I remember your horn. When you say too aggressive, does that mean there is HF falloff? It's easy to scale plan with printer prior to cutting to get your size.

I got ~6dB of gain from 400Hz to 4kHz and a roll-off above this, too much.

IG

Plan for Tractrix Horn in pdf

Here is the outline plan traced from the actual pieces used for the horn. It is in pdf so you can scale it to fit your throat width to match driver.

Let me know how it works out.

Have fun.

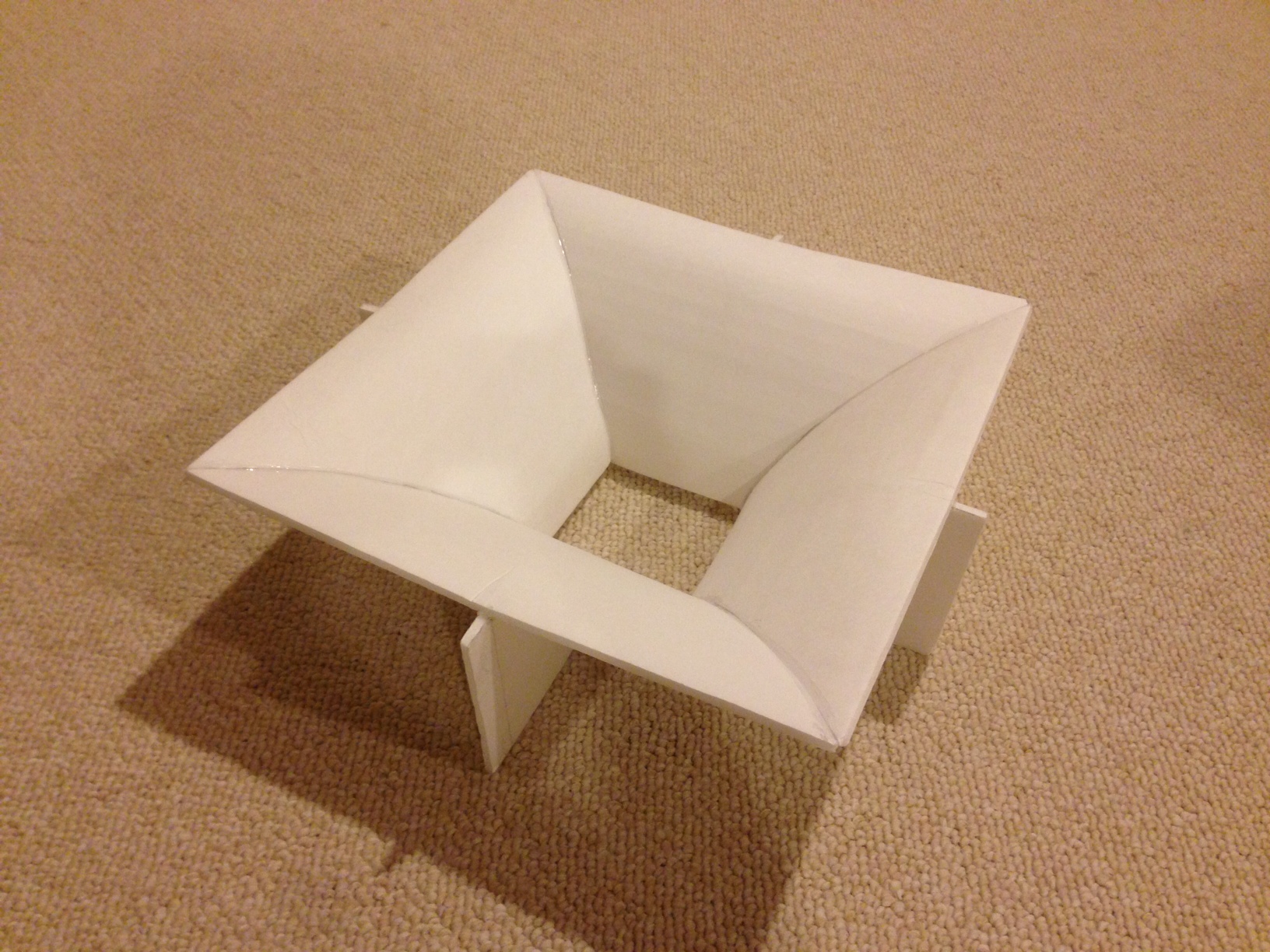

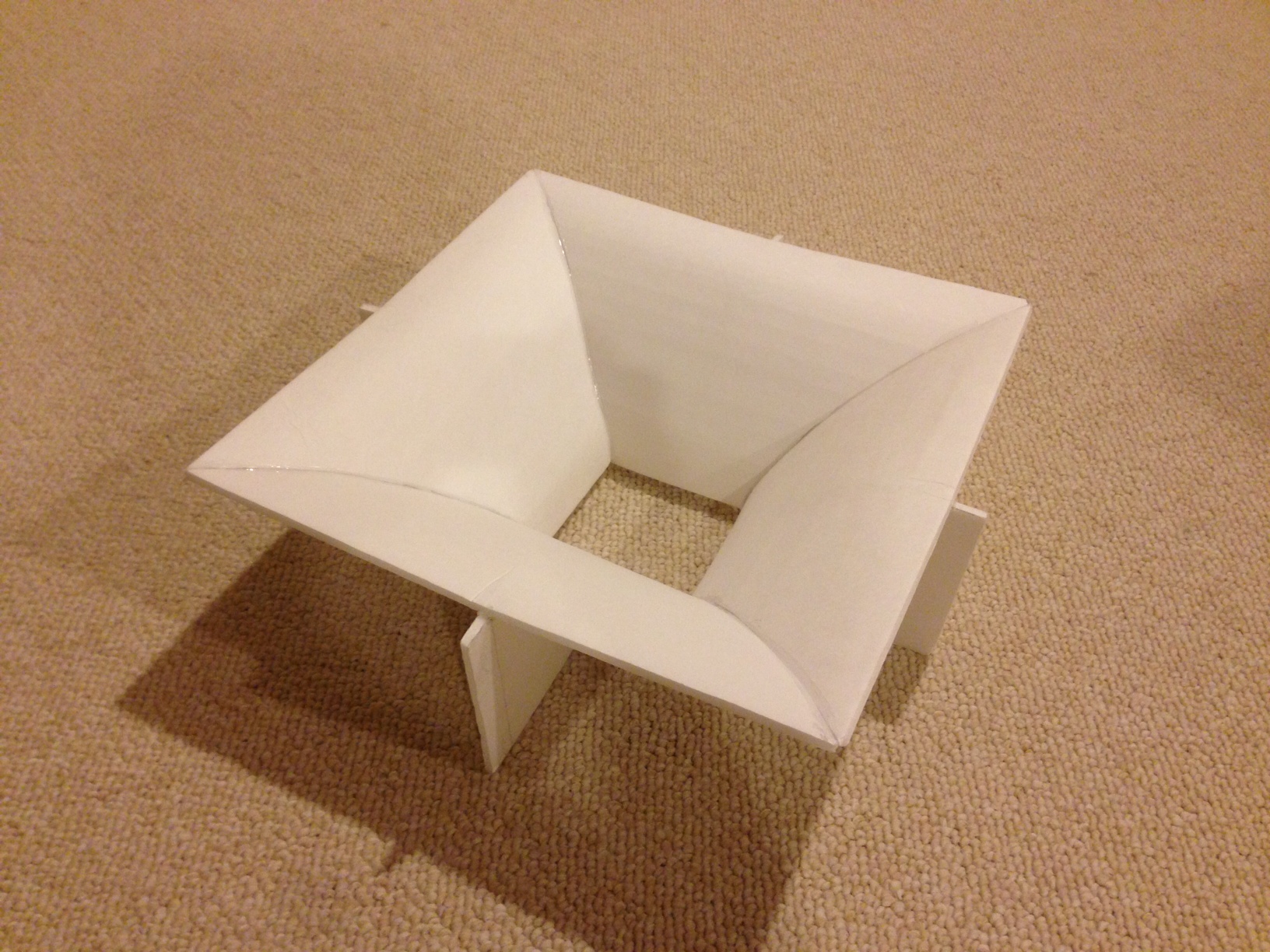

I finally finished the tractrix front horns. It was easy to make using the 'score the concave curved side' technique. The hard part was coming up with the pattern - I did it with regular paper by trial and error to get close, then the final foam still needed some trimming. The resulting horn has a 4 in x 4 in throat and a 13 in x 13 in mouth with a 4.5 in length. I did a quick test by taping it to the front of the FH3-inspired FC speakers and wow, you really notice the gain in mids and highs from a distance away. Also the presentation was wider, you can walk around more and still hear the highs clearly. The trick is to make the brace first with the correct profile, hot melt the horn panel to that first. Make 4 of those sets and then glue the seams together one by one. If anyone is interested in the pattern, I can scan that and post it.

Here is the outline plan traced from the actual pieces used for the horn. It is in pdf so you can scale it to fit your throat width to match driver.

Let me know how it works out.

Have fun.

Attachments

Yes for now, they will be forward firing. My listening room precludes rear facing to a certain extent as it also doubles as my movie room and one corner has a sub and the other a built-in av rack.

Foamcore works out to $13NZ per 20x30" sheet. A sheet of reasonable ply (hardwood) is $50 for a 4x8x 1/2 "

You can get Foamcore a bit cheaper: NZD$14.40 for a sheet of 1015mm x 810mm.

Available here: Foam Board 5mm (Art Board: Foam Board) ~ Takapuna Art Supplies (World HQ)

I'll be picking up some next week, when my Vifa drivers arrrive so I can have a crack at a 20" Cornu a la xrk971. This will be my first ever DIY project..

Have you tried these places for foam core fringy?

https://maps.google.ca/maps?ie=UTF-...w=text&ei=s6_MUZbsDqr-igKpj4C4BQ&ved=0CC8QtQM

https://maps.google.ca/maps?ie=UTF-...w=text&ei=s6_MUZbsDqr-igKpj4C4BQ&ved=0CC8QtQM

It is in pdf so you can scale it to fit your throat width to match driver.

Scaling horns generally doesn't pan out well.

GM

Have you tried these places for foam core fringy?

https://maps.google.ca/maps?ie=UTF-...w=text&ei=s6_MUZbsDqr-igKpj4C4BQ&ved=0CC8QtQM

Hi Cal.

Thanks for that, to be honest, I have never looked, but am in town today, so will check them out

Scaling horns generally doesn't pan out well.

GM

So true, as the length controls the cutoff frequency. But this design was made without any math other than approx expansion ratio desired and need to try making a tractrix for fun. I have no idea how it measures as I have not had chance to get the measurement. To my ears it sounds like there is a definite impact on sound level gain in miss and moderate highs. Probably scaled to 3 in throat will be better for HF as length is shorter? I haven't figured out how to put a tractrix profile horn in AkAbak yet.

Potential Fun FC Build with Mini Karlsonator

You will have seen this if you have been following the "A Speaker that Kicks Butt in Large Spaces" thread. I have been running simulations of a scaled down 0.53X size Karlsonator (a ML-TQWT with a Karlson aperture). I think this is a reasonable build to try out in FC with a couple of inexpensive Vifa TC9FD's. This is a high Qts driver normally not suited for Karlsons but as a mass loaded TL with a large volume, it allows a deeper bass extension and the K-aperture lets it throw a good bass shelf at a distance.

The link to the simulation of the mini Karlsonator is here: http://www.diyaudio.com/forums/full-range/237948-speaker-kicks-butt-large-spaces-19.html#post3553874

It is a 9 in wide x 9.4 in deep x 16.4 in tall cabinet - a perfect size for FC builds. For those not familiar with this design:

You will have seen this if you have been following the "A Speaker that Kicks Butt in Large Spaces" thread. I have been running simulations of a scaled down 0.53X size Karlsonator (a ML-TQWT with a Karlson aperture). I think this is a reasonable build to try out in FC with a couple of inexpensive Vifa TC9FD's. This is a high Qts driver normally not suited for Karlsons but as a mass loaded TL with a large volume, it allows a deeper bass extension and the K-aperture lets it throw a good bass shelf at a distance.

The link to the simulation of the mini Karlsonator is here: http://www.diyaudio.com/forums/full-range/237948-speaker-kicks-butt-large-spaces-19.html#post3553874

It is a 9 in wide x 9.4 in deep x 16.4 in tall cabinet - a perfect size for FC builds. For those not familiar with this design:

An externally hosted image should be here but it was not working when we last tested it.

You want Gatorboard. It is very stiff and lightweight but costs more than BB ply.

No I don't

I get plastic faced foamcore for free from my job, you see (marketing/R&D posters from events past). I've laminated it for a turntable platform to great effect (love the idea of light and rigid and well damped to dissipate vibrational energy as heat), running underneath my beloved LP12. For this I used 3M spray adhesive, but would prefer something a little less unpleasant.

I mind fumes- testing water based contact cement tonight, and Aleene's Craft Glue (PVA). Thus far I think the longer cure/greater stability of the PVA is winning, but we'll see. I've previously used 3M type 90 which is nasty stuff, but darned effective. My turntable rests on a 10 layer platform made bonded with it, but it's caustic, unpleasant and not ideal if I want to make a lot of layers for a big box.

Last edited:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?