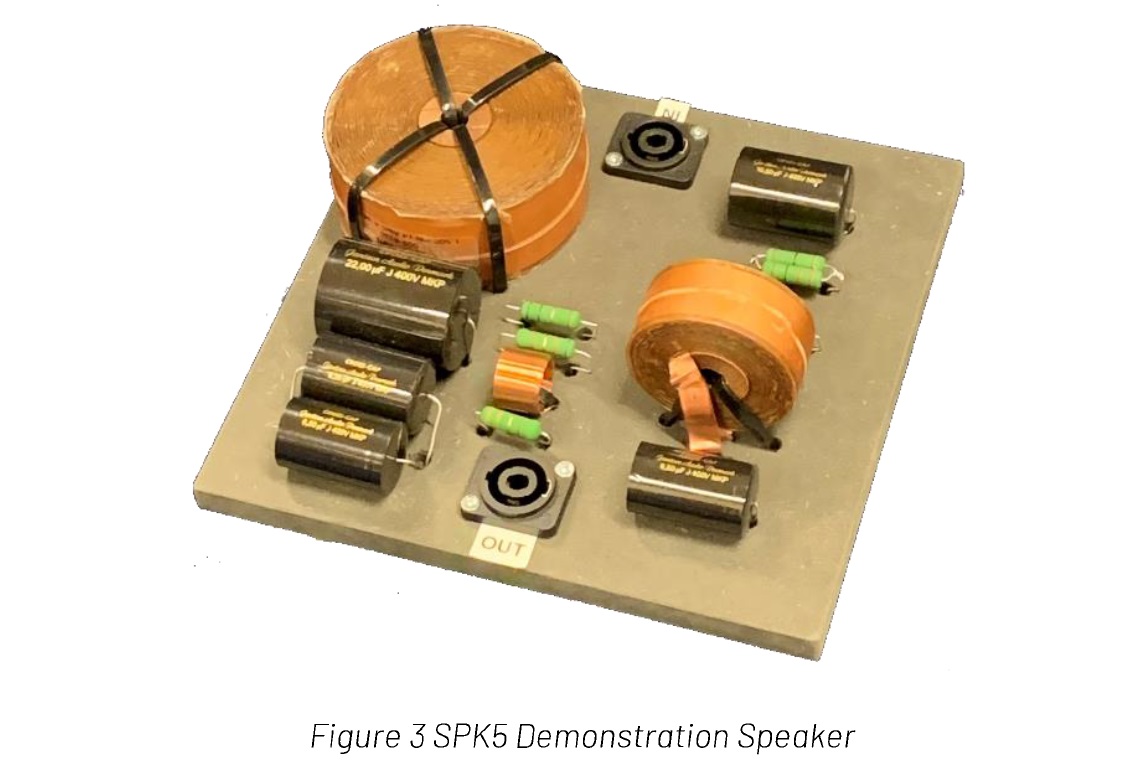

Here is the Purifi 6.5 two-way reference XO, nice wax and copper foil air core inductors, but those green resistors look like metal thick film to me. Does anyone know if these are premium resistors, and what brand?

Here is the teardown of the Dayton "Audio Grade" 10ohm 10W 2% resistor (which measured in at 4% tolerance, btw):

Here is what an ultralow distortion 10R 300W resistor looks like (normally bolted to a heatpipe CPU cooler with a fan):

Here is the Purifi 6.5 two-way reference XO, nice wax and copper foil air core inductors, but those green resistors look like metal thick film to me. Does anyone know if these are premium resistors, and what brand?

Attachments

Last edited:

I thought those were KOA SPR series 5w carbon film, but looking more closely at them, they don't have quite the right shape.

I use Mills MRA series in my crossovers, but have been meaning to try some Ohmite TA series, thick film planar resistors.

TA810PW10R0J Ohmite | Resistors | DigiKey

I got a nice selection recently, very inexpensively, might try them at some point.

You could always make your own:

GRAPHITE RESISTORS

I was going to make a bunch of values to use in l-pads for my mid/hf horns, but I ended up getting some autoformers, and they work extremely well

I use Mills MRA series in my crossovers, but have been meaning to try some Ohmite TA series, thick film planar resistors.

TA810PW10R0J Ohmite | Resistors | DigiKey

I got a nice selection recently, very inexpensively, might try them at some point.

You could always make your own:

GRAPHITE RESISTORS

I was going to make a bunch of values to use in l-pads for my mid/hf horns, but I ended up getting some autoformers, and they work extremely well

Thanks for the link on making your own graphite resistors! Cool stuff!

No need to burn your own pencils to get the leads out. Just use drafting pencil leads (no wood)! Staedtler Mars etc. I actually have a bunch of them on hand. The silver brazing of the wire leads is a pain though.

No need to burn your own pencils to get the leads out. Just use drafting pencil leads (no wood)! Staedtler Mars etc. I actually have a bunch of them on hand. The silver brazing of the wire leads is a pain though.

Thanks for the link on making your own graphite resistors! Cool stuff!

No need to burn your own pencils to get the leads out. Just use drafting pencil leads (no wood)! Staedtler Mars etc. I actually have a bunch of them on hand. The silver brazing of the wire leads is a pain though.

Yeah, I just bought leads too. I used bare copper wire, small gauge, 24-28 or so. Get a maap gas or similar torch, heat an end then add solder, generously.

I used phenolic tube with some epoxy to house them, it seemed to work well. I think high temp potting compound would work better, as certain types are designed with better thermal parameters.

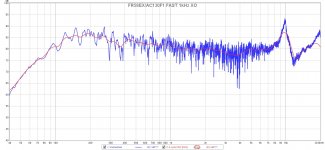

Are the fast fluctuations all long a product of mic or real measurement?

By the way the way, i recently got my hands on these little bugs...thay have the fastest more agile bass i have ever heard in any driver, ran fullrange (form limited experience i admit), but they sounds a little bit «weird», in closed of ported box, and i wonder if it it not the continuous sharp dips and spikes seen in the graphic joined.... (most pronounced around 4Khz)

By the way the way, i recently got my hands on these little bugs...thay have the fastest more agile bass i have ever heard in any driver, ran fullrange (form limited experience i admit), but they sounds a little bit «weird», in closed of ported box, and i wonder if it it not the continuous sharp dips and spikes seen in the graphic joined.... (most pronounced around 4Khz)

Attachments

Last edited:

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor