...it is still at trial and error stage?

Yes. The iBIBk is a concept needing empirical detailinhg. Must be an even number of years ago i did it.

Start small and expand as needed?

That is the best plan. Up to about a 3rd the length of the pipe (ie 2/3rds of the box height). If i was doing it i'd accomplish it with an increasing number of drilled holes. And i'd put half the slot on each side (i can't remeber what i drew.

dave

a Sapkowski patent holey Karlson port straight cross-section line might be something to investigate with foam board - - don't know how it might work overall - "???????" ??? ??????????. - ?????? ??? ??????

a Sapkowski patent holey Karlson port straight cross-section line might be something to investigate with foam board - - don't know how it might work overall - "???????" ??? ??????????. - ?????? ??? ??????

Klassno link.

I wonder, can one attenuate the 3/4, 5/4, 7/4, etc, modes in a pipe by drilling small de-Q'ing holes at the corresponding anti-nodal points - without affecting the fundamental QW mode too much? I suppose I could test it easily enough.

IG

IG,

Drilling small de'Q'ing holes would indeed reduce the other modes but at the expense of collapsing the strength of the fundamental mode - as anyone who has played a flute knows how the smallest leak in one of the pads or finger holes will make the low note disappear. I discovered this first hand in my recent BIB (FIB) build when I did not seal the bottom on well because I was adjusting stuffing. There was no deep bass at all. Once it was sealed properly the low note came in strong.

Drilling small de'Q'ing holes would indeed reduce the other modes but at the expense of collapsing the strength of the fundamental mode - as anyone who has played a flute knows how the smallest leak in one of the pads or finger holes will make the low note disappear. I discovered this first hand in my recent BIB (FIB) build when I did not seal the bottom on well because I was adjusting stuffing. There was no deep bass at all. Once it was sealed properly the low note came in strong.

IG,

Drilling small de'Q'ing holes would indeed reduce the other modes but at the expense of collapsing the strength of the fundamental mode

Might reduce the QW mode too much to be worth it I suppose. It might only work for real far-up modes, like 7/4 and more, where the holes could be well away from the pressure antinode for the fundamental (mouth), but this is easily dealt with using stuffing.

IG

The use of foam for lightweight enclosures is reminiscent of my first speaker project...in 1955. The November 1955 issue of Popular Electronic featured an article, by the now noted author David Weems, on building a corner labyrinth style enclosure using a sheet of Celotex. I remember this enclosure well, as my mother was very angry that I messed up her Kitchen when cutting out the panels for same. It used an 8 inch driver, of which mine came from a junked Zenith TV set. As I recall it worked very well with my Alliied Radio S 723 10 Watt amp.

Some other material which you might like to try is the 1/2 foam paper backed insulation board sold under the John Mansville name. It very light weight, cuts easily with a carton knife, and can be cemented with Tacky Craft glue or the caulking gun type of glues made for foam products. Another, some what heavier and dense product is Homasote, It is used for sound deadening and insulation. It cuts with a saw and takes most wood glues and can even be nailed. There are a lot of materials that can be used as an alternative to MDF or wood for enclosures, just keep your eyes and mind open for them.

Some other material which you might like to try is the 1/2 foam paper backed insulation board sold under the John Mansville name. It very light weight, cuts easily with a carton knife, and can be cemented with Tacky Craft glue or the caulking gun type of glues made for foam products. Another, some what heavier and dense product is Homasote, It is used for sound deadening and insulation. It cuts with a saw and takes most wood glues and can even be nailed. There are a lot of materials that can be used as an alternative to MDF or wood for enclosures, just keep your eyes and mind open for them.

KlBIrd,

Thanks for the tip on the half inch foam board from John Mansville. Is this something available at Lowes or HD, or is it mostly available for building contractors? Is this that pink egg carton like foam with paper cover? I seem to recall seeing it at construction sites. So the famous Weems did foam core speakers back in 1955? And I thought I was on to something new

Thanks for the tip on the half inch foam board from John Mansville. Is this something available at Lowes or HD, or is it mostly available for building contractors? Is this that pink egg carton like foam with paper cover? I seem to recall seeing it at construction sites. So the famous Weems did foam core speakers back in 1955? And I thought I was on to something new

You should be able to find it a Lowes or your local lumber dealer. Its called Johns Mansville AP Sheathing. The outer paper is white with yellow inner foam Contact me via my web site at; Ken Bird.com and I will send you a PDF of the 1955 Weem's article.

Ken Bird,

I saw this foam which is very cost effective and has a poly facer sheet. This just may be the thing to try for a larger Cornu horn build. It will keep things light weight yet provide more rigidity since it is half inch thick. Just need to cover with wall paper or the like as the markings are pretty ugly compared to plain white foam board. Have you used polyisocyanurate foam before? Maybe the John Mansville stuff is similar?

Shop Insulfoam 1/2-in x 2-ft x 4-ft Expanded Polystyrene Insulated Sheathing at Lowes.com

http://www.lowes.com/pd_42729-236-268421_0__?productId=3686550&Ntt=polyisocyanurate+foam+board&pl=1¤tURL=%3FNtt%3Dpolyisocyanurate%2Bfoam%2Bboard&facetInfo=

I saw this foam which is very cost effective and has a poly facer sheet. This just may be the thing to try for a larger Cornu horn build. It will keep things light weight yet provide more rigidity since it is half inch thick. Just need to cover with wall paper or the like as the markings are pretty ugly compared to plain white foam board. Have you used polyisocyanurate foam before? Maybe the John Mansville stuff is similar?

Shop Insulfoam 1/2-in x 2-ft x 4-ft Expanded Polystyrene Insulated Sheathing at Lowes.com

http://www.lowes.com/pd_42729-236-268421_0__?productId=3686550&Ntt=polyisocyanurate+foam+board&pl=1¤tURL=%3FNtt%3Dpolyisocyanurate%2Bfoam%2Bboard&facetInfo=

Last edited:

IG,

Drilling small de'Q'ing holes would indeed reduce the other modes but at the expense of collapsing the strength of the fundamental mode - as anyone who has played a flute knows how the smallest leak in one of the pads or finger holes will make the low note disappear. I discovered this first hand in my recent BIB (FIB) build when I did not seal the bottom on well because I was adjusting stuffing. There was no deep bass at all. Once it was sealed properly the low note came in strong.

On my second FIB build I found that the "Contact Paper" (used to line drawers) works as an excellent temporary seal tape for foam core boards. It provides an airtight seal to adjust stuffing while being easy to peel off without damaging the facer paper of the foam core boards.

What about simple camping mattresses?

Or are they not air tight enough??

An externally hosted image should be here but it was not working when we last tested it.

Or are they not air tight enough??

The neoprene foam camping mattress should be a great gasket material (cheap and you can get long strips). For wood enclosures with screws or other means to clamp and apply pressure to make a seal in the neoprene this is fine. For foam core enclosures with no clamping screws (perhaps books applied on the face or cap to be sealed with gasket) it is more difficult. The removable tape using the Contact Paper (TM) brand covering is great because of its special adhesive which allows easy removal from the foam core without damaging the paper whatsoever. I am using it to seal the bottom cap on my Flatter (Bigger) Is Better or FIB design (http://www.diyaudio.com/forums/full-range/66173-terry-cains-bib-why-does-work-does-anyone-have-those-fostex-craft-handbooks-514.html) and it makes a perfect seal that I can measure.

The camping mattress may also be useful for a sound absorber/damping material for lining the wall directly behind driver?

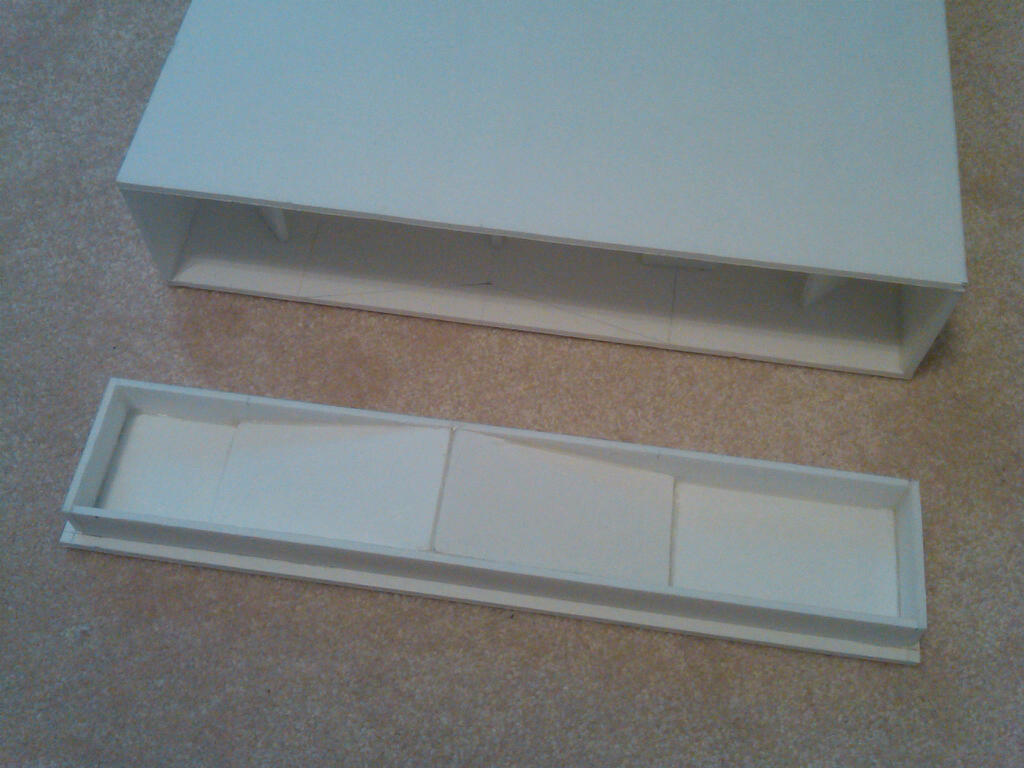

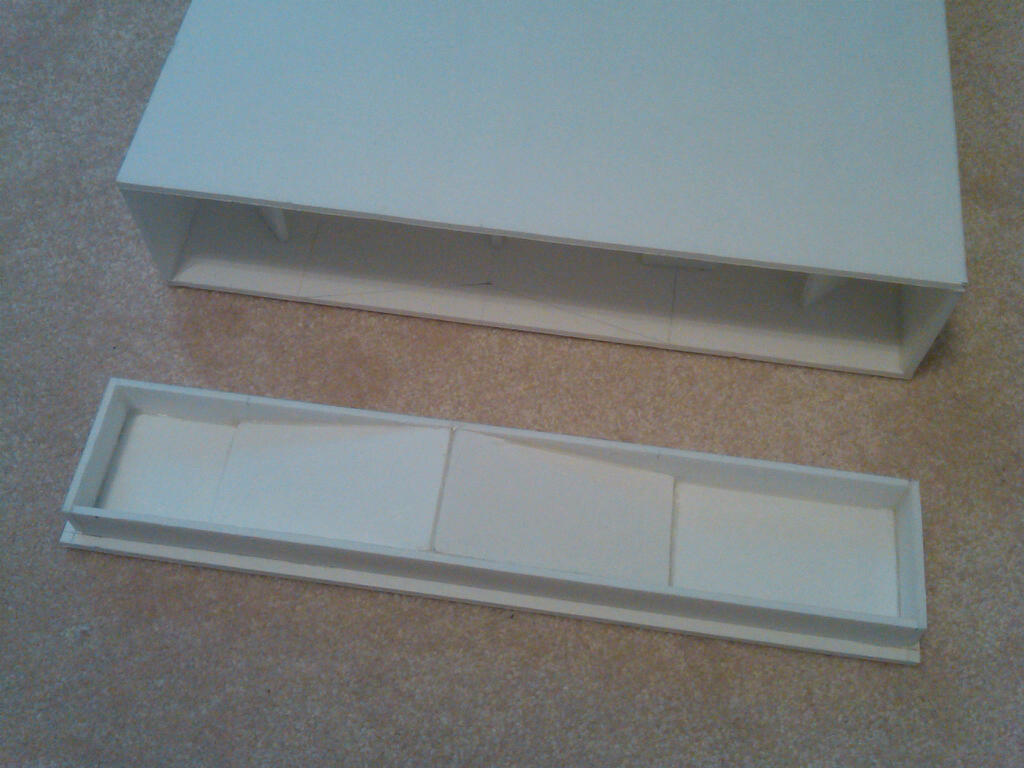

Below is a picture of the bottom cap on the FIB that I ended up taping with the Contact Paper.

The camping mattress may also be useful for a sound absorber/damping material for lining the wall directly behind driver?

Below is a picture of the bottom cap on the FIB that I ended up taping with the Contact Paper.

Completed Flatter is Better (FIB)

Here is a photo of my completed FIB next to the FH3-inspired speaker so you can get a sense of scale. It is 27 in tall x 16 in wide x 3 in deep and is a good size for wall mounting or covering with a painting or poster. I need to start decorating my speakers one of these days instead of leaving them in their all white glory. If you are interested in the FIB, the discussion is in the Terry Cain BIB thread. These sound very nice and they can get quite loud for how small the driver is. If you are looking for another wall mount speaker, this is an option.

Here is a photo of my completed FIB next to the FH3-inspired speaker so you can get a sense of scale. It is 27 in tall x 16 in wide x 3 in deep and is a good size for wall mounting or covering with a painting or poster. I need to start decorating my speakers one of these days instead of leaving them in their all white glory. If you are interested in the FIB, the discussion is in the Terry Cain BIB thread. These sound very nice and they can get quite loud for how small the driver is. If you are looking for another wall mount speaker, this is an option.

Attachments

Here is a photo of my completed FIB next to the FH3-inspired speaker so you can get a sense of scale. It is 27 in tall x 16 in wide x 3 in deep and is a good size for wall mounting or covering with a painting or poster. I need to start decorating my speakers one of these days instead of leaving them in their all white glory. If you are interested in the FIB, the discussion is in the Terry Cain BIB thread. These sound very nice and they can get quite loud for how small the driver is. If you are looking for another wall mount speaker, this is an option.

Looks good! Bye-bye baffle-step!

I might have a foam-core monstrosity to post later on...

IG

IG,

Yes, one of my favorite reasons for wall mount speakers is no need for baffle step comp.

Looking forward to seeing your creation, and I am sure it's not a monstrosity. I might take a razor to the side of the FIB and cut a Karlson aperture in it. Start small and cut more as needed. Good test bed for experiments like this.

I might take a razor to the side of the FIB and cut a Karlson aperture in it. Start small and cut more as needed. Good test bed for experiments like this.

Yes, one of my favorite reasons for wall mount speakers is no need for baffle step comp.

Looking forward to seeing your creation, and I am sure it's not a monstrosity.

Here is my build. Inspired by the Nagaoka F-81, I wanted to provide more of a load to the driver than the F-81 at 12ft long (!) so made the pipe 224cm long, in order to tune it at 1/3 the driver's Fs and provide some acoustical impedance at Fs via the ¾-wave mode. Tuning ended-up at 36Hz compared to the 38Hz aim - not bad at the first try. I also wanted the terminus to be on the floor, at the side of the enclosure in order to load it with the floor, back-wall and enclosure side up to a certain point. No need for BSC here too. Some stuffing to eliminate the 7/4 and 9/4 modes above 200Hz would be necessary in a serious effort.

Here is the F-81 to have some background, just scroll down a bit:

SPI sound plaza Ida / handmade speaker basic lecture (3)/8.10cm speaker.page

Three internal segments with two folds, 30" high, 10.5" deep, 4.5" wide, with doubled-up 3/16" foam-core, here it is:

It's quite rough, with tons of hot-melt glue, but works. It's meant to be a very quick build for proof-of-concept after all.

There is bass down to 70Hz and good sound overall. Has the typical foam-core coloration, or so I find. Limited in SPL - yes - but good for small rooms.

IG

Here is the F-81 to have some background, just scroll down a bit:

SPI sound plaza Ida / handmade speaker basic lecture (3)/8.10cm speaker.page

Three internal segments with two folds, 30" high, 10.5" deep, 4.5" wide, with doubled-up 3/16" foam-core, here it is:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

It's quite rough, with tons of hot-melt glue, but works. It's meant to be a very quick build for proof-of-concept after all.

There is bass down to 70Hz and good sound overall. Has the typical foam-core coloration, or so I find. Limited in SPL - yes - but good for small rooms.

IG

Last edited:

IG,

Nice work there! Very cool to see someone taking on an old design and modding it quickly and cheaply. Thanks for the link to the Nagaoka speaker lecture - very interesting stuff there, lots of potential ideas for trying in foam core. The Flamingo and cobra are just plain crazy looking but interesting. What are the internal dimensions of your flow paths because it looks like it is expanding? Also, is that an FF85k driver?

Nice work there! Very cool to see someone taking on an old design and modding it quickly and cheaply. Thanks for the link to the Nagaoka speaker lecture - very interesting stuff there, lots of potential ideas for trying in foam core. The Flamingo and cobra are just plain crazy looking but interesting. What are the internal dimensions of your flow paths because it looks like it is expanding? Also, is that an FF85k driver?

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?