Double channel refers to original design where a middle plate separates the channels for 8 total. Requires middle plate to have thin cuts to fit channels in. This way is really much more difficult than single sided glued in foam core. You can double channel by gluing on both sides rather than dealing with cutting a spiral slit to fit channels in.

Well, I've started on this project.

I don't like the foam board...any way I manipulate it, following the curves of the template is difficult, and the tape I'm using to 'hold' the curves isn't always successful.

But, I tend towards woodworking, so I think I would cut channels of the spirals into one of the baffles, and bend a veneer into those...or something. Maybe there's a thick card (not corrugated) that I could use instead...something that's easier to bend that will also retain its shape...?

I don't like the foam board...any way I manipulate it, following the curves of the template is difficult, and the tape I'm using to 'hold' the curves isn't always successful.

But, I tend towards woodworking, so I think I would cut channels of the spirals into one of the baffles, and bend a veneer into those...or something. Maybe there's a thick card (not corrugated) that I could use instead...something that's easier to bend that will also retain its shape...?

The process is to score the foam board on the concave side with a razor to pierce the paper skin - approx 1/4 in apart cuts. The start hot gluing sections of 3 to 4 in at a time hold in place with fingers until glue hardens (30 sec). Continue until complete. No tape, no clamps, just fingers. Very easy and makes great smooth curves.

And even closer on the tighter curves near the center.approx 1/4 in apart cuts.

Thanks gentlemen. I apologise, yesterday was frustrating in general, and I shouldn't have started on a day like that!

I think I'd read too much. However, I'll do some more reading of the thread with some targeted questions in mind.

It appears that the plan is to glue the foam to the baffle, though I've seen others create the curved pieces first, before gluing. Is there an 'easy' way of transferring a template to the wood?

I think I'd read too much. However, I'll do some more reading of the thread with some targeted questions in mind.

It appears that the plan is to glue the foam to the baffle, though I've seen others create the curved pieces first, before gluing. Is there an 'easy' way of transferring a template to the wood?

Thanks for some cool ideas folks. Unfortunately, this thread suffers from an all too common ailment, too long. It would take a lot of time to read this.

I think I have most of the concept down, but I don't want to spend many hours searching for the answer to one question. Hopefully, somebody can answer the question. Sorry, here goes...

I am curious about the depth of the speaker. Is the idea to have the driver pressed up against the back of the speaker wall? Or is there clearance needed, etc?

I think I have most of the concept down, but I don't want to spend many hours searching for the answer to one question. Hopefully, somebody can answer the question. Sorry, here goes...

I am curious about the depth of the speaker. Is the idea to have the driver pressed up against the back of the speaker wall? Or is there clearance needed, etc?

Clearance needed as the baffles are not very thick and can't be used to brace the driver.

Thanks. So is there some sort of formula? Does a 2" driver need X amount of clearance? How is the depth determined? Thanks again.

I really need a CNC machine. I've started gluing the spirals, and it looks like a mess. I did what I could while the glue was setting, but my inaccuracy frustrates me...especially in a project where precision is so important. I'll try to get some more done to it this week, because finishing the project would be nice!

I really need a CNC machine. I've started gluing the spirals, and it looks like a mess. I did what I could while the glue was setting, but my inaccuracy frustrates me...especially in a project where precision is so important. I'll try to get some more done to it this week, because finishing the project would be nice!

Work in short sections at a time. You should be able to hold a 3 in section steady while the hot melt glue sets. You have about 15 sec to move it around before it hardens. The accuracy at the begining of the spiral where the channel spacing is tight is more critical than the wider parts. Don't worry if it is not exact. If you are scoring the foam with lots of cuts it should not be hard to curve it and hold it at a desired curvature while glue sets in 30 seconds.

I'm going to let xrk971 do the calculating but it seems to be close to the driver size. IIRC, my 4.5" driver have a 4.5" depth and same with the 3" drivers, a 3" depth.

Cal is correct in how to approximately size the channel depth. It works out that way and if is quite forgiving. I only use 2.38 in for my 3.5 in driver and it works fine. If you give me T/S params for your driver I can run a sim and tell you what the optimal depth is.

Okay. I spent a few hours reading halfway through the posts. I feel more confused.

I thought I could simply take the original diagrams and scale to match driver. Now I read about throat sizes, etc.

I am going to build a pair of these. And I hope somebody can fill in the blanks: how deep should the cavity be? Can I just scale from the PDF found on page 3 for my drivers or do I need to adjust for my specific drivers (throat size etc)? I assume 36cm is the correct size for my drivers... or could I put these in the 50cm? My drivers will be HiWave BMR12.

PRODUCT SPECIFICATIONS

Nominal Diameter 2"

Power Handling (RMS)12 Watts

Power Handling (max)24 Watts

Impedance8 ohms

Frequency Response 150 to 16,000 Hz

Sensitivity 83 dB 1W/1m

Resonant Frequency (Fs)164 Hz

DC Resistance (Re)8.13 ohms

Voice Coil Inductance (Le)0.12 mH

Mechanical Q (Qms)2.37

Electromagnetic Q (Qes)0.89

Total Q (Qts)0.65

Compliance Equivalent Volume (Vas)0.0063 ft.³

Maximum Linear Excursion (Xmax)3 mm

Overall Outside Diameter 2.56"

Baffle Cutout Diameter 2.05"

Depth 0.81"

I thought I could simply take the original diagrams and scale to match driver. Now I read about throat sizes, etc.

I am going to build a pair of these. And I hope somebody can fill in the blanks: how deep should the cavity be? Can I just scale from the PDF found on page 3 for my drivers or do I need to adjust for my specific drivers (throat size etc)? I assume 36cm is the correct size for my drivers... or could I put these in the 50cm? My drivers will be HiWave BMR12.

PRODUCT SPECIFICATIONS

Nominal Diameter 2"

Power Handling (RMS)12 Watts

Power Handling (max)24 Watts

Impedance8 ohms

Frequency Response 150 to 16,000 Hz

Sensitivity 83 dB 1W/1m

Resonant Frequency (Fs)164 Hz

DC Resistance (Re)8.13 ohms

Voice Coil Inductance (Le)0.12 mH

Mechanical Q (Qms)2.37

Electromagnetic Q (Qes)0.89

Total Q (Qts)0.65

Compliance Equivalent Volume (Vas)0.0063 ft.³

Maximum Linear Excursion (Xmax)3 mm

Overall Outside Diameter 2.56"

Baffle Cutout Diameter 2.05"

Depth 0.81"

Hey guys,

I uploaded the Autocad file that I used.

You can download it here:

https://dl.dropboxusercontent.com/u/21694574/Cornu.dwg

When CNCing the spiral, I would recommend to set the drill depth to some micras less than the total depth of the middle plate, so the drill doesn't go through the entire plate. That gives consistency and prevents the central plate from breaking, because when most of the spiral is cnc'd, the middle plate loses consistency and starts moving and it's quite a mess.

Once you have cnc'd the entire spiral, you can get easily rid of the thin layer of wood with a screwdriver or something.

Another good thing to do would be to start the drilling process from the inner part of the spiral outwards to the middle plate's edges.

Not sure if I explained what I meant in an understandable way hahaha, but hope it helps Kuroguy!!

I uploaded the Autocad file that I used.

You can download it here:

https://dl.dropboxusercontent.com/u/21694574/Cornu.dwg

When CNCing the spiral, I would recommend to set the drill depth to some micras less than the total depth of the middle plate, so the drill doesn't go through the entire plate. That gives consistency and prevents the central plate from breaking, because when most of the spiral is cnc'd, the middle plate loses consistency and starts moving and it's quite a mess.

Once you have cnc'd the entire spiral, you can get easily rid of the thin layer of wood with a screwdriver or something.

Another good thing to do would be to start the drilling process from the inner part of the spiral outwards to the middle plate's edges.

Not sure if I explained what I meant in an understandable way hahaha, but hope it helps Kuroguy!!

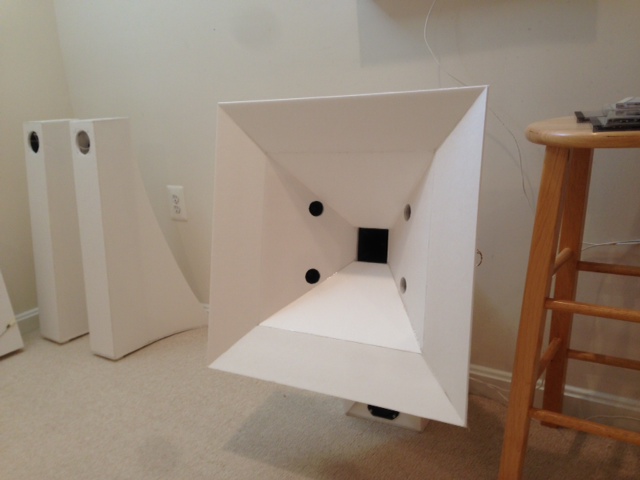

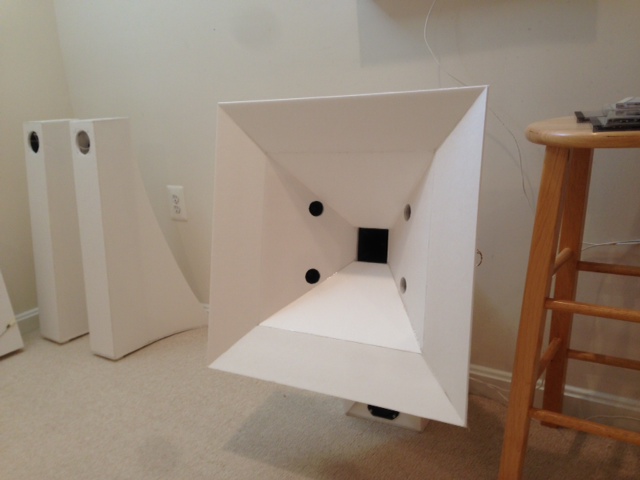

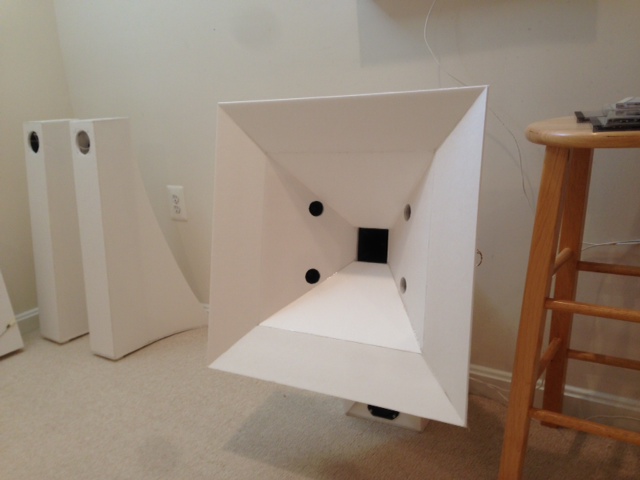

Here's an idea, looking at the later Cornu with the horn at the front

and X's experiment with a synergy in foam core...

Why not combine the two?

X is running them open back but why not put a Cornu style back horn on there... you've got 4 mids... They need to be a little closer to the entry of the horn and the vifa's being band passed you'd probably need a tweeter at the entry of the horn.

An externally hosted image should be here but it was not working when we last tested it.

and X's experiment with a synergy in foam core...

Why not combine the two?

X is running them open back but why not put a Cornu style back horn on there... you've got 4 mids... They need to be a little closer to the entry of the horn and the vifa's being band passed you'd probably need a tweeter at the entry of the horn.

Okay. I spent a few hours reading halfway through the posts. I feel more confused.

I thought I could simply take the original diagrams and scale to match driver. Now I read about throat sizes, etc.

I am going to build a pair of these. And I hope somebody can fill in the blanks: how deep should the cavity be? Can I just scale from the PDF found on page 3 for my drivers or do I need to adjust for my specific drivers (throat size etc)? I assume 36cm is the correct size for my drivers... or could I put these in the 50cm? My drivers will be HiWave BMR12.

PRODUCT SPECIFICATIONS

Nominal Diameter 2"

Power Handling (RMS)12 Watts

Power Handling (max)24 Watts

Impedance8 ohms

Frequency Response 150 to 16,000 Hz

Sensitivity 83 dB 1W/1m

Resonant Frequency (Fs)164 Hz

DC Resistance (Re)8.13 ohms

Voice Coil Inductance (Le)0.12 mH

Mechanical Q (Qms)2.37

Electromagnetic Q (Qes)0.89

Total Q (Qts)0.65

Compliance Equivalent Volume (Vas)0.0063 ft.³

Maximum Linear Excursion (Xmax)3 mm

Overall Outside Diameter 2.56"

Baffle Cutout Diameter 2.05"

Depth 0.81"

14 in x 2 in deep should work. Just scale drawing.

X

Here's an idea, looking at the later Cornu with the horn at the front

An externally hosted image should be here but it was not working when we last tested it.

and X's experiment with a synergy in foam core...

Why not combine the two?

X is running them open back but why not put a Cornu style back horn on there... you've got 4 mids... They need to be a little closer to the entry of the horn and the vifa's being band passed you'd probably need a tweeter at the entry of the horn.

Are you saying a 4 driver Cornu with Synergy front horn? You will need channels to route back wave to Cornu center - a common box for all 4 drivers would work. A piezo or dome tweeter in middle will help cover highs lost by bandpassing fullrange drivers. Interesting...

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!