Hello all,

thank you very much for your replies.

Some data:

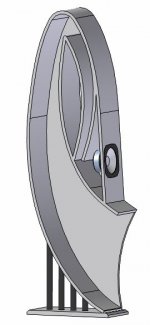

Material: Birch Plywood

Size: H=1520 mm, W=246 mm, D=505mm

Pressure chamber app. 6 litre (after adjusting it with sand app. 3litre )

Exponential flare

Design: conventional calculated by hand and checked with Hornresp.

Sound (my subjective impressions): balanced, detailed, very good imaging also out of axis. After adjusting the pressure chamber sound was locking in (I´m more and more believing in the "Resonance Theorie" of www.hornlautsprecher.de - solutions in sound) Ears are the best measurement device.http://dict.leo.org/ende/index_de.h...oc=0&resultOrder=basic&multiwordShowSingle=on

Next planed modifikation: Phase plugs

Steini

thank you very much for your replies.

Some data:

Material: Birch Plywood

Size: H=1520 mm, W=246 mm, D=505mm

Pressure chamber app. 6 litre (after adjusting it with sand app. 3litre )

Exponential flare

Design: conventional calculated by hand and checked with Hornresp.

Sound (my subjective impressions): balanced, detailed, very good imaging also out of axis. After adjusting the pressure chamber sound was locking in (I´m more and more believing in the "Resonance Theorie" of www.hornlautsprecher.de - solutions in sound) Ears are the best measurement device.http://dict.leo.org/ende/index_de.h...oc=0&resultOrder=basic&multiwordShowSingle=on

Next planed modifikation: Phase plugs

Steini

Stunning is a great word to describe these. You did a very nice job! Do you have construction pictures so we can see the inside???

Steini, as I said in the fullrange photos thread, these are beautiful! I'm wondering, though, about that tight plywood turn at the top. Are you willing to say what you did to accomplish that? Even with 1/4 inch plywood that's a tight turn. But with heavier material like 3/4 inch/19mm, that's just about impossible in my experience.

Anyway, congratulations on your build. As Planet10 says, you nailed it!

Anyway, congratulations on your build. As Planet10 says, you nailed it!

Hello Carl,

you are right the arc radius on the top is to small to bend it.

The inner layer of the speakers top is segmented. The finish layer

is made by a birch plywood sheet, thickness 4mm. To make it bendable

you need heat and humidity. You have simply to "cook" it in the baking oven in a water filled casserole dish for approximately 20 Min. at 250°C. After this procedure you can easily bend it over the top by hand and screw it on. Leave it there for app. 2 days trim it and glue it to the speakers.

If there is a interest in plans for the "Steini´s Alphorn" I can draw some, and can compose a "how to do manual". They are made without a complex bending form. The only power tools you need is a wood router, jigsaw and a cordless drilling machine.

Price for the plans would be 25€

Regards Steini

you are right the arc radius on the top is to small to bend it.

The inner layer of the speakers top is segmented. The finish layer

is made by a birch plywood sheet, thickness 4mm. To make it bendable

you need heat and humidity. You have simply to "cook" it in the baking oven in a water filled casserole dish for approximately 20 Min. at 250°C. After this procedure you can easily bend it over the top by hand and screw it on. Leave it there for app. 2 days trim it and glue it to the speakers.

If there is a interest in plans for the "Steini´s Alphorn" I can draw some, and can compose a "how to do manual". They are made without a complex bending form. The only power tools you need is a wood router, jigsaw and a cordless drilling machine.

Price for the plans would be 25€

Regards Steini

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- New Fe166en Project: Alphorn