Drivers ordered....and now they are on backorder....ugh....

I have not read of any catastrophe's regarding folks building their enclosures prior to receiving the drivers.... Is there something I am missing? My thoughts were, that I could build everything but cutting out the hole for the front panel (3.25" opening). Does a hole saw in the foam board cut easily after it is put together?

No worries, I cut the hole last always with an xacto.

Hi guys!

Finally received the drivers and did a quick test of the speakers!

I bolted it in place and with the rest of the speaker facing upwards, left the front plate just sitting on top without applying any glue to it. I also added some sheep wool damping material to the cavity of the driver and provisionally wired a twisted pair between the fostex and one of the channels of my lm1875 amp. Then plugged a laptot as input for the lm1875 amp.

All I can say is WOW!!! Even with that provisional setup, it sounds better than I could ever have imagined!

Bass is awesome (maybe it will improve after adding damping material, don't you think so?? ), mids are well defined and highs are really clear. I played several music styles and it scored well in all of them. Classical, acoustic, blues and electronic music sounded great, and vocals sounded so clear… you felt like the singer was just there before you. Rock music, I must admit, though sounding good it was a little muddy :S Hope it gets fixed after gluing the front plate and adding damping in the horn mouths.

Not to mention movies, the speaker reproduced them very very good!!

Can’t wait to have the speakers totally glued and damped and hear how the sound improves! I’m very happy that even unfinished, the speaker exceeds my expectations and is totally worth the effort!!

I'm quite a newbie in all this, and don't have much to compare with. Anyway, I couldn't be happier with the result!!

Thank you all so much for the support and help, hopefully I'll have the speaker lacquered and finished in a couple of days!!

Here I attached a couple of pictures of the provisional setup. You can find some more pictures, etc inside the last post at my blog! 22 nanofarads | Audio & Electronics Blog

Kind regards,

Fran

Finally received the drivers and did a quick test of the speakers!

I bolted it in place and with the rest of the speaker facing upwards, left the front plate just sitting on top without applying any glue to it. I also added some sheep wool damping material to the cavity of the driver and provisionally wired a twisted pair between the fostex and one of the channels of my lm1875 amp. Then plugged a laptot as input for the lm1875 amp.

All I can say is WOW!!! Even with that provisional setup, it sounds better than I could ever have imagined!

Bass is awesome (maybe it will improve after adding damping material, don't you think so?? ), mids are well defined and highs are really clear. I played several music styles and it scored well in all of them. Classical, acoustic, blues and electronic music sounded great, and vocals sounded so clear… you felt like the singer was just there before you. Rock music, I must admit, though sounding good it was a little muddy :S Hope it gets fixed after gluing the front plate and adding damping in the horn mouths.

Not to mention movies, the speaker reproduced them very very good!!

Can’t wait to have the speakers totally glued and damped and hear how the sound improves! I’m very happy that even unfinished, the speaker exceeds my expectations and is totally worth the effort!!

I'm quite a newbie in all this, and don't have much to compare with. Anyway, I couldn't be happier with the result!!

Thank you all so much for the support and help, hopefully I'll have the speaker lacquered and finished in a couple of days!!

Here I attached a couple of pictures of the provisional setup. You can find some more pictures, etc inside the last post at my blog! 22 nanofarads | Audio & Electronics Blog

Kind regards,

Fran

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Fran,

Congratulations! I am glad it sounds good and was worth the effort. When you say that you have not glued the front plate - do you mean the main front wood baffle panel is still not glued yet? If this is the case, the sound will improve dramatically once you glue it because without the glue the smallest air leak will really reduce the bass. Also, it will even be better sounding once mounted on a wall. So I think you still have more pleasant surprises in the sound once you glue the top panel on. They look really good by the way.

Btw, you have built some really ice amps there!

Congratulations! I am glad it sounds good and was worth the effort. When you say that you have not glued the front plate - do you mean the main front wood baffle panel is still not glued yet? If this is the case, the sound will improve dramatically once you glue it because without the glue the smallest air leak will really reduce the bass. Also, it will even be better sounding once mounted on a wall. So I think you still have more pleasant surprises in the sound once you glue the top panel on. They look really good by the way.

Btw, you have built some really ice amps there!

Thanks xrk971!!

Yes, the front baffle is not glued yet. That's really encouraging!!!

Can't wait to get it glued, and I'm happy that you liked my amps!!

Forgot to mention that the sound is really loud! Don't know if that's because of the sensitivity of the fe108ez or the speaker design itself, but I couldn't even turn the amp volume half the way up with a single speaker!!

Yes, the front baffle is not glued yet. That's really encouraging!!!

Can't wait to get it glued, and I'm happy that you liked my amps!!

Forgot to mention that the sound is really loud! Don't know if that's because of the sensitivity of the fe108ez or the speaker design itself, but I couldn't even turn the amp volume half the way up with a single speaker!!

Hi Zigis,

Do you mean RCA connectors? I'll be using some connectors like these:

For now, I just connected the speaker directly to the amp for testing.

Do you mean RCA connectors? I'll be using some connectors like these:

An externally hosted image should be here but it was not working when we last tested it.

For now, I just connected the speaker directly to the amp for testing.

I got a little carried away last night. While the cat was away, I decided to push my luck a little. I had been talking music with the captain (Morgan) so I was feeling no pain and wanted to see what happens when you let the volume control slip a bit. I am running the Tascam 30 watt mini PA amp. The drivers are the CSS VWR126's with a big ol' choke and the JVC white cones with a 50 µfd cap.

They did not disappoint. They held their own like you would expect a party speaker to do. Lots 'o' bass and the highs were nicely controlled like you hope to get from a small driver. Not sure you could call this a FAST system but why not? I had those little drivers just a pumpin' and this morning my ears were still ringing.

Yes, I was surprised, yes I was stupid to push the expensive CSS drivers like that but what the hey, they handle a lot more than I was putting into them and I was sitting there with a big audio woody once again.

Thanks X, there's a lot of fun to be had here.

I like the look of the white speakers. I wonder why more drivers are not made in different colors.

Well I finally got around to getting my pictures off my camera.

I've been enjoying these Cornu's for the past few months. 24"x24" with 4.5" channels. I went with the tangband 4" bamboo driver and love them!

I have many friends that can't believe the sound these put out. Such great low freq extension.

I monkeyed with the stuffing a bit behind the speaker a bit and it sounds great.

Fyi the foamcore doesn't really like latex paint. haha It separated from the foam when I got too wet. I just turned that horn to ceiling so no one could see it. Lesson learned.

Thanks for all your help. This is a great place to get ideas for sure!

I've been enjoying these Cornu's for the past few months. 24"x24" with 4.5" channels. I went with the tangband 4" bamboo driver and love them!

I have many friends that can't believe the sound these put out. Such great low freq extension.

I monkeyed with the stuffing a bit behind the speaker a bit and it sounds great.

Fyi the foamcore doesn't really like latex paint. haha It separated from the foam when I got too wet. I just turned that horn to ceiling so no one could see it. Lesson learned.

Thanks for all your help. This is a great place to get ideas for sure!

Attachments

Ryani,

Those look great! You are the first one I know who went with the 24x4.5 with TB bamboo. I guess it worked out well. How did you arrive at the dimensions? Very nice work. I wish I could hear it. Now I am thinking the next drivers to get are thr 4 in bamboos. Is that the 1337sdf's?

X

Those look great! You are the first one I know who went with the 24x4.5 with TB bamboo. I guess it worked out well. How did you arrive at the dimensions? Very nice work. I wish I could hear it. Now I am thinking the next drivers to get are thr 4 in bamboos. Is that the 1337sdf's?

X

Thanks for the compliments.

Actually I used an old pillow for stuffing. I did it three times. The first time I had too much in....very low output from the horns. The next time I took too much out...way too many high frequencies. The final time was just right...at least I was happy with it.

prezden I think many light coats of spray paint will work better, making sure its dry between each coat. I did a little experimenting with some scrap after the fact.

I was in Hobby lobby last week and found many many colors of foamcore. So you can use the cheap white stuff on the inside and then use the colored stuff on the outside horn. No painting at all.

Actually I used an old pillow for stuffing. I did it three times. The first time I had too much in....very low output from the horns. The next time I took too much out...way too many high frequencies. The final time was just right...at least I was happy with it.

prezden I think many light coats of spray paint will work better, making sure its dry between each coat. I did a little experimenting with some scrap after the fact.

I was in Hobby lobby last week and found many many colors of foamcore. So you can use the cheap white stuff on the inside and then use the colored stuff on the outside horn. No painting at all.

Clothoid Horn Cornu w/ B3N's

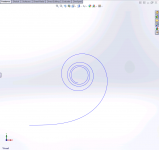

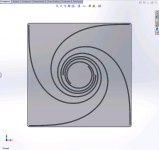

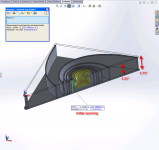

I'm new to speaker building, but thinking about trying this out as well! I have a few Hivi B3N drivers lying around that seem like they would work. I'm also planning to use a true clothoid curve profile for the horn.

See attached pics for what I've drawn up so far. I've trimmed the full curve to 1.875 turns for the inner set of walls ones and 1 turn for the outer ones, following the lead of the existing posted design.

I would like to keep these boxes as thin as possible, but I'm not sure how to figure out what the area of the opening into the central speaker chamber (highlighted green on the last pic) should be. Does it have to match the Effective Piston Area (Sd) of the driver? The current opening is only 0.000125m^2, so I'd have a ways to go before getting to the 0.0030m^2 of the B3N.

I'll most likely CNC machine these parts and am thinking to start out with foam core to see how it pans out. What do you guys think?

I'm new to speaker building, but thinking about trying this out as well! I have a few Hivi B3N drivers lying around that seem like they would work. I'm also planning to use a true clothoid curve profile for the horn.

See attached pics for what I've drawn up so far. I've trimmed the full curve to 1.875 turns for the inner set of walls ones and 1 turn for the outer ones, following the lead of the existing posted design.

I would like to keep these boxes as thin as possible, but I'm not sure how to figure out what the area of the opening into the central speaker chamber (highlighted green on the last pic) should be. Does it have to match the Effective Piston Area (Sd) of the driver? The current opening is only 0.000125m^2, so I'd have a ways to go before getting to the 0.0030m^2 of the B3N.

I'll most likely CNC machine these parts and am thinking to start out with foam core to see how it pans out. What do you guys think?

Attachments

Chandra,

Nice work on getting the clothoid equation into Solidworks! Were you able to directl run the equations in SW or did you import a parametric curve? I found I had to do the latter. The cloithoid or true Cornu spiral is very tight near the middle and this will make the freq cutoff very high and not good for bass. It will take some tweaking with curve parameters to widen up. But yes to first order adjust throat area to be no less than 50% of Sd of driver.

X

Nice work on getting the clothoid equation into Solidworks! Were you able to directl run the equations in SW or did you import a parametric curve? I found I had to do the latter. The cloithoid or true Cornu spiral is very tight near the middle and this will make the freq cutoff very high and not good for bass. It will take some tweaking with curve parameters to widen up. But yes to first order adjust throat area to be no less than 50% of Sd of driver.

X

X & Cal,

Thanks for the feedback - I'll update the design with a looser spiral and 50% Sd throat area. I'll probably overlay the existing design to see how it compares. What is the "normal" size for a 3" driver using the existing spiral design?

Also - the curve is a "curve through points" using point data generated in excel.

Thanks for the feedback - I'll update the design with a looser spiral and 50% Sd throat area. I'll probably overlay the existing design to see how it compares. What is the "normal" size for a 3" driver using the existing spiral design?

Also - the curve is a "curve through points" using point data generated in excel.

Chandra,

A typical cornu speaker with 3 in driver will be about 20 in x 20 in x 3.5 in deep. I had to import my curves the same way. There is a way to do a spiral directly in SW with a variable pitch. It won't be a clothoid but approximates the cornu spesker well if it were round without the square corners.

A typical cornu speaker with 3 in driver will be about 20 in x 20 in x 3.5 in deep. I had to import my curves the same way. There is a way to do a spiral directly in SW with a variable pitch. It won't be a clothoid but approximates the cornu spesker well if it were round without the square corners.

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!