@Vunce:

Those are really looking like TL speakers! Great work, Vunce. Very neat and tidy work. It has to be neat and tidy as you are doing it in the kitchen it looks like. 🙂

I forgot to mention this earlier but we will need to add som bracing in the front to back direction along the long run on the back wall. As well as side to side between the two side walls where the walls are free more than 4-5in to reduce drum head flex modes under pressurization.

When making in 3/4in BB ply, a lot of bracing is not needed as the internal dividers act as the bracing.

@Sarathsca: thanks for the links - those cabinets appear to be of similar size as these but use a dome tweeter and are all bass reflex. IMO, a full range driver integrates so much better than a dome tweeter with the RS225. At first I was thinking these boxes were too big, but no - that’s just what stand mount speakers look like.

Those are really looking like TL speakers! Great work, Vunce. Very neat and tidy work. It has to be neat and tidy as you are doing it in the kitchen it looks like. 🙂

I forgot to mention this earlier but we will need to add som bracing in the front to back direction along the long run on the back wall. As well as side to side between the two side walls where the walls are free more than 4-5in to reduce drum head flex modes under pressurization.

When making in 3/4in BB ply, a lot of bracing is not needed as the internal dividers act as the bracing.

@Sarathsca: thanks for the links - those cabinets appear to be of similar size as these but use a dome tweeter and are all bass reflex. IMO, a full range driver integrates so much better than a dome tweeter with the RS225. At first I was thinking these boxes were too big, but no - that’s just what stand mount speakers look like.

Last edited:

Vunce, good progress!

With the bracing as advised by X, you have some work to keep the elves busy. 🙂

With the bracing as advised by X, you have some work to keep the elves busy. 🙂

Thanks Fellas,

Yes, bracing is a must with this size enclosure.

Zman, the Elves are always busy 😀

Yes, bracing is a must with this size enclosure.

Zman, the Elves are always busy 😀

The Elves were busy again this evening, the interior pieces of 1/2” XPS were glued in to form the TL. It’s starting to look like a speaker enclosure now 🙂

Progress will pause for a bit until I receive all the drivers and XO parts.

very nicely done!

very clean cuts and looks sealed well.

All done with a hand held knife?

I'm all for prototyping with XPS foam. Easier to cut, doesn't cost much, and can really give a good idea of the size and sound.

very clean cuts and looks sealed well.

All done with a hand held knife?

Hi Perceval,

I used a segmented snap blade knife and a drywall T-square to cut the XPS within a half inch of the final panel size. Then I go to the table saw with a 60 tooth blade and fine cut to the dimensions needed. This assures all square cuts and the pieces are all the exact same width.

Definitely cuts like Buttah! 😀

Last edited:

Vunce, great work on the cabinet, and X, nice design. I have 2 burning questions:

1. X, does your software design the internal pathway of of the TL enclosure?. I am wondering how you come up with the pathway, and the rectangular box near the bottom.

2. I have 2 x 4R 6.5" Dayton drivers and a 8R 1-1/8" Dayton silk dome tweeter. I bought these a while ago to make an 8R MTM by wiring the 2 x 6.5" drivers in series. I really am not a fan of how MTM's look, so wondering if the TL cabinet can be modified to accept the 2 x 6.5" drivers wired in series (in place of the RS225) with the dome tweeter below them. If possible I would prototype this design. (I have lots of XPS left over from house construction). If the 2 x 6.5" drivers idea works, I can always prototype a FR if I do not like the sound of the silk dome tweeter.

Let me know your thoughts?

Merry Xmas and Happy New year to all.

1. X, does your software design the internal pathway of of the TL enclosure?. I am wondering how you come up with the pathway, and the rectangular box near the bottom.

2. I have 2 x 4R 6.5" Dayton drivers and a 8R 1-1/8" Dayton silk dome tweeter. I bought these a while ago to make an 8R MTM by wiring the 2 x 6.5" drivers in series. I really am not a fan of how MTM's look, so wondering if the TL cabinet can be modified to accept the 2 x 6.5" drivers wired in series (in place of the RS225) with the dome tweeter below them. If possible I would prototype this design. (I have lots of XPS left over from house construction). If the 2 x 6.5" drivers idea works, I can always prototype a FR if I do not like the sound of the silk dome tweeter.

Let me know your thoughts?

Merry Xmas and Happy New year to all.

Hi Myles,

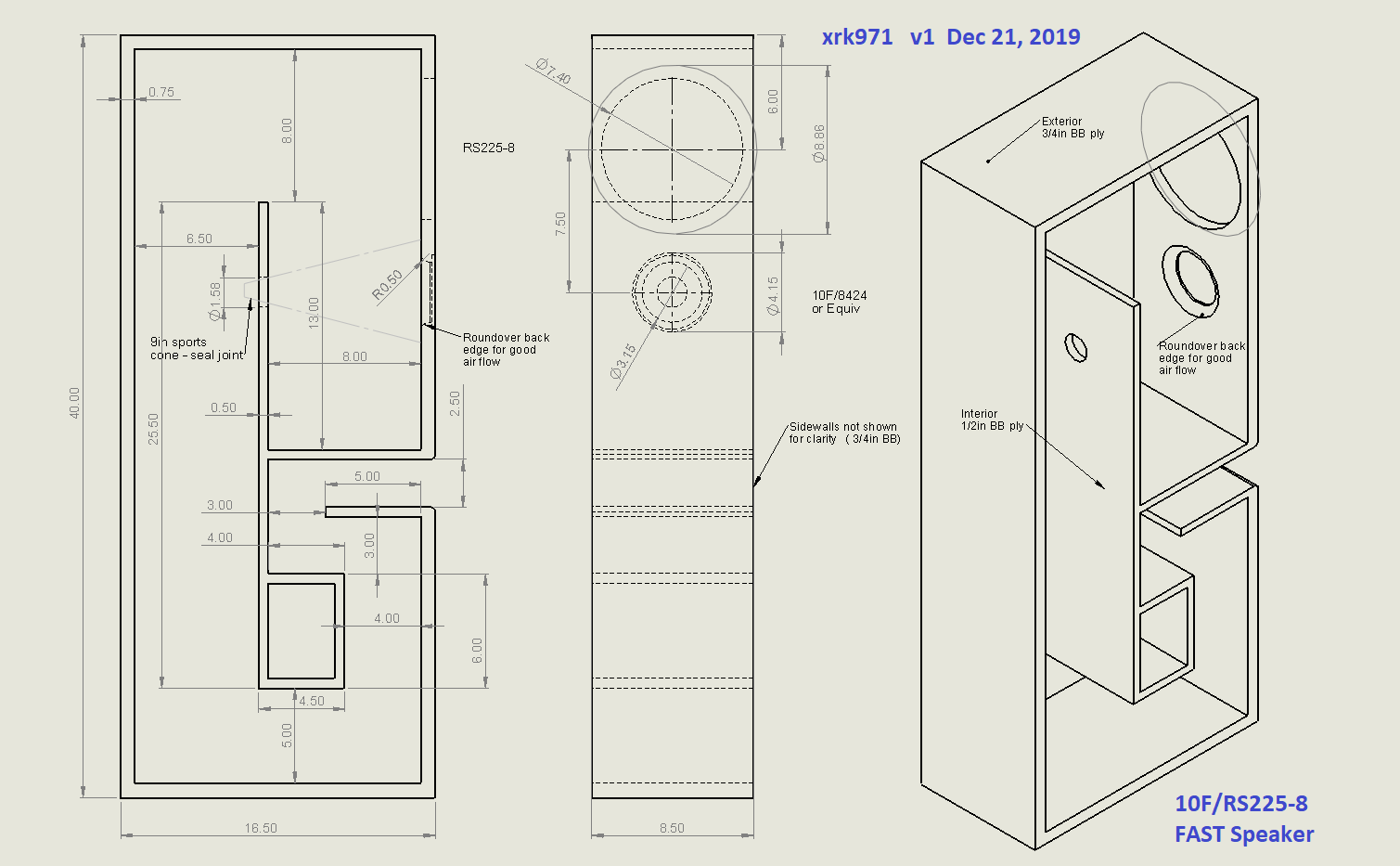

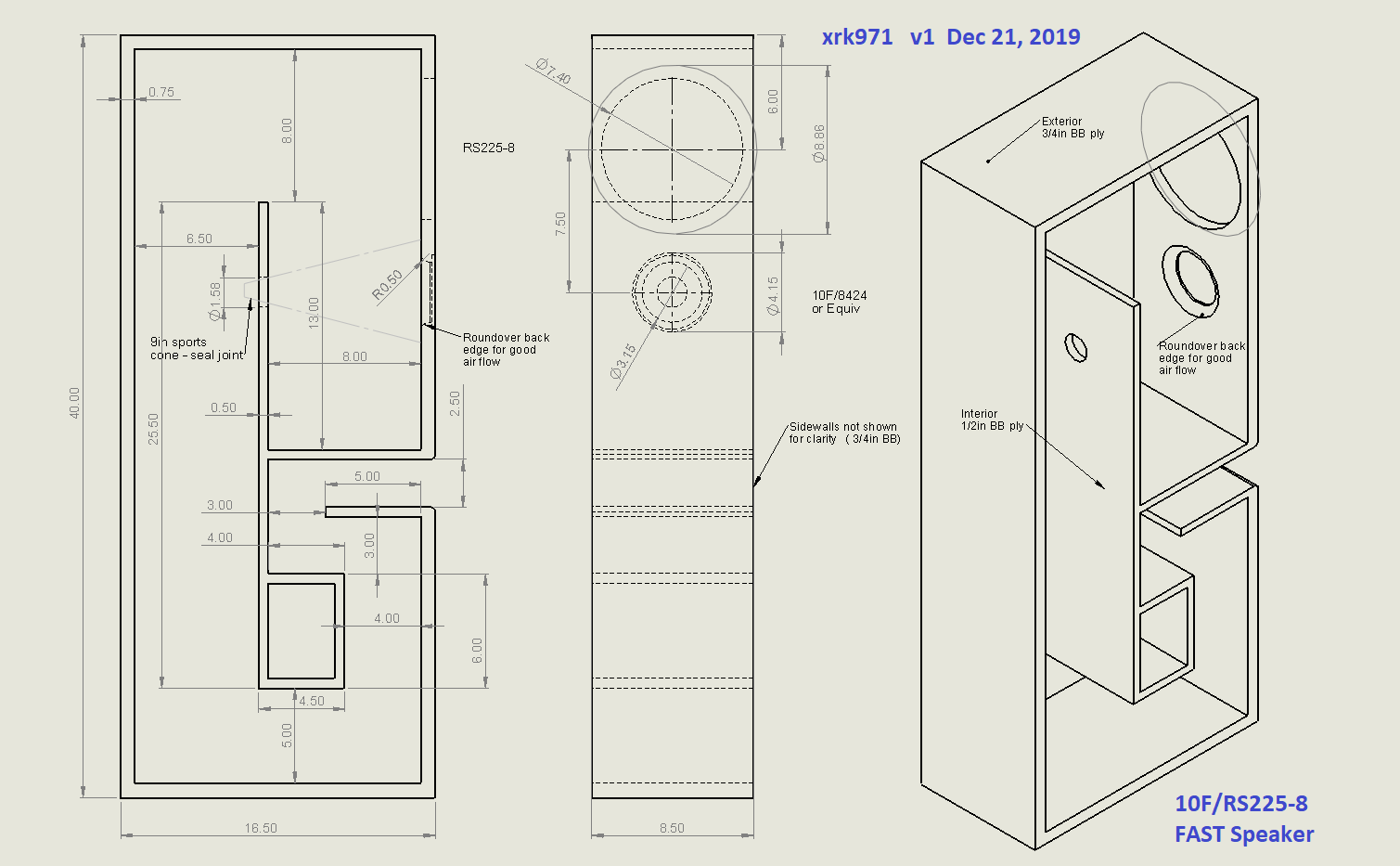

I use Akabak software to model and simulate the TL. Every bend and turn. That hollow box turned out as a result of needing to get a certain path and a narrowing taper to the TL. It goes from 8in to 6.5in to 5in to 4in to 3in to 2.5in at the exit. Also, a desire to put the exit near the full range for good integration.

Your Dayton 6.5in drivers probably could be made to work but it would probably need a redesign. If you mount your drivers in a cabinet and measure them at a fixed distance and produce and FRD and ZMA file, I can help you design a crossover. It’s an elaborate process - basically what the entire Multi-way forum is dedicated to doing.

I helped out member Hdspeakerman with something similar and he got me an FRD and ZMA data for a FR58EX and AC130F1. I made a XO with similar topology as this one with the data and it turned out nice. Ready on it here and see if it’s sonething you want to try. Dual 6.5in woofers make a nice TL too. About same area as an 8in I think.

FR58EX and AC130F1 micro-FAST / WAW

I use Akabak software to model and simulate the TL. Every bend and turn. That hollow box turned out as a result of needing to get a certain path and a narrowing taper to the TL. It goes from 8in to 6.5in to 5in to 4in to 3in to 2.5in at the exit. Also, a desire to put the exit near the full range for good integration.

Your Dayton 6.5in drivers probably could be made to work but it would probably need a redesign. If you mount your drivers in a cabinet and measure them at a fixed distance and produce and FRD and ZMA file, I can help you design a crossover. It’s an elaborate process - basically what the entire Multi-way forum is dedicated to doing.

I helped out member Hdspeakerman with something similar and he got me an FRD and ZMA data for a FR58EX and AC130F1. I made a XO with similar topology as this one with the data and it turned out nice. Ready on it here and see if it’s sonething you want to try. Dual 6.5in woofers make a nice TL too. About same area as an 8in I think.

FR58EX and AC130F1 micro-FAST / WAW

Thanks for the quick reply and the offer to help at a future date. I knew that a new crossover would have to be worked on. Thanks for confirming that using 2 drivers at the top of the enclosure would be possible. Is Akabak a steep learning curve and is it expensive to acquire?. I am retired and will have lots of time to put towards electronics soon.

Regards

Regards

Akabak is free but requires a 32bit Windows machine or a virtual machine. Learning curve is steep but you can start with sample code and go from there. There is even a thread on DIYA on how to use it. If you can program in other languages and understand the concept of nodes in a 1-dim FEM, you are good. Of all the audio programs, it is probably the most difficult to use but the most flexible and powerful. It does complex horns and TL’s very well.

The 10/81414 is a 3.5in driver - very much like a TC9FD but in fiberglass cone and more powerful motor. I am not sure it is quite sized to drive a 28in Cornu - designed for a 4in driver. You should try putting a TC9FD there and if that works, the 8414 will work but sound better - smoother, lower distortion, maybe better bass as motor is more powerful.

I tried modelling the RS225 in hornresp but I think I must be doing something wrong. Can you tell me:

1. The size of the first chamber

2. The length of the line from the beginning of the first chamber

3. The area of the line at the beginning.

4. The area of the line at the exit

thanks!

1. The size of the first chamber

2. The length of the line from the beginning of the first chamber

3. The area of the line at the beginning.

4. The area of the line at the exit

thanks!

It's all here in the CAD drawing - I am not sure what you are missing?

The internal channel width is 8.5in.

There are no "chambers" per se - it is a contracting channel. It is modeled as a series of straight to expanding to contracting waveguides which model the corners.

The first node is 15in long to the driver, then 1 more inch to the start of the corner which is a 4in long expansion from 8in to 11.3in (45deg diag). More examples of how to model this can be found in the Subwoofer forum for example, where they model tapped horns and you can see the fold plan stretched out into a long line. Like this:

I have a similar drawing but it is a messy hand sketch.

Area of line at begining is 8.0in x 8.5in or 439cm^2

Area at exit vent is 2.5in x 8.5in or 137cm^2

Total line length including bends and corners is about 89in or 2.26m which gives a 1/4-wave fundamental corner freq of 39Hz not including the effect of the taper - which will lower the frequency.

The internal channel width is 8.5in.

There are no "chambers" per se - it is a contracting channel. It is modeled as a series of straight to expanding to contracting waveguides which model the corners.

The first node is 15in long to the driver, then 1 more inch to the start of the corner which is a 4in long expansion from 8in to 11.3in (45deg diag). More examples of how to model this can be found in the Subwoofer forum for example, where they model tapped horns and you can see the fold plan stretched out into a long line. Like this:

I have a similar drawing but it is a messy hand sketch.

Area of line at begining is 8.0in x 8.5in or 439cm^2

Area at exit vent is 2.5in x 8.5in or 137cm^2

Total line length including bends and corners is about 89in or 2.26m which gives a 1/4-wave fundamental corner freq of 39Hz not including the effect of the taper - which will lower the frequency.

Last edited:

xrk971: Great design, both fun and educating. Havent read all the pages yet though.

How would you compare RS225-8 to some of the other 8" mentioned in the thread. For examble the SB23? And would you use the 4 ohm variant of the RS225, if the XO is pure digital DSP. Or still stick with the RS225-8?

How would you compare RS225-8 to some of the other 8" mentioned in the thread. For examble the SB23? And would you use the 4 ohm variant of the RS225, if the XO is pure digital DSP. Or still stick with the RS225-8?

xrk971 good afternoon (here). What is this "10/81414" ? I'm trying to find some datasheets from yesterday, but in vane. Can you please post here a link to datasheets ?

Sorry about the typo.

Scanspeak Discovery 10F/8414G-10 4" Full Range: Madisound Speaker Components

@Roky

How would you compare RS225-8 to some of the other 8" mentioned in the thread. For examble the SB23? And would you use the 4 ohm variant of the RS225, if the XO is pure digital DSP. Or still stick with the RS225-8?

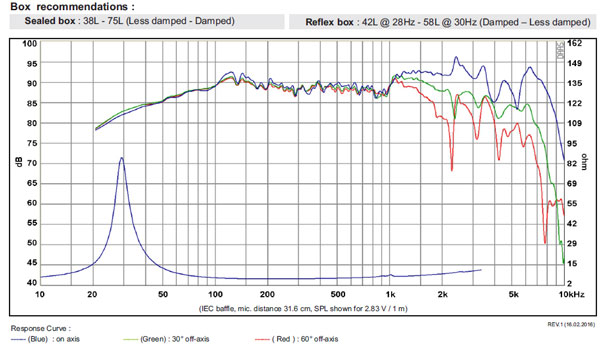

RS225-8 is a unique driver, unmatched by other brands at any price. It offers a very flat wide and response that makes the passive 1st order XO work. It also has a lot of Xmax, the right Qts and Vas for a sealed alignment or a vented alignment, and lightweight aluminum cone for tight, articulate midbass.

The SB23 offers deeper bass extension but requires more filtering as not as flat. If going active DSP, you can use almost any driver as EQ is available to flatten. It is also paper cone and has a different sound. I listened to mine in an OB for months with DSP. But still prefer RS225-8. 4ohm is for people who use car audio amps, I see no reason for home use.

Last edited:

xrk971: Thank you for your answer! Seems I must begin saving up for a pair 🙂!

I have the Vifa TC9 at hand - Currently waiting to buy some foamcore.

Have you tried making a comparison between the dagger enclosure and a more conventional shaped enclosure (ie. rectangular)? Im sure the dagger will win, but it would be interesting to know how big the difference actually is.

I have the Vifa TC9 at hand - Currently waiting to buy some foamcore.

Have you tried making a comparison between the dagger enclosure and a more conventional shaped enclosure (ie. rectangular)? Im sure the dagger will win, but it would be interesting to know how big the difference actually is.

Not a direct A/B test but I have made many “box” rear chambers and know from sound quality that I hear and lack of artifacts that the Dagger is as close as you can come to an open baffle (no back chamber) in terms of low distortion sound quality with no reflections. There was a measurement where I superimposed the measurement from the Dagger and an OB and they are virtually identical. The orange soccer/football training cones/pylons are very close to a Dagger and easy to use and low cost. Their slightly soft rubbery material but with a form shape is actually ideal as it doesn’t resonate like a hard plastic chamber.

You just have to look at the frequency response below 2kHz to see why this driver works so well. The 7mm Xmax is also another hard to find feature in an 8in moderate/low Qts driver.

https://www.parts-express.com/pedocs/specs/295-356--rs225-8-spec-sheet.pdf

They are on sale at present for $50 - a very good price.

The SB23 has almost as much Xmax and similar Qts but Vas is 94L vs RS225’s 57L. And has quite a rough frequency response jump at 1kHz:

I’ll try to design a passive XO around the SB23 but think that the XO will have to go lower and probably the woofer will have less of an impact on the midbass which is where the RS225 shines.

You just have to look at the frequency response below 2kHz to see why this driver works so well. The 7mm Xmax is also another hard to find feature in an 8in moderate/low Qts driver.

https://www.parts-express.com/pedocs/specs/295-356--rs225-8-spec-sheet.pdf

They are on sale at present for $50 - a very good price.

The SB23 has almost as much Xmax and similar Qts but Vas is 94L vs RS225’s 57L. And has quite a rough frequency response jump at 1kHz:

I’ll try to design a passive XO around the SB23 but think that the XO will have to go lower and probably the woofer will have less of an impact on the midbass which is where the RS225 shines.

Last edited:

It's all here in the CAD drawing - I am not sure what you are missing?

The internal channel width is 8.5in.

There are no "chambers" per se - it is a contracting channel. It is modeled as a series of straight to expanding to contracting waveguides which model the corners.

The first node is 15in long to the driver, then 1 more inch to the start of the corner which is a 4in long expansion from 8in to 11.3in (45deg diag). More examples of how to model this can be found in the Subwoofer forum for example, where they model tapped horns and you can see the fold plan stretched out into a long line. Like this:

I have a similar drawing but it is a messy hand sketch.

Area of line at begining is 8.0in x 8.5in or 439cm^2

Area at exit vent is 2.5in x 8.5in or 137cm^2

Total line length including bends and corners is about 89in or 2.26m which gives a 1/4-wave fundamental corner freq of 39Hz not including the effect of the taper - which will lower the frequency.

i'm wondering if this setup still requires subwoofer or not...

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor