Ok, I think I've read just about everything thread and article on diffraction and I still have questions:

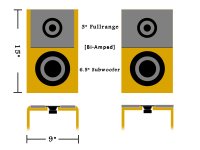

1.) I was thinking of making the baffle out of felt, so-to-speak... i.e. where the tweeter is flush or just under the felt. In the following pic, the felt is 1/2" and the FR driver would be mounted on a cylinder of 1/2" thickness MDF with the same diameter as the driver's mounting flange. Would this work or would it just create a much higher BS frequency? I just do not understand why the felt has to be on top of the baffle since it is *the baffle* that is responsible for the diffraction.

2.) I used the BSC calculator on this site and it suggests values for a zobel network. Normally this would just be used for woofers since they are usually crossed over before 3-4KHz. Would this not have the effect of dramatically and increasingly lowering the high frequency output? Look at the frequency response and impedance curve of the driver:

It seems to me that as the driver impedance increases in the high freq range, that there would be increasingly more current flow through the Zobel network and therefore lower the current passing through the driver at the higher frequencies. Is that correct?

Thanks,

Kevin

1.) I was thinking of making the baffle out of felt, so-to-speak... i.e. where the tweeter is flush or just under the felt. In the following pic, the felt is 1/2" and the FR driver would be mounted on a cylinder of 1/2" thickness MDF with the same diameter as the driver's mounting flange. Would this work or would it just create a much higher BS frequency? I just do not understand why the felt has to be on top of the baffle since it is *the baffle* that is responsible for the diffraction.

2.) I used the BSC calculator on this site and it suggests values for a zobel network. Normally this would just be used for woofers since they are usually crossed over before 3-4KHz. Would this not have the effect of dramatically and increasingly lowering the high frequency output? Look at the frequency response and impedance curve of the driver:

It seems to me that as the driver impedance increases in the high freq range, that there would be increasingly more current flow through the Zobel network and therefore lower the current passing through the driver at the higher frequencies. Is that correct?

Thanks,

Kevin

Kevin,

The felt will absorb many of the higher frequencies that would come off the front baffle itself. That is not exactly the same thing as what happens when the waves are large enough, meaning low enough, to reach the edge of the enclosure, that is where you will get the diffraction from. The front baffle works more like an infinite baffle at the higher frequencies as they can use the front surface to reflect. The felt will attenuate the higher frequencies depending on the thickness and density of the felt. But waves that are smaller than the diameter of the cone will still beam, that is another separate issue.

The felt will absorb many of the higher frequencies that would come off the front baffle itself. That is not exactly the same thing as what happens when the waves are large enough, meaning low enough, to reach the edge of the enclosure, that is where you will get the diffraction from. The front baffle works more like an infinite baffle at the higher frequencies as they can use the front surface to reflect. The felt will attenuate the higher frequencies depending on the thickness and density of the felt. But waves that are smaller than the diameter of the cone will still beam, that is another separate issue.

Kevin,

The felt will absorb many of the higher frequencies that would come off the front baffle itself. That is not exactly the same thing as what happens when the waves are large enough, meaning low enough, to reach the edge of the enclosure, that is where you will get the diffraction from. The front baffle works more like an infinite baffle at the higher frequencies as they can use the front surface to reflect. The felt will attenuate the higher frequencies depending on the thickness and density of the felt. But waves that are smaller than the diameter of the cone will still beam, that is another separate issue.

I understand what you mean about frequencies that have wavelengths smaller than mounting flange being "stepped" still, but the felt is not a (practically) reflective material so there should be no diffraction for the longer wavelengths, right?

Thanks for your response.

You don't have a problem with edge diffraction until the wavelengths are equal to the distance from the cone to the edge. So the lower the frequency the greater the diffraction around the edge. At very low frequencies that is why these frequencies become basically omni-directional. The cabinet no long is large enough to affect very long wavelengths. This is one of the factors that goes into choosing the cross-over frequency, but only one of them.

... the FR driver would be mounted on a cylinder of 1/2" thickness MDF with the same diameter as the driver's mounting flange.

I would use a cylinder that allows for more side to side breathing room... 4" PVC pipe would be a better choice. With ~1/8 walls you would not have something with much bigger outsides than a 1/2" MDF pipe, and have something stiffer.

dave

You don't have a problem with edge diffraction until the wavelengths are equal to the distance from the cone to the edge. So the lower the frequency the greater the diffraction around the edge. At very low frequencies that is why these frequencies become basically omni-directional. The cabinet no long is large enough to affect very long wavelengths. This is one of the factors that goes into choosing the cross-over frequency, but only one of them.

That makes perfect sense... so the fullrange I am using is 3" in diameter, the distance from the center to the baffle edge is 4.5" and the distance from the edge of the driver cone to the baffle edge is 3". That means that the frequencies from ~2600 - 4000 will be severely affected. Do you think the felt will combat this sufficiently if it is mounted flush with the fullrange?

I would use a cylinder that allows for more side to side breathing room... 4" PVC pipe would be a better choice. With ~1/8 walls you would not have something with much bigger outsides than a 1/2" MDF pipe, and have something stiffer.

dave

That's a pretty good idea but I'm not sure how to mount it. The driver is a 3" and there's very little room between the mounting holes and the basket.

bermtoog,

You would be far ahead of most in the regards of early reflections with the felt. It is a good idea, most people just don't like the look.

Thank you for imparting your knowledge. I don't like the look either but if it were flush it would be slightly more appealing... and easier to cover with a grill.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Baffle step and diffraction idea? Help needed