Check out Homasote green building boards fiberboard sound proof for details on their product. Don't have a definite design as yet but it may be dual speaker FR TL with the Visatons. I've got to look at Augsburger's or King's design data tables to get a final size.

The standard board is 1/2 inch grey in color with a slightly rough texture from the press.

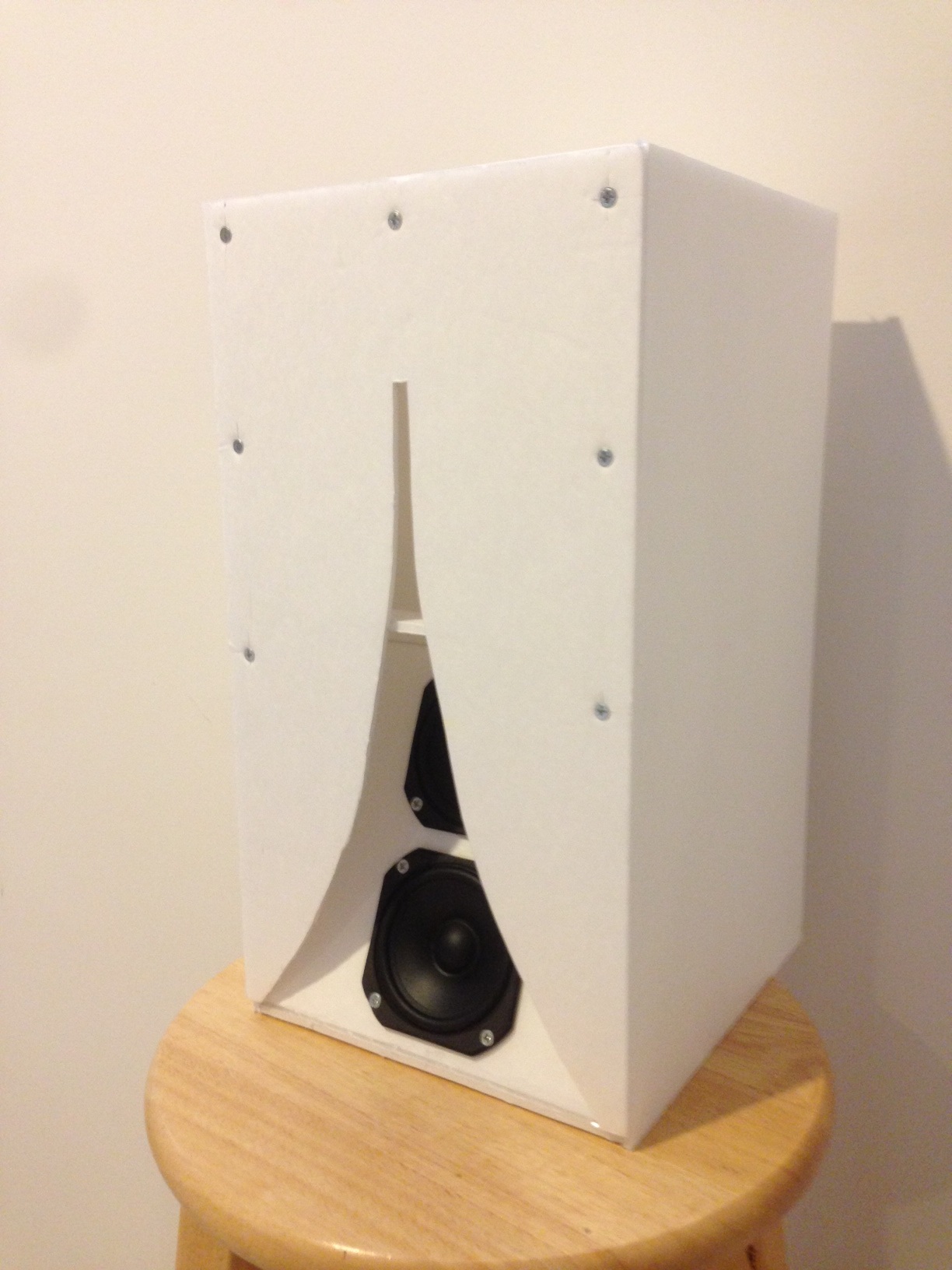

It looks like a thick piece of card board, which it really is. It qualifies as a "green" material being made of recycled paper. It been around since the 1940's. I used it for sub roadbed on my model railroad some years ago. I glued up a small MTM enclosure today with the Visaton's mounted there in. It makes a very solid vibration free enclosure.

It looks like a thick piece of card board, which it really is. It qualifies as a "green" material being made of recycled paper. It been around since the 1940's. I used it for sub roadbed on my model railroad some years ago. I glued up a small MTM enclosure today with the Visaton's mounted there in. It makes a very solid vibration free enclosure.

I was nerdy enough to look into this. I guess Homasote and Celotex were competitors for many years, and both of their (namesake) products are/were pretty similar. The production methods were a little different.

I recall Celotex had a slightly finer texture, being made from wood pulp instead of recycled paper. It was pretty much exactly the same as ceiling tiles. Those would make a good substitute for small projects. (Keep in mind some ceiling tiles are rigid fiberglass, which is totally different. ) I like the idea of adding a hard tile outer layer, glued on with construction glue.

I recall Celotex had a slightly finer texture, being made from wood pulp instead of recycled paper. It was pretty much exactly the same as ceiling tiles. Those would make a good substitute for small projects. (Keep in mind some ceiling tiles are rigid fiberglass, which is totally different. ) I like the idea of adding a hard tile outer layer, glued on with construction glue.

I have been working with George Augspurger's transmission line tables but he does not make it clear if, in a chamber loaded system, does the chamber count in the pipe length? Has anyone built a chamber loaded TL? I've got a design for a bipole FR TL with the drivers in a chamber, loaded into the pipe, based his design tables.

Ken,

If the chamber has a throat leading to the TL the throat establishes the boundary condition for the TL length so, no, it will not count in the length. But if no real constriction or throat then yes it counts to the TL length. Before you build, I can try modeling it for you in AkAbak if you share the plans.

If the chamber has a throat leading to the TL the throat establishes the boundary condition for the TL length so, no, it will not count in the length. But if no real constriction or throat then yes it counts to the TL length. Before you build, I can try modeling it for you in AkAbak if you share the plans.

Thanks, I thought that was the logical answer and am happy that you confirmed it. That is what makes this forum and its collective knowledge so valuable.

Augspuger's paper and article left out a lot of details that he assumed we should know.

I will get a drawing together in a day or two.

Augspuger's paper and article left out a lot of details that he assumed we should know.

I will get a drawing together in a day or two.

Has anyone tried using foam board (paper laminated with foam core) as quick and dirty speaker enclosures? There is something really satisfying in using nothing more than an x-acto knife and a hot melt glue gun to build transmission lines, horns, etc to try out designs on smaller 3 in and 2 in low power full range drivers. Interestingly, they actually sound pretty good and weigh nothing compared to mdf. I am just wondering if I am the only trying this sort of stuff before cutting real wood. My latest build is a stereo pair transmission line that is very flat and hangs like a picture on a wall. Lots of fun and very quick and clean. The foam core actually has built in damping capabilities. I do find that it sometimes resonates like a guitar body but that is not necessarily bad.

http://www.diyaudio.com/forums/full-range/237948-speaker-kicks-butt-large-spaces-21.html#post3560234

I used these materials to build an extension speaker for my portable guitar amps (a Pignose 7-100 and a Dayton DTA-1) using eight HiWave BMR12 2" square flat drivers. I mounted them much as you say, with the exception of adhesive silicone instead of hot glue. After mounting and wiring, I glued a sheet of styrofoam of the same size to the back and then inserted that into a wooden box the same size and depth. The extra styrofoam between the foam board and the box dampened them well.

I think your idea would work well for building small (ie. tweeter or mid-tweeter) Karlson Klams. But I do think your baffle would need to be something more resilient that plain foam board.

I think your idea would work well for building small (ie. tweeter or mid-tweeter) Karlson Klams. But I do think your baffle would need to be something more resilient that plain foam board.

I actually built a Karlsonator with double layered foam core on the front. Sounds great!

http://www.diyaudio.com/forums/full-range/239338-mini-karlsonator-0-53x-dual-tc9fds.html

The use of foam for lightweight enclosures is reminiscent of my first speaker project...in 1955. The November 1955 issue of Popular Electronic featured an article, by the now noted author David Weems, on building a corner labyrinth style enclosure using a sheet of Celotex. I remember this enclosure well, as my mother was very angry that I messed up her Kitchen when cutting out the panels for same. It used an 8 inch driver, of which mine came from a junked Zenith TV set. As I recall it worked very well with my Alliied Radio S 723 10 Watt amp.

Some other material which you might like to try is the 1/2 foam paper backed insulation board sold under the John Mansville name. It very light weight, cuts easily with a carton knife, and can be cemented with Tacky Craft glue or the caulking gun type of glues made for foam products. Another, some what heavier and dense product is Homasote, It is used for sound deadening and insulation. It cuts with a saw and takes most wood glues and can even be nailed. There are a lot of materials that can be used as an alternative to MDF or wood for enclosures, just keep your eyes and mind open for them.

I remember making this enclosure, or one like it in '55, using a Wharfedale 8 inch full range speaker. My first speaker and enclosure. Been a Wharfedale (and Celestron) fan ever since.

Any possibility that you'd have the dimensions, as I'd like to build it again with my grand daughter, who had discovered good audio.

I have the general layout in my head, and probably could cobble something comparable if all else fails, but I'd like to re-share that moment with my g-daughter as we build it together.

I missed that one, but did the $3 12" MkII variant the next year, which thanks to Freddyi, I have a copy of if anyone's interested. I assume it's the same basic layout as the 8" $2 Baffle.

GM

Possible to get a copy of the plans?? If they're similar, it might spark my pea brain for the missing details of the 8 inch enclosure, AND, I just happen to have a pair of 12 inch red magnet (alnico) Wharfies that I could use for woofers in a larger enclosure.

$2.00 Baffle

Attached is a PDF of the $2.00 Weem's baffle. It was a simple yet effective corner enclosure using the acoustic labyrinth principle. I have many of his projects in PDF format gleaned from Popular Electronics and other publication. David Weems is still with us, but at 91 he no longer builds speakers. He called me last week to announce that he has auctioned off all his old drivers and test equipment to benefit the Civil War battlefield park in his home town of Newtonia, MO. You can read a bio on him I did in the October 2009 issue of Audio Xpress.

Attached is a PDF of the $2.00 Weem's baffle. It was a simple yet effective corner enclosure using the acoustic labyrinth principle. I have many of his projects in PDF format gleaned from Popular Electronics and other publication. David Weems is still with us, but at 91 he no longer builds speakers. He called me last week to announce that he has auctioned off all his old drivers and test equipment to benefit the Civil War battlefield park in his home town of Newtonia, MO. You can read a bio on him I did in the October 2009 issue of Audio Xpress.

Possible to get a copy of the plans??

Not sure.........They're in a Flickr photo album, 'Weems Celotex TL', but Flickr has been 'improved' and at a glance don't see how to post them to the general public other than what's up in the address bar: Weems Celotex TL - a set on Flickr

Clicking on the thumbnails to blow them up still doesn't give me a link other than in the address bar, so give it a try and let me know.........

GM

Just send email me at klbird@embarqmail.com and I will send you the PDF direct.

Don't know. Let's see if I can upload one....... in the advanced new reply window, clicking on the attachments option [paperclip symbol] opens a pop-up window to choose where in my computer to upload the attachment. Once found, I double click on it to 'pin' it to DIYaudio, then click on the 'upload' button. It will display the current attachments and 'remove' buttons down below.

Note that when you expand the pop-up window it shows the various file size limits or 976.6 kb for pdfs and while it will try to upload, it ultimately gives you an error message telling you why it failed.

I assume then that the pdf is either too large and/or if your computer displays like mine, i.e. the pop-up window opens up very small, not showing anything but the 'choose folder section', so have to expand it see the 'upload' button, etc., the 'problem' I initially had with trying to upload stuff.

The Karlson slot loaded TL is Norman Fuller's realization of the attached patent. It sims plenty good enough using current generic M.I. or '50s era 15" driver specs.

GM

Note that when you expand the pop-up window it shows the various file size limits or 976.6 kb for pdfs and while it will try to upload, it ultimately gives you an error message telling you why it failed.

I assume then that the pdf is either too large and/or if your computer displays like mine, i.e. the pop-up window opens up very small, not showing anything but the 'choose folder section', so have to expand it see the 'upload' button, etc., the 'problem' I initially had with trying to upload stuff.

The Karlson slot loaded TL is Norman Fuller's realization of the attached patent. It sims plenty good enough using current generic M.I. or '50s era 15" driver specs.

GM

Attachments

Last edited:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?