They have 12 mm or half in thick paper-foam-paper foam core in the US too but kind of pricey.

40 x 60" White Foamboard S-13721 - Uline

40 x 60" White Foamboard S-13721 - Uline

Thanks, I followed the link to the catalog page. 25 sheets for $18 - am I reading that right?

I could build a half dozen Klisphorns with that.

Still like to find something with the multiple layers.

I could build a half dozen Klisphorns with that.

Still like to find something with the multiple layers.

Last edited:

Among other things, that the speaker did not fit, so I had to build a small box behind the magnet. Wait that was not really my fault i guess.

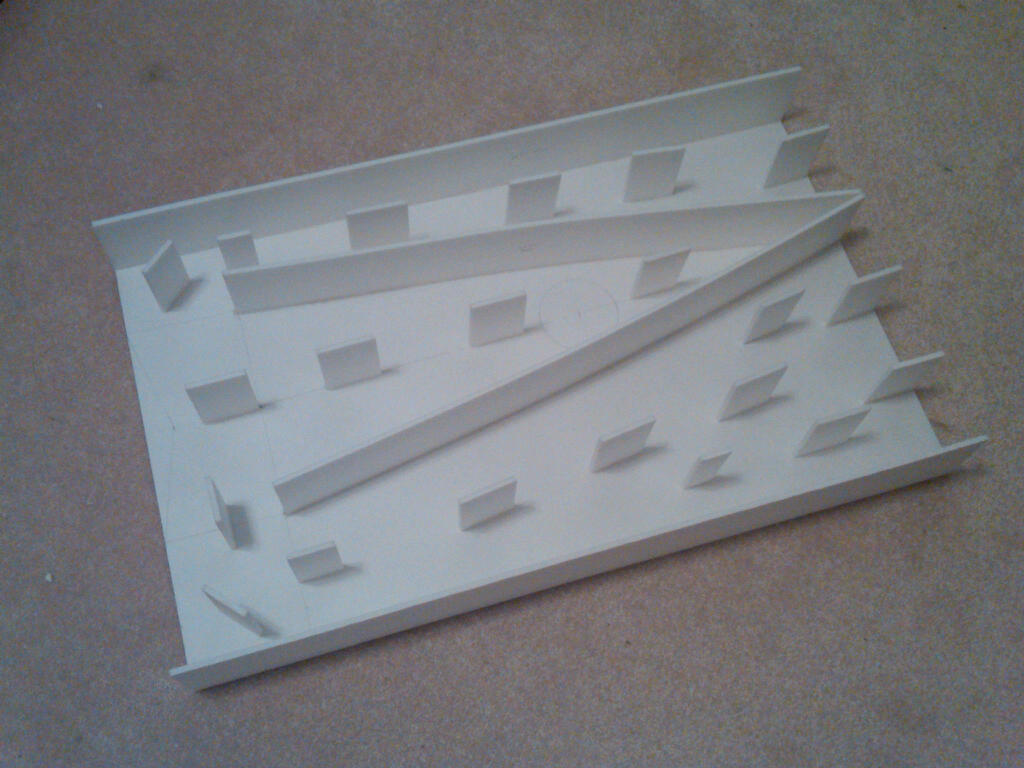

Maybe you can use the curved inner divider trick that I used when building my Flat BIB (FIB). Score the paper on the driver side of the divider - enough to pierce the paper with closely space lines parallel to bend direction. Glue the portion of the divider at the top and a couple inches down with hot melt. Then bend the divider in a smooth arc enough to make room for driver and slowly glue sections of the curved divider at a time. You will end up with a slightly different horn profile which is now parabolic to exponential. It should sound about the same, the tuning freq may shift slightly higher due to exponential opening versus conical opening. Anyhow, you solved it with a box - nice.

Thanks, I followed the link to the catalog page. 25 sheets for $18 - am I reading that right?

I could build a half dozen Klisphorns with that.

Still like to find something with the multiple layers.

I wish.

Still tempting for someone with a serious addiction to foam.

Klisphorn Build A.

Klisphorn Build B

Plans

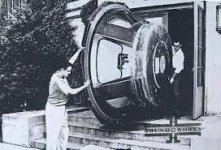

The Real Thing!

$375 vs. $4,500.00 hummmmm

Klisphorn Build A.

Klisphorn Build B

Plans

The Real Thing!

$375 vs. $4,500.00 hummmmm

Last edited:

Bcmbob,

I see your point. Building those horns in wood looks like a real pain in the a**. I can imagine how much easier if one could just cut all those edges with a box cutter and straight edge and glue together with tacks of hot melt and seal with PVA. Hardly any clamping would be needed. There is no denying the fun you would have, not to mention, some decent sounding speakers for a mere $375!

Hope you go for it!

I see your point. Building those horns in wood looks like a real pain in the a**. I can imagine how much easier if one could just cut all those edges with a box cutter and straight edge and glue together with tacks of hot melt and seal with PVA. Hardly any clamping would be needed. There is no denying the fun you would have, not to mention, some decent sounding speakers for a mere $375!

Hope you go for it!

I actually built one with wood back in the 60s. (Just the bottom). When I plugged it in, it blew the door to my daughters bedroom wide open. Just used a cheap generic driver and never could afford the top end horn (student w/ two little ones). Might try again this summer with foam.

When I brought this one home the WAF said

"No Way" , grabbed the kids and left for her mothers house.

When I brought this one home the WAF said

"No Way" , grabbed the kids and left for her mothers house.

Attachments

Last edited:

They have 12 mm or half in thick paper-foam-paper foam core in the US too but kind of pricey.

40 x 60" White Foamboard S-13721 - Uline

Hmmmm... One could use these 48 x 96" Black Foamboard S-13724 - Uline

...to build a pair of black Silburys.

EDIT: Wait a minute... $53 EACH! I thought that was for 12 of them!

Baltic Birch is only about 20% more and it is "the real thing".

Last edited:

Hmmmm... One could use these 48 x 96" Black Foamboard S-13724 - Uline

...to build a pair of black Silburys.

EDIT: Wait a minute... $53 EACH! I thought that was for 12 of them!

Baltic Birch is only about 20% more and it is "the real thing".

Yes it is the real thing, but perhaps the big difference is that BB can't be cut with a boxcutter in your dining room and makes lots of sawdust. For those of us without a workshop, it is the only means of making a DIY speaker. Oh, and the final product can be lifted with one hand

I understand the attraction, which is why I am reading the thread and looking at the foam core boards.

I just had no idea how ridiculous the prices can get.

I will build something in foam core, for sure, but it will not be Silburys! It will need to be limited to whatever size they sell at the dollar store.

I just had no idea how ridiculous the prices can get.

I will build something in foam core, for sure, but it will not be Silburys! It will need to be limited to whatever size they sell at the dollar store.

One quick question; how the heck do you get the drivers mounted in the foam core? It is hard to imagine the screws holding well enough in that stuff.

Or, perhaps it is because you have all been typically using quite small drivers, with light magnets.

I would hesitate to put a pair of Alpair 10.2 in foam core without some re-enforcement.

Or, perhaps it is because you have all been typically using quite small drivers, with light magnets.

I would hesitate to put a pair of Alpair 10.2 in foam core without some re-enforcement.

Cogitech,

An option is to either butt-join the smaller 20x30 sheets from the dollar store with a simple hot-melt strip of 2 in wide foam core on one side and stiff paper and PVA on the other side. Build it as large as you need - the problem may be how thin it is. Can double up foam core sheets to 3/16 in thick as IG has done. Alternatively, 4x8 sheets in 0.5 in and 0.75 in thick isocyanuratae foam sheathing at HD or Lowes can serve nicely as the main side panels on a large double horn like the Silbury. These foam sheets are only $12 ea, although I don't think they have a paper facing so something like acrylic adhesive or caulking might be used as the glue. Hot melt works too but you have such long runs it can get expensive in glue. Or use hot melt to tack, and caulk to adhere and seal.

R-Matte Plus 3 R-3.2 1/2 in. 4 ft. x 8 ft. Foam Insulating Sheathing-754404 at The Home Depot

An option is to either butt-join the smaller 20x30 sheets from the dollar store with a simple hot-melt strip of 2 in wide foam core on one side and stiff paper and PVA on the other side. Build it as large as you need - the problem may be how thin it is. Can double up foam core sheets to 3/16 in thick as IG has done. Alternatively, 4x8 sheets in 0.5 in and 0.75 in thick isocyanuratae foam sheathing at HD or Lowes can serve nicely as the main side panels on a large double horn like the Silbury. These foam sheets are only $12 ea, although I don't think they have a paper facing so something like acrylic adhesive or caulking might be used as the glue. Hot melt works too but you have such long runs it can get expensive in glue. Or use hot melt to tack, and caulk to adhere and seal.

R-Matte Plus 3 R-3.2 1/2 in. 4 ft. x 8 ft. Foam Insulating Sheathing-754404 at The Home Depot

Cogitech,

To mount the drivers in foam core, you need to reinforce the cutout area. Typically, for smaller drivers I glue small pieces of wood to the back where the screws go and drill through that so the screws have something to grab. For an Alpair 10, it weighs quite a bit, so double up on the foam for the baffle and reinforce with thin hobby plywood if needed - cut with a knife or small hand jigsaw - as long as you don't use a real power tool (gasp, shudder, heaven forbid the thought ). If you go with the half inch sheathing foam insulation, it is probably quite strong but needs wood to reinforce where the screws go. Dr Boar had great success with OSB on the MJK Horn thread in case you haven't see that. What are you thinking of building first? If you are new to this, believe it or not, the Cornu spiral is a great beginner project - it is easy to make, doesn't take much foam, and the rewarding beautiful sound can't be imagined considering what it all started as. If you want to try a more traditional looking box speaker, certainly a MLTL is very doable and they sound great in foam. A little more challenging but awesome sounding and looking is the FH3-inspired horn - one of my favorites. I also love the look and sound of the Flat BIB (FIB). Or you can make a regular BIB like s Mag did - they sound really good and are easy to make. You can also take one of your $10 W3-881si and build another nanotower, this time do some sims to make it an optimized MLTL. The 881si works great in a Cornu too.

). If you go with the half inch sheathing foam insulation, it is probably quite strong but needs wood to reinforce where the screws go. Dr Boar had great success with OSB on the MJK Horn thread in case you haven't see that. What are you thinking of building first? If you are new to this, believe it or not, the Cornu spiral is a great beginner project - it is easy to make, doesn't take much foam, and the rewarding beautiful sound can't be imagined considering what it all started as. If you want to try a more traditional looking box speaker, certainly a MLTL is very doable and they sound great in foam. A little more challenging but awesome sounding and looking is the FH3-inspired horn - one of my favorites. I also love the look and sound of the Flat BIB (FIB). Or you can make a regular BIB like s Mag did - they sound really good and are easy to make. You can also take one of your $10 W3-881si and build another nanotower, this time do some sims to make it an optimized MLTL. The 881si works great in a Cornu too.

Good luck!

To mount the drivers in foam core, you need to reinforce the cutout area. Typically, for smaller drivers I glue small pieces of wood to the back where the screws go and drill through that so the screws have something to grab. For an Alpair 10, it weighs quite a bit, so double up on the foam for the baffle and reinforce with thin hobby plywood if needed - cut with a knife or small hand jigsaw - as long as you don't use a real power tool (gasp, shudder, heaven forbid the thought

Good luck!

Last edited:

Cogitech,

To mount the drivers in foam core, you need to reinforce the cutout area. Typically, for smaller drivers I glue small pieces of wood to the back where the screws go and drill through that so the screws have something to grab. For an Alpair 10, it weighs quite a bit, so double up on the foam for the baffle and reinforce with thin hobby plywood if needed - cut with a knife or small hand jigsaw - as long as you don't use a real power tool (gasp, shudder, heaven forbid the thought). If you go with the half inch sheathing foam insulation, it is probably quite strong but needs wood to reinforce where the screws go.

Thanks for the pointers. I have all kinds of tools, both manual and power, so I'll figure something out.

Dr Boar had great success with OSB on the MJK Horn thread in case you haven't see that.

I didn't see that, actually, but everything I know about OSB makes me think it would be a fantastic (much cheaper) alternative to BB as long as attention is paid to bracing. Throw some veneer on and who would know the difference?

What are you thinking of building first? If you are new to this, believe it or not, the Cornu spiral is a great beginner project - it is easy to make, doesn't take much foam, and the rewarding beautiful sound can't be imagined considering what it all started as. If you want to try a more traditional looking box speaker, certainly a MLTL is very doable and they sound great in foam. A little more challenging but awesome sounding and looking is the FH3-inspired horn - one of my favorites. I also love the look and sound of the Flat BIB (FIB). Or you can make a regular BIB like s Mag did - they sound really good and are easy to make. You can also take one of your $10 W3-881si and build another nanotower, this time do some sims to make it an optimized MLTL. The 881si works great in a Cornu too.

Good luck!

I really want to get a pair of A10.2 going. My friend and I each have a pair and he wants me to build his first, but neither of us can decide what cabinets we want. He seems to have chickened out on the Silburys and I think he has almost decided that Jim Griffin's MLTL is the one for him. I am very, very interested in the Silburys, but haven't made the commitment ($$ - plans) yet.

I was considering building FH3 to see if I like "horns" or not, but I don't think a FH3 will tell me anything about Silbury.

Perhaps I will start by building my buddy's A10.2s into foam core Jim Griffin MLTL and go from there. I'd like to at least start burning in a pair of them, as I have had them for weeks and feel guilty every time I see the boxes.

I think Cornu looks cool, but A10.2 in Cornu would have to be what... 8 feet by 8 feet?

Oh, and the W3-881SI are staying exactly where they are. That, my friend is synergy defined.

Last edited:

Cogitech,

Here is the OSB horn thread. http://www.diyaudio.com/forums/full-range/227240-mjks-fostex-ff125wk-blh-project.html

Here is the OSB horn thread. http://www.diyaudio.com/forums/full-range/227240-mjks-fostex-ff125wk-blh-project.html

In the famous Stromberg-Carlson Acoustic labyrinth or, transmission line, of the 1930s, the tunnel was made of heavy cardboard with felt damping. The radios sold from $300 to $900 and were the high end audio of the day. So we learn that they did it first, and if foam had been available, they would have no doubt used it also.

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?