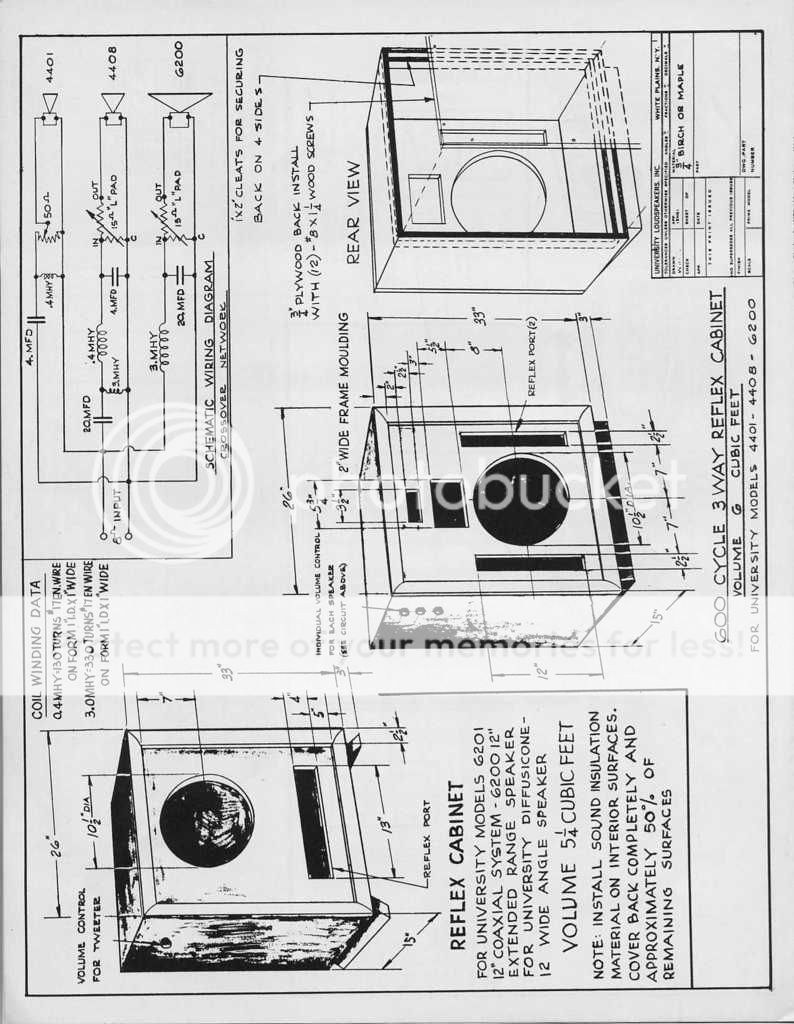

Thank you everyone. Open baffle or two drive is not an option for me. I have very little experience in speakers, but my friend said they are sounding very good in this cab. Bass is also very good. There is one similar design for University 6201 drivers, which are quite similar (without diffucone) to my drivers.

http://www.hifilit.com/hifilit/University/1952-B-4.jpg

Regards

Sachin

http://www.hifilit.com/hifilit/University/1952-B-4.jpg

Regards

Sachin

I think I have a similar problem with a very expensive driver I have shipped to Taiwan.

If the pole has shifted through shock, would it not be possible to mount the driver in a baffle with the narrow gap in the VC on the bottom, and then holding the baffle only,

slam the baffle edge down on a hard surface? We have little to lose and much to gain.

the driver is unusable now and the man has no one to fix it. It will be expensive to ship

back and then the hassle of trying to make a shipping claim begins. he is very happy with the sound of the other driver (Jensen g600). I am not sure I will ever ship something like this again. ea. driver was in its own max. size box mounted on baffle and double boxed as per Great Plains Audio instructions. thanks for your help.

If the pole has shifted through shock, would it not be possible to mount the driver in a baffle with the narrow gap in the VC on the bottom, and then holding the baffle only,

slam the baffle edge down on a hard surface? We have little to lose and much to gain.

the driver is unusable now and the man has no one to fix it. It will be expensive to ship

back and then the hassle of trying to make a shipping claim begins. he is very happy with the sound of the other driver (Jensen g600). I am not sure I will ever ship something like this again. ea. driver was in its own max. size box mounted on baffle and double boxed as per Great Plains Audio instructions. thanks for your help.

Please define 'thick' since to me it refers to high density carpet underlayment to get that ultra plush thick carpet 'feel', so way too dense for most speaker cab alignments [tunings].

Typically, I did/do/recommend what Altec, University, Jensen and some others did way back when, which is to use 1" or 2" thick acoustic fiberglass insulation [Owens-Corning 703 or similar duct board for damping heat/AC ducts].

Note that University's 'cryptic' damping instructions means to line the top [or the end wall that's furthest from the vent], back and one side with damping material. IOW, only one of any parallel walls with the understanding that if it still sounds a bit 'boxy'/'hollow', then either add more on top of existing and/or start lining other walls and if the vent is near an end wall, then only do it as a last resort before beginning to add stuffing.

Altec Valencia [846A] shown: http://classicaudio.ru/forum/uploads/monthly_08_2014/post-1619-0-29283900-1407423058.jpg

Another option, and the one I recommend is that if you need more than the basic lining, then damp the vent using an impulse signal [AKA the 'click' test'. This removes any 'hangover'/'boom' from the system [AKA 'critically' damping the vent]: https://www.flickr.com/photos/515b/5408539714/in/dateposted-public/

Of course if you can do a proper impulse response test it will be more accurate than your hearing.

GM

Typically, I did/do/recommend what Altec, University, Jensen and some others did way back when, which is to use 1" or 2" thick acoustic fiberglass insulation [Owens-Corning 703 or similar duct board for damping heat/AC ducts].

Note that University's 'cryptic' damping instructions means to line the top [or the end wall that's furthest from the vent], back and one side with damping material. IOW, only one of any parallel walls with the understanding that if it still sounds a bit 'boxy'/'hollow', then either add more on top of existing and/or start lining other walls and if the vent is near an end wall, then only do it as a last resort before beginning to add stuffing.

Altec Valencia [846A] shown: http://classicaudio.ru/forum/uploads/monthly_08_2014/post-1619-0-29283900-1407423058.jpg

Another option, and the one I recommend is that if you need more than the basic lining, then damp the vent using an impulse signal [AKA the 'click' test'. This removes any 'hangover'/'boom' from the system [AKA 'critically' damping the vent]: https://www.flickr.com/photos/515b/5408539714/in/dateposted-public/

Of course if you can do a proper impulse response test it will be more accurate than your hearing.

GM

The carpet is very similar to the one use on car flooring, not very thick. My friend has built Altec 602 lined with similar cloth without any additional damping. Thanks for posting Altec pic and another links. I think will do similar arrangements. Should I line them with felt without any additional damping? or use some Polywool sheets(I am not sure on availability of Glasswool in my area) on back,top and one side of cab?

Some people also suggested to cover reflex port with felt from inside.

Regards

Sachin

Some people also suggested to cover reflex port with felt from inside.

Regards

Sachin

You're welcome!

OK, assuming nothing's changed over the decades, we call this type felt 'jute', which is way too dense for this app IME, so wouldn't be surprised if your friend's are somewhat over-damped by 'vintage' standards, though as always it's how it sounds to the owner that matters. Since you already have it, try it with sheets cut to cover only 70-80% of the panel and if you still hear any 'ringing'/'hollowness', etc., then add more, but don't use on the vent unless you want to roll off much/most of its bass response.

No experience with Polywool sheets. I'm curious, if no easy access to fiberglass insulation, then what's used to damp-insulate heat/AC ductwork and building walls? If Polywool, then backless R-19 rated will work.

Also, just remembered that in recent years many folks been happy with the inexpensive recycled shredded cotton [jeans] as a'good enough' substitute.

GM

OK, assuming nothing's changed over the decades, we call this type felt 'jute', which is way too dense for this app IME, so wouldn't be surprised if your friend's are somewhat over-damped by 'vintage' standards, though as always it's how it sounds to the owner that matters. Since you already have it, try it with sheets cut to cover only 70-80% of the panel and if you still hear any 'ringing'/'hollowness', etc., then add more, but don't use on the vent unless you want to roll off much/most of its bass response.

No experience with Polywool sheets. I'm curious, if no easy access to fiberglass insulation, then what's used to damp-insulate heat/AC ductwork and building walls? If Polywool, then backless R-19 rated will work.

Also, just remembered that in recent years many folks been happy with the inexpensive recycled shredded cotton [jeans] as a'good enough' substitute.

GM

Thanks GMYou're welcome!

OK, assuming nothing's changed over the decades, we call this type felt 'jute', which is way too dense for this app IME, so wouldn't be surprised if your friend's are somewhat over-damped by 'vintage' standards, though as always it's how it sounds to the owner that matters. Since you already have it, try it with sheets cut to cover only 70-80% of the panel and if you still hear any 'ringing'/'hollowness', etc., then add more, but don't use on the vent unless you want to roll off much/most of its bass response.

No experience with Polywool sheets. I'm curious, if no easy access to fiberglass insulation, then what's used to damp-insulate heat/AC ductwork and building walls? If Polywool, then backless R-19 rated will work.

Also, just remembered that in recent years many folks been happy with the inexpensive recycled shredded cotton [jeans] as a'good enough' substitute.

GM

I will follow your advice. The felt is not thick.Please find the pic attached

An externally hosted image should be here but it was not working when we last tested it.

I have searched for glass wool. Its available in loos(in kgs). Sheets are available only in bulk. I will search few more shops.

BTW: speaker cabs got first coat of primer and ready to sand and paint.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Regards

Sachin

Last edited:

You're welcome!

Hmm, I misunderstood, I thought you were using the sound deadening padding under the carpet. Carpet is even worse and in retrospect I should have posted that you use the 'blow' test to determine how dense an insulation material is and as a general rule you should be able to blow through it rather easily since the actual power intensity of any reflections in a typical speaker cab is tiny.

Yes, normally sold in bulk, but scrap and particularly what's been ripped out of a building can usually be had for free around here, but in retrospect probably not in your country.

Regardless, loose works too, just cover the back of the driver and vent with cheesecloth, mosquito netting or similar and just toss it in as stuffing or make a 'damping' ball/bag of it with the cheesecloth and suspend it behind the driver:

Cheesecloth: http://img0098o.psstatic.com/97866050_rare-pair-of-altecheathkit-legato-2-15-horn-driver-ebay.jpg

GM

Hmm, I misunderstood, I thought you were using the sound deadening padding under the carpet. Carpet is even worse and in retrospect I should have posted that you use the 'blow' test to determine how dense an insulation material is and as a general rule you should be able to blow through it rather easily since the actual power intensity of any reflections in a typical speaker cab is tiny.

Yes, normally sold in bulk, but scrap and particularly what's been ripped out of a building can usually be had for free around here, but in retrospect probably not in your country.

Regardless, loose works too, just cover the back of the driver and vent with cheesecloth, mosquito netting or similar and just toss it in as stuffing or make a 'damping' ball/bag of it with the cheesecloth and suspend it behind the driver:

Cheesecloth: http://img0098o.psstatic.com/97866050_rare-pair-of-altecheathkit-legato-2-15-horn-driver-ebay.jpg

GM

Update:

Just saw a recent recommendation for aquarium filter wool as having been used successfully in TL, BIB pipe horn apps, so should work fine for you if readily available:

http://www.diyaudio.com/forums/full-range/296489-best-damping-stuff-fullrange.html#post4827405

https://www.google.com/search?q=Aqu...er&aqs=chrome..69i57&sourceid=chrome&ie=UTF-8

GM

Just saw a recent recommendation for aquarium filter wool as having been used successfully in TL, BIB pipe horn apps, so should work fine for you if readily available:

http://www.diyaudio.com/forums/full-range/296489-best-damping-stuff-fullrange.html#post4827405

https://www.google.com/search?q=Aqu...er&aqs=chrome..69i57&sourceid=chrome&ie=UTF-8

GM

Thanks Gm,That looks very similar to Polyfill or Decron sheets. Decron sheets are easily available here.Update:

Just saw a recent recommendation for aquarium filter wool as having been used successfully in TL, BIB pipe horn apps, so should work fine for you if readily available:

http://www.diyaudio.com/forums/full-range/296489-best-damping-stuff-fullrange.html#post4827405

https://www.google.com/search?q=Aqu...er&aqs=chrome..69i57&sourceid=chrome&ie=UTF-8

GM

Regards

Sachin

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- University 312 Triaxial