I am getting to the finish line with this horn soon. But lets not forget that it is it a compact horn

Dr Boar, I love that Schmackshorn behind it!

I had one of those myself, I loved it.

Thanks for the tip about the mp3 I have already glued braces now, next time

That is not the Schmacks for 8-9" drivers but the Klinger for 12" drivers.

The glued box (green) is has sharper peaks than the final open one (blue). Using flexing walls to absorb vibrations is not new the Decca Corner horn from the 50s was "improved" by removing a brace. Still I am surpriced that me on top of the side of the box was not enough to make it inert. I have to make some frequency measurements as well to see how far of I am. Those last minute surprices...

That is not the Schmacks for 8-9" drivers but the Klinger for 12" drivers.

The glued box (green) is has sharper peaks than the final open one (blue). Using flexing walls to absorb vibrations is not new the Decca Corner horn from the 50s was "improved" by removing a brace. Still I am surpriced that me on top of the side of the box was not enough to make it inert. I have to make some frequency measurements as well to see how far of I am. Those last minute surprices...

Dr Boar,

Could the sharper response be more due to a tight seal rather than stiffer walls? If it is indeed a seal issue, could tiny pinhole controlled "leaks" be added to smooth it back down? Yes, the efficiency will suffer but it looked like there was already plenty of output with the clamped and gasketed version.

Could the sharper response be more due to a tight seal rather than stiffer walls? If it is indeed a seal issue, could tiny pinhole controlled "leaks" be added to smooth it back down? Yes, the efficiency will suffer but it looked like there was already plenty of output with the clamped and gasketed version.

Regarding leaks vs wall vibration, I have no way of measure either way, your guess is as good as mine. But with continous closed foam strips on the edges and horn side facing down on a flat suface and the strips being compressed by the weight of the horn and then some 175 lb of me as well, I find leaks unlikely but not impossible.

I have noted that free edges makes walls prone to vibrate, like the opening of the horn. In the gasketed version the top, bottom, front, back and all internal partitions are all with a free edge. Free to vibrate with not much of mechanical interlocking being done by the gasket compared to glued board.

If I could go back in time the control experiment would be to measure impedance and frequency in gasketed version and gasket plus extensive crossbraces close to the free edges that would mechnically lock the varius partitions and walls to each other.

While not the same thing I could try to knock out the braces I put in remeasure and then both glue in some braces as well as use clamps externaly to reduce vibrations. The third harmonic has pressure maxima at 1/3 and 2/3 of the lenght of the pipe, shifted by flare and folds but somewhere in those regions.

I have noted that free edges makes walls prone to vibrate, like the opening of the horn. In the gasketed version the top, bottom, front, back and all internal partitions are all with a free edge. Free to vibrate with not much of mechanical interlocking being done by the gasket compared to glued board.

If I could go back in time the control experiment would be to measure impedance and frequency in gasketed version and gasket plus extensive crossbraces close to the free edges that would mechnically lock the varius partitions and walls to each other.

While not the same thing I could try to knock out the braces I put in remeasure and then both glue in some braces as well as use clamps externaly to reduce vibrations. The third harmonic has pressure maxima at 1/3 and 2/3 of the lenght of the pipe, shifted by flare and folds but somewhere in those regions.

What do you think of building a horn like this out of polyisocyanurate foam sheathing instead of osb?

Shop Rmax 1/2-in x 4-ft x 8-ft Polyisocyanurate Insulated Sheathing at Lowes.com

Shop Rmax 1/2-in x 4-ft x 8-ft Polyisocyanurate Insulated Sheathing at Lowes.com

Why not, the idea of building speakers out of low mass material to get a low energy storage is something that has been tested over the years. The big Klinger horn on a previous post is built in soft and very light soft board, this date 50-60 years back. In the 80s Celestion had the 600 speaker with airolam walls, thin alumnium skins draped over a honeycomb lattice, light and stiff. I do not know how stiff the "polyisocyanurate foam sheathing" is stiff enough otherwise one could buy those fake plastic "glass panes" and laminate with that on both sides, that ought to become very stiff.

I have some left over MDF that I intend to use to test how different foldning affects the harmonics of a pipe. Now it appears I have to be carful about how I design access points into the box. Build and learn!

I have some left over MDF that I intend to use to test how different foldning affects the harmonics of a pipe. Now it appears I have to be carful about how I design access points into the box. Build and learn!

This is the combined responce and it looks pretty good, the near field measurement is very close to the phase plug as close to the voice coil as I could get it. Horn is measured at center of opening as before.

Cone output is supressed from 90 to 150 Hz and also at 38-50 Hz. How much the 40-80 Hz octave can be brought up to level with the 80-160 Hz remains to be seen.

Now I have to ponder on were to put my horn for the listening session and for measurement of room integration.

Cone output is supressed from 90 to 150 Hz and also at 38-50 Hz. How much the 40-80 Hz octave can be brought up to level with the 80-160 Hz remains to be seen.

Now I have to ponder on were to put my horn for the listening session and for measurement of room integration.

I tested some other drivers, from Altec Lansing, Audax, Bravox, Coral and Quadral. They are hardly current of the shelf units but they cover a range of parameters that should cover the space of many current drivers.

They were all mounted with the face towards the cabinet as they all were bigger than the cutout. So the driver close range is as close as I could get to the cone

Altec Lansing A 405

Bravox 5FDRPRP polopropylene cone and foam edge.

Coral 4L-81

Quadral M132/25/8/PF

I will get back about the Audax driver...

Dr Boar, did you make the above measurements with the horn in the corner of a room? It seems from MJK's white paper that this is really critical for testing the design.Cone output is supressed from 90 to 150 Hz and also at 38-50 Hz. How much the 40-80 Hz octave can be brought up to level with the 80-160 Hz remains to be seen.

Now I have to ponder on were to put my horn for the listening session and for measurement of room integration.

This is measured at the opening of the horn and for that it does not matter as it measures the same in corner and freestanding. I will come back to the real corner measurement tomorrow.

Corner loading should change the response even when measuring at the mouth of the horn.

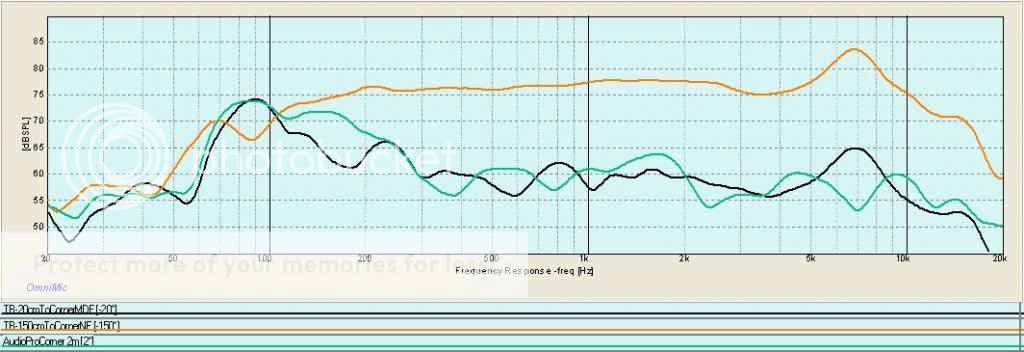

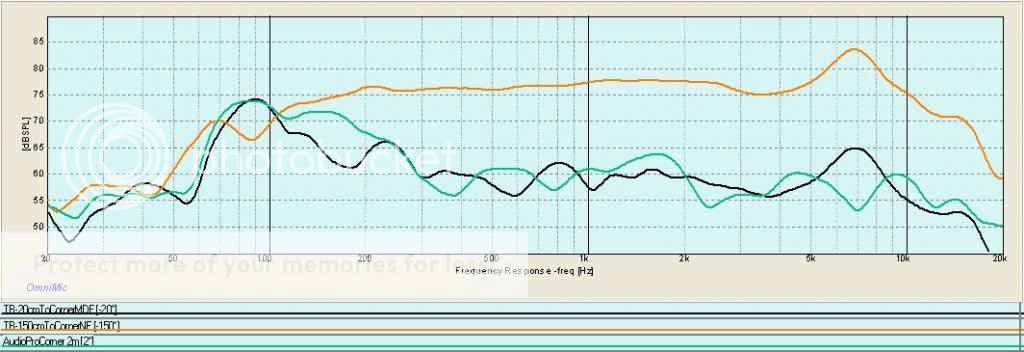

To take room effects I have done like this:

1.Microphone 2 m from corner and at driver hight for the horn

2.Measure AudioPro 2.14Live speaker put in the corner of the room. It is a conventional good bass reflex 6.5" & 1"dome, large abberations are due to room not speaker

3.Put horn opening 150 cm from corner, the driver at the front is then quite close to the microphone.

4. Stepwise back the horn into the corner 80-40-20cm

Note that while one wall is a proper concrete wall the other that also is a concrete wall has a gyprock wall 10 cm in front of it

Or with just the core curves

Top orange is near field (150cm out) dip at 90 and 40 Hz visable.

Green is the Audiopro and black the Tangband King compact horn.

It looks good apart from the depression 120-200 Hz, if this is due to my deviations from Kings design or not is for others to elucidate.

How it sounds

In my living rom, side wall is a proper concrete wall, back wall is a flimsy thing, a similar wall with the Klipsch Corner Horn killed 6-8 dB below 80 Hz as I recall.

NAD 20 years of music (NAD and Sheffield Lab)

Not bad at all you clearly hear the kick drum and it suggest some weight, but the "slam" is missing. Higher up the the TB is really good, that peak at 7 kHz does not sound to bad unless you sit straigt on axis. Way better than the Philips 9710.

The Committments original soundtrack

Mustang Sally got me up and dancing

"Chain of fools" I can feel the bass both in the floor vibrations and in the backrest of the couch, that is darn impressive for a 4" driver. The previous horn I tried had 12" drivers that is 500cm2 instead of 50 cm2

So to conclude (my iteration of the design). It has surprising amount of bass that is dry and well defiened not one note lumpy as I feared. The TB have quite a lenght of cone travel ( I can't stand the rain is really good, grin) with the Fostex that has far less and so the bass output and slam has to bee seen in it's context. In a 25m2 room (300 sqf) I can play quite loud and then the TB run out of steam without sounding harsh or strident.

Proper corners are important, I wish I had some!

1.Microphone 2 m from corner and at driver hight for the horn

2.Measure AudioPro 2.14Live speaker put in the corner of the room. It is a conventional good bass reflex 6.5" & 1"dome, large abberations are due to room not speaker

3.Put horn opening 150 cm from corner, the driver at the front is then quite close to the microphone.

4. Stepwise back the horn into the corner 80-40-20cm

Note that while one wall is a proper concrete wall the other that also is a concrete wall has a gyprock wall 10 cm in front of it

Or with just the core curves

Top orange is near field (150cm out) dip at 90 and 40 Hz visable.

Green is the Audiopro and black the Tangband King compact horn.

It looks good apart from the depression 120-200 Hz, if this is due to my deviations from Kings design or not is for others to elucidate.

How it sounds

In my living rom, side wall is a proper concrete wall, back wall is a flimsy thing, a similar wall with the Klipsch Corner Horn killed 6-8 dB below 80 Hz as I recall.

NAD 20 years of music (NAD and Sheffield Lab)

Not bad at all you clearly hear the kick drum and it suggest some weight, but the "slam" is missing. Higher up the the TB is really good, that peak at 7 kHz does not sound to bad unless you sit straigt on axis. Way better than the Philips 9710.

The Committments original soundtrack

Mustang Sally got me up and dancing

"Chain of fools" I can feel the bass both in the floor vibrations and in the backrest of the couch, that is darn impressive for a 4" driver. The previous horn I tried had 12" drivers that is 500cm2 instead of 50 cm2

So to conclude (my iteration of the design). It has surprising amount of bass that is dry and well defiened not one note lumpy as I feared. The TB have quite a lenght of cone travel ( I can't stand the rain is really good, grin) with the Fostex that has far less and so the bass output and slam has to bee seen in it's context. In a 25m2 room (300 sqf) I can play quite loud and then the TB run out of steam without sounding harsh or strident.

Proper corners are important, I wish I had some!

Hajj

To prove me right I measured impedance and frequency response in horn mouth, this time in a true concrete corner. Really crammed with a large IKEA computer desk close by, but solid walls.

This is what I got

Identical curves below 70 Hz and above 130 Hz but between that more swings up and down in the 70-130 Hz range.

I then did the frequency response, and the corner mesurement is actually a bit different and better

Your were right and I wrong, thanks.

Now for the horn in proper concrete corner

Now it looks even better, the output in the 40-30 Hz range is better than other loudspeaker. The are not completly matched, with the bass reflex and horn opening close to the corner the AudioPro Woofer is 40 cm from the corner and about 25 off the floor. The Tangband is a full meter from the corner and 75 cm or so off the floor, so they may add upp differently.

A brief listen confirm previous findings, deep bass is there but the slam is not there but I guess that you simply need more cone area to get that effect.

I do recomend anyone with small fullrange drivers to give this design a try, thank you so much Mr King for this little gem! Time to get some IPA.

Time to get some IPA.

To prove me right I measured impedance and frequency response in horn mouth, this time in a true concrete corner. Really crammed with a large IKEA computer desk close by, but solid walls.

This is what I got

Identical curves below 70 Hz and above 130 Hz but between that more swings up and down in the 70-130 Hz range.

I then did the frequency response, and the corner mesurement is actually a bit different and better

Your were right and I wrong, thanks.

Now for the horn in proper concrete corner

Now it looks even better, the output in the 40-30 Hz range is better than other loudspeaker. The are not completly matched, with the bass reflex and horn opening close to the corner the AudioPro Woofer is 40 cm from the corner and about 25 off the floor. The Tangband is a full meter from the corner and 75 cm or so off the floor, so they may add upp differently.

A brief listen confirm previous findings, deep bass is there but the slam is not there but I guess that you simply need more cone area to get that effect.

I do recomend anyone with small fullrange drivers to give this design a try, thank you so much Mr King for this little gem!

Time to get some IPA.

Time to get some IPA.

Last edited:

Dr Boar,

Thank you so much for taking the time to do all these careful measurements and for your observations. Truly one of the best series of measurements and analysis for a new design that I have seen someone show in detail. Since you recommend this design now, and you have some modifications/changes to optimize, can you please summarize what those are so that we can have a clear plan when building?

Truly one of the best series of measurements and analysis for a new design that I have seen someone show in detail. Since you recommend this design now, and you have some modifications/changes to optimize, can you please summarize what those are so that we can have a clear plan when building?

Thanks,

X

Thank you so much for taking the time to do all these careful measurements and for your observations.

Truly one of the best series of measurements and analysis for a new design that I have seen someone show in detail. Since you recommend this design now, and you have some modifications/changes to optimize, can you please summarize what those are so that we can have a clear plan when building?

Truly one of the best series of measurements and analysis for a new design that I have seen someone show in detail. Since you recommend this design now, and you have some modifications/changes to optimize, can you please summarize what those are so that we can have a clear plan when building?Thanks,

X

Thanks for the kind words, xrk971

Any opimization is a compromise between different conflicting characteristics. When I removed the damping of the pipe I gained more output in the 40-80 Hz region but the price is more harmonics getting through.

I am sure there is gains to be made with further work on the damping, but with hand holes not a complete side that is detatched. And even measure in a good corner not on a table like I did.

To my defence I must state with the detached side and measured in a corner with one concrete and one plaster wall there was no difference in impedance compared to the pipe opening in free field.

I recently did a series of measurement on the much larger Klinger horn using a whole range of 12" bass drivers. The surprise was that the high Fr low Q driver had deeper bass than the low resonance drivers. If you look on my set of drivers for Kings compact horn the Quadral mid range driver with Fr of 120 Hz has good output from the pipe in the 40-80 Hz range. Perhaps those kind of drivers do some kind of reactance anulling?

Perhaps something like

http://www.fane-acoustics.com/professional.aspx?diameter=5-6

Or other fullrange/ extended range pro driver, built like tanks and xmax of 2.5-4.5mm! The one with a Fr of 164 Hz might have better bass then the sibling with an fr of 58 Hz, when coupled to a backloaded horn.

Regarding the missing "slam". By rearanging the speaker a bit the current side could be the front with the driver centrally placed and having the horn opening along the back lower edge towards the corner on the opposite "side". Such an arrangement would lower the baffle step frequency about one octave and might add some slam to the mix. Adding wings to a slim design just looks odd I think it better to change the layout to get better corner loading, perhaps with the IHR above the driver to exend the baffle also upwards.

Many years ago I built the Accousta 115 using Philips 9710, the 10 dB lift above 2 kHz gave a very directional piercing sharp sound and the horn had no bass what so ever below 80 Hz. This compact horn is less than a 1/3 of the Accousta and the TB has less than 1/4 the cone area of the 9710. So when that 7 kHz peak showed up I thought that that would spoil the system. It did not and I am happy with both the driver and the horn.

Any opimization is a compromise between different conflicting characteristics. When I removed the damping of the pipe I gained more output in the 40-80 Hz region but the price is more harmonics getting through.

I am sure there is gains to be made with further work on the damping, but with hand holes not a complete side that is detatched. And even measure in a good corner not on a table like I did.

To my defence I must state with the detached side and measured in a corner with one concrete and one plaster wall there was no difference in impedance compared to the pipe opening in free field.

I recently did a series of measurement on the much larger Klinger horn using a whole range of 12" bass drivers. The surprise was that the high Fr low Q driver had deeper bass than the low resonance drivers. If you look on my set of drivers for Kings compact horn the Quadral mid range driver with Fr of 120 Hz has good output from the pipe in the 40-80 Hz range. Perhaps those kind of drivers do some kind of reactance anulling?

Perhaps something like

http://www.fane-acoustics.com/professional.aspx?diameter=5-6

Or other fullrange/ extended range pro driver, built like tanks and xmax of 2.5-4.5mm! The one with a Fr of 164 Hz might have better bass then the sibling with an fr of 58 Hz, when coupled to a backloaded horn.

Regarding the missing "slam". By rearanging the speaker a bit the current side could be the front with the driver centrally placed and having the horn opening along the back lower edge towards the corner on the opposite "side". Such an arrangement would lower the baffle step frequency about one octave and might add some slam to the mix. Adding wings to a slim design just looks odd I think it better to change the layout to get better corner loading, perhaps with the IHR above the driver to exend the baffle also upwards.

Many years ago I built the Accousta 115 using Philips 9710, the 10 dB lift above 2 kHz gave a very directional piercing sharp sound and the horn had no bass what so ever below 80 Hz. This compact horn is less than a 1/3 of the Accousta and the TB has less than 1/4 the cone area of the 9710. So when that 7 kHz peak showed up I thought that that would spoil the system. It did not and I am happy with both the driver and the horn.

Last edited:

Closing the old driver hole for the 4" drivers as I wanted to test some more 5" units....

As I had to cut a hole for the 5" drivers why not relocate it to the side to get more baffle loadning?

And then move the horn opening as well

That scrap side wing might have to go when I try to get in corner.

Now the glue have to harden and a be cleared before I can make any meaningful measurements.

The scientist in me cringe at changing both layout and set of drivers at the same time but, what can I say, I am lazy.

As I had to cut a hole for the 5" drivers why not relocate it to the side to get more baffle loadning?

And then move the horn opening as well

That scrap side wing might have to go when I try to get in corner.

Now the glue have to harden and a be cleared before I can make any meaningful measurements.

The scientist in me cringe at changing both layout and set of drivers at the same time but, what can I say, I am lazy.

Closing the old driver hole for the 4" drivers as I wanted to test some more 5" units....

As I had to cut a hole for the 5" drivers why not relocate it to the side to get more baffle loadning?

Relocating the driver will also have an influence on the horn's response due to a shift in the resonant frequency of the chamber.

Might be too small to notice, but just a heads up.

And btw, this might just be the most interesting thread I've read this far on DIYaudio. Kudos

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- MJK's Fostex FF125wk BLH project