Oops - I accidentally posted this in another thread earlier. Here it is in the right place!

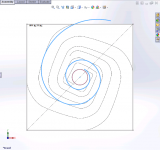

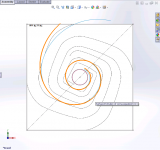

Quick update on the spiral cornu progress. I used the existing design as an underlay and did a first pass at the spiral using arc sections (see pic1, blue highlight). Then I mapped the clothoid (hyperbolic) over top of it. It turns out to be pretty close once you use the right part of the clothoid curve (see pic2, orange highlight). The cool part about the equation is that the wall curvature is now totally smooth. Seems close enough to me - what do you think?

Quick update on the spiral cornu progress. I used the existing design as an underlay and did a first pass at the spiral using arc sections (see pic1, blue highlight). Then I mapped the clothoid (hyperbolic) over top of it. It turns out to be pretty close once you use the right part of the clothoid curve (see pic2, orange highlight). The cool part about the equation is that the wall curvature is now totally smooth. Seems close enough to me - what do you think?

Attachments

Looks better but you need to end in a zero deg tangent to box edge to get the full horn expansion. If you are looking for smooth round spiral, I believe there is a set of plans in pdf by Endia in post #30. It may not be a clothoid but it is a smoother spiral and ends in tangent to edge.

Last edited:

Smooth walls are definitely cool and fun but will not filter out unwanted "mid-range" frequencies from the horn output. Smooth would be desirable in a front horn but not a backhorn. A front horn has output at the mouth; a backhorn has output at the mouth(s) and speaker membrane, if the same frequencies are originating at different points there is cancellation/combing and, I guess, "time smear" due to different path lengths(?). I'm thinking of going opposite of smooth, with some Nagaoka style hard bends, in my next Cornu.

Build a smooth one anyway, it's cheap enough to build for experimentation. This way you will be able to say you actually experienced the effect... or maybe you will like the weird effect, or it will sound awesome all the way and you can tell me to go suck an egg

Build a smooth one anyway, it's cheap enough to build for experimentation. This way you will be able to say you actually experienced the effect... or maybe you will like the weird effect, or it will sound awesome all the way and you can tell me to go suck an egg

The W5-1611 is a fine driver and very big! I don't think anyone has made a cornu with one yet but scale the design up to a 30 inch x 30 inch x 5.5 inches deep and it should work. The bass will be incredible on this thing.

Good luck!

Thanks

I haven't been thinking about diy audio for a few years - but just read through this post end to end and it's got me thinking.

I know I have an old pair (circa 2005) Tang Band 4" full rangers that I had in an old pair of BD-pipes sitting in a box in my basement. Seems like a trip to the foam-core store might be in order.

Not at home now - but will dig up the TB model number and specs next week and post them for input on sizing and dimensions.

not sure they will replace the FE206-ES in my old MLTL builds - but I'm sure the W.A.F. will be onside.

Steve in N.Vancouver (aka sapdog)

I know I have an old pair (circa 2005) Tang Band 4" full rangers that I had in an old pair of BD-pipes sitting in a box in my basement. Seems like a trip to the foam-core store might be in order.

Not at home now - but will dig up the TB model number and specs next week and post them for input on sizing and dimensions.

not sure they will replace the FE206-ES in my old MLTL builds - but I'm sure the W.A.F. will be onside.

Steve in N.Vancouver (aka sapdog)

Oops - I accidentally posted this in another thread earlier.

Oops, I accidentally answered it and came to the same conclusion as Illusus

Oops, I accidentally answered it and came to the same conclusion as Illusus

Cal will recall that the very first foam core Cornu speaker I built (20 in x 20 in x 2.38 in deep with Vifa TC9FD), I manually added sharper corners internally to increase the amount of low-pass filtering available. I am not sure if all this is needed... because the other thing that really has an impact on how much high frequency leaks out is the ratio of the throat to driver chamber volume. The smaller that is, the lower the upper cutoff frequency. So a small slit with a large chamber will really limit high frequencies, but carried to an extreme and you won't have enough to fill in the gap left by the main radiation from the front of the driver. I think the equation for the upper cutoff freq is fh = (C * So)/(2*pi*Vol_driver) where C is speed of sound, So is throat area, Vol_driver is chamber volume.

As an example, take an average Cornu, with a driver chamber of about 6 in dia x 4.5 in deep with a throat gap of 1.2 in. This gives a Vol_driver of 2654 cm^3. The throat area is 70 cm^2, C is 34,200 cm/sec. So fh = 143 Hz, which is not a bad upper cutoff for a bass horn. Independent of sharp corners internally, the driver chamber and throat are already providing some nice low-pass filtering. This equation raises the novel idea of tuning fh by adding inert-volume blocks inside the driver chamber. This will have effect of raising fh. The actual magnet assembly of the driver and the stuffing to a certain extent do this so one can expect the fh to be upwards of 200 to 250 Hz.

Alternatively, one can add an extra extension just below the driver to increase the volume without increasing the throat area and this will reduce the fh value.

The second Cornu I built had smooth spirals with no sharp bends and it still sounded pretty good. So depending on your design and how big the throat is, YMMV.

I haven't been thinking about diy audio for a few years - but just read through this post end to end and it's got me thinking.

I know I have an old pair (circa 2005) Tang Band 4" full rangers that I had in an old pair of BD-pipes sitting in a box in my basement. Seems like a trip to the foam-core store might be in order.

Not at home now - but will dig up the TB model number and specs next week and post them for input on sizing and dimensions.

not sure they will replace the FE206-ES in my old MLTL builds - but I'm sure the W.A.F. will be onside.

Steve in N.Vancouver (aka sapdog)

Just about any TB 4 inch full range driver will work. TB W4's typically clock-in at 55 to 57 cm^2 for Sd. This will mean that the Cornu will be sized between 24 and 27 inches at 4.5 to 5 in deep.

When adding corners to the spiral paths to reduce HF transmission, do not make the walls between the corners completely straight. They need some curvature to prevent flexing. That's one reason why foam core works well for Cornu horns, the curved walls resist flexing because of the curves and the front and back panels are prevented from flexing because of the many closely-spaced walls acting as braces.

I think the curved walls provide a more stable support structure because the curved portion that contacts the baffle defines a plane rather than a line if it were straight. It self triangulates? The acoustic pressures are minimal but they are there and we want to reduce flex which absorbs energy and makes sound less efficient.... although that is the basis of damping which we want some amount of. So I guess it depends. But your point of why foam core works well as a speaker still holds...  ramble....

ramble....

No, I haven't done a speaker with it yet. My daughters use it for school projects and I've been eyeing it, wondering about speaker enclosure use, hence my interest in these foam core threads. I do have some suitable 3 inch drivers culled from HTIB systems, waiting for me to get a round tuit for measuring their T-S parameters.

As for its suitability for Cornu spiral enclosures, it's simple physics. It flexes, so it needs bracing. A Cornu spiral horn as implemented here is well suited - the spiral walls are braced by their own curvature and their relatively shallow depth, and the front and rear are braced by the spirals - closely spaced near the throat where pressures are highest, and further apart near the mouths.

It flexes, so it needs bracing. A Cornu spiral horn as implemented here is well suited - the spiral walls are braced by their own curvature and their relatively shallow depth, and the front and rear are braced by the spirals - closely spaced near the throat where pressures are highest, and further apart near the mouths.

As for its suitability for Cornu spiral enclosures, it's simple physics.

In a horn, aren't the pressures actually highest at the exit or mouth? The velocity is highest at driver and lowest at mouth. The horn serves as the flow diffuser to match the impedance from the driver to ambient. I just think about it like a subsonic diffuser with the pressure and velocity described by Bernoulli equation. But then this is acoustics and it may be different, but I think it's the same physics just oscillatory flows.

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!