Thanks for the info Dave & Chris... I do like the look of the uFonken [dMar-Ken7.3 preferably] & woofT setup. Is the woofT design scalable for larger drivers, lets say the Peerless 830875 6.5" as a maximum?

Going to try the Peerless 835026 in a sealed box as a helper woofer to the FH3 as a starting point. Then go from there regarding a FAST build.

Paul

Going to try the Peerless 835026 in a sealed box as a helper woofer to the FH3 as a starting point. Then go from there regarding a FAST build.

Paul

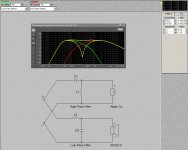

A7 Gold RS225-8 SIM

Here is a quick sim with the RS225-8 in 38L @ 35hz.

This would be a 3" port about 9" long.

This doesn't take any baffle step comp. into consideration but you could easily build your baffle width to be close to 300hz unless you want a slim cabinet.

Here is a quick sim with the RS225-8 in 38L @ 35hz.

This would be a 3" port about 9" long.

This doesn't take any baffle step comp. into consideration but you could easily build your baffle width to be close to 300hz unless you want a slim cabinet.

Attachments

6.5" as a maximum?

It is a limit if you give yourself a limit of a side mounted woofer if retaining the

footprint of the mid-tweeter is rigid. If one is willing to extend the depth, or to take on the challenge of tapered sides or back, a larger woofer could be fitted.

The rectangular versions can support larger drivers, an 8" can just fit on the back of the dMar-Ken. Likely larger of the bigger rectangles.

dave

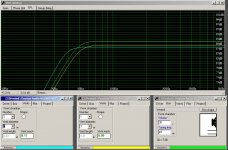

Woofer Comparisons

Here are a few box sims for dual peerless, dual dayton RS150 and single dayton RS180S-8.

The RS180 has the same OD as the Peerless but the peerless has a truncated frame that makes it .75" narrower.

If that extra .75" is a deal breaker then so be it but for a similar cabinet size and half the driver numbers and cost you get an extra 12hz @ -3db and 10hz @-6db.

The RS180 will be well out of its breakup around 4-10k if you were to cross over at around 300hz.

Here are a few box sims for dual peerless, dual dayton RS150 and single dayton RS180S-8.

The RS180 has the same OD as the Peerless but the peerless has a truncated frame that makes it .75" narrower.

If that extra .75" is a deal breaker then so be it but for a similar cabinet size and half the driver numbers and cost you get an extra 12hz @ -3db and 10hz @-6db.

The RS180 will be well out of its breakup around 4-10k if you were to cross over at around 300hz.

Attachments

How do they sound?

Very good. Really neutral. Image well. Decent bass (it creeps up on you).

I think our best effort to date.

dave

How do these gorgeous pieces of work looks from the inside and how you do manufacture these wide curvatures?

The A7 TL is created by a horozontal partition just below. and a couple small partitions to lengthen and taper the terminus side of the line. The rest is a sealed space.

Chris saw an opportunity to try-out some vacuum bag techniques (original drawing was for an irregular 12-sided polygon) and to use rubber ply. I'll leave it to Chris to describe all that,

dave

Hmmm passive at 200Hz

Don't forget to model the passive crossover in your bass box sims folks> DCR changes driver Q and sensitivity

the inductors will probably not be air cored for dcr losses and costs. they will be huge and pricey! as we use to say BFL's big F'n Inductors

Don't forget to model the passive crossover in your bass box sims folks> DCR changes driver Q and sensitivity

the inductors will probably not be air cored for dcr losses and costs. they will be huge and pricey! as we use to say BFL's big F'n Inductors

Last edited:

The A7 TL is created by a horozontal partition just below. and a couple small partitions to lengthen and taper the terminus side of the line. The rest is a sealed space.

Chris saw an opportunity to try-out some vacuum bag techniques (original drawing was for an irregular 12-sided polygon) and to use rubber ply. I'll leave it to Chris to describe all that,

dave

Ya com-on Chris show us

a vaccum system was on my list way back there when I saw an article in I believe Shop Notes mag about building one with your compressor,venture valves etc.

gotta thinkin, that that could knock the price down and move it on up the “need to have list”speaking of which

horizontal drum sander , you know how much joy can come from hours of belt sanding and ro sanding panel after panel afterrrrr day after day after yearrrrrr…....... 100,120,150............YA i need that next

CNC router, does that say 9/32”, so all I need to do is run to my local supplier for a 19/64 no what 17/64” strait cutter for my circle jig thats easy “right” or maybe there is another way

Well at least one more thing is checked off my list: when I get home from wooork(sorry hard to say that word on a weekend) there should be a 1hp gi drill press waiting for setup that should open up more posabilitys here in the shop

I really regret not hearing those at DIY Fest.

They were only connected breifly. Both them and the Facets still needed a bit of detailing. The ellipise-like FAST is also so neutral they really need a longer listening session to appreciate their assets.

dave

Maybe I'll have to stop by when they are back with you!

Km

As mentioned earlier, they very likely need a much larger room to fully blossom than my den in which the photos were taken.

As it turns out, Dave does have the requisite space, and they'll probably be in his hands within the week.

xylkus / Robert:

Nothing particularly high tech about the fabrication - CNC was used for routing of plywood elliptical ribs and solid plates for space frame, MDF ribs for the vacuum bagging form, and machining of driver baffles.

All else was just old school manual labour - well, I cheated with routers, brad nailer and air powered sander.

The Quarter cut Sapele with a nice medium red stain and sprayed lacquer certainly does look sharp.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Alpair 7.3 FAST / WAW