Hello all!

I haven't been around in a while but the speaker building and design bug is always there. Anyone interested in a public build, open source small BLH/TL for the Dayton RS100-4? I just purchased a pair and spent some time working within a few parameters that I have decided I need in a small driver point source build. The build must meet the following:

1. Easy to build (less than 20 pieces and no complex angles).

2. Cheap to build if desired by the average builder.

3. I am not trying to cover so much of the spectrum as many (including myself in the past) have. I don't really want the unit to go below 55-60 Hz as I want to be able to play fairly complex music and might even high pass the speaker so as to allow for higher volume with lower distortion or more complexity with lower distortion.

4. I want it to be compact.

5. Above all sound quality will be king. I don't want to use too many "room tricks" to gain what I have set out to build. I want the mouth fairly close to the driver so they merge more effectively.

6. Will use an independently powered sub of some sort for the real low material so keeping the horn and TL working within the limits of the driver are a reality.

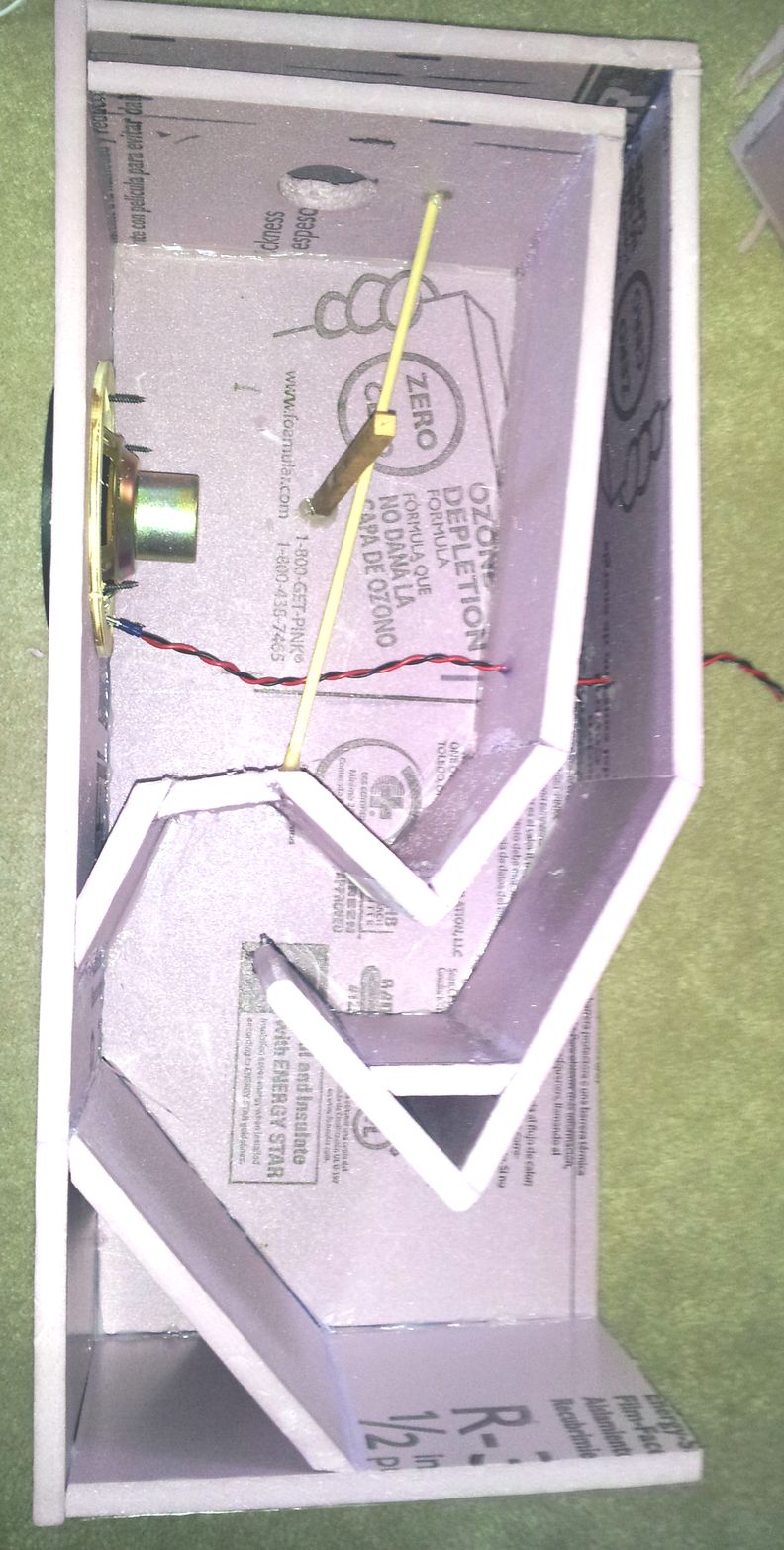

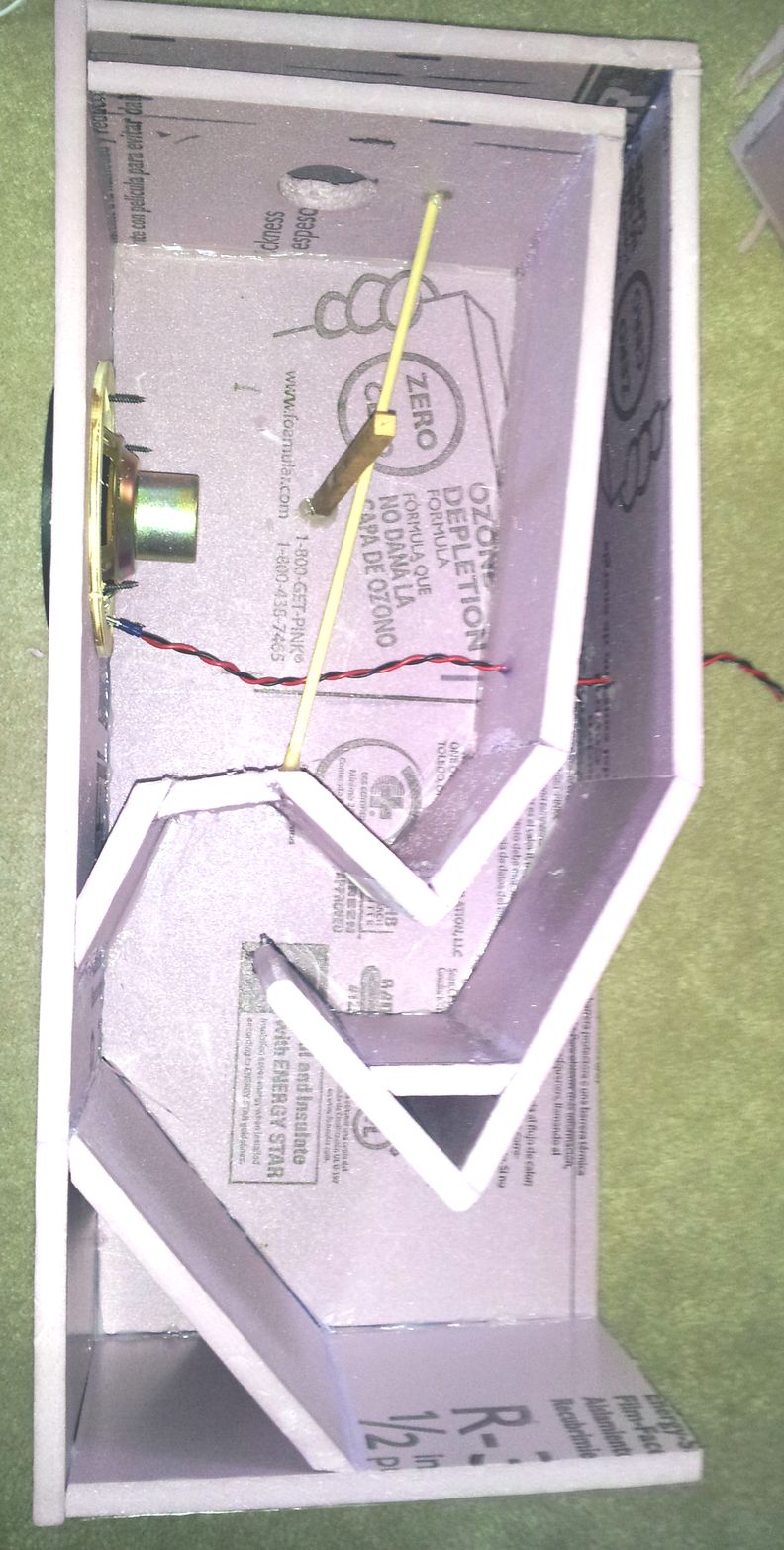

I attached a Sketchup rendering of what I have so far and would absolutely love if others wanted to build with me so we can all work on whats right, wrong and could be better. Leave a message in this thread if you want to take a shot at it. I'll draw up the full plans and post them here for all to use. Any input from Martin, Dave, Scott, GM, Chris or anyone else with advanced knowledge of what I am working with is always welcome! Now for a couple of specs on the enclosure I have drawn up so far.

-760 Hz mouth

-50 Hz flare

-55Hz TL length

-F3 of 55 Hz or so

Martin, I will be over on your page within a week or so to pay for firing up the worksheets again.

I haven't been around in a while but the speaker building and design bug is always there. Anyone interested in a public build, open source small BLH/TL for the Dayton RS100-4? I just purchased a pair and spent some time working within a few parameters that I have decided I need in a small driver point source build. The build must meet the following:

1. Easy to build (less than 20 pieces and no complex angles).

2. Cheap to build if desired by the average builder.

3. I am not trying to cover so much of the spectrum as many (including myself in the past) have. I don't really want the unit to go below 55-60 Hz as I want to be able to play fairly complex music and might even high pass the speaker so as to allow for higher volume with lower distortion or more complexity with lower distortion.

4. I want it to be compact.

5. Above all sound quality will be king. I don't want to use too many "room tricks" to gain what I have set out to build. I want the mouth fairly close to the driver so they merge more effectively.

6. Will use an independently powered sub of some sort for the real low material so keeping the horn and TL working within the limits of the driver are a reality.

I attached a Sketchup rendering of what I have so far and would absolutely love if others wanted to build with me so we can all work on whats right, wrong and could be better. Leave a message in this thread if you want to take a shot at it. I'll draw up the full plans and post them here for all to use. Any input from Martin, Dave, Scott, GM, Chris or anyone else with advanced knowledge of what I am working with is always welcome! Now for a couple of specs on the enclosure I have drawn up so far.

-760 Hz mouth

-50 Hz flare

-55Hz TL length

-F3 of 55 Hz or so

Martin, I will be over on your page within a week or so to pay for firing up the worksheets again.

Last edited:

Go for it Tom, looks an interesting project.

Without extra details, I can't offer much (I could fake up something similar, but that wouldn't be a whole lot of use ), other than to say I like the nominal excess of LF gain under 1/2 space conditions, so you won't have any issues with step loss; upper corner looks reasonably low & should come nicely into line with some damping. Either way, looks solid to me based on what's shown thus far. They'll need to be angled back somewhat, or put on a low stand given the relatively modest height

), other than to say I like the nominal excess of LF gain under 1/2 space conditions, so you won't have any issues with step loss; upper corner looks reasonably low & should come nicely into line with some damping. Either way, looks solid to me based on what's shown thus far. They'll need to be angled back somewhat, or put on a low stand given the relatively modest height

Without extra details, I can't offer much (I could fake up something similar, but that wouldn't be a whole lot of use

Last edited:

Thank you Scott! Good to see you responded!

Now, as for the details, I will get them up as soon as I amass the drawings and information. Unlike my other builds this one I am going to just release everything. All the information regarding sims and building materials etc. I'll put together one of my plan pamphlets with all the information and get it up here. The bug has been scratching in my brain for a long time but my teaching always took precedence therefore I've been fairly paralyzed as far as building and designing over the last few years. I resigned from my position at the university a couple of weeks ago and decided to make my way in the world as an actual working artist (instead of a teaching artist that never works on his art). My wife and I decided it was practical to do so now so I will be spending most of my time on that but being a sculptor I will be in my studio all the time and will be able to squeeze in my love of loudspeakers as well. I am giving myself a year to see if I can manage this new path in life. If I haven't made significant strides towards living as a showing artist then back to teaching for me. That said, I have been dying for a project like this. I want the spirit of open source and the community of speaker builders to come together over a build like this. I hope this will be the one we all do that on.

Talk to you soon!

Now, as for the details, I will get them up as soon as I amass the drawings and information. Unlike my other builds this one I am going to just release everything. All the information regarding sims and building materials etc. I'll put together one of my plan pamphlets with all the information and get it up here. The bug has been scratching in my brain for a long time but my teaching always took precedence therefore I've been fairly paralyzed as far as building and designing over the last few years. I resigned from my position at the university a couple of weeks ago and decided to make my way in the world as an actual working artist (instead of a teaching artist that never works on his art). My wife and I decided it was practical to do so now so I will be spending most of my time on that but being a sculptor I will be in my studio all the time and will be able to squeeze in my love of loudspeakers as well. I am giving myself a year to see if I can manage this new path in life. If I haven't made significant strides towards living as a showing artist then back to teaching for me. That said, I have been dying for a project like this. I want the spirit of open source and the community of speaker builders to come together over a build like this. I hope this will be the one we all do that on.

Talk to you soon!

Hi,

http://www.quarter-wave.com/Horns/Back_Horn.pdf

And more sensibly :

http://www.quarter-wave.com/Horns/BLH_Design_Article.pdf

I completely disagree with the premise of (5.), its very wrong.

They cannot merge due to path length differences ever and

consequently the second MJK article IMO is the business.

rgds, sreten.

http://www.quarter-wave.com/Horns/Back_Horn.pdf

And more sensibly :

http://www.quarter-wave.com/Horns/BLH_Design_Article.pdf

I completely disagree with the premise of (5.), its very wrong.

They cannot merge due to path length differences ever and

consequently the second MJK article IMO is the business.

rgds, sreten.

Last edited:

Sreten, I am well aware of the issues of line length difference as well as phase differentiation. You are still dealing with the effective merging of the signal insofar as your ears and brain will believe they have merged. Martin has been my guide through all of my education on the subject and this design is no different. I used his theory and practices during this process and my design should effectively deal with or at least minimize the problems we are aware of. In my experience, front mouth is far superior to rear mouth for sound quality. As I can't even begin to ask the horn to provide much below 780 Hz, I decided that the front placement would fight step loss far more effectively as well. In addition, by not asking the driver to perform too low in the frequency range I will gain clarity and lack of distortion while allowing a dedicated unit to manage those pesky low notes.

Tom

Tom

Streten, I just read that latest article (The last one) and I was blown away. I really do need the new sheets. My designs are always of my own folding and simulation so it should be interesting to see if the software actually laying out the internals is a superior method.

Tom

Tom

That's a good suggestion but I want them to also function somewhat full range for near field or desktop use. That way if I. Don't want to fire up the subs, I can still listen and be satisfied. That flute looks cool by the way! I am going to try to get those plans drawn up today after I'm done with my studio time. I need to hit the hardware store this morning too so I'll grab some wood. Maybe I'll be able to start a set this weekend.

I think for the prototype I'll use MDF. I know, I don't like it either but it's cheap and easily sourced.

Tom

I think for the prototype I'll use MDF. I know, I don't like it either but it's cheap and easily sourced.

Tom

Foamcore sure is a quick way to a prototype if one does not have a shop ready at a second's notice for some wooducutting action. I can always dream...

Such a BLH can be a fun way to play with smaller FR drivers, here, have a look at something I've done just over a year ago:

http://www.diyaudio.com/forums/full-range/222798-little-diy-back-load-horn-ff85wk.html

I mostly wanted to check how the build would come out compared to Hornresp simulations, which was not too bad IIRC. It could probably be bettered upon easily by a designer more experienced than me in this type of enclosure.

Good luck!

IG

Such a BLH can be a fun way to play with smaller FR drivers, here, have a look at something I've done just over a year ago:

http://www.diyaudio.com/forums/full-range/222798-little-diy-back-load-horn-ff85wk.html

I mostly wanted to check how the build would come out compared to Hornresp simulations, which was not too bad IIRC. It could probably be bettered upon easily by a designer more experienced than me in this type of enclosure.

Good luck!

IG

GM, I decided on cabinet grade Birch for the prototype. I feel the same as you do. I hate MDF. Once i hammer out the problems and such I will build them from BB. I tried to do MDF but once I was at the store looking at it I just couldn't bring myself to use that wretched stuff.

Tom

Tom

GM, I just reread what you wrote and think i misread. I like to prototype in wood. It's a days work to get something that you can mess with infinitely and will sound far closer to what you will build in the end. I did try some foamcore on my last little project and it worked quite well but when i built then in wood I don't believe the false resonances translated and therefore the sound was drastically different.

IG81, I like the look of those! Did they end up being everything you hoped they would?

Tom

IG81, I like the look of those! Did they end up being everything you hoped they would?

Tom

Actually, you took it the both ways I intended, i.e. prototyping a horn in MDF for a BB build is a fool's errand IME as its resonant structure is completely different, so might as well do it with minimal effort in foam core, which will still be good enough as a POC as IG noted; and if you start with a high enough Qts driver, FC is good enough for a finished product by simply veneering the exterior with thick wallpaper/whatever, assuming kids, large pets aren't an issue.

GM

GM

It's funny GM, I noticed that there are a lot of people prototyping in foam-core for all sorts of designs. I just can't bring myself to that. I still can't manage a build in MDF any longer. (It was good to see cabinet grade birch was only ten dollars more). I believe some years ago you and I had a discussion somehow relating to this (or maybe I was lurking) and I think that had such a profound effect on me in regards to the negative aspects of MDF that I haven't used it to prototype since then. In defense of those using FC, I think those super odd esoteric spiral horn builds might warrant it just to make sure of theoretical suspicion or intuitions. Either way, I did use FC once to knock together a mini table top TL that I wanted to find out if my thoughts on its design in very general terms were correct. It did prove that my idea at least works.

On another note, I managed to cut my piece of cabinet grade birch down to manageable sizes just to get it out out the cold last night. Maybe in the next few days, if it warms up, I will be able to get all the parts cut and begin the base assembly. I can't wait to hear if my ideas for this piece are "sound" or if I missed the boat entirely.

Tom

On another note, I managed to cut my piece of cabinet grade birch down to manageable sizes just to get it out out the cold last night. Maybe in the next few days, if it warms up, I will be able to get all the parts cut and begin the base assembly. I can't wait to hear if my ideas for this piece are "sound" or if I missed the boat entirely.

Tom

IG81, I like the look of those! Did they end up being everything you hoped they would?

Tom

I could answer 'yes', but then again my expectations were not sky-high. The "horn" works in the sense that baffle-step is compensated for, but in a rough kind of way. I think if one is not going to go for a large enough mouth to really have some useful horn-loading going on, the implementation of modern TL techniques such as driver offset and mass-loading would likely give a superior result. Like I mentioned, my basic design is probably not as good as it could be anyway, within its own paradigm - I'm pretty sure something quite enjoyable could be made with this more old-school approach.

IG

In defense of those using FC, I think those super odd esoteric spiral horn builds might warrant it just to make sure of theoretical suspicion or intuitions.

This is exactly the thing FC is good for, but as GM pointed out, with a high Qts driver, it actually sounds really good - and can measure really well too. There is no easier method for making smooth curves or spirals. My latest effort with a spiral closed end TL worked out very well (http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures-203.html#post3734447), and I am now working on a teardrop shaped enclosure out of FC.

These prototype take a few hours, cost almost nothing, and get me the general idea of how it may sound if I could actually make it out of something more durable one day when I have a workshop.

Glad that you tried your TL in FC. Your BLH could be done with 3/4 in thick XPS foam sheathing from a home DIY place. Bcmbob made the Decware DNA BLH with this stuff and it worked to produce a speaker that made 30 Hz.

I like the design of your BLH - good luck on your build!

I could answer 'yes', but then again my expectations were not sky-high. The "horn" works in the sense that baffle-step is compensated for, but in a rough kind of way. I think if one is not going to go for a large enough mouth to really have some useful horn-loading going on, the implementation of modern TL techniques such as driver offset and mass-loading would likely give a superior result. Like I mentioned, my basic design is probably not as good as it could be anyway, within its own paradigm - I'm pretty sure something quite enjoyable could be made with this more old-school approach.

IG

Yes, the TL is mandatory on a small build. As you see I included, well technically anyway full TL action in my design. I'm hoping for a really nice midbass as a result. It would be nice as you said to be able to listen late at night without a sub on or a giant set of speakers shaking my neighbors wall (I live in a row house in the District of Columbia).

Tom

This is exactly the thing FC is good for, but as GM pointed out, with a high Qts driver, it actually sounds really good - and can measure really well too. There is no easier method for making smooth curves or spirals. My latest effort with a spiral closed end TL worked out very well (http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures-203.html#post3734447), and I am now working on a teardrop shaped enclosure out of FC.

These prototype take a few hours, cost almost nothing, and get me the general idea of how it may sound if I could actually make it out of something more durable one day when I have a workshop.

Glad that you tried your TL in FC. Your BLH could be done with 3/4 in thick XPS foam sheathing from a home DIY place. Bcmbob made the Decware DNA BLH with this stuff and it worked to produce a speaker that made 30 Hz.

I like the design of your BLH - good luck on your build!

Thank you! I hope it will turn out as planned. I love that you are doing those really interesting designs with the FC. The XPS is fun stuff! I always had my students glue it up and carve it in my "Introduction to Sculpture" class. I will have to try some of my more "interesting" ideas that I don't want to drop fifty bucks on a sheet of plywood for sometime soon.

Tom

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- BLH/TL Build for Dayton RS100-4