More shots of the build. You can see the stuffing/lining, and the BSC which is on a small board attached to the side--and accessible through the driver hole in case it should need to be changed later.

The back side and exit area of the TL are painted flat black. And for the first time, I used a terminal cup rather than having binding posts standing proud of the surface where they are mounted.

Now let’s talk about veneer. SWMBO wanted something other than the red oak I have been using for years now. She chose red cedar. Have to say, it looks really nice. So I ordered 6 sheets (2’ x 8’), enough to do this project and at least one more that I have in mind. I haven’t seen another project done with red cedar, so this may be unique.

Well, there is a reason why red cedar isn’t more popular: Unfortunately, the stuff is very brittle. And some of the knots are popping off as I unroll the sheets. So I had to pick through all six sheets and cut strips from them to cover the sides. I had no trouble wrapping the red oak around a 3/8” round over. The cedar, on the other hand, turns into splinters! In order to cover the round overs, I had to moisten the cedar to soften it. What a nightmare! More expensive to start with, and then a lot of it is simply waste. Never again! (As they say, “Its been a great learning experience.”)

The final photo shows the new PTL next to the F120A Metronome I build a couple years ago.

As I mentioned earlier, I am happy with the sound. Each driver has its own characteristics. The FF225wk isn’t the last word in resolution--which is a good thing. I feel it makes the most of less than perfect recordings, such as Benny Goodman’s 1938 Carnegie Hall concert. (Great music, but a technically inferior recording.) It doesn’t suffer the quirks of whizzered drivers, and the highs are good enough for me with the added tweeter.

Hopefully, measurements will follow in a couple of weeks.

Cheers, Jim

The back side and exit area of the TL are painted flat black. And for the first time, I used a terminal cup rather than having binding posts standing proud of the surface where they are mounted.

Now let’s talk about veneer. SWMBO wanted something other than the red oak I have been using for years now. She chose red cedar. Have to say, it looks really nice. So I ordered 6 sheets (2’ x 8’), enough to do this project and at least one more that I have in mind. I haven’t seen another project done with red cedar, so this may be unique.

Well, there is a reason why red cedar isn’t more popular: Unfortunately, the stuff is very brittle. And some of the knots are popping off as I unroll the sheets. So I had to pick through all six sheets and cut strips from them to cover the sides. I had no trouble wrapping the red oak around a 3/8” round over. The cedar, on the other hand, turns into splinters! In order to cover the round overs, I had to moisten the cedar to soften it. What a nightmare! More expensive to start with, and then a lot of it is simply waste. Never again! (As they say, “Its been a great learning experience.”)

The final photo shows the new PTL next to the F120A Metronome I build a couple years ago.

As I mentioned earlier, I am happy with the sound. Each driver has its own characteristics. The FF225wk isn’t the last word in resolution--which is a good thing. I feel it makes the most of less than perfect recordings, such as Benny Goodman’s 1938 Carnegie Hall concert. (Great music, but a technically inferior recording.) It doesn’t suffer the quirks of whizzered drivers, and the highs are good enough for me with the added tweeter.

Hopefully, measurements will follow in a couple of weeks.

Cheers, Jim

Attachments

... She chose red cedar. Have to say, it looks really nice... I haven’t seen another project done with red cedar, so this may be unique.

Cedar is a really interesting building material.

Bernie has done a number of boxes out of Western Red Cedar including a couple prototype uFonkenSET flat-paks.

I have a FAST 1st heard last WE that is targeted at a 1/4-3/8" covering of red cedar over the plywood.

dave

Hi Dave,

At 1/4" thick I can see that cedar might be reasonable to work with. I had thought that the paper backed veneer ( 1/32" thick) could work if I avoided having to cut through a knot on an edge or bend one over the 3/8" round over.

Clearly I should have consulted a woodworker like Chris first!

Cheers, Jim

At 1/4" thick I can see that cedar might be reasonable to work with. I had thought that the paper backed veneer ( 1/32" thick) could work if I avoided having to cut through a knot on an edge or bend one over the 3/8" round over.

Clearly I should have consulted a woodworker like Chris first!

Cheers, Jim

Jim,

The speakers look really fantastic in red cedar. I love that look. I wonder if building the speaker out of solid cedar is a possibility? Is it expensive wood? Probably not as decks and furniture for the patio is built with it. You may have to glue strips together for a wide board though? Nice work!

Are you going to make little cubes or something for the tweeters? A little red cedar box?

The speakers look really fantastic in red cedar. I love that look. I wonder if building the speaker out of solid cedar is a possibility? Is it expensive wood? Probably not as decks and furniture for the patio is built with it. You may have to glue strips together for a wide board though? Nice work!

Are you going to make little cubes or something for the tweeters? A little red cedar box?

I wonder if building the speaker out of solid cedar is a possibility?

Is it expensive wood?

They grow in my back yard.

dave

Hi Dave,

At 1/4" thick I can see that cedar might be reasonable to work with. I had thought that the paper backed veneer ( 1/32" thick) could work if I avoided having to cut through a knot on an edge or bend one over the 3/8" round over.

Clearly I should have consulted a woodworker like Chris first!

Cheers, Jim

for working with solid you really want to talk to Bernie - Dave did you get a group shot of the 6 pairs of microfonkens at last week's event?

note that red cedar such as in the photo above is soft enough that it's very easily scratched / gouged by handling, while Oak. Locust, and even Cherry is much harder

Last edited:

Dave did you get a group shot of the 6 pairs of microfonkens at last week's event?

Ruth got some. I haven't seen them yet.

dave

Love that luster and shine! Congrats Dave

Dave: Those are gorgeous! Don't see any knots.

Chris: No way I'm trying solid wood. I know I'm not that good a wood worker! I was guessing that if I asked you about cedar veneer, you would have set me straight & told me to look for something that is easier to work.

X: The tweeters will go in small boxes with cedar veneer. That won't happen until after MJK does measurements. No time at the moment anyway, as it's summer theater camp time at STC; with 21 kids age 8 to 14, we have our hands full--and they do wear me out. This year we have more kids interested in sound, so I'm having great fun teaching them how to use the sound gear & run a show.

Cheers, Jim

Chris: No way I'm trying solid wood. I know I'm not that good a wood worker! I was guessing that if I asked you about cedar veneer, you would have set me straight & told me to look for something that is easier to work.

X: The tweeters will go in small boxes with cedar veneer. That won't happen until after MJK does measurements. No time at the moment anyway, as it's summer theater camp time at STC; with 21 kids age 8 to 14, we have our hands full--and they do wear me out. This year we have more kids interested in sound, so I'm having great fun teaching them how to use the sound gear & run a show.

Cheers, Jim

Last edited:

Well Jim, to be honest, cedar or even VG Doug fir aren't really on my list of favorite materials for furniture or speaker enclosures, and when it comes to veneers, I always seem to fall back on the reliable Cherry, Walnut or quarter cut Sapele / ribbon grain mahogany

like when I used to eat ice cream, you can dally with the mint chocolate chip, mango-coconut, tutti-fruiti, rocky road, et al, but good old French Vanilla with fresh strawberries ... hmmm - I digress

Avoid the reconstituted / simulated quarter cut veneers such as Brookside, etc for designs that call for a lot of folding around hard corners - it's great for flat surfaces, but easily splits longitudinally when folded, and can chip out on cross grain trims if using a router.

The finish on the cedar boxes would have been nitro-cellulose lacquer - 40dg sheen

like when I used to eat ice cream, you can dally with the mint chocolate chip, mango-coconut, tutti-fruiti, rocky road, et al, but good old French Vanilla with fresh strawberries ... hmmm - I digress

Avoid the reconstituted / simulated quarter cut veneers such as Brookside, etc for designs that call for a lot of folding around hard corners - it's great for flat surfaces, but easily splits longitudinally when folded, and can chip out on cross grain trims if using a router.

The finish on the cedar boxes would have been nitro-cellulose lacquer - 40dg sheen

Chris,

Thanks for the tips! I have been purchasing peel & stick veneer from tapeease.com (source recommended by Bob Brines) for some years. I have been very satisfied with their flat-cut red oak, and presume their other products are equally good. Just my bad for selecting a difficult material.

Forgotten details:

Grills: I couldn’t buy genuine Fostex grills for the FF225wk, so: magnets are embedded underneath the veneer; another magnet is put on top of the veneer (to space the grill out a bit from the driver); then Parts Express 10” grills (260-373) are held on by the magnets. Not very pretty, but they provide protection. And they can easily be removed/replaced in a jiffy.

Feet: I added adjustable glides (intended for chairs or tables) from the hardware store as feet.

Cheers, Jim

Thanks for the tips! I have been purchasing peel & stick veneer from tapeease.com (source recommended by Bob Brines) for some years. I have been very satisfied with their flat-cut red oak, and presume their other products are equally good. Just my bad for selecting a difficult material.

Forgotten details:

Grills: I couldn’t buy genuine Fostex grills for the FF225wk, so: magnets are embedded underneath the veneer; another magnet is put on top of the veneer (to space the grill out a bit from the driver); then Parts Express 10” grills (260-373) are held on by the magnets. Not very pretty, but they provide protection. And they can easily be removed/replaced in a jiffy.

Feet: I added adjustable glides (intended for chairs or tables) from the hardware store as feet.

Cheers, Jim

Nice job on the speakers Jim. I can see that would be a hard veneer to bend with knots in it, around here we use cedar like that for fencing. The real nice cedar comes from the west coast of Vancouver Island. The cedar I've been using is all reclaimed and is a joy to work with.

Last edited:

hobbers:

Wow! Those are gorgeous!

As a re-purposed (retired) analytical chemist, I am only a poor hack wood worker. I do the best I can with plywood, then cover it over with peel & stick veneer. (yes, yes, it's the route of sloth & indigence) I view this project as an expensive and painful lesson in due diligence required before trying different veneers.

Cheers, Jim

Wow! Those are gorgeous!

As a re-purposed (retired) analytical chemist, I am only a poor hack wood worker. I do the best I can with plywood, then cover it over with peel & stick veneer. (yes, yes, it's the route of sloth & indigence) I view this project as an expensive and painful lesson in due diligence required before trying different veneers.

Cheers, Jim

Real wood is both harder and easier to work with, and more rewarding once you've negotiated a truce with it. Most veneers are so very thin now that there will be no sanding out a dent or scratch. Try it. You might like it. I enjoy the advice in old speaker books that solid wood won't work. Motivation!

FWIW, when I was ~ 'forced' to do the finish work and painting wasn't an option, I used high end wallpaper [including wood grained] since it was quick, easy, cheaper and reasonably durable. Within reason, easier to repair too when accosted by kids/pets, though obviously even those I clear coated couldn't compete visually with the 'over the top' finishes posted here.

GM

GM

Here is the final chapter in my build!

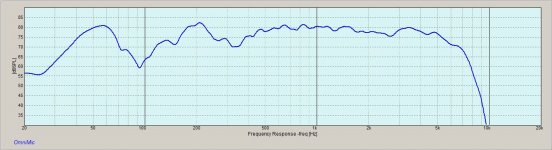

MJK brought over his PE OmniMic and measured my speakers. The response curve below is for the right channel with the grill off. We tried with grill on and grill off--didn’t seem to make any significant difference. Bottom line is that the measurement looks good: reasonably flat, no nasty peaks. I believe that the suck-out centered at 92 Hz is a function of the room, as the curve follows the MathCAD model pretty well. I estimate the F10 at 37 Hz, which is deep enough for me. If I want more extension, then a sub could be added, but I can’t see bothering with it at this time.

The FF225wk has a nice smooth sound, and I like it a bit more than the FE167e and FE206e which I have used in prior builds. It does need a tweeter on top to give cymbals the proper ‘zing’. I like their sound; my wife likes them; and now Martin has given them his blessing. So, I’m declaring ‘mission accomplished!’, and I can recommend both the FF225wk and the Pappa’s TL design.

Cheers, Jim

MJK brought over his PE OmniMic and measured my speakers. The response curve below is for the right channel with the grill off. We tried with grill on and grill off--didn’t seem to make any significant difference. Bottom line is that the measurement looks good: reasonably flat, no nasty peaks. I believe that the suck-out centered at 92 Hz is a function of the room, as the curve follows the MathCAD model pretty well. I estimate the F10 at 37 Hz, which is deep enough for me. If I want more extension, then a sub could be added, but I can’t see bothering with it at this time.

The FF225wk has a nice smooth sound, and I like it a bit more than the FE167e and FE206e which I have used in prior builds. It does need a tweeter on top to give cymbals the proper ‘zing’. I like their sound; my wife likes them; and now Martin has given them his blessing. So, I’m declaring ‘mission accomplished!’, and I can recommend both the FF225wk and the Pappa’s TL design.

Cheers, Jim

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Pappa's TL