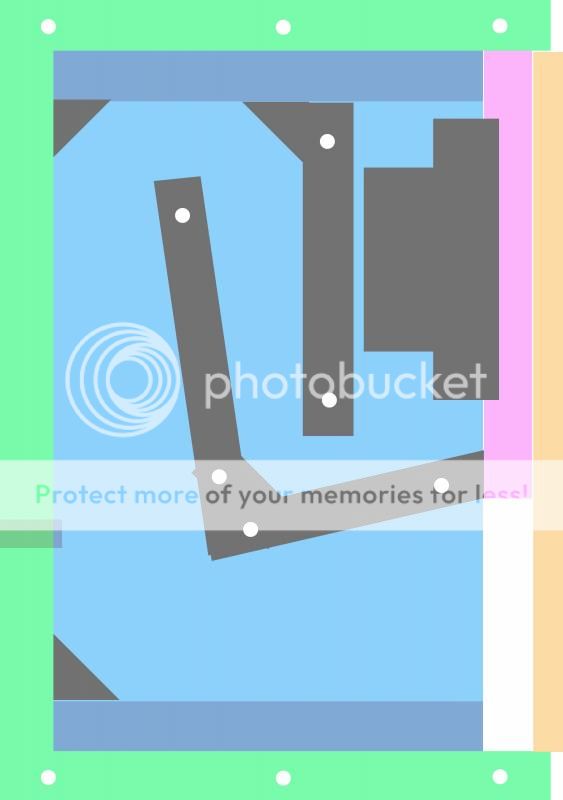

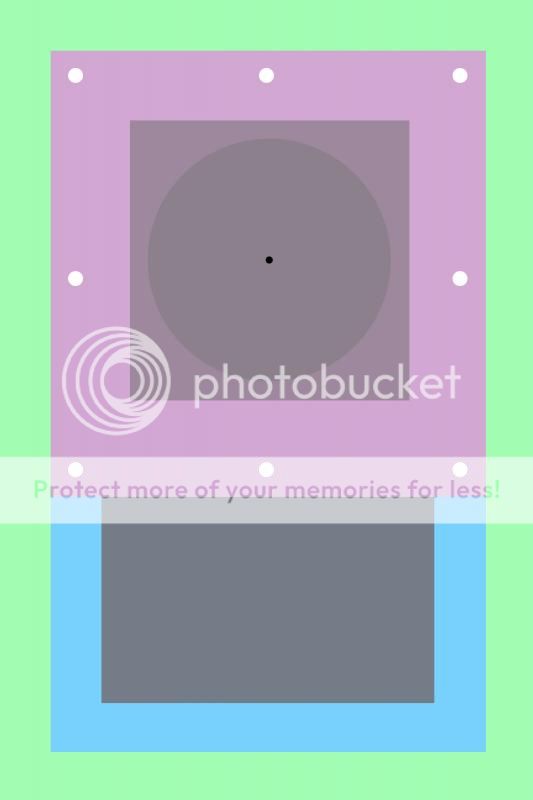

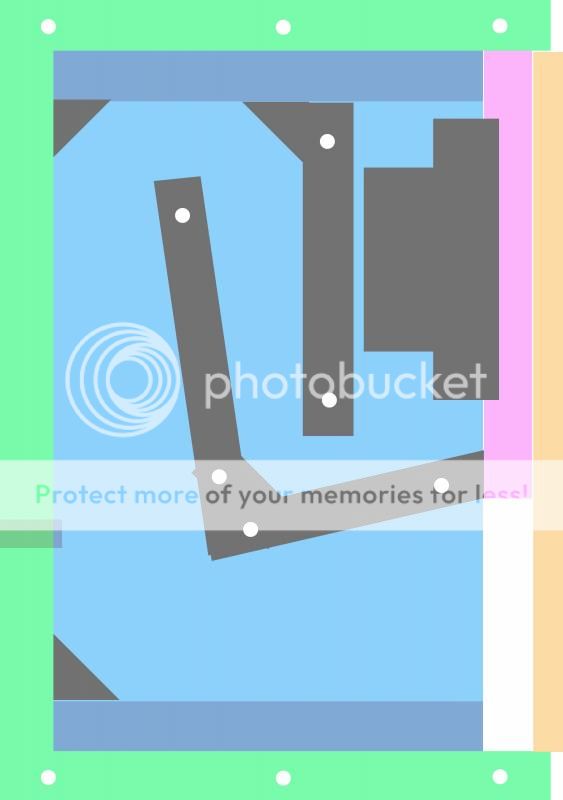

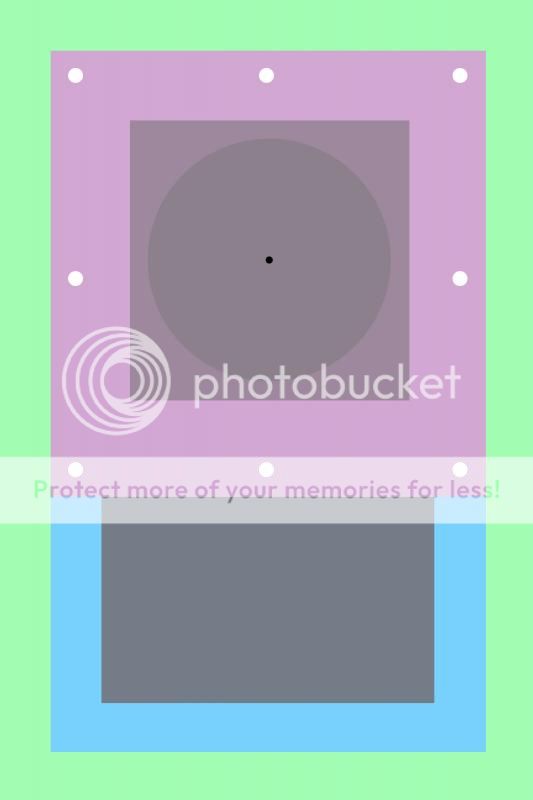

This is my first time at making my own speakers. I brought a table saw and a router. Knowing well this will be a learning experience, as I have never used any power tools, and the end results will not be perfect. I designed the speakers in Photoshop. I'm a photo retoucher and have no clue in using auto cad and other computer programs.

I chose back loaded horn speakers because I'm curious what it will sound like and I wanted a challenge in woodworking and learn different techniques. I brought a set full range speakers off of ebay, wished I have heard of parts express.com then.

I chose pine wood because I like the look of natural wood.

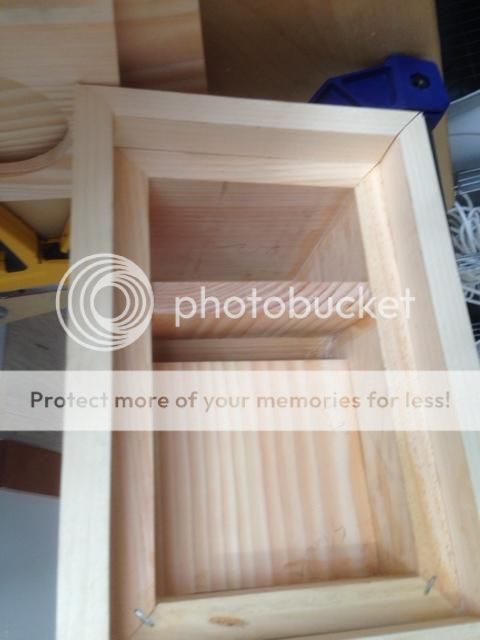

Using a table saw for the first time was intimating. Boy! safety googles are a must.

Practicing with the router and cutting the speaker openings.

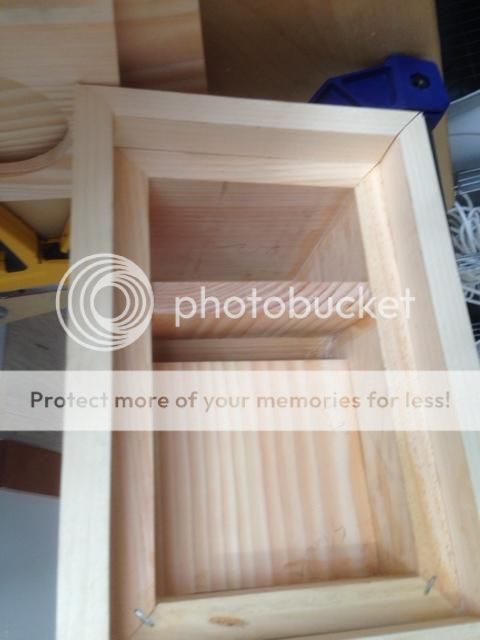

After cutting the sides, I wanted to see how they look.

Setting up the interior folds and glueing everything.

The back, I didn't have a big enough router bit for the speaker terminal. Decided to scrap that and have the cables connected to the amplifier. To seal all the inside folds, front and back panel, I used clear corking, the stuff used for window and doors.

In the end, they look alright. I learned a lot and it was a lot of fun. How do the speakers sound? They sound alright, not great. They need to broken in and might sound better. I think they sound a little open then conventional speakers. The bass lack depth, I'm getting some soft foams to stuff the inside. Hopefully this will help.

Are there any fellow diy'ers in the NYC area? I would love to learn about cross overs and stuff.

With this one done, I'm currently working on a t-line full range speaker. I'm using plywood this time. Would love to hear from everyone, thanks for reading.

Best,

G

I chose back loaded horn speakers because I'm curious what it will sound like and I wanted a challenge in woodworking and learn different techniques. I brought a set full range speakers off of ebay, wished I have heard of parts express.com then.

I chose pine wood because I like the look of natural wood.

Using a table saw for the first time was intimating. Boy! safety googles are a must.

Practicing with the router and cutting the speaker openings.

After cutting the sides, I wanted to see how they look.

Setting up the interior folds and glueing everything.

The back, I didn't have a big enough router bit for the speaker terminal. Decided to scrap that and have the cables connected to the amplifier. To seal all the inside folds, front and back panel, I used clear corking, the stuff used for window and doors.

In the end, they look alright. I learned a lot and it was a lot of fun. How do the speakers sound? They sound alright, not great. They need to broken in and might sound better. I think they sound a little open then conventional speakers. The bass lack depth, I'm getting some soft foams to stuff the inside. Hopefully this will help.

Are there any fellow diy'ers in the NYC area? I would love to learn about cross overs and stuff.

With this one done, I'm currently working on a t-line full range speaker. I'm using plywood this time. Would love to hear from everyone, thanks for reading.

Best,

G

Hi, nice work, at least from the exteriors.

The inside is a little tiny. The wall just behind the speaker is bad.

Take a look at M.J.King work ay quarter-wave.com

the last article, "A Method for Designing a Compact Back Loaded Horn Loudspeaker System (added 06/21/12)" is intersting and doable-

Horn Theory

The inside is a little tiny. The wall just behind the speaker is bad.

Take a look at M.J.King work ay quarter-wave.com

the last article, "A Method for Designing a Compact Back Loaded Horn Loudspeaker System (added 06/21/12)" is intersting and doable-

Horn Theory

Nice first effort and I think you got some good practice cutting wood. But as you say, it doesn't sound great. It is tough to make a BLH by guess and cut and try and expect anything but "ehh". I have done this method myself when first starting so you are not alone. Don't give up though because you are starting a truly fun journey and there is much to learn. If you want to experiment to see how something may work make it out of foam core and it will be fast and hardly cost anything (if you have access to dollar store foam core sheets). Look at the foam core speaker thread for ideas. Try making a proven design first to hear what works and what it can sound like.

If you want a low cost example of a nice sounding and easy to make full range BLH/TL speaker check out the mini Karlsonator thread. That is a proven to sound great design using a pair of $12 drivers. It can be adapted to your current drivers which look like the Air 3 inches? If you are interested post your driver TS specs in mini K thread and I will come up with a design for you.

Good luck!

If you want a low cost example of a nice sounding and easy to make full range BLH/TL speaker check out the mini Karlsonator thread. That is a proven to sound great design using a pair of $12 drivers. It can be adapted to your current drivers which look like the Air 3 inches? If you are interested post your driver TS specs in mini K thread and I will come up with a design for you.

Good luck!

Last edited:

As for your woodworking skills you are doing great. My first project was a Karlson K15 and I used a lot of bondo auto body filler (no good caulks avaiable back then). If you haven't already done so check out lumberjocks.com for a lot of useful info on table saw miter sleds, router jigs and etc.

As for your woodworking skills you are doing great. My first project was a Karlson K15 and I used a lot of bondo auto body filler (no good caulks avaiable back then). If you haven't already done so check out lumberjocks.com for a lot of useful info on table saw miter sleds, router jigs and etc.

Well, not really. All the wood pieces were poorly cut, it doesn't help when some of the pine broads were not perfectly flat. They seem flat when I selected them at home depot. It was only when I finished cutting that I should have checked all the alignments on the table saw, I have a Kobolt table saw by the way. I went to youtube and saw a few videos on alignments. It's a good table saw for the money. I have it working 92-95%, not perfect.

Hi, nice work, at least from the exteriors.

The inside is a little tiny. The wall just behind the speaker is bad.

Take a look at M.J.King work ay quarter-wave.com

the last article, "A Method for Designing a Compact Back Loaded Horn Loudspeaker System (added 06/21/12)" is intersting and doable-

Horn Theory

Thanks, I'll read up on King's work. But I have to say, all the formulas and technical stuff really puts me to sleep.

Nice first effort and I think you got some good practice cutting wood. But as you say, it doesn't sound great. It is tough to make a BLH by guess and cut and try and expect anything but "ehh". I have done this method myself when first starting so you are not alone. Don't give up though because you are starting a truly fun journey and there is much to learn. If you want to experiment to see how something may work make it out of foam core and it will be fast and hardly cost anything (if you have access to dollar store foam core sheets). Look at the foam core speaker thread for ideas. Try making a proven design first to hear what works and what it can sound like.

If you want a low cost example of a nice sounding and easy to make full range BLH/TL speaker check out the mini Karlsonator thread. That is a proven to sound great design using a pair of $12 drivers. It can be adapted to your current drivers which look like the Air 3 inches? If you are interested post your driver TS specs in mini K thread and I will come up with a design for you.

Good luck!

Thanks so much, I will look for the mini k thread. As I have a couple fostex drivers and a 12" Berman guitar amp speaker that I'm interested in making enclosures for. As of now I'm just really curious. I have a pair of Spendor LS3 speakers that I love, which I use as reference. If I can make a pair of speakers that sound as good as the Spendors, I'll be happy. That's my goal. Would this be difficult? I don't need bass to shake the house, I want something that sound tight, detail, and dynamic.

As to your question, the drivers in my BLH are HiEnd 5"

Again, thanks for your help.

You can not expect that much bass from a 5" full range driver to start with, and your speakers are not really horns but short resonance pipes. A small Voigt pipe (http://www.lencoheaven.net/forum/index.php?topic=1960.30) will get you bass down to 40 Hz! Do note that the 5" driver still will run out of steam quickly if you crank it up.

You can not expect that much bass from a 5" full range driver to start with, and your speakers are not really horns but short resonance pipes. A small Voigt pipe (http://www.lencoheaven.net/forum/index.php?topic=1960.30) will get you bass down to 40 Hz! Do note that the 5" driver still will run out of steam quickly if you crank it up.

Thanks for your comments. How can I make them "more" horn? The larger opening for the horn and more narrow beginning? After reading on King's work, the bass coming out my speakers are more in the mid range than bass.

But I have to say, all the formulas and technical stuff really puts me to sleep.

Hi,

Sadly some grasp of what is going on is needed to design

a half decent box, and understand the difference between

stuff that works and stuff that looks like it might work but

in fact doesn't do what you wanted, and does stuff you

really don't want it to do, but don't understand that either.

Your BLH has no bass, and never will, whatever you do.

IMO you'd be better off building MJK's BLH, scaled up a little

(120%) for a 5" FR *. FWIW you've no hope of building a

decent T-line by just guessing, ot a BLH for that matter,

and even if you can't follow the theory, reading between

the lines for the general gist of what is said is necessary.

rgds, sreten.

* No harm will come of converting the sections to tapered.

Scale width and depth, don't worry about the height much.

Last edited:

Actually, you may get some undesirable side effects from shifting to ~continuous expansion rather than using an expanding cascade of untapered manifolds. The smoother expansion promotes efficiency at the top end of the horn's BW -which in a back horn is generally where you don't need / want it. The sharper edges etc. will give a more effective low-pass, in addition to the chamber & acoustic notch from the internal Helmholtz. The lower wavelengths are too long to be significantly affected. In fairness, probably not much in it, but it's not likely to bring improvements.

Those are cute looking full range speakers. They're probably fine, I would'nt worry whether they are the best possible They look as good as any out there. I found the auction and info:

Qts .513

VAS 14.47L

Fs 59.5Hz

The VAS is proportional to the enclosure size that the driver will be "happy" in, and so is Qts. Qts also indicates a few things about what enclosures are going to work and how. 0.513 is a fairly versatile Qts, but is high-ish, as is the VAS, will mean the cabinets will be fairly large relative to some 5" drivers.

For these speakers drivers, a very easy solution would be to put them in10 litre (roughly) sealed cabinets (or convert the cabinets you already have) and add an active subwoofer for the <100Hz range. Depending on what's locally available, it might be simplest to obtain a cheap PC system (satellites and sub) and replace the satellites with your boxes. If the sub has an adjustable gain and cutoff, you're set.

You could always upgrade from there if the urge to DIY remains (eg brace and stuff the sub)

Qts .513

VAS 14.47L

Fs 59.5Hz

The VAS is proportional to the enclosure size that the driver will be "happy" in, and so is Qts. Qts also indicates a few things about what enclosures are going to work and how. 0.513 is a fairly versatile Qts, but is high-ish, as is the VAS, will mean the cabinets will be fairly large relative to some 5" drivers.

For these speakers drivers, a very easy solution would be to put them in10 litre (roughly) sealed cabinets (or convert the cabinets you already have) and add an active subwoofer for the <100Hz range. Depending on what's locally available, it might be simplest to obtain a cheap PC system (satellites and sub) and replace the satellites with your boxes. If the sub has an adjustable gain and cutoff, you're set.

You could always upgrade from there if the urge to DIY remains (eg brace and stuff the sub)

Thanks Scottmoose and Hollowboy.

I'm going to play around with stuffing and see how it goes. The 5" drivers are limited. I'll try to salvage them by making mini Karlson. It seems I'm just waiting time and money if I just built enclosures blindly. I need to study up.

Hollowboy, what dimensions should I make mini Karlson for this 5" driver? Is this determined by VAS values? And how to convert VAS litre values to a Karlson enclosure? Thanks.

I'm going to play around with stuffing and see how it goes. The 5" drivers are limited. I'll try to salvage them by making mini Karlson. It seems I'm just waiting time and money if I just built enclosures blindly. I need to study up.

Hollowboy, what dimensions should I make mini Karlson for this 5" driver? Is this determined by VAS values? And how to convert VAS litre values to a Karlson enclosure? Thanks.

You want a mini Karlsonator not a Karlson as those do not scale well below 12 inches. They have no bass when scaled that small. A mini Karlsonator on the other hand can reach to 50 or 60 Hz with a 5in driver.

Look in this thread for more info:

http://www.diyaudio.com/forums/full-range/239338-mini-karlsonator-0-53x-dual-tc9fds.html

I am guessing that 0.53x scale mini Karlsonator will be the right size. What remains is how wide to scale it to match the driver Vas and Qts. That will require a simulation.

Look in this thread for more info:

http://www.diyaudio.com/forums/full-range/239338-mini-karlsonator-0-53x-dual-tc9fds.html

I am guessing that 0.53x scale mini Karlsonator will be the right size. What remains is how wide to scale it to match the driver Vas and Qts. That will require a simulation.

Another speaker DIY'er in Brooklyn! I figured as much from your moniker. I was in the same boat as you about 10-15 years ago, when I built my first cabinet. I have a router but still don't have a table saw, although I now have a circular saw and a compound miter saw, neither of which were used for speaker building.

I did have a contractor friend cut some boards one time on a table saw, but his guy didn't really know how to use it and they didn't come out with straight cuts. I had to take the router and use a straight edge to correct them.

As for advice on design, well you've got the right people replying here. I can fumble my way through building a cabinet, but I couldn't design one.

I did have a contractor friend cut some boards one time on a table saw, but his guy didn't really know how to use it and they didn't come out with straight cuts. I had to take the router and use a straight edge to correct them.

As for advice on design, well you've got the right people replying here. I can fumble my way through building a cabinet, but I couldn't design one.

When you said your first time using power tools the hair stood on end. Your to be complimented at your first attempt, make sure you write a date on these two speakers. Years down the road they will make excellent conversational pieces.

Every time you tackle a project it gets easier and easier this site is the place to be for all you need to know about building speakers. Good Luck on the next pair and by all means have fun in your learning curve.

Every time you tackle a project it gets easier and easier this site is the place to be for all you need to know about building speakers. Good Luck on the next pair and by all means have fun in your learning curve.

Actually, you may get some undesirable side effects from shifting to ~continuous expansion rather than using an expanding cascade of untapered manifolds. The smoother expansion promotes efficiency at the top end of the horn's BW -which in a back horn is generally where you don't need / want it. The sharper edges etc. will give a more effective low-pass, in addition to the chamber & acoustic notch from the internal Helmholtz. The lower wavelengths are too long to be significantly affected. In fairness, probably not much in it, but it's not likely to bring improvements.

Does the Fib Horn use four untapered coupled chambers expanding in volume according to the Fibonacci principle? The maker claims response to 38 Hz.

You need to look up some speaker design software.

As others have said your speaker is way too small for bass.

The sound from the rear obviously travels at the speed of sound around the bends.

It should be in phase with the top output by the time it reaches the exit of the cabinet.

Your short path will not be long enough for this to happen.

As others have said your speaker is way too small for bass.

The sound from the rear obviously travels at the speed of sound around the bends.

It should be in phase with the top output by the time it reaches the exit of the cabinet.

Your short path will not be long enough for this to happen.

Another speaker DIY'er in Brooklyn! I figured as much from your moniker. I was in the same boat as you about 10-15 years ago, when I built my first cabinet. I have a router but still don't have a table saw, although I now have a circular saw and a compound miter saw, neither of which were used for speaker building.

I did have a contractor friend cut some boards one time on a table saw, but his guy didn't really know how to use it and they didn't come out with straight cuts. I had to take the router and use a straight edge to correct them.

As for advice on design, well you've got the right people replying here. I can fumble my way through building a cabinet, but I couldn't design one.

Yes, south Brooklyn. Everyone on the forum have been great.

Reverse mounted?

Hi all.

I just want to as a question. Don't want to bother with a new thread since it may have a short answer and then the thread would just be eating up space.

Anyway, I was simming a BLH for a PS180, and when wanted to calculate for the Vtc I had a thought. Can we build a BLH with the face of the driver facing in, and the rear facing out? Never seen it built this way. Any reason?

Plus, the rear of the PS180 is actually very pretty.

Hi all.

I just want to as a question. Don't want to bother with a new thread since it may have a short answer and then the thread would just be eating up space.

Anyway, I was simming a BLH for a PS180, and when wanted to calculate for the Vtc I had a thought. Can we build a BLH with the face of the driver facing in, and the rear facing out? Never seen it built this way. Any reason?

Plus, the rear of the PS180 is actually very pretty.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Backloaded Horn Speaker