Mass-Loaded Voigt. You can reduce the ripple by tapping the driver in part way down the line (Hoe you would do that phyisically is a different challenge.

dave

I was thinking that this can be implemented by making a driver chamber offset from the main spiral box and having 4 holes (slots) leading from driver chamber to 1/3 of the way from closed end of Voigt pipe. This will make a bump out chamber and not look so flat anymore. Although the horizontal dimensions would be reduced as the closed ends of each pipe can start in middle now.

Just talked with Dave on the phone and it sounds like he will have something for me in a couple of weeks so in the meantime I need the true spiral drawing [not the rounded square one] so can you point me in the right direction or even post it again so I can get things ready?

Thanks.

EDIT: I found I have it downloaded already so I can go ahead with that.

Thanks.

EDIT: I found I have it downloaded already so I can go ahead with that.

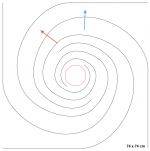

I had a look at the PDF I downloaded and I have some concerns. The channel is wider at the red arrow than the blue. Is that a problem?

Yes. The original i traced from was not very good. I've not had a chance to rework from 1st principals.

dave

I had a look at the PDF I downloaded and I have some concerns. The channel is wider at the red arrow than the blue. Is that a problem?

Cal,

The easy fix if you are in a hurry is to hand draw the spirals to make the round parts transition to the flats in a way that the tangent (slope) is zero. This can be done by moving the square external boundaries out to allow for more expansion of the curved part. It probably doesn't make too much of a difference.

An externally hosted image should be here but it was not working when we last tested it.

Cut up a box, taped it tight, dropped in some 3 inch FR drivers hooked it up and it sounds good.

For a free box.

I was thinking about trying out a Cornu spiral out of card board and dropping in these drivers.

Is a 24" or smaller size a safe way to go with these 3" drivers? They aren't too deep maybe 2.5".

Thanks Xrk971

The foam core thread is a long one- It took me days to read through all that info

My plan is to build 18" units with 3" channels. I hope I got the dimensions right. I scaled the curves from Dave's drawing (thanks Dave) printed and tiled it to size. Taped the drawing to a piece of Sintra and used the pin hole transfer method mentioned earlier in this thread. Sintra is a pvc board used in the sigh industry and I happened to have some lying around so... I'll be using TB W3-881SJF drivers. Recently I used these in another small project- liked the sound but found the bass to be insufficient so I thought they might be good in the Cornu spiral.

I will post some photos as things progress.

The foam core thread is a long one- It took me days to read through all that info

My plan is to build 18" units with 3" channels. I hope I got the dimensions right. I scaled the curves from Dave's drawing (thanks Dave) printed and tiled it to size. Taped the drawing to a piece of Sintra and used the pin hole transfer method mentioned earlier in this thread. Sintra is a pvc board used in the sigh industry and I happened to have some lying around so... I'll be using TB W3-881SJF drivers. Recently I used these in another small project- liked the sound but found the bass to be insufficient so I thought they might be good in the Cornu spiral.

I will post some photos as things progress.

Nice to see more on board.

I have done a hand rendering of the new curve for the spiral drawing so I have something to take to the repro place. Wasn't that hard, just continued the curve to the outside of the page and it eliminated the narrowing near the mouth. Crude but usable.

I have done a hand rendering of the new curve for the spiral drawing so I have something to take to the repro place. Wasn't that hard, just continued the curve to the outside of the page and it eliminated the narrowing near the mouth. Crude but usable.

Attachments

Thanks Xrk971

The foam core thread is a long one- It took me days to read through all that info

My plan is to build 18" units with 3" channels. I hope I got the dimensions right. I scaled the curves from Dave's drawing (thanks Dave) printed and tiled it to size. Taped the drawing to a piece of Sintra and used the pin hole transfer method mentioned earlier in this thread. Sintra is a pvc board used in the sigh industry and I happened to have some lying around so... I'll be using TB W3-881SJF drivers. Recently I used these in another small project- liked the sound but found the bass to be insufficient so I thought they might be good in the Cornu spiral.

I will post some photos as things progress.

Prezden,

The PVC signage material sounds promising. The cool thing with PVC is that it can be heat bent (hold over a gas stove burner) to form channels and the whole thing could be sealed with PVC cement to form a solid PVC horn with no leaks. It would take some careful handywork to bend segments of the PVC channels to the exact shape though. Foam channels are definitely faster. The W3-881SJF looks like a nice driver for this application.

Nice to see more on board.

I have done a hand rendering of the new curve for the spiral drawing so I have something to take to the repro place. Wasn't that hard, just continued the curve to the outside of the page and it eliminated the narrowing near the mouth. Crude but usable.

Looks very nice Cal. What driver will be used with this build?

Okay, some progress has been made. I'll admit that getting started was a bit tricky, but I got much better as things rolled along. Unfortunately the chamber and horn throats are a bit crude but there's no going back now.  I haven't even checked how far off the throats are from spec (11/16" by my reckoning, for my driver).

I haven't even checked how far off the throats are from spec (11/16" by my reckoning, for my driver).

Next is to stuff the horns and glue the backs onto the cabinets. I may or may not wait for the drivers to arrive before I do this...

Next is to stuff the horns and glue the backs onto the cabinets. I may or may not wait for the drivers to arrive before I do this...

Attachments

I had a look at the PDF I downloaded and I have some concerns. The channel is wider at the red arrow than the blue.

that was my mistake! i hadn't pay attention to channel wideness while i was focusing to curving lines..

i made one more drawing just for experiment to get truly spiral paths which can be adjustable for scaling..

btw, i don't want to cause any mess about pdf files and this is the original cornu layout for who wants to build the original;

http://www.diyaudio.com/forums/full...-board-speaker-enclosures-23.html#post3266494

Attachments

I think Dave said he has some Audax on the way, not sure the model. Dave?

Aura NS3. The expensive ones.

I'm also going to be getting someof these, but you'd need to decide to spend the extra $10 each. The Madisound Speaker Store (black or silver, 4 or 8). Next step up the Fountek FR88ex (i still should have 5 at cleanance prices -- i could ship those pretty quick, just need to get a pair back from Bernie),

dave

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!