X- My for last Cornu's I laminated foam core and 1/8" ply for the front and back panels so I will try that again. It gives them more strength without increasing the weight too much and can still be cut with a knife. 1/8" mahogany ply is pretty cheap which is a good thing.

I'm still undecided as to whether to build the FH3 or the Metronome- have to finish the 24" Cornu's first.

cheers- prez

I'm still undecided as to whether to build the FH3 or the Metronome- have to finish the 24" Cornu's first.

cheers- prez

Hi Guys

Here is the Metronome design I'm planning to use with a pair of TB W4-1320SIF drivers.

The dimensions were provided by xrk971. Hope I got them right. Please take a look and let me know how they could be improved.

They will be made with a 1/4" foam core and 1/8" plywood laminate with 3/4" ply on top and bottom.

Here is the Metronome design I'm planning to use with a pair of TB W4-1320SIF drivers.

The dimensions were provided by xrk971. Hope I got them right. Please take a look and let me know how they could be improved.

They will be made with a 1/4" foam core and 1/8" plywood laminate with 3/4" ply on top and bottom.

Attachments

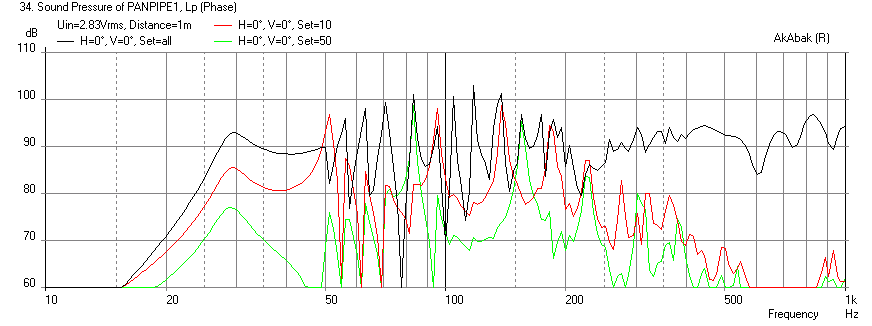

The Panpipe BLH

I just posted a sim for a 5-horn BLH speaker here: http://www.diyaudio.com/forums/full-range/236335-dblh-2.html#post3506867

Clearly, this is a project for the advanced Foam Core diehard looking for a challenge. The cabinet will be a reasonable size as the horns are 5 in x 8 in at the mouth for four and the big one is 5 in x 12 in. I estimate the cabinet to be 4 ft tall x 2 ft wide x 18 in deep.

The cabinet will be a reasonable size as the horns are 5 in x 8 in at the mouth for four and the big one is 5 in x 12 in. I estimate the cabinet to be 4 ft tall x 2 ft wide x 18 in deep.

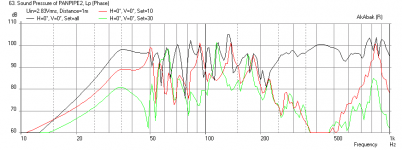

Here is the total output (black), longest horn mouth (red), shortest horn mouth (green).

If there are any takers I will make the detailed construction plans.

I just posted a sim for a 5-horn BLH speaker here: http://www.diyaudio.com/forums/full-range/236335-dblh-2.html#post3506867

Clearly, this is a project for the advanced Foam Core diehard looking for a challenge.

Here is the total output (black), longest horn mouth (red), shortest horn mouth (green).

If there are any takers I will make the detailed construction plans.

If there are any takers I will make the detailed construction plans.

No promises, but since I'm already firmly impaled on your hook, lets see what you come up with.

Just received the Panasonic mic pods a few minutes ago.

Last edited:

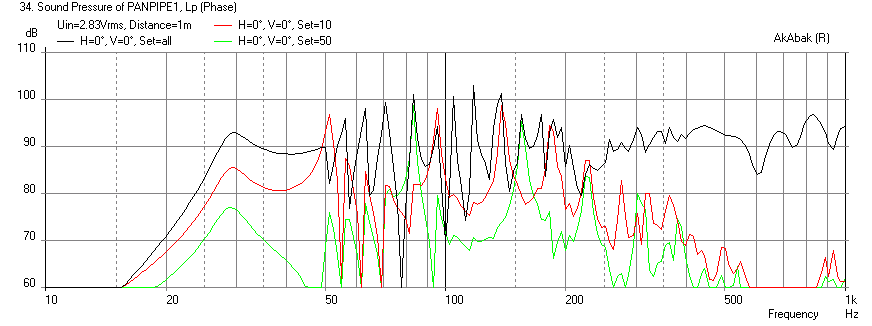

Panpipe with W8-1772

This may work with the budget 5 inch Celestion $13 driver - I will check. But in case you are interested in a 95 dB sensitivity premium version, here is a Panpipe BLH with Tang Band's flagship 8 inch W8-1772 full range driver.

No promises, but since I'm already firmly impaled on your hook, lets see what you come up with.

Just received the Panasonic mic pods a few minutes ago.

This may work with the budget 5 inch Celestion $13 driver - I will check. But in case you are interested in a 95 dB sensitivity premium version, here is a Panpipe BLH with Tang Band's flagship 8 inch W8-1772 full range driver.

Attachments

The black curve looks good! Can you get the 40-50hz above 90db without sacrificing the response out to 1khz?

I'll play around with it a little more but to increase gain requires a bigger mouth. Maybe increasing mouths is in order but that may make spikey peaks go up too although they will be smoothed with damping material.

I don't think I have seen another horn have such good fill between those peaks which are typically 40 to 60 Hz apart.

Panpipe with SP50X

Ryan,

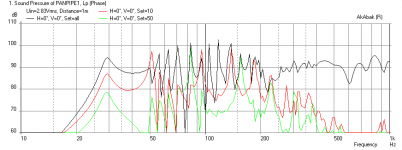

I am surprised that the SP50X works so well. Here is the sim with nothing more than the T/S params swapped for the SP50X. This may work out if you don't mind the slight exaggerated bass hump at 30 Hz.

X

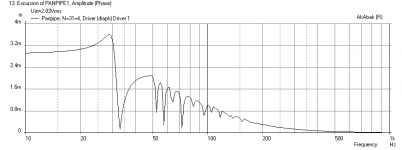

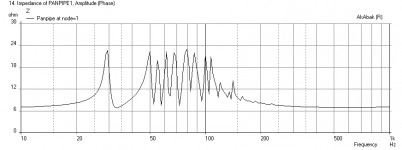

Update: I redid the sim with a smaller driver chamber volume (12 liters) and it seemed to improve the smoothness of the response somewhat. However, it would be fine to keep it the same as original plan allowing a driver upgrade should you ever want to do it.

I also have the driver displacement and impedance curves, and freq response with 12 liter chamber (last plot).

I'd be in on a set of plans X. Would the Monacor sp50x be a candidate for the Pentahorn? The youngest would be floored with a massive set of enclosures. May dirt bike stickers and posters could fit on it.

Ryan,

I am surprised that the SP50X works so well. Here is the sim with nothing more than the T/S params swapped for the SP50X. This may work out if you don't mind the slight exaggerated bass hump at 30 Hz.

X

Update: I redid the sim with a smaller driver chamber volume (12 liters) and it seemed to improve the smoothness of the response somewhat. However, it would be fine to keep it the same as original plan allowing a driver upgrade should you ever want to do it.

I also have the driver displacement and impedance curves, and freq response with 12 liter chamber (last plot).

Attachments

Last edited:

Thanks X. I just happen to have some of those on hand. That's the reason I ask. For a boy's room the SP50X and out of foam it would be perfect fit. If the design is proven that way, I would spend more on drivers and then build out of wood. The uncle has an amazing woodworking shop.

Excellent open baffles. I used a inexpensive prints to cover a couple of mine. Find something to suit your tastes at your local arts and crafts store. Then use some elmers spray glue to attach. Re cut your driver holes and you are finished.

Attachments

sagamotto,

You can also build a frame that matches the baffle and use regular grill cloth. Just tape the cloth taught on a flat surface. Apply spray glue or contact cement on the frame face (test on scrap to insure I doesn't penatrate).

Lay the frame on the cloth and let it dry. You can either pull the cloth around to the back of the frame and secure with hot glue, or make a sandwich by placing another thin frame (wood veneer works well) on the front. Make sure the frame is deep enough to avoid interfering with the x-max of the bass driver. I've used double sided carpet tape to easily attach to the speaker.

Fabric stores and even Walmart have products very similar to high dollar grill cloth.

You can also build a frame that matches the baffle and use regular grill cloth. Just tape the cloth taught on a flat surface. Apply spray glue or contact cement on the frame face (test on scrap to insure I doesn't penatrate).

Lay the frame on the cloth and let it dry. You can either pull the cloth around to the back of the frame and secure with hot glue, or make a sandwich by placing another thin frame (wood veneer works well) on the front. Make sure the frame is deep enough to avoid interfering with the x-max of the bass driver. I've used double sided carpet tape to easily attach to the speaker.

Fabric stores and even Walmart have products very similar to high dollar grill cloth.

Attachments

Bcmbob,

I gotta tell you after listening to my OB on foam core sheet baffle, I am not going to put it back on the 2" ply baffle again....

I might try to make the baffle grill out of foam core as well and reinforce the foam baffle with a thin wood frame on the back. What do you think?

I gotta tell you after listening to my OB on foam core sheet baffle, I am not going to put it back on the 2" ply baffle again....

I might try to make the baffle grill out of foam core as well and reinforce the foam baffle with a thin wood frame on the back. What do you think?

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?